Niobic acid sodium potassium lithium radical leadless piezo-electric ceramic and preparation method thereof

A technology based on lead-free piezoelectricity and potassium sodium lithium niobate, applied in ceramics, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of low piezoelectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

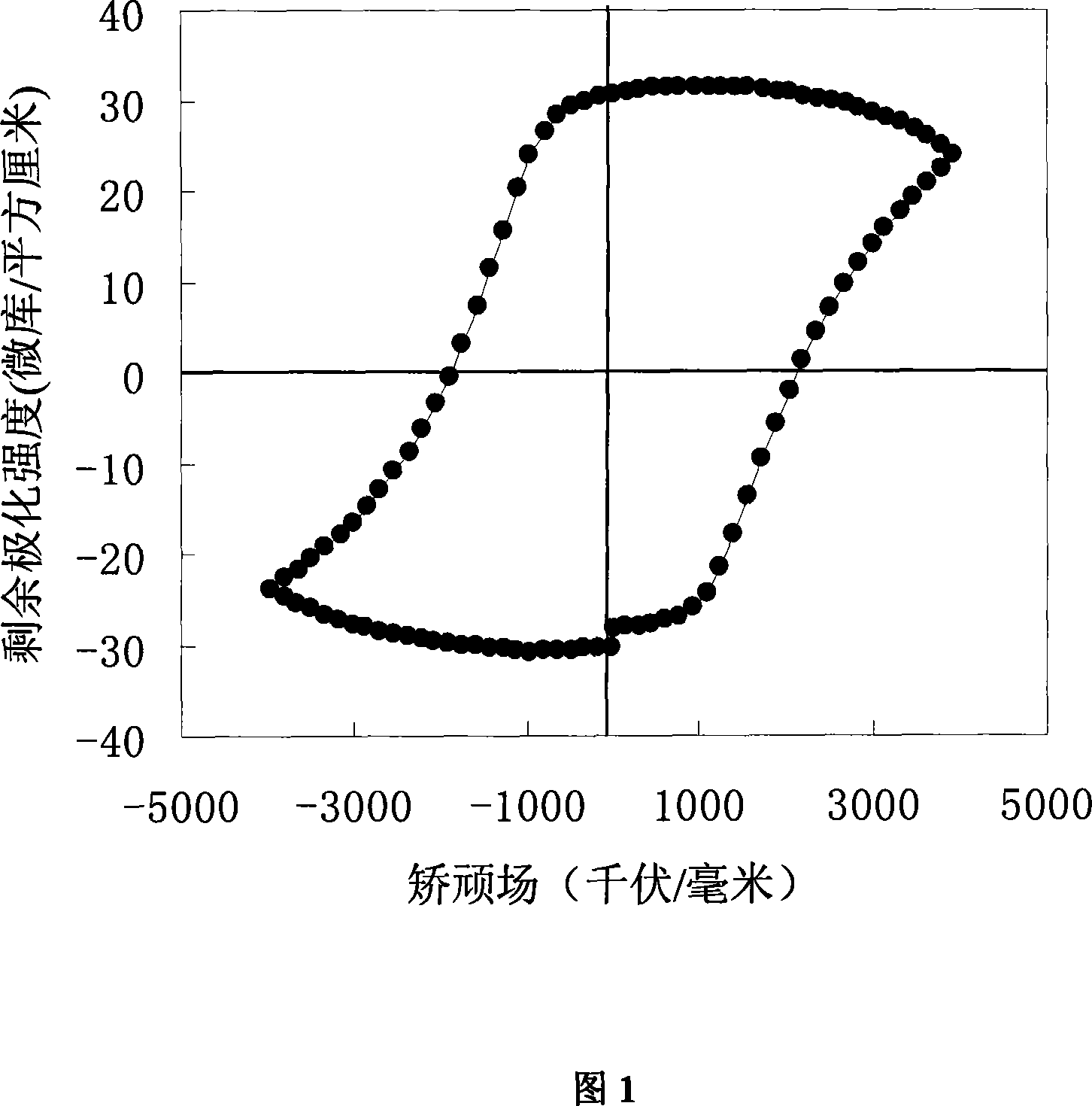

[0016] Example 1: First the raw materials are pressed by the equation (Na 0.569 Kb 0.485 Li 0.40 )(Nb 0.850 Ta 1.5 )O 3 Weighing, the quality of each substance is: 0.7912g sodium carbonate, 0.9255g potassium carbonate, 0.1255g lithium carbonate, 3.5581g niobium pentoxide, 6.5713g tantalum pentoxide. Put the raw materials into a ball mill jar, add 30ml of absolute ethanol as a medium, ball mill at a speed of 160 rpm for 1 hour, transfer the slurry and dry at 80°C for 8 hours. Then the dried powder was calcined at 500° C. for 10 hours. Put the pre-fired powder into a φ20mm mold and press it into shape. Then put the molded powder into a sintering furnace for sintering, and keep it in the atmosphere for 5 hours at 600°C for sintering. Coat the potassium-sodium niobate-based piezoelectric ceramic disk with a baked silver electrode, and polarize it in silicone oil. During the polarization, the temperature is gradually increased from room temperature to 100°C, and then the tim...

example 2

[0017] Example two: first raw material is pressed by equation (Na 0.716 Kb 0.630 Li 0.823 )(Nb 0.220 Ta 0.213 Sb 0.421 )O 3 Weighing, the specific mass of each substance is: 0.2395g sodium carbonate, 0.3722g potassium carbonate, 1.2197g niobium pentoxide, 2.4293g tantalum pentoxide, 0.1520g lithium carbonate, 2.45126 antimony trioxide. Put the raw materials into a ball mill jar, add 30ml of absolute ethanol as a medium, ball mill at a speed of 160 rpm for 1 hour, transfer the slurry and dry at 80°C for 8 hours. Then the dried powder was calcined at 900° C. for 1 hour. Put the pre-fired powder into a φ5mm mold and press it into shape. Then put the formed powder into a sintering furnace for sintering, and keep it in the air for 5 hours at a temperature of 1200°C. Coat the potassium-sodium niobate-based piezoelectric ceramic disc with a baked silver electrode, and polarize it in silicone oil. During the polarization, the temperature is gradually increased from room temper...

example 3

[0018] Example three: first the raw materials are pressed by the equation (Na 0.456 Kb 0.630 Li 0.412 )(Nb 0.360 Ta 0.213 Sb 0.421 )O 3 -0.045-CaO is weighed, and the specific mass of each substance is: 0.4295g sodium carbonate, 0.6522g potassium carbonate, 3.1197g niobium pentoxide, 4.7164g tantalum pentoxide, 0.3521g lithium carbonate, 6.3124 antimony trioxide, 0.1211 g calcium oxide. Put the raw materials into a ball mill jar, add 30ml of absolute ethanol as a medium, ball mill at a speed of 160 rpm for 8 hours, transfer the slurry and dry at 80°C for 8 hours. Then the dried powder was calcined at 700° C. for 3 hours. Put the pre-fired powder into a φ16mm mold and press it into shape. Then put the formed powder into a sintering furnace for sintering, and keep it in the air for 5 hours at a temperature of 1020°C. Coat the potassium-sodium niobate-based piezoelectric ceramic disk with a baked silver electrode, and conduct polarization in silicone oil. During polariza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com