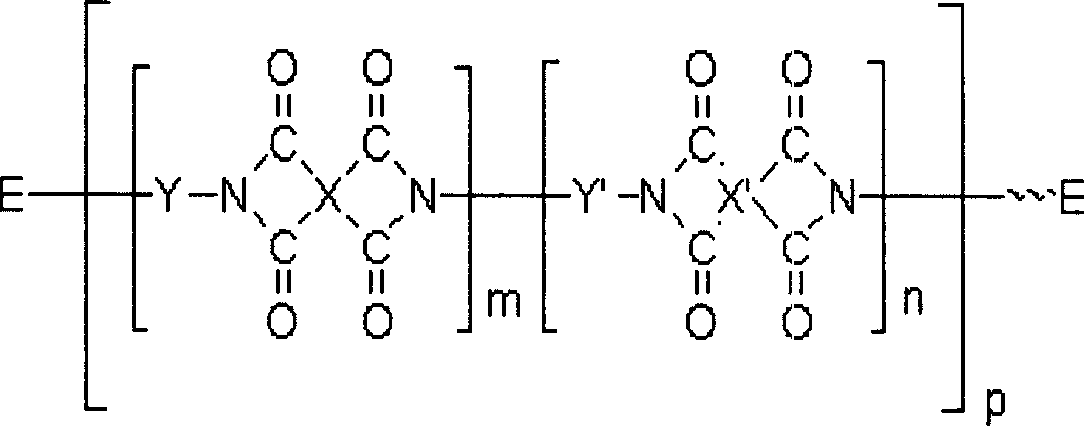

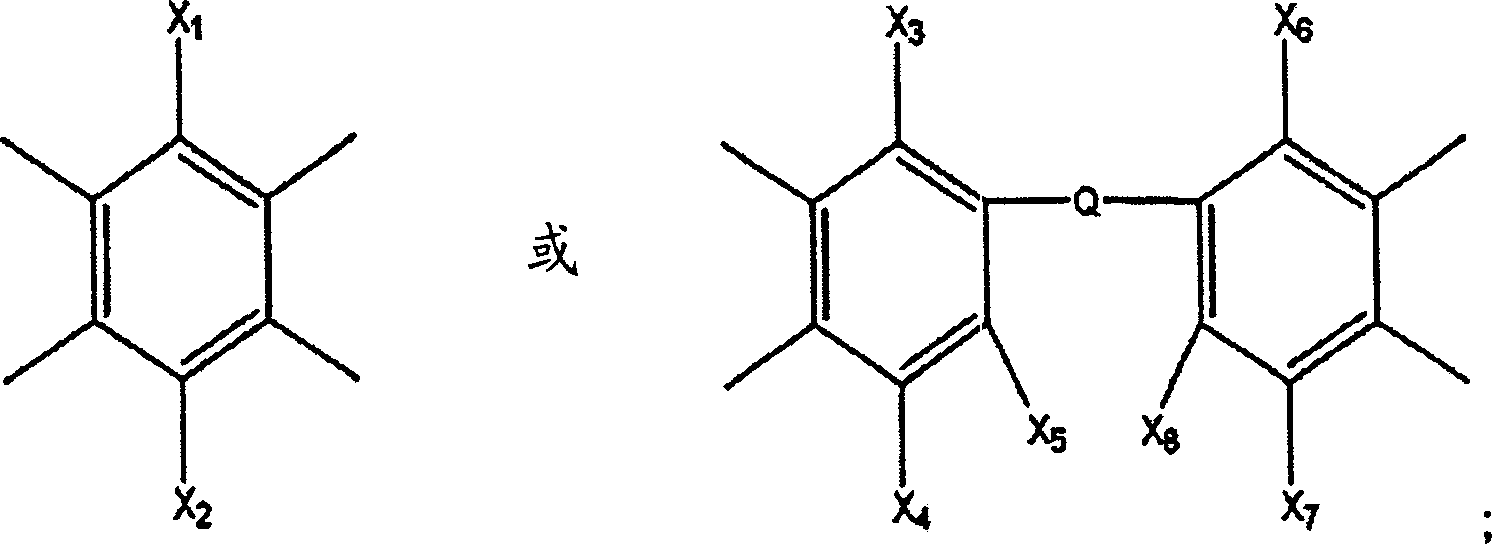

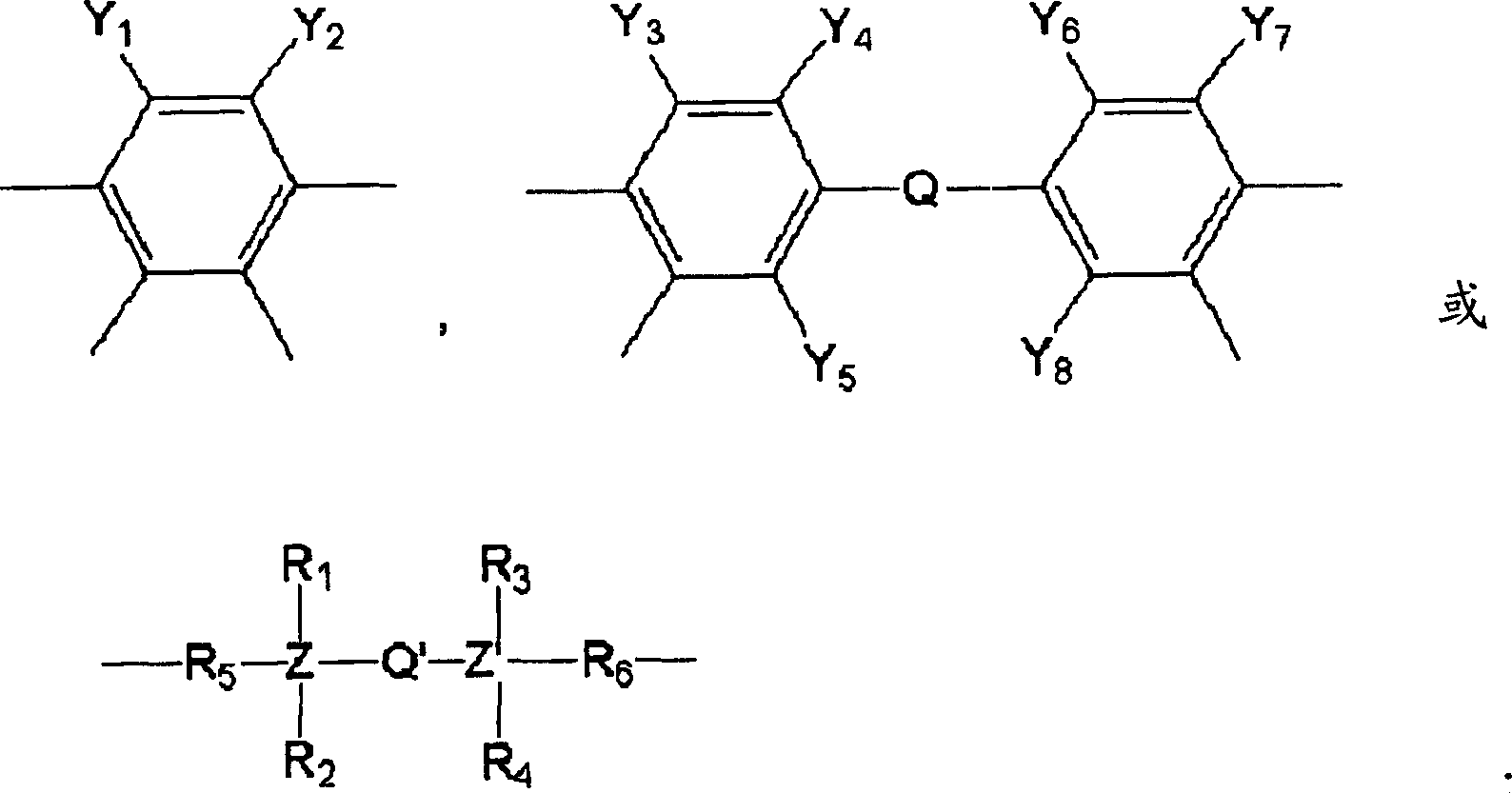

Polymer electrolyte membrane, method of manufacturing the same and fuel cell including the same

A technology of electrolyte membrane and polymer, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of lack of ionic conductivity, methanol permeation inhibition ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] (1) Synthesis of polyamic acid with reactive end groups

[0127] 10.01g of 4,4'-diaminophenyl ether (ODA) and 57.5g of N-methyl-2-pyrrolidone (NMP) were sequentially added to a 1L round-bottom jacketed reactor, stirred slowly and allowed to Dissolve completely. The jacket temperature of the reactor was maintained at 20° C., and 13.18 g of 4,4′-oxydiphthalic anhydride (ODPA) was slowly added and stirred to dissolve it. Then, the reaction solution was stirred for 2 hours to fully react, then 1.47 g of maleic anhydride (MA) was slowly added, and stirred at room temperature for 16 hours to obtain liquid polyamic acid. The average degree of polymerization of polyamic acid was 35.

[0128] (2) Preparation of polymer electrolyte membrane

[0129] 30 parts by weight of the sulfonated poly(arylene ether sulfone) of formula 2 having an average degree of polymerization of 250, 70 parts by weight of the polyamic acid having reactive end groups prepared in (1) as an ion-conductin...

Embodiment 2

[0133] A polymer electrolyte membrane (membrane thickness: about 34 μm) was prepared in the same manner as in Example 1, except that 40 parts by weight of the sulfonated poly(arylene ether sulfone) having an average degree of polymerization of 250 was used, and 60 parts by weight The polyamic acid having reactive terminal groups prepared in (1) as an ion-conductive polymer.

Embodiment 3

[0135] A polymer electrolyte membrane (membrane thickness: about 36 μm) was prepared in the same manner as in Example 1, except that 50 parts by weight of the sulfonated poly(arylene ether sulfone) having an average degree of polymerization of 250 was used, and 50 parts by weight The polyamic acid having reactive terminal groups prepared in (1) as an ion-conductive polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com