Method for synthesizing veratric acid

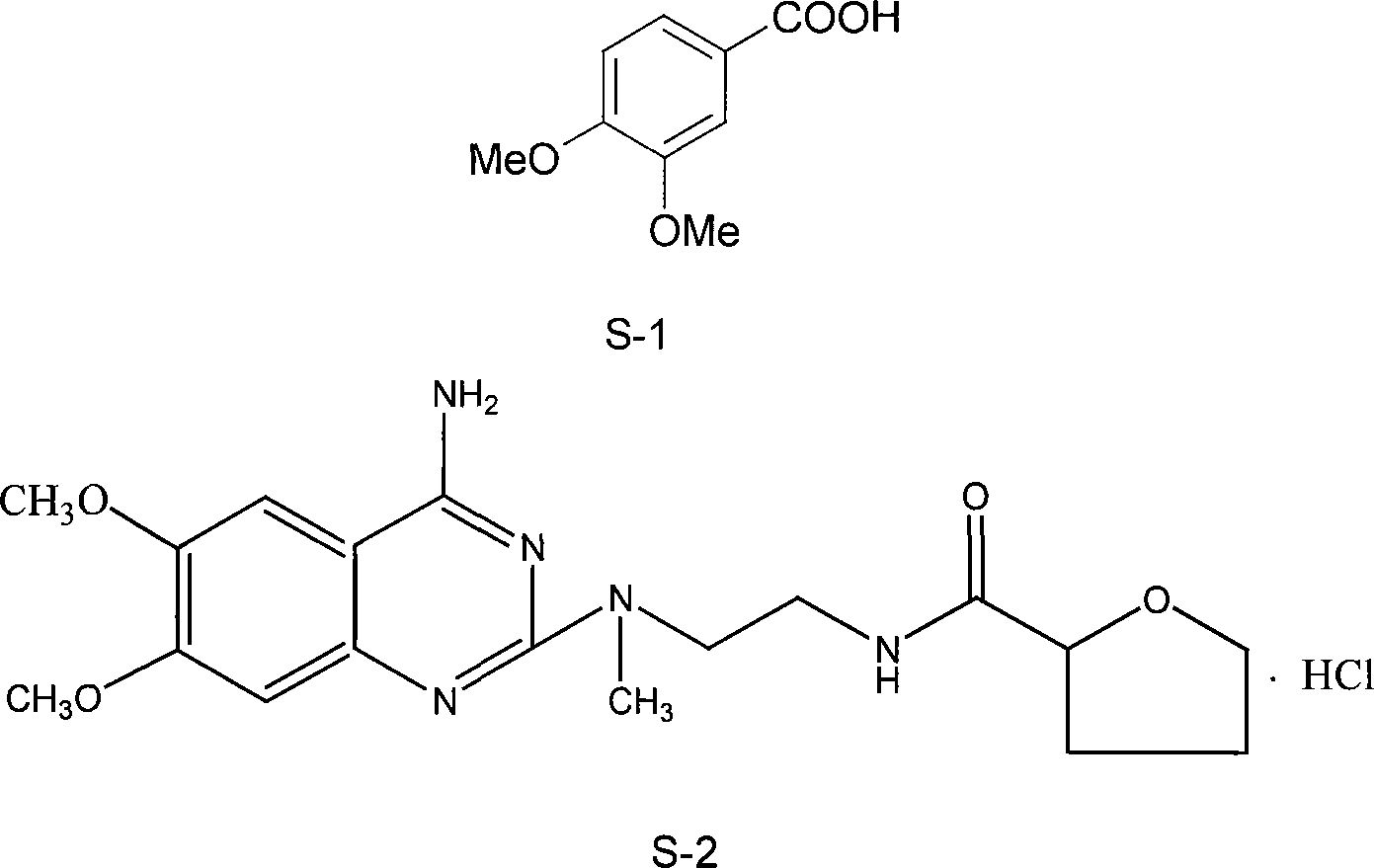

A synthesis method and technology of veratrol are applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve the problems of consumption of potassium tert-butoxide, high price of veratrol, etc., and achieve a short production cycle. , the effect of reducing costs and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

