Atmospheric quick preparing method for carbon gas gel electrode material for super grade capacitor

A supercapacitor, carbon aerogel technology, applied in capacitor electrodes, electrode manufacturing, capacitor parts and other directions, can solve the problems of no supercapacitor value, no supercapacitor research, long drying time, etc., to save the solvent The effect of exchanging processing steps, shortening the preparation cycle, and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the molar ratio R / F of resorcinol and formaldehyde is 0.5, the molar ratio R / C of resorcinol and lactic acid as an additive is 0.2, and the mass ratio of resorcinol and deionized water is 0.2. , Dissolve resorcinol in deionized water, then add additive lactic acid, then add formaldehyde solution, and mix well. Put it in a sealed reactor with a constant temperature of 90°C and complete the gelation process in 0.5 hours to become a hydrogel. Under the action of ammonia gas, the temperature was raised to 850° C., and the temperature was kept constant for 1.5 hours to complete the preparation of carbon airgel.

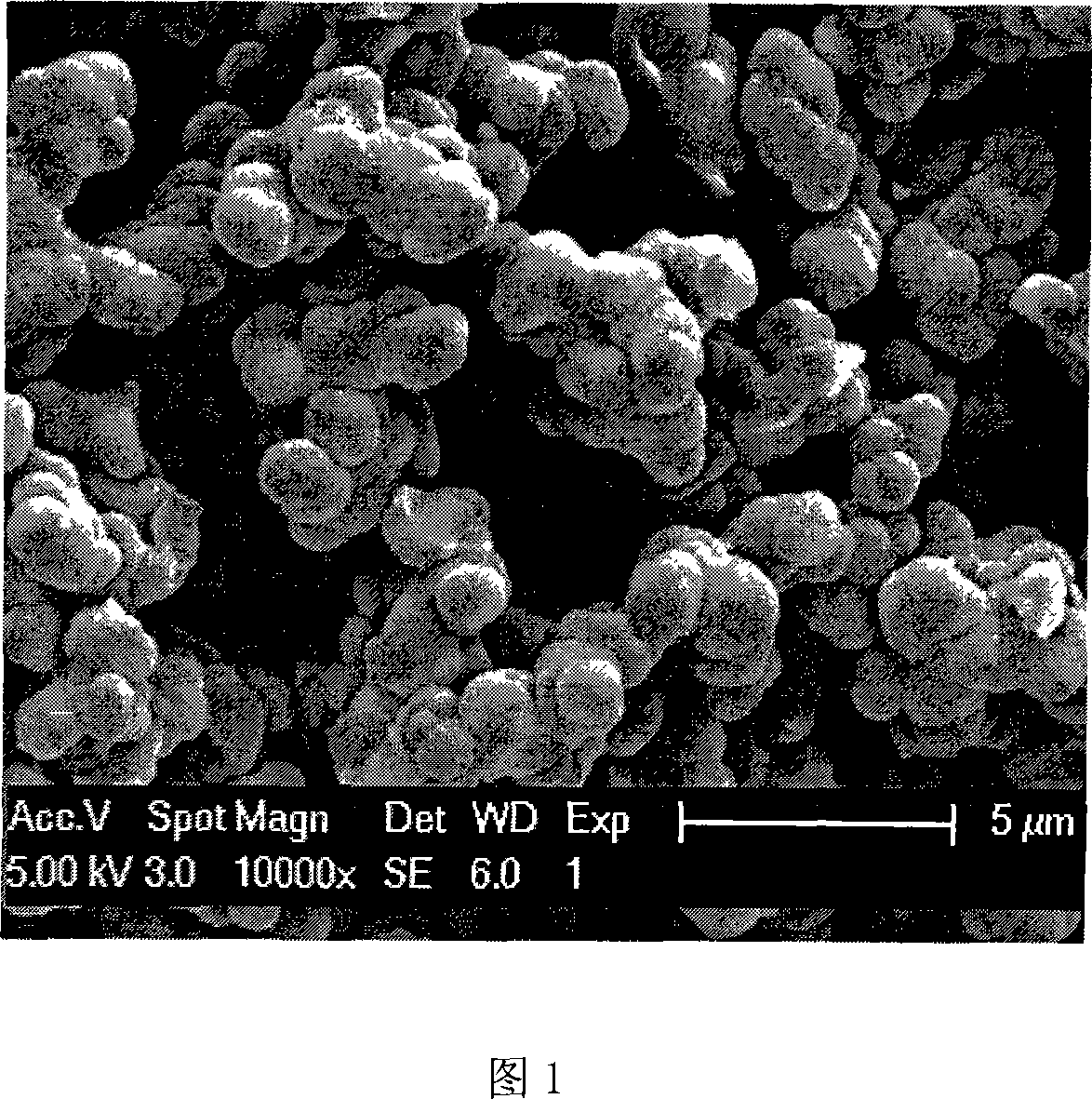

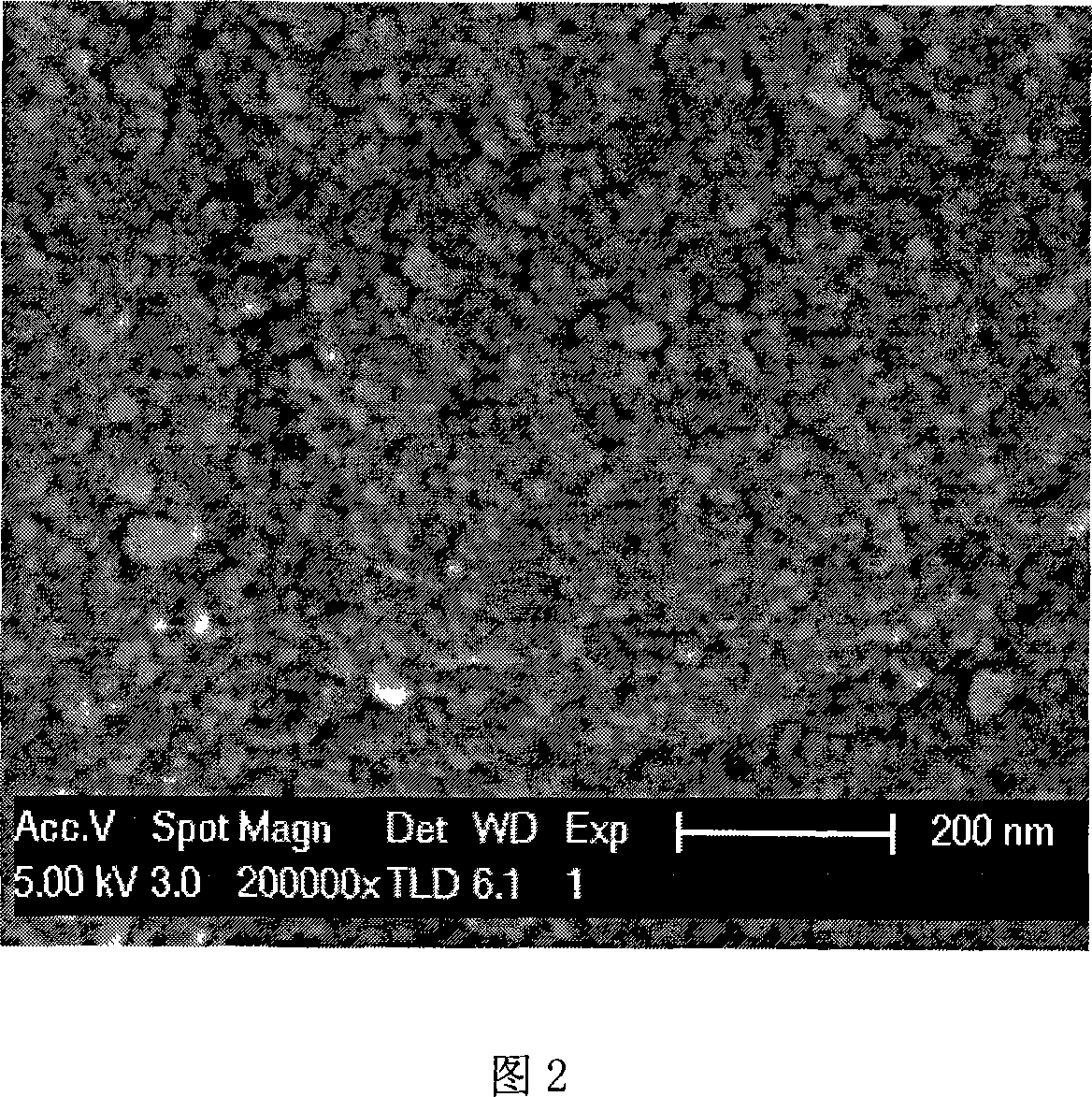

[0033] The morphology of the prepared carbon airgel is shown in Fig. 1 and Fig. 2 . Figure 1 is a field-effect scanning electron microscope (FESEM) image of the carbon airgel structure with a magnification of 10,000 times, from which it can be seen that evenly distributed interconnected microspheres and a large number of holes provide channels for the ...

Embodiment 2

