Composite bipolar plate for miniature fuel cell and its preparing method

A micro-fuel cell and bipolar plate technology, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of inability to process a true three-dimensional microstructure and high cost of bipolar plate manufacturing process, and achieve simple structure, Create handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

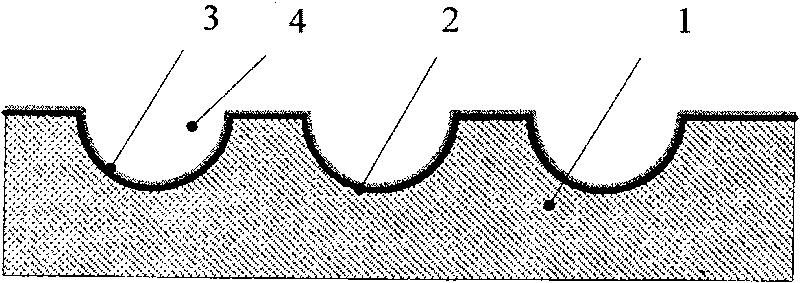

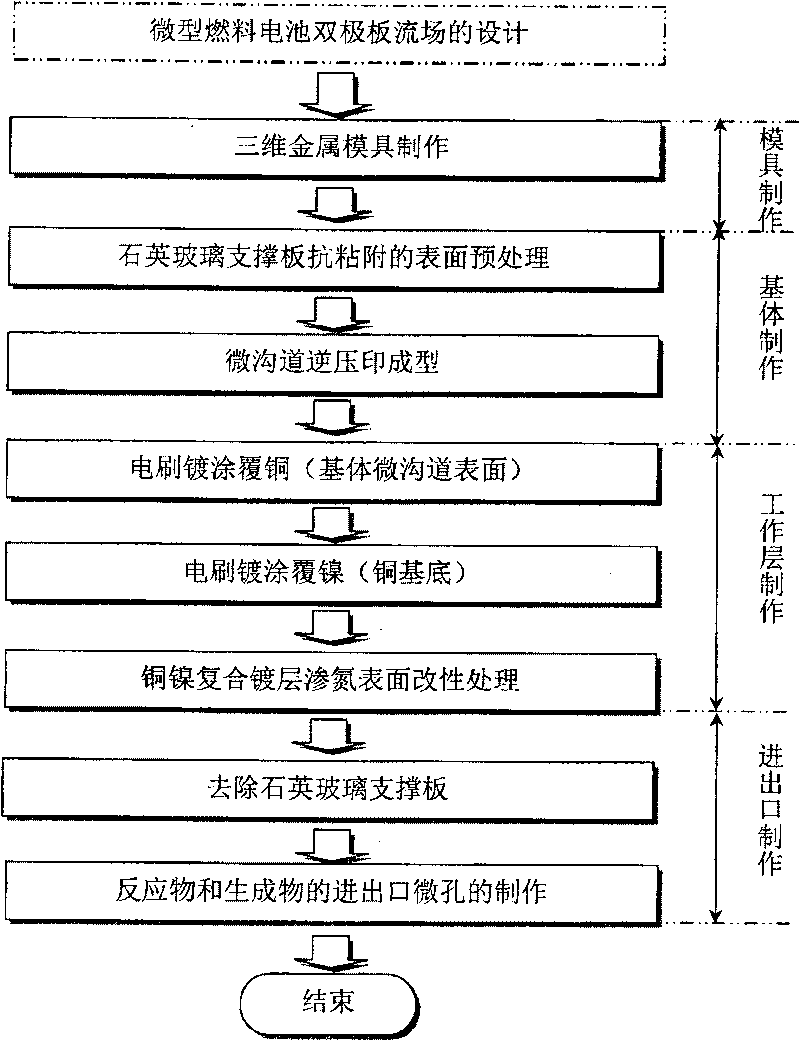

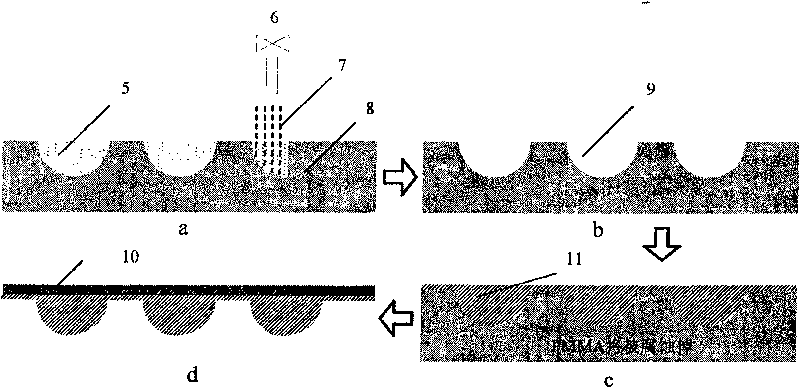

[0054] figure 1 Among them, the composite bipolar plate used for micro-fuel cells has a substrate 1 on which several three-dimensional microchannels 4 are regularly arranged, and a conductive layer 2 is attached to the upper surface of the overall substrate 1. On the conductive layer 2 with a protective layer 3 attached. Among them, the substrate 1 is a UV-curable polymer conductive material, the conductive layer 2 is made of high-conductivity copper, and the anti-corrosion protection layer 3 is made of bright nickel. The three-dimensional microchannels 4 are arranged in parallel and evenly spaced.

[0055] The composite bipolar plate of the micro-fuel cell of the present invention uses a UV-curable polymer conductive material as a matrix, high-conductivity copper as a conductive layer, and bright nickel as an anti-corrosion protection layer. Its prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com