Method of preparing peach gum octenyl succinate

A technology of octenyl succinic acid and octenyl succinic anhydride is applied in the field of modification of natural products, can solve problems such as no emulsification, and achieve the effects of low production cost, abundant resources, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

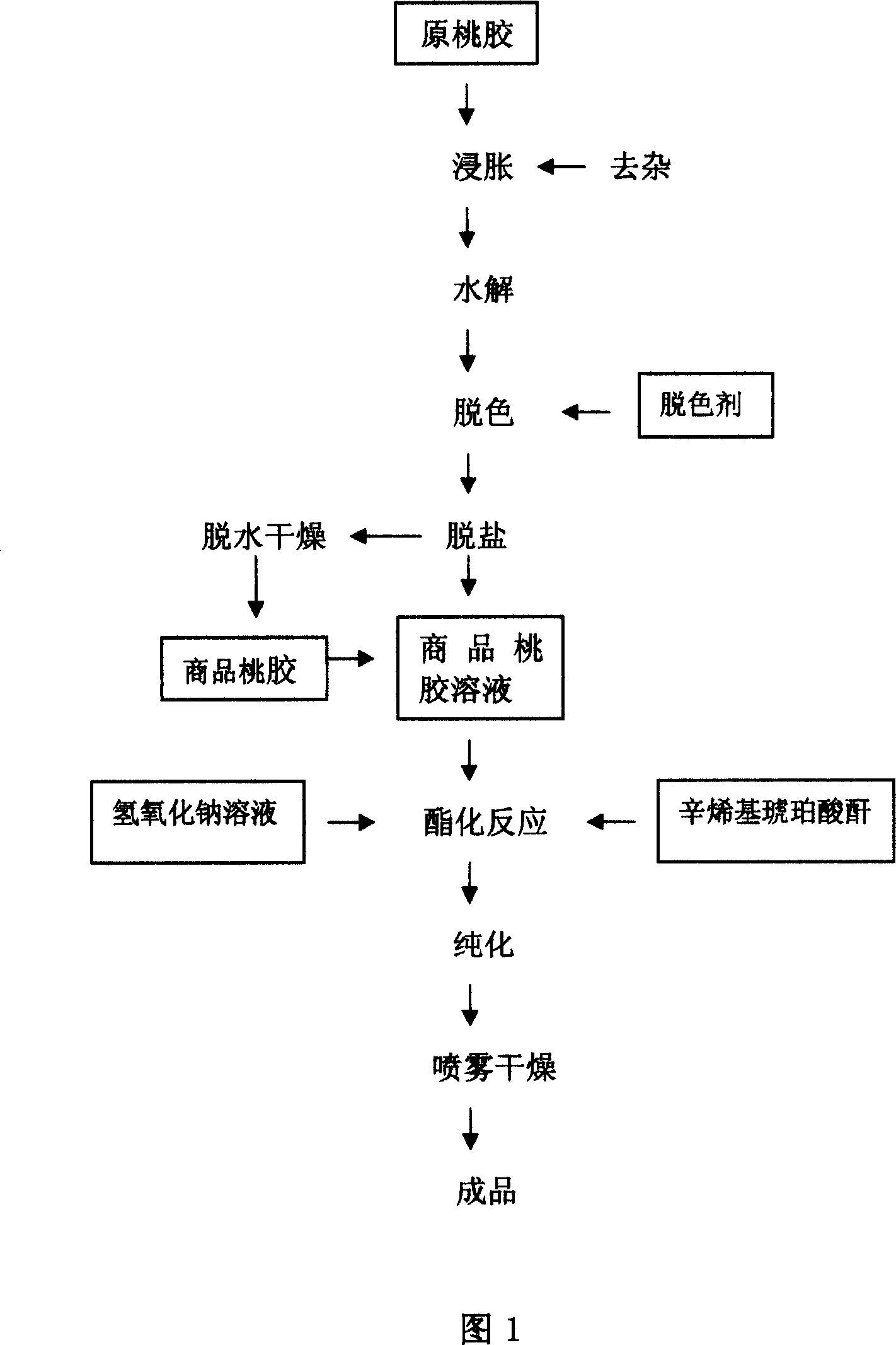

Method used

Image

Examples

Embodiment 1

[0041] Clean the raw peach gum, remove bark, soil and other impurities, soak it with clean water to make it fully swell, add a sodium hydroxide solution with a pH value of 10, beat it into a slurry with a beater, and place it at 80°C for 2 Hours, the hydrolyzate was decolorized with 3% hydrogen peroxide solution. The peach gum hydrolyzate was passed through 001 * 7 After desalting the cation exchange resin, dry it in an oven at 80°C to obtain peach gum powder. Dissolve peach gum powder in deionized water to prepare 20% peach gum solution. Use 3% (w / w) sodium hydroxide solution to adjust its pH value to 8.5, place it in a constant temperature water bath box at 35°C, slowly add octenyl succinic anhydride to the solution, and the addition amount is peach gum dry base 5% (w / w) of the amount, and the solution was stirred for reaction. Pass the reacted solution through 001 * 7 Cation exchange resin, to exchange sodium ions and hydrogen ions in the solution, and then pass through...

Embodiment 2

[0043] Clean the raw peach gum, remove bark, soil and other impurities, soak it with clean water to make it fully swell, add a sodium carbonate solution with a pH value of 9, grind it into a slurry with a beater, and place it at 85°C for 5 Hours, the hydrolyzate was decolorized with 2% sodium hypochlorite solution. After the peach gum hydrolyzate is desalted with D001 cation exchange resin, adjust its pH value to 9.0 with 3% (w / w) ammonia water, place it in a constant temperature water bath at 45°C, and slowly add octenyl amber to the solution The acid anhydride is added in an amount of 1% (w / w on a dry basis) of the amount of peach gum, and the solution is stirred for reaction. The solution after the reaction is passed through the D001 cation exchange resin to exchange the sodium ion and the hydrogen ion in the solution, and then pass through the AB-8 macroporous resin to remove the remaining octenyl succinic anhydride and octenyl succinic acid in the solution, thereby A pur...

Embodiment 3

[0045]Clean the raw peach gum, remove bark, soil and other impurities, soak it with clean water to make it fully swell, add an ammonia solution with a pH value of 11, use a beater to grind it into a slurry, and place it at 95°C for 4 hours , the hydrolyzate was decolorized with 3% sodium sulfite solution. The peach gum hydrolyzate was desalted with D201 cation exchange resin, and dried in an oven at 65°C to obtain peach gum powder. Dissolve the peach gum powder in deionized water to prepare a 30% peach gum solution. With 3% (w / w) NaHCO 3 The pH value of the solution is adjusted to 8.5, placed in a constant temperature water bath at 35°C, and octenyl succinic anhydride is slowly added to the solution in an amount of 3% (w / w on a dry basis) of the amount of peach gum, stirred The solution reacts. Pass the reacted solution through D201 cation exchange resin to exchange sodium ions and hydrogen ions in the solution, and then pass through D1300 macroporous resin to remove the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com