Double-electrolyte system lithium sulphur battery and preparing method thereof

A dual-electrolyte, lithium-sulfur battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve the problems of low active sulfur content in electrodes, difficult to meet, cumbersome process, etc., achieve high stability and inhibit corrosion effect of behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

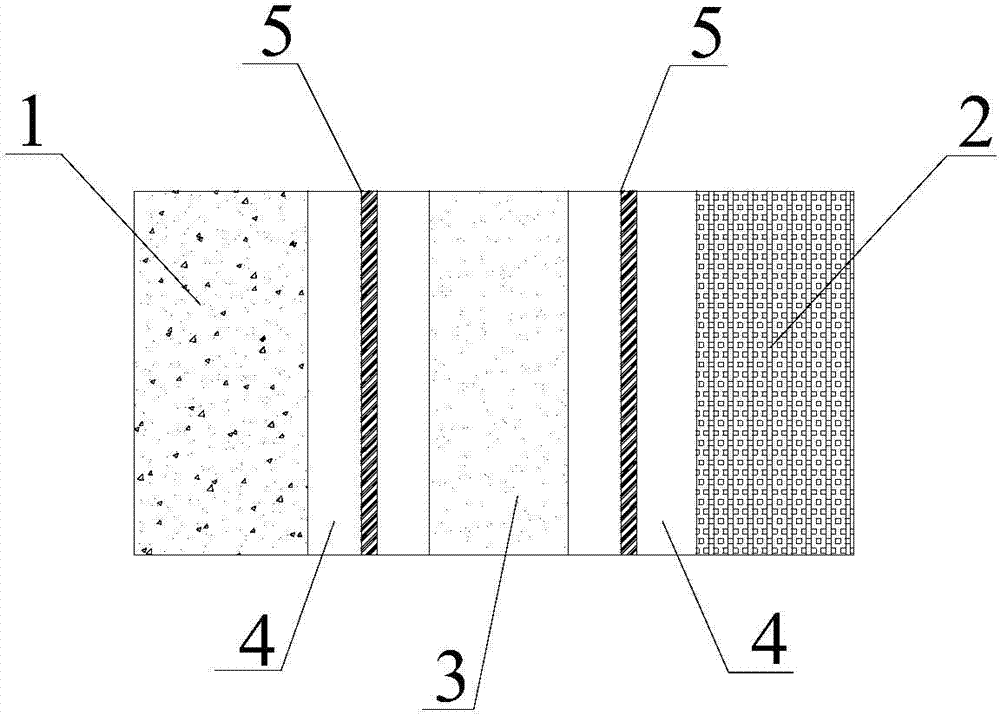

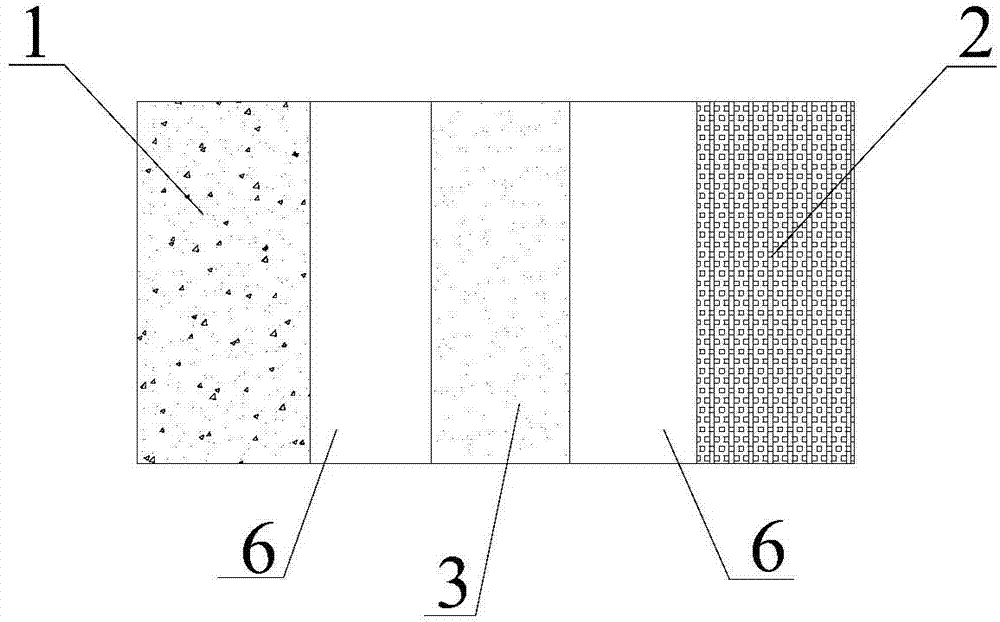

[0038] 1. Mix conductive carbon black and sublimated sulfur uniformly by ball milling. After the solvent volatilizes, conduct vacuum heat treatment at 155°C to obtain sulfur / carbon composites. After coating, dry to prepare the positive electrode of the battery;

[0039] Two, will Li 2 CO 3 , α-Al 2 o 3 、GeO 2 , NH 4 h 2 PO 4 According to the atomic ratio of Li:Al:Ge:P=1.5:0.5:1.5:3, carry out ball milling, drying, and sieving, and roast the obtained powder at 800°C for 6h to obtain LAGP powder, and press the LAGP powder After sintering at 900°C for 12 hours to obtain LAGP ceramic sheets;