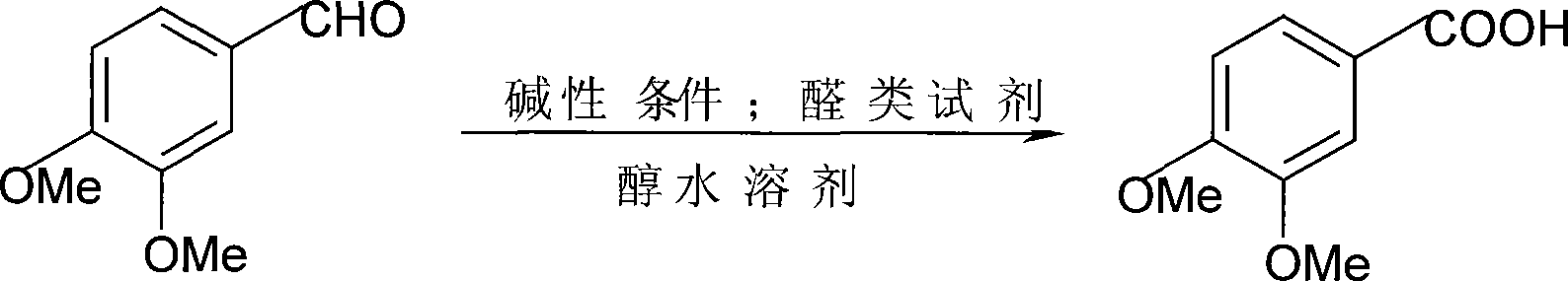

[0018] (1) Preparation of Veratrate:

[0019] In the flask equipped with stirring, condenser and thermometer, add veratraldehyde (33.2g, 0.20mol), calcium hydroxide (74g, 1.0mol), isopropanol aqueous solution (250mL, water content is 10% (v) ), formalin solution (45.0g, 35%wt), and reacted for 2.5h at a temperature of about 50°C. Filtration yielded a yellow solid, veratrate.

[0020] (2) Preparation of veratrol product:

[0021] At room temperature, sulfuric acid aqueous solution (20%wt) was added dropwise to veratrate for 0.5h, and the pH at the end point of acidification was 4. After filtering, washing and drying, 16.32 g of a light yellow solid was obtained, which was a veratronic acid product, and the yield was 88.5%.

[0022] The measurement results of the physical properties of the veralic acid product: a light yellow solid with a melting point of 177-178°C, which is consistent with the value in the literature (Phytochemistry, 1990, 29(3), 1014-1016).

