Method and apparatus for treating stepless discharging liquid

A liquid treatment and discharge area technology, applied in the field of ion technology and water treatment, can solve the problems of high conductivity efficiency drop, electrode melting, etc., and achieve the effect of increasing the generation probability and improving the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

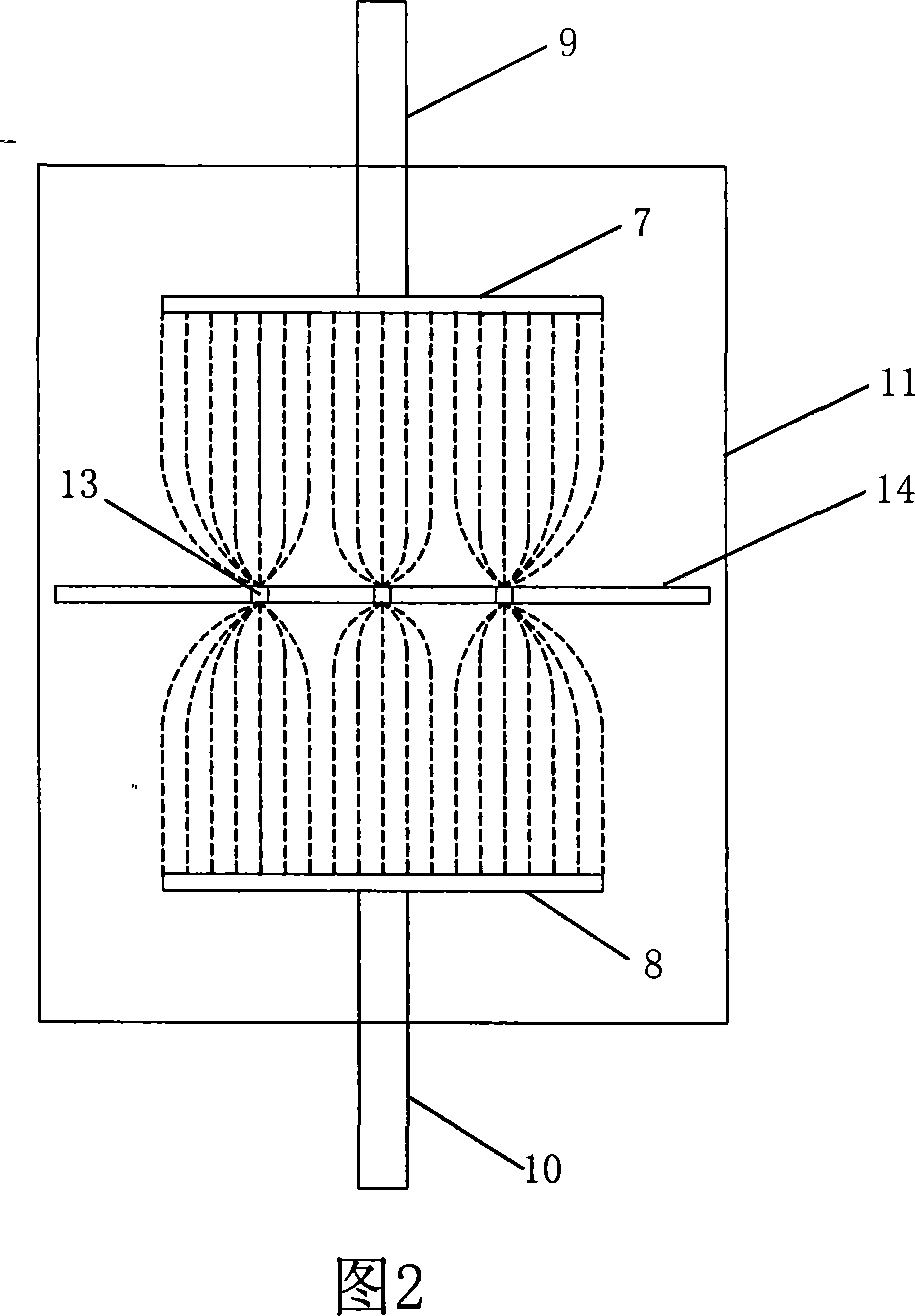

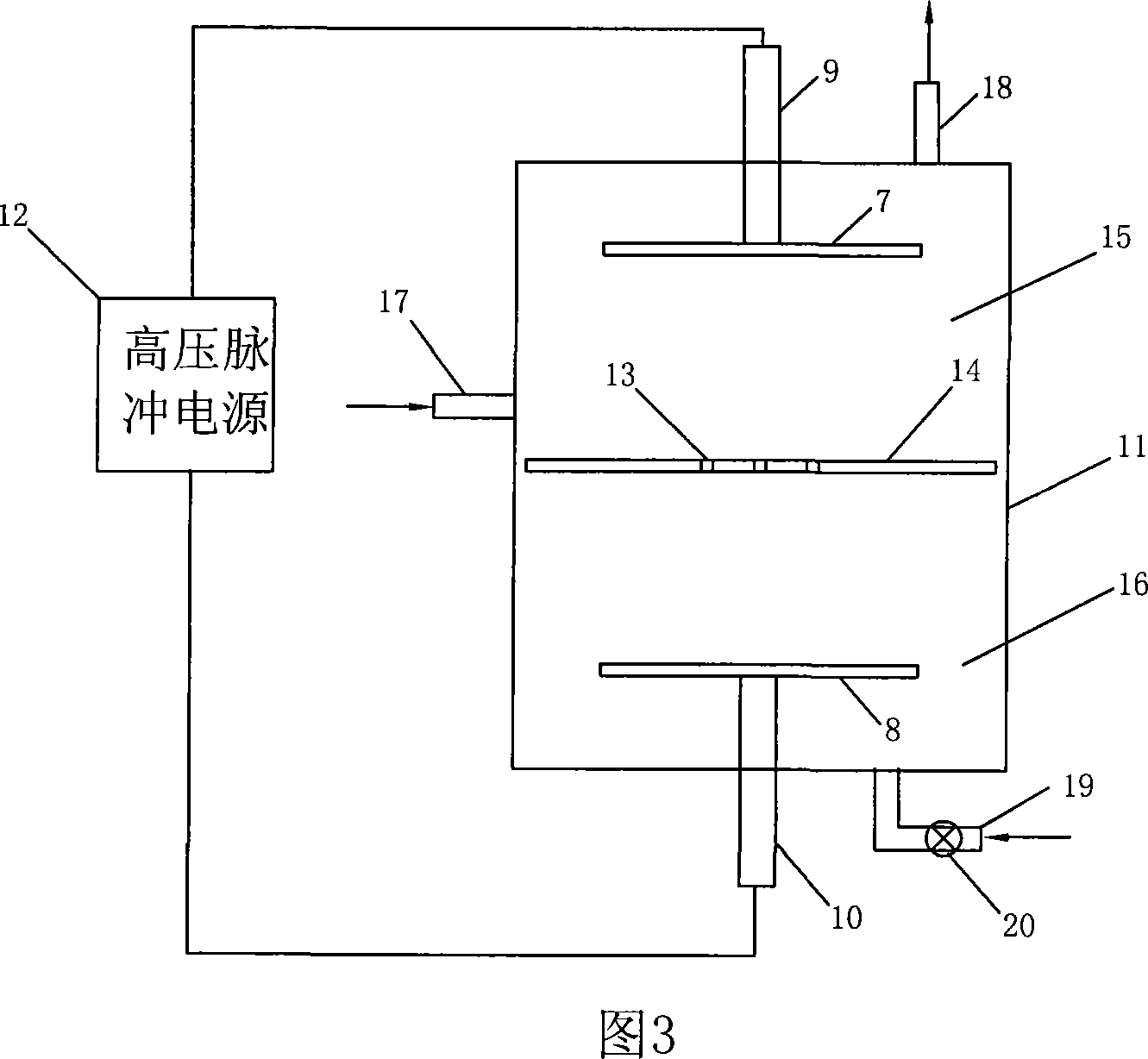

[0021] As shown in Figures 2 and 3, the electrodeless discharge pulse plasma liquid-gas discharge device for wastewater treatment includes a high-voltage pulse power supply 12, a plate electrode 7, a plate electrode 8, an electrode support 9, an electrode support 10 and an insulating plate 14 The discharge vessel 11. The discharge vessel 11 is an insulating box, the insulating box is a cylinder with a diameter of 45 mm, the insulating plate 14 is a ceramic plate, the electrode support 9 and the electrode support 10 are two metal rods, and the plate electrode 7 and the plate electrode 8 with a diameter of 40 mm pass through the The two metal rods described above are horizontally fixed above and below the insulating plate 14 in the insulating box. One or more small holes 13 of 0.5-3 mm are opened on the insulating plate 14 , and the insulating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com