Etching liquor for laminated film of aluminium metal film and molybdenum metal film

An etching solution and metal film technology, applied in the field of etching solution, can solve the problems of difficult molybdenum metal taper angle control, undisclosed, difficult concentration management, etc., to achieve excellent etching characteristics and prevent wire breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

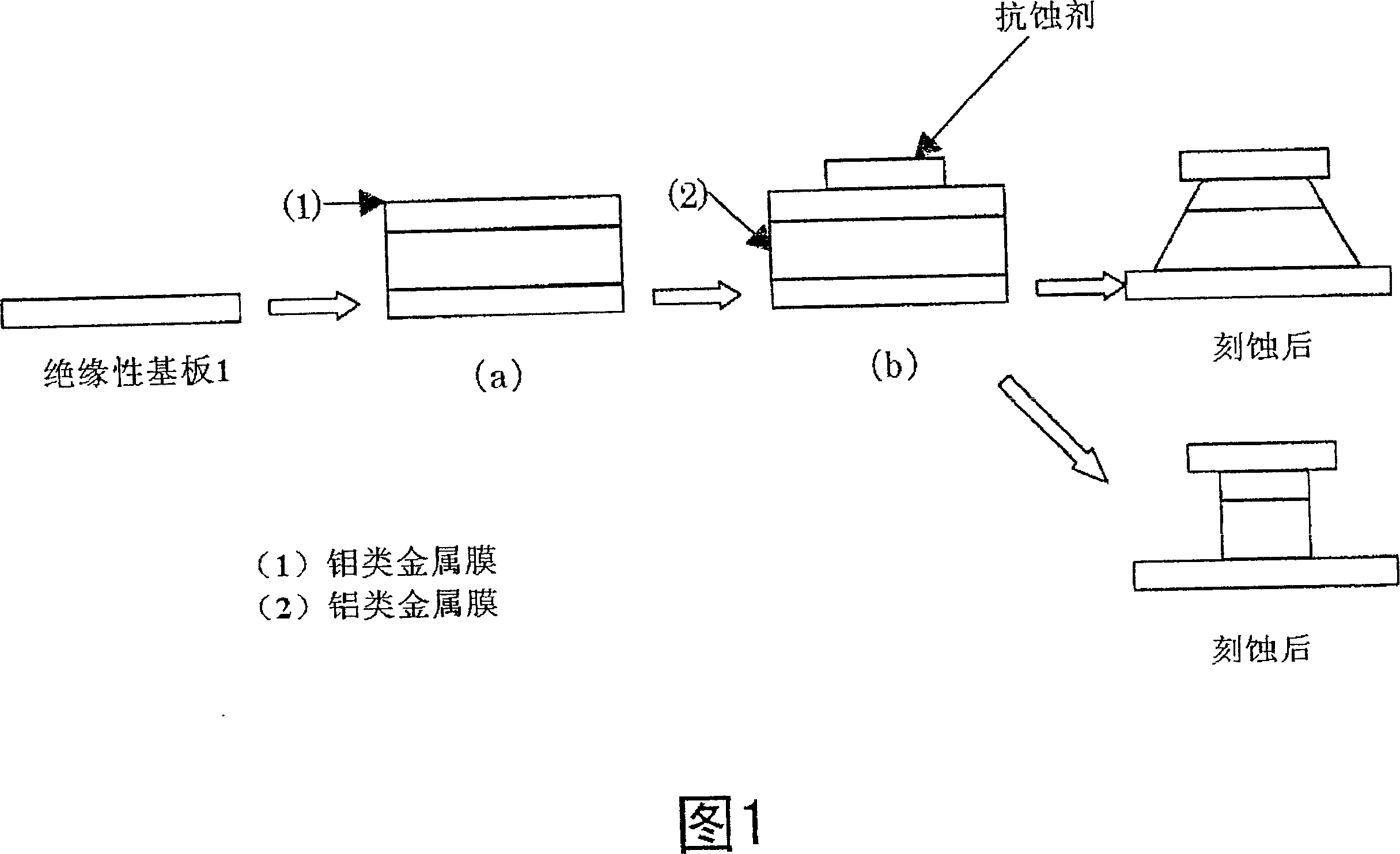

[0048] As shown in FIG. 1(a), a film of aluminum niobium (3000 Ȧ) was formed by sputtering on an insulating substrate 1 made of glass or the like, and a film of molybdenum tungsten (1000 Ȧ) was formed on the upper layer to produce substrate.

[0049] Then, as shown in FIG. 1( b ), the substrate was patterned using a resist, and immersed in the etching solutions of Examples 1 to 10 in Table 1 (etching temperature: 40° C.). At this time, the etching time was measured. Then, after washing with ultrapure water and drying with a nitrogen gas flow, the shape of the substrate was observed with an electron microscope. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com