[0036] According to the molar ratio R / F of resorcinol and formaldehyde is 0.5, the molar ratio R / C of resorcinol and the malonic acid as additive is 10, the mass ratio of resorcinol and deionized water is 0.2 For proportioning, dissolve resorcinol in deionized water, then add the additive malonic acid, then add formaldehyde solution, and mix well. Put it in a sealed reactor with a constant temperature of 90°C and complete the gelation process in 3 hours to become a hydrogel. Under the action of ammonia gas, the temperature was raised to 900°C and kept at a constant temperature for 1.5 hours.

[0037] According to the test, the compacted density of the prepared carbon aerogel is 0.51g / cm 3 , 90% of the pores are below 5nm, the average pore diameter is 2.5nm, and the specific surface area is 971m 2 / g, in 1mol / L of H 2 SO 4 In the electrolyte, the specific capacitance of the cyclic voltammetry test at a scanning speed of 50mv / s is 246F / g, and the specific capacitance of the ...

Embodiment 3

[0039] According to the mol ratio R / F of resorcinol and formaldehyde is 0.3, the mass ratio R / C of resorcinol and the piperazine citrate as additive is 400, the mass ratio of resorcinol and deionized water is For a ratio of 0.2, take resorcinol and dissolve it in deionized water, then add the additive piperazine citrate, then add formaldehyde solution, and mix well. Put it in a sealed reactor with a constant temperature of 85°C and complete the gelation process in 4 hours to become a hydrogel. Under the action of ammonia gas, the temperature was raised to 1100°C, and the temperature was kept constant for 1 hour.

[0040] According to the test, the compacted density of the prepared carbon aerogel is 0.35g / cm 3 , the specific surface area is 767m 2 / g, in 1mol / L of H 2 SO 4 In the electrolyte, the specific capacitance of the cyclic voltammetry test at a scanning speed of 50mv / s is 196F / g, and the specific capacitance of the cyclic voltammetry test at a scanning speed of 2mv / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com