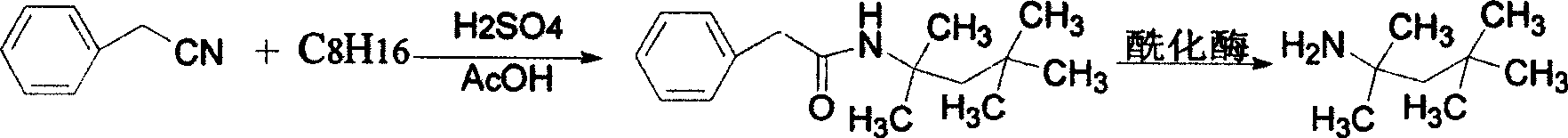

Process for preparing tert-octylamine

A technology of tert-octylamine and tert-octylphenylacetamide, which is applied in the field of preparation of tert-octylamine, can solve problems such as high equipment and operation requirements, no industrial value, and shortened hydrolysis reaction time, achieving important environmental protection significance, Improve the effect of industrial application value and output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 93.2ml of diisobutylene and 57.6ml of phenylacetonitrile into a reaction flask containing 286ml of glacial acetic acid, add 3ml of water, add 50ml of concentrated sulfuric acid dropwise while stirring, and control the temperature in a water bath to not exceed 50°C. After the dropwise addition, the stirring reaction was continued at 40-45°C for 6 hours. Detection, benzyl nitrile has reacted completely.

[0019] The reaction feed liquid was distilled under reduced pressure to collect glacial acetic acid and unreacted diisobutylene, and 500 grams of ice-water mixture was added to the remaining viscous liquid, and a large amount of light brown solids were precipitated. Under vigorous stirring, 5% aqueous sodium hydroxide solution was added to adjust the pH to 5.0. Stand at 0-5°C for 6 hours, filter, wash, and dry to obtain 111.6 g of N-tert-octylphenylacetamide.

[0020] 99 g of N-tert-octylphenylacetamide was dissolved in 400 ml of dimethyl sulfoxide, 600 ml of 0.5N p...

Embodiment 2

[0023] Add 232.9ml of diisobutene and 57.6ml of phenylacetonitrile into a reaction flask containing 428ml of glacial acetic acid, add 3ml of water, add 75ml of concentrated sulfuric acid dropwise under stirring, and control the temperature in a water bath to not exceed 50°C. After the dropwise addition was completed, the stirring reaction was continued at 20-45° C. for 5 hours. Detection, benzyl nitrile has reacted completely.

[0024] The reaction feed liquid is distilled under reduced pressure to collect glacial acetic acid and unreacted diisobutene, and the feed liquid in the distillation bottle is obviously viscous and the distillate speed is slow to stop the distillation under reduced pressure. Add ice-water mixture to the remaining viscous liquid, add 5% sodium hydroxide aqueous solution to adjust pH under vigorous stirring, let stand, filter, wash and dry to obtain 118.3 g of N-tert-octylphenylacetamide.

[0025] Dissolve 99 g of N-tert-octylphenylacetamide in 400 ml o...

Embodiment 3

[0028] Add 116.2ml of diisobutylene and 57.6ml of phenylacetonitrile into a reaction flask containing 400ml of glacial acetic acid, add 3ml of water, add 80ml of concentrated sulfuric acid dropwise under stirring, and control the temperature in a water bath to not exceed 50°C. After the dropwise addition, the stirring reaction was continued at 40-50° C. for 4 hours. Detection, benzyl nitrile has reacted completely.

[0029] The reaction feed liquid is distilled under reduced pressure to collect glacial acetic acid and unreacted diisobutene, and the feed liquid in the distillation bottle is obviously viscous and the distillate speed is slow to stop the distillation under reduced pressure. Add ice-water mixture to the remaining viscous liquid, add 5% sodium hydroxide aqueous solution to adjust pH under vigorous stirring, let stand, filter, wash and dry to obtain 112.8 g of N-tert-octylphenylacetamide.

[0030] Dissolve 99 g of N-tert-octylphenylacetamide in 400 ml of dimethyl s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com