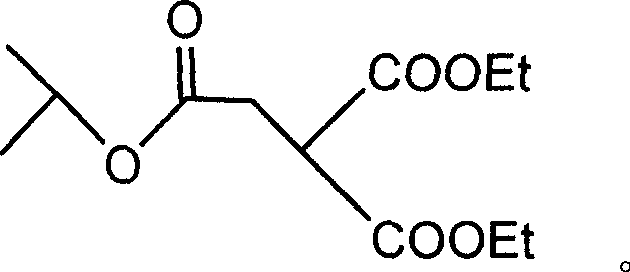

Preparation and application of isopropyl diethyl carboxylate

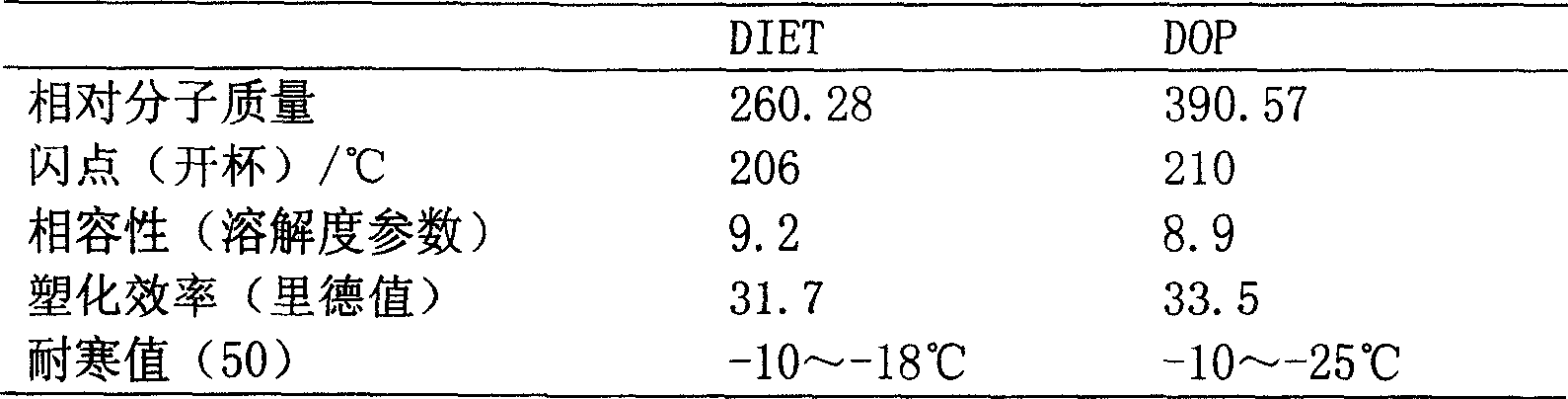

A technology of isopropyl diethyl carboxylate and diethyl malonate, which is applied in the field of preparation of isopropyl diethyl carboxylate, can solve the problems of environmental pollution, large emissions, and long process , to achieve the effects of short reaction time, mild reaction conditions, and simple post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

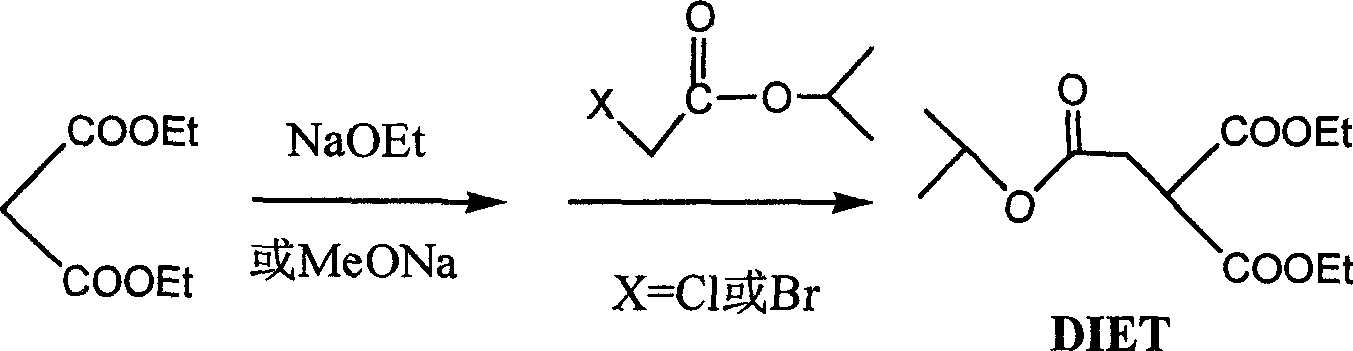

Method used

Image

Examples

Embodiment 1

[0028] 1) Add diethyl malonate into ethanol solution with a concentration of 20.0% by mass percentage of sodium ethoxide under stirring, the molar ratio of diethyl malonate to sodium ethoxide is 1:1, heat up to 85°C and react for 30 minutes;

[0029] 2) Add catalyst potassium iodide, the mass ratio of potassium iodide to diethyl malonate is 1:120;

[0030] 3) Add isopropyl bromoacetate dropwise, the molar ratio of isopropyl bromoacetate to diethyl malonate is 1:1, the dropwise addition time is 20 minutes, react at 85°C for 4 hours, and cool down to room temperature;

[0031] 4) adding water to dissolve the separated inorganic salts, separating the oil layer and distilling under reduced pressure to collect products in the boiling point range, while reclaiming unreacted raw materials and solvent ethanol. The yield was 90% based on diethyl malonate.

Embodiment 2

[0033] 1) Add methanol solution with a mass percentage concentration of 19.5% sodium methoxide to diethyl malonate under stirring, the molar ratio of diethyl malonate to sodium methoxide is 1:1.1, heat up to 80°C and react for 20 minutes;

[0034] 2) adding catalyst elemental iodine, the mass ratio of elemental iodine to diethyl malonate is 1:180;

[0035] 3) Add isopropyl chloroacetate dropwise, the molar ratio of isopropyl chloroacetate to diethyl malonate is 1.03:1, the dropwise addition time is 30 minutes, react at 80°C for 10 hours, and cool down to room temperature;

[0036] 4) filter the separated out inorganic salt, distill under reduced pressure, collect the product of boiling point range, reclaim unreacted raw material and solvent methanol simultaneously. The yield was 89% based on diethyl malonate.

Embodiment 3

[0038] 1) Diethyl malonate was added to the ethanol solution with a concentration of 20.0% by mass percentage of sodium ethoxide under stirring, the molar ratio of diethyl malonate to sodium ethoxide was 1:1.05, and the temperature was raised to 75°C for 15 minutes;

[0039] 2) adding catalyst elemental iodine, the mass ratio of elemental iodine to diethyl malonate is 1:200;

[0040] 3) Add isopropyl chloroacetate dropwise, the molar ratio of isopropyl chloroacetate to diethyl malonate is 1.01:1, the dropwise addition time is 30 minutes, react at 75°C for 12 hours, and cool down to room temperature;

[0041] 4) filter the separated out inorganic salt, distill under reduced pressure, collect the product of boiling point range, reclaim unreacted raw material and solvent ethanol simultaneously. The yield was 90% based on diethyl malonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com