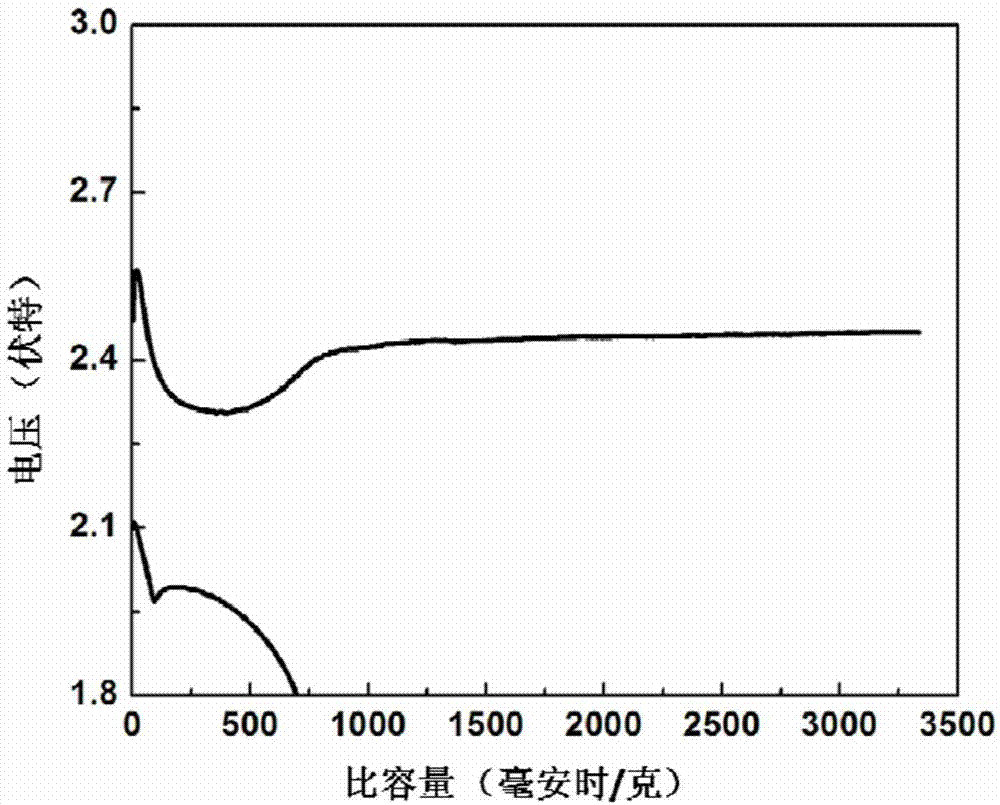

[0040] 3. Seal the ceramic sheet in the designed mold, and use glass fiber membrane to absorb 1mol / L bis(trifluoromethylsulfonate)imide lithium 1,3-dioxolane / ethylene glycol dimethyl ether based electrolysis After the liquid (LiTFSI DME / DOL), paste it on the side of the ceramic sheet, and then press the lithium sheet on the glass fiber membrane to seal the negative electrode side; a...

Embodiment 2

[0044] 1. Ultrasonically disperse graphene into water, add sodium thiosulfate to stir, add hydrochloric acid dropwise to hydrolyze sodium thiosulfate to generate nano-sulfur on the surface of graphene, and finally obtain a self-supporting graphene / sulfur battery positive electrode by suction filtration;

[0045] Two, will Li 2 CO 3 , α-Al 2 o 3 、GeO 2 , NH 4 h 2 PO 4 According to the atomic ratio Li:Al:Ge:P=1.5:0.5:1.5:3, perform ball milling, drying, and sieving, and roast the obtained powder at 800°C for 6 hours to obtain LAGP powder, and press the powder into tablets Afterwards, sinter at 900°C for 12 hours to obtain LAGP ceramic sheets;

[0046] 3. Seal the LAGP ceramic sheet in the designed mold, absorb 1mol / L LiTFSIDME / DOL organic electrolyte with a glass fiber membrane and stick it on one side of the LAGP ceramic sheet, then press a lithium sheet on the glass fiber membrane, and place the negative side For sealing, a layer of 0.3M LiTFSI+0.2M Li is also adsorbed...

Embodiment 3

[0048] 1. Treat the carbon nanotubes with concentrated nitric acid to form functional groups on the surface, then ultrasonically disperse them into the aqueous solution, and finally obtain the positive electrode of the carbon nanotube membrane battery by suction filtration;

[0049] Two, will Li 2 CO 3 , α-Al 2 o 3 、TiO 2 , NH 4 h 2 PO 4 According to the atomic ratio of Li:Al:Ti:P=1.4:0.4:1.6:3, perform ball milling, drying, and sieving, and the obtained powder is first calcined at 350°C for 2h, and then calcined at 800°C for 0.5h , to obtain LATP powder, press the powder into tablets and sinter at 900°C for 6 hours to obtain LATP ceramic sheets;

[0050] 3. Seal the ceramic sheet in the designed mold, absorb 1mol / L LiTFSI DME / DOL organic electrolyte with a glass fiber membrane and stick it on one side of the ceramic sheet, then press a lithium sheet on the glass fiber membrane, and place the negative electrode side Sealed, add a layer of 2M Li on the positive side 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com