Organic ultraviolet detector

An organic ultraviolet light and detector technology, which is applied in the direction of photometry using electric radiation detectors, can solve the problems of high cost, inapplicability to large-area applications, and complicated preparation process of inorganic ultraviolet light detectors, achieving small size, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

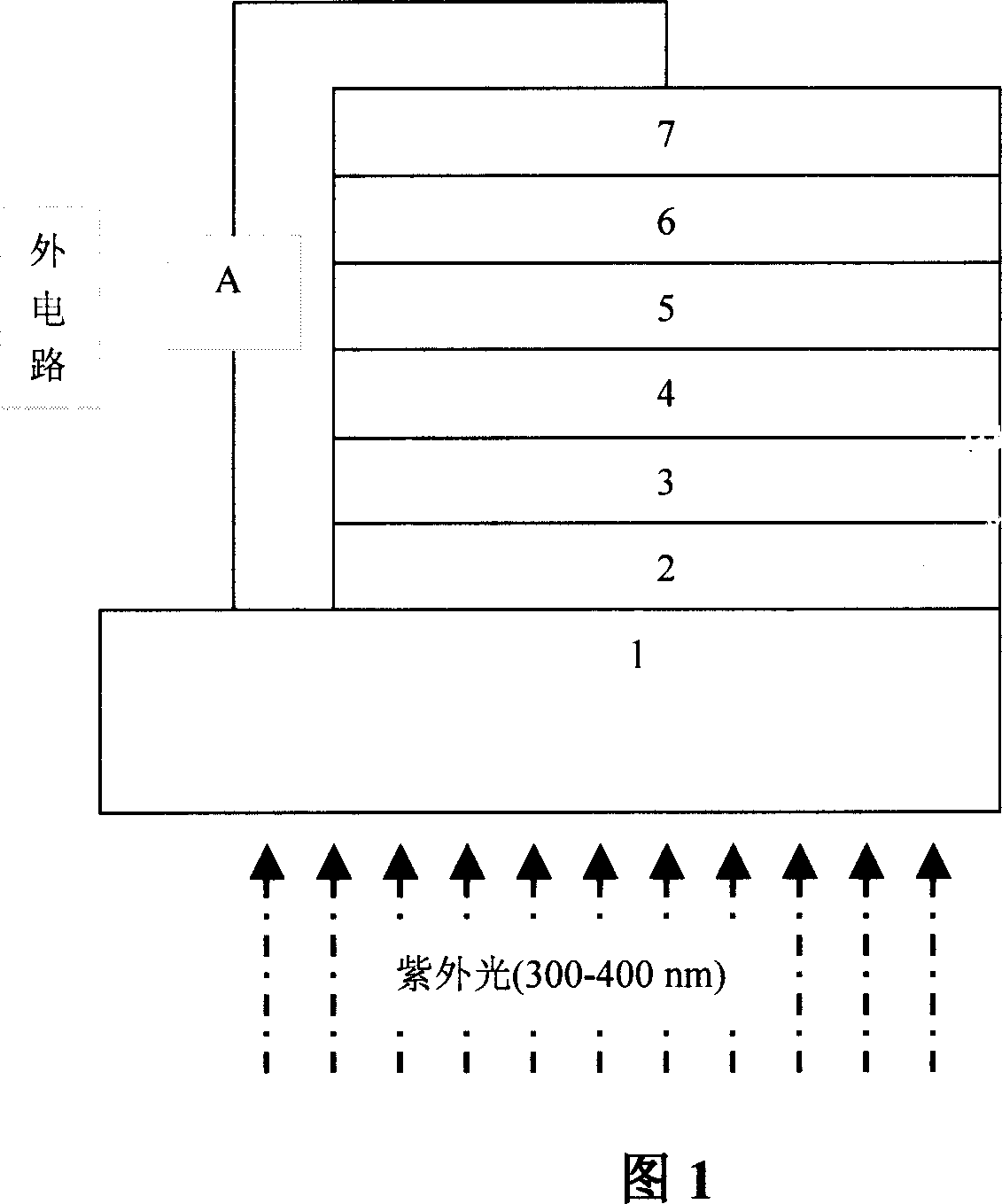

[0030] The utility model selects the device structure shown in Fig. 1 for use. In the present embodiment, at first the transparent conductive film 2 selects the ITO film as the hole collecting electrode, and after cleaning the transparent conductive film 2 on the substrate 1, at first it is cleaned in a high vacuum (3-2×10 -4Pa), on the transparent conductive film 2, deposit a layer of thickness of 10nm electron donor layer 3TPD, and then deposit electron donor TPD and electron acceptor PBD ratio on the electron donor layer 3 with a ratio of 1:1 and a thickness of 5nm. The mixed layer 4 and the electron acceptor layer 5 are deposited on the mixed layer 4 with a thickness of 10nm or 20nm or 30nm. Afterwards, the electron collecting layer 6 is deposited, and the material is LiF, and its thickness is 0.8nm; finally, the electron collecting electrode 7 is deposited, and the metal Al material is used. All of the above films were deposited using thermal evaporation processes. The ...

Embodiment 2

[0033] On the basis of Example 1, the electron donor layer is selected from the m-MTDATA material, and the thickness is 10nm, and then the electron donor m-MTDATA and the electron acceptor Gd (DBM) are deposited on the layer 3 3 The phen ratio is 1:1, the mixed layer 4 with a thickness of 5nm, and then the electron acceptor layer Gd (DBM) is deposited on the mixed layer 4 3 The thickness of phen5 is selected as 10nm or 20nm or 30nm. Afterwards, the electron collecting layer 6 is deposited, and the material is LiF, and its thickness is 0.8nm; finally, the electron collecting electrode 7 is deposited, and the metal Al material is used. All of the above films were deposited using thermal evaporation processes. The thickness of the film is monitored with a film thickness monitoring instrument, and the open circuit voltage and short circuit current are detected with a voltage-ammeter. When irradiating with one side of the ultraviolet photoconductive film 2 and using an external c...

Embodiment 3

[0036] On the basis of Example 1, the hole collection layer 3 is made of m-MTDATA material with a thickness of 10 nm, a mixed layer 4 with a ratio of m-MTDATA and PBD of 1:1 and a thickness of 5 nm, and then electron acceptors are deposited on the mixed layer 4 The thickness of the layer PBD5 is selected to be 10nm or 20nm or 30nm. Other manufacturing conditions remain unchanged. Effect: the power is 4mW / cm 2 When the central wavelength is 365nm UV light irradiation, the electrical signal that can be obtained is; open circuit voltage Voc=2.0V short circuit current Jsc=49μA / cm 2 , When visible light longer than 400nm is irradiated from the side of the ITO transparent electrode, no electrical signal can be detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com