Preparation method of ceramic-metal composite material

A metal composite material and ceramic technology, which is applied in the field of preparation of ceramic-metal composite materials, can solve the problems of uneven mixing of the matrix and the second phase material, cracks in the composite material, etc., and achieves superior high temperature performance, low thermal conductivity, and comprehensive performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

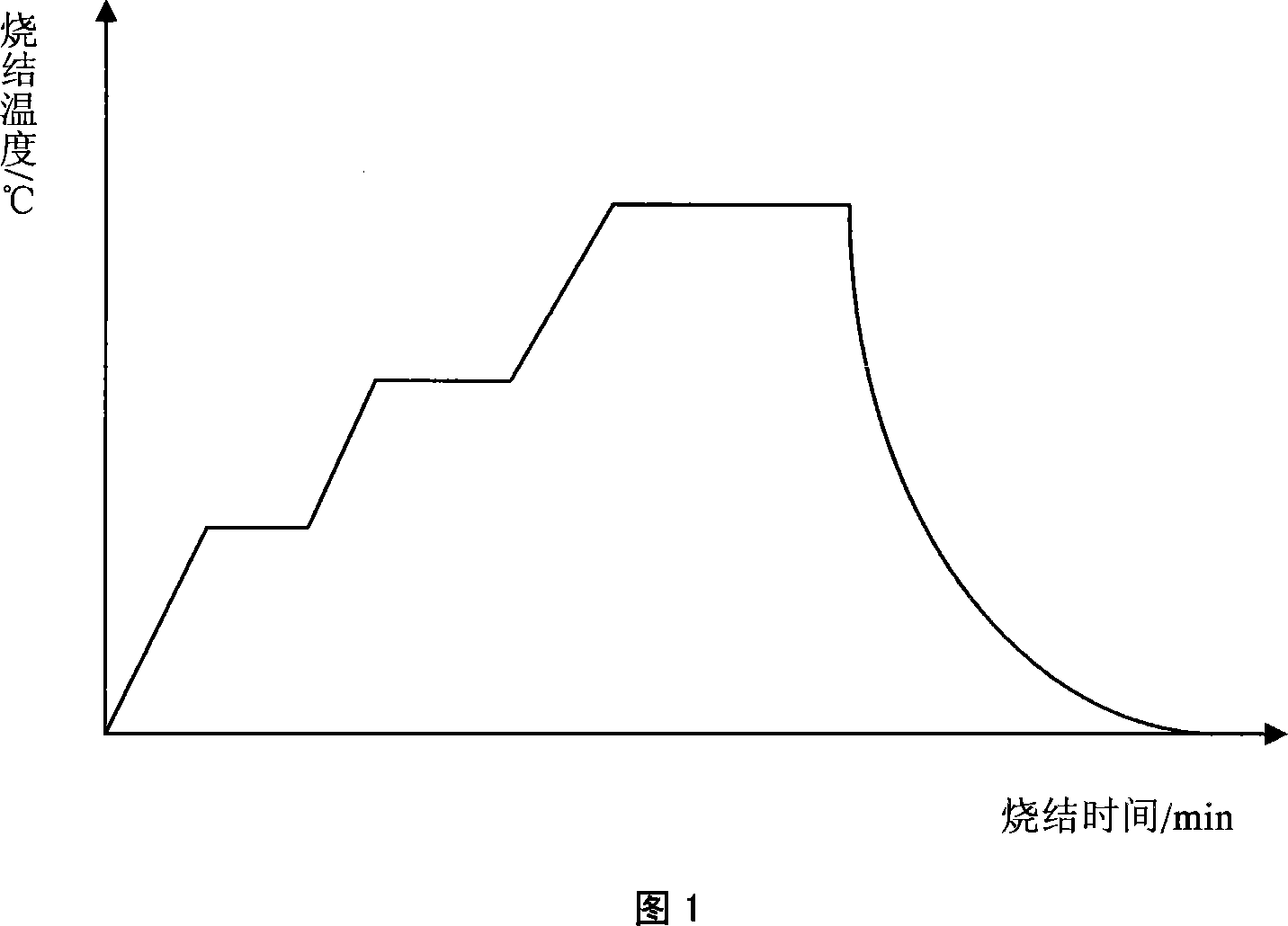

Method used

Image

Examples

Embodiment 1

[0078] Example 1 Preparation of Ceramic-Metal Composite Material

[0079] 1), matrix alloy ratio: 2Cr33Ni48WC10MoFe8 nickel-based metal is used as the matrix alloy, according to the composition ratio (weight ratio) in the 2Cr33Ni48WC10MoFe8 nickel-based metal, 2 parts of Cr powder, 33 parts of Ni powder, 48 parts of WC powder, Mo powder 10 parts and 8 parts of Fe powder are mixed evenly to prepare matrix alloy material;

[0080] 2), the preparation of composite ceramic phase particles: according to Ti powder and spherical Al 2 o 3 The particle weight ratio is 1:0.03, adding Ti powder to Al 2 o 3 Add PVB (polyvinyl butyral) alcohol solution binder to the granules, the amount of binder added is 5-10 ml per 100 grams of raw materials, stir and mix, so that the Ti powder is evenly coated on the oxidized The surface of aluminum particles is prepared as Al with a particle size of 0.8 mm and coated with Ti powder. 2 o 3 Composite ceramic phase particles.

[0081] 3), batching ...

Embodiment 2

[0093] Example 2 Preparation of Ceramic-Metal Composite Material

[0094] 1), matrix alloy ratio: 2Cr33Ni48WC10MoFe8 nickel-based metal is used as the matrix alloy, according to the composition ratio (weight ratio) in the 2Cr33Ni48WC10MoFe8 nickel-based metal, 2 parts of Cr powder, 33 parts of Ni powder, 48 parts of WC powder, Mo powder 10 parts and 8 parts of Fe powder are mixed evenly to prepare matrix alloy material;

[0095] 2), the preparation of composite ceramic phase particles: according to Ti powder and spherical Al 2 o 3 The particle weight ratio is 1:0.01, adding Ti powder to Al 2 o 3 Add PVB (polyvinyl butyral) alcohol solution binder to the granules, the amount of binder added is 5 ml per 100 grams of raw materials, stir and mix, so that the Ti powder is evenly coated on the alumina granules Surface, made of Ti powder-coated Al with a particle size of 1.0 mm 2 o 3 Composite ceramic phase particles.

[0096] 3), batching and granulation: According to the vol...

Embodiment 3

[0108] Example 3 Preparation of Ceramic-Metal Composite Material

[0109] 1), matrix alloy ratio: 2Cr33Ni48WC10MoFe8 nickel-based metal is used as the matrix alloy, according to the composition ratio (weight ratio) in the 2Cr33Ni48WC10MoFe8 nickel-based metal, 2 parts of Cr powder, 33 parts of Ni powder, 48 parts of WC powder, Mo powder 10 parts and 8 parts of Fe powder are mixed evenly to prepare matrix alloy material;

[0110] 2), the preparation of composite ceramic phase particles: according to Ti powder and spherical Al 2 o 3 The particle weight ratio is 1:0.05, adding Ti powder to Al 2 o 3 Add PVB (polyvinyl butyral) alcohol solution binder dropwise to the granules, add 10 ml of binder dropwise per 100 grams of raw material, stir and mix, so that the Ti powder is evenly coated on the alumina granules Surface, prepared as Ti powder-coated Al with a particle size of 0.5 mm 2 o 3 Composite ceramic phase particles.

[0111] 3), batching and granulation: According to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com