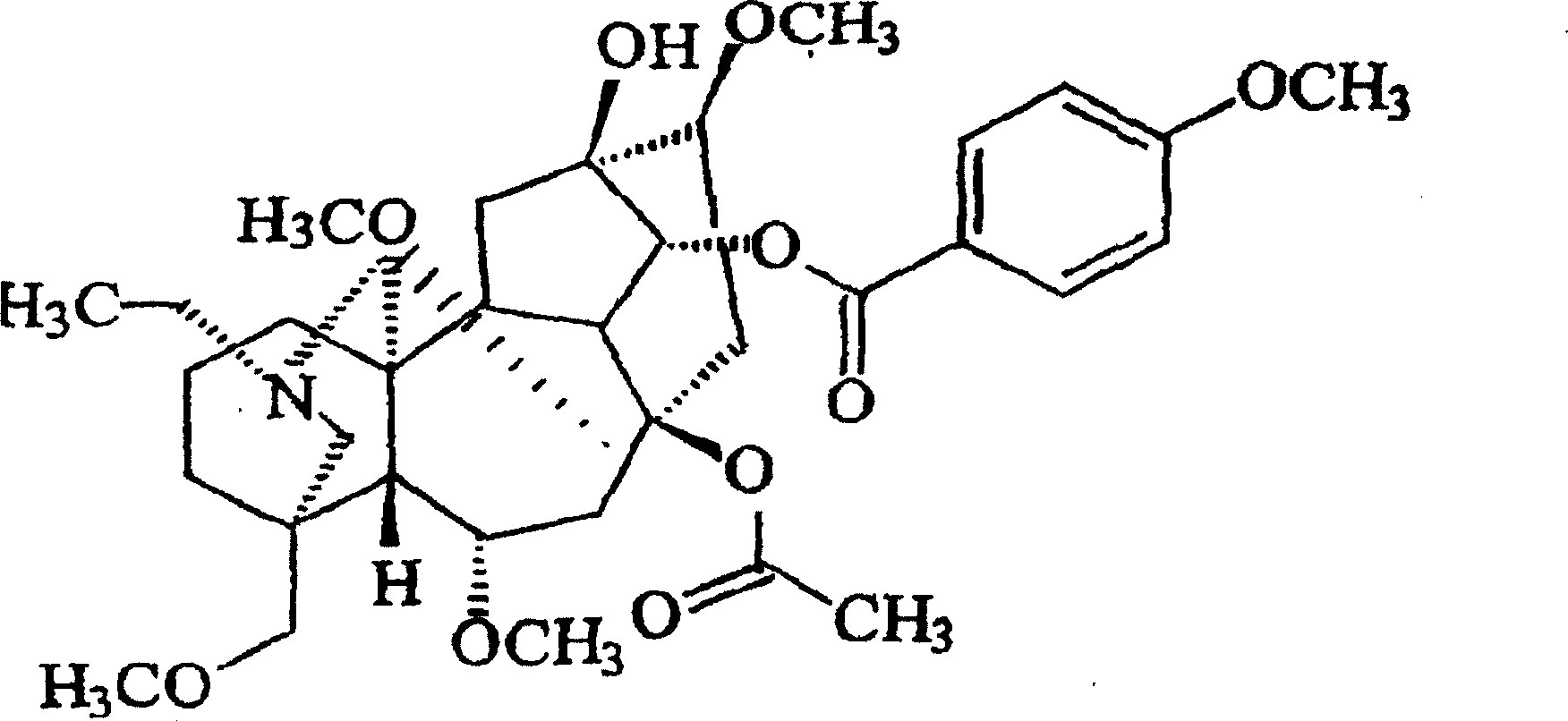

Bulleyaconitin A dry emulsion and its preparation method and application

A technology of sulfamethoxine and dry emulsion, which is applied in the field of pharmaceutical dosage forms in the field of medical technology, can solve problems such as the destruction of drugs and auxiliary materials, the large volume of fat emulsion infusion, the breaking of emulsion droplets, etc. The effect of controllable content and mature production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) In the preparation equipment, dissolve 0.005 g of aconitin in 300 ml of safflower oil;

[0047] 2) Mix 10g of lecithin with an appropriate amount of water for injection, and add 50gV c ;

[0048] 3) Add 2) into 1) under the condition of stirring, and after stirring at 20° C., pass through a homogenizer to homogenize the solution repeatedly to obtain a uniform solution. Prepare a total of 2000ml of liquid medicine;

[0049] 4) Add 80% mannitol as a protective agent, remove moisture through spray drying, and obtain dry aconitin dry emulsion;

[0050] 5) Add water to the prepared dry emulsion according to the required amount, revert to emulsion after hydration and shaking.

Embodiment 2

[0052] 1) In the preparation equipment, dissolve 0.4 g of aconitin in 25 ml of safflower oil for injection;

[0053] 2) Mix 9g of lecithin with an appropriate amount of water for injection, and add 1g of sodium oleate;

[0054] 3) Add 2) into 1) under the condition of stirring, and after stirring at 30° C., pass through a homogenizer to homogenize the solution repeatedly to obtain a uniform solution. Prepare a total of 1000ml of liquid medicine;

[0055] 4) adding 12% glucose as a protective agent, and removing moisture by freeze-drying to obtain a dry curicaconin dry emulsion;

[0056] 5) Add water to the prepared dry emulsion according to the required amount, revert to emulsion after hydration and shaking.

Embodiment 3

[0058] 1) In the preparation equipment, dissolve 8 g of aconitin in acetone, and then evenly disperse the acetone solution in 1000 ml of olive oil;

[0059] 2) Mix 5g of poloxamer, 0.1g of natural stevioside with water, and add 40g of ethylparaben

[0060] 3) Add 2) to 1) under the condition of stirring, and after stirring at 80° C., pass through a homogenizer to homogenize the solution repeatedly to obtain a uniform solution. Prepare the liquid medicine of 4000ml;

[0061] 4) adding 40% maltose as a protective agent, distilling off the water under reduced pressure, and adding silicon dioxide to absorb excess water to obtain a dried aconitin dry emulsion;

[0062] 5) Add water to the prepared dry emulsion according to the required amount, revert to emulsion after hydration and shaking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com