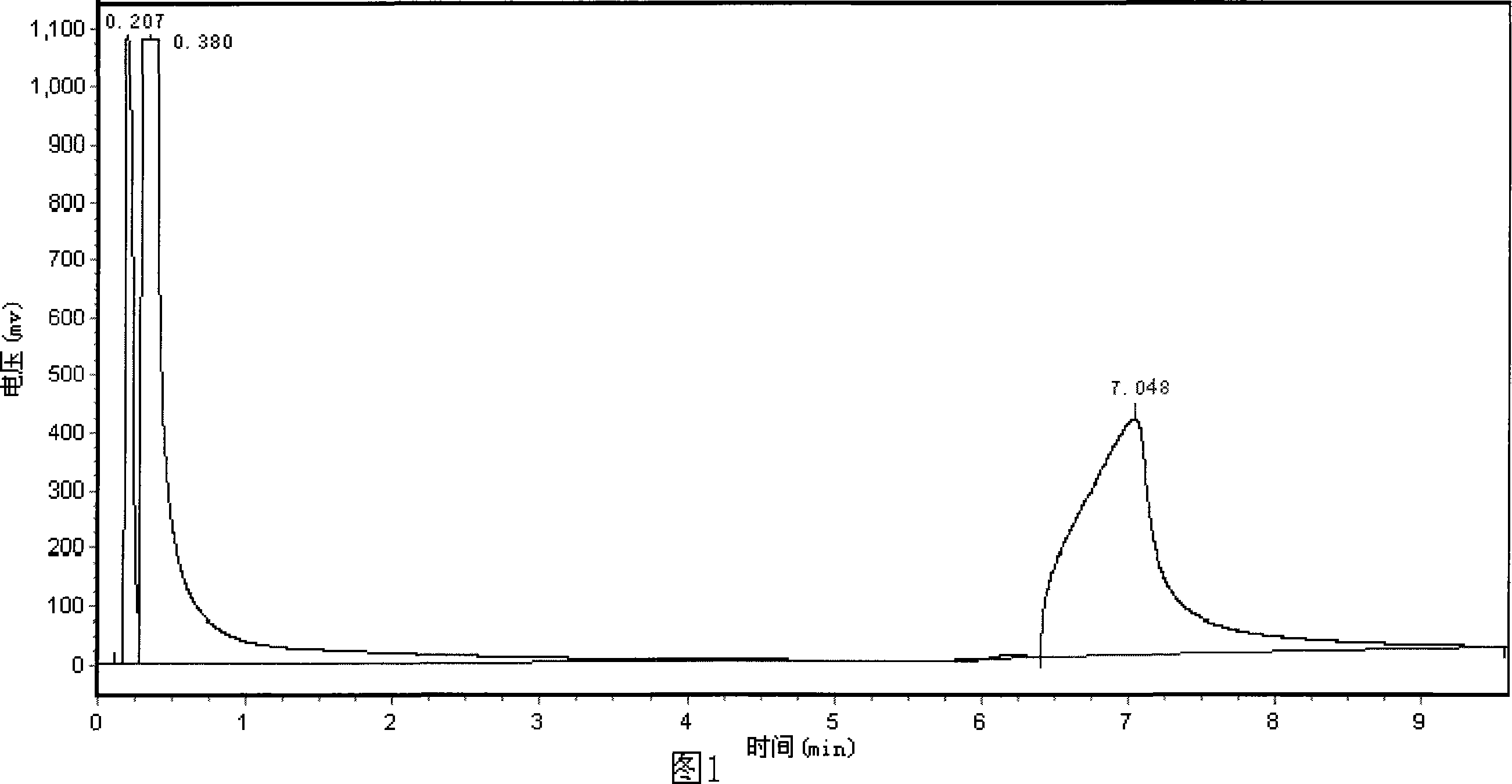

[0023] Gas ch...

Embodiment 2

[0026] In the flask equipped with stirring, condenser and thermometer, add veratraldehyde (63.1g, 0.38mol), sodium carbonate (60.4g, 0.57mol), n-butanol aqueous solution (550mL, water content is 15% (v) ), formalin solution (60.0g, 35%wt), and reacted for 1.5h at a temperature of about 50°C. A yellow solid was obtained as veratrate. At room temperature, sulfuric acid aqueous solution (30%wt) was added dropwise to the veratrate for 2 hours, and the pH at the end point of the acidification was 2. 28.95 g of the product was obtained, and the yield was 82.6%.

Embodiment 3

[0028] In the flask equipped with stirring, condenser and thermometer, add veratraldehyde (107.9g, 0.65mol), potassium hydroxide (218.4g, 3.9mol), aqueous ethanol (700mL, water content is 25% (v)) , Paraformaldehyde (97.5g, 3.25mol), reacted at a temperature of about 100°C for 4h. A yellow solid was obtained as veratrate. At room temperature, nitric acid aqueous solution (5%wt) was added dropwise to veratrate for 1.5h, and the pH at the end point of acidification was 3. 56.16 g of the product was obtained with a yield of 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com