Organic electroluminescence display of black electrode structure and its manufacturing method

A technology of electrode structure and manufacturing method, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unfavorable mass production of OLED devices, etc., and achieve the effects of prolonging the production takt time, matching well, and improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

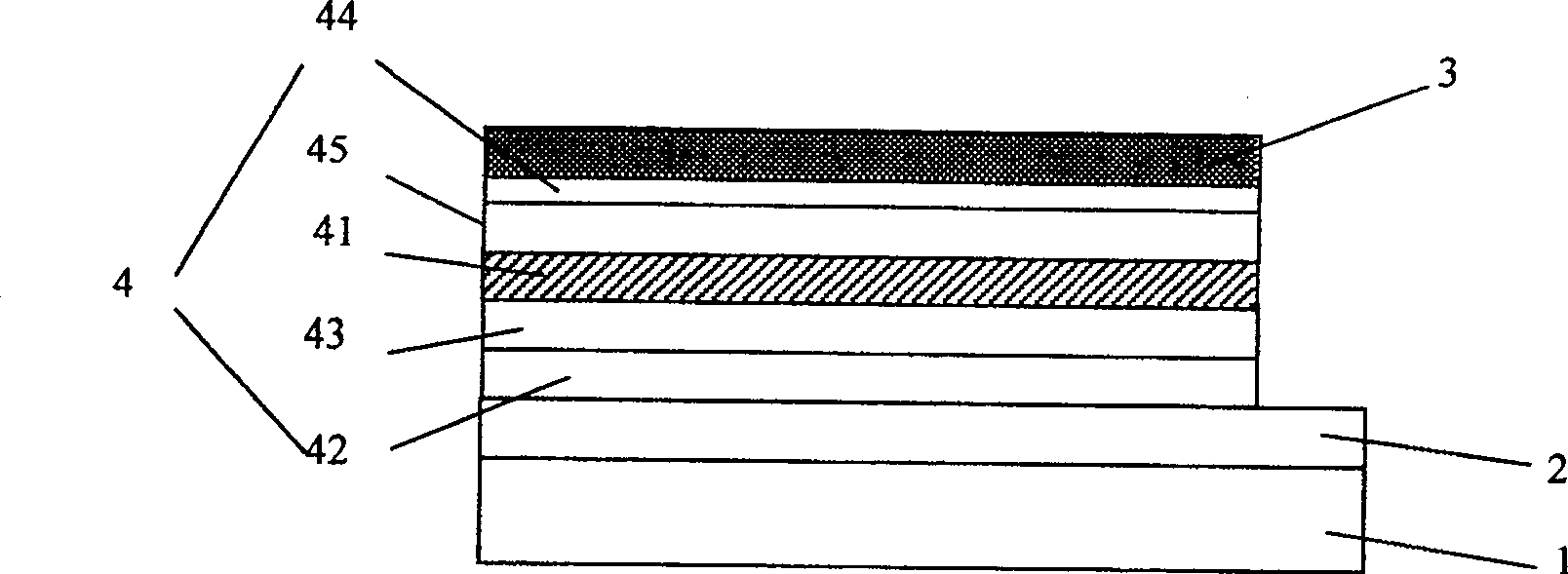

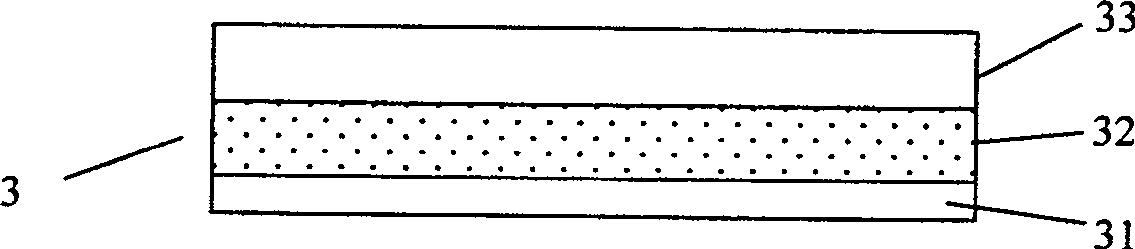

Method used

Image

Examples

Embodiment 1

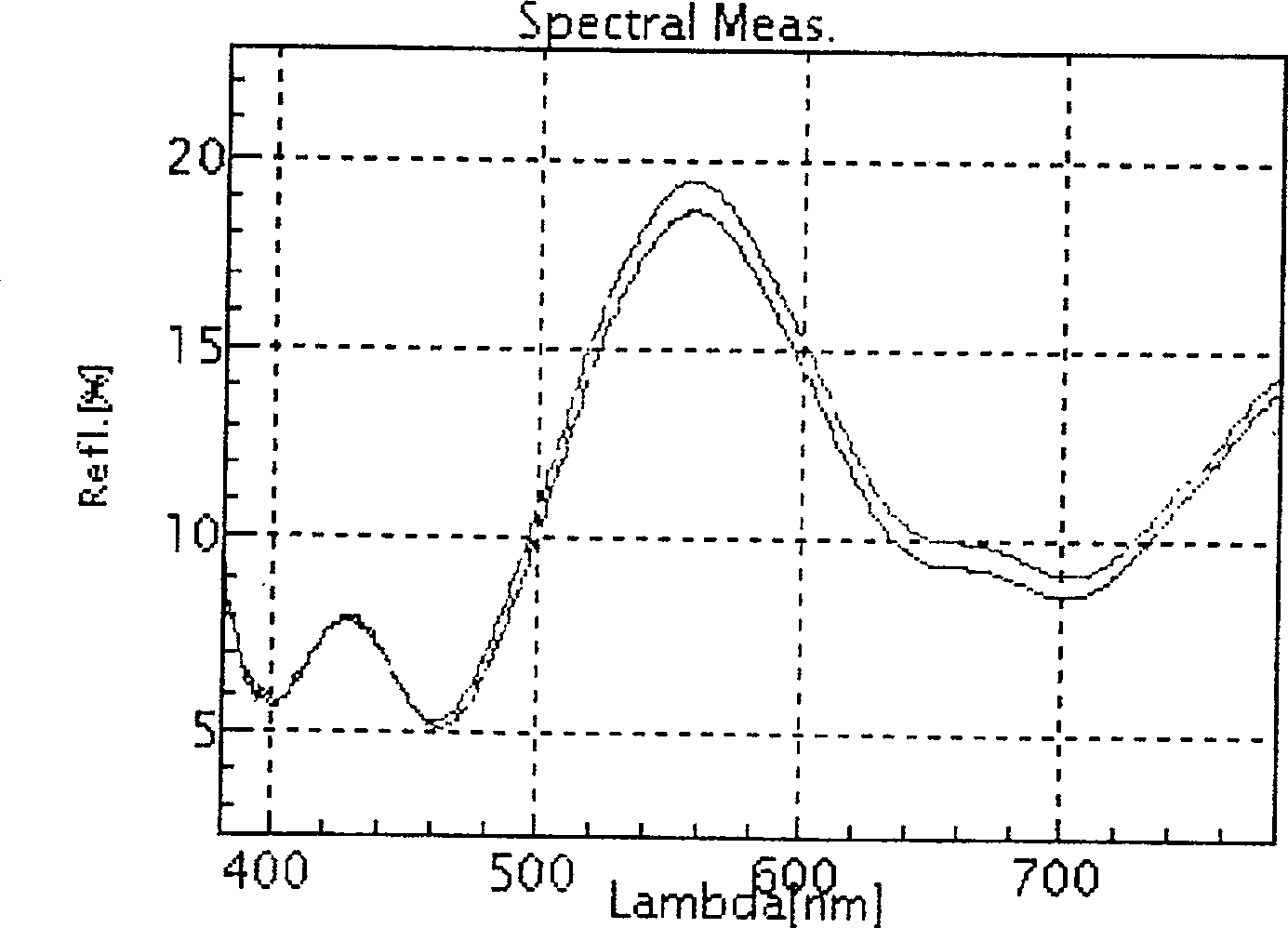

[0027] Embodiment 1, the thin metal electrode reflective layer 31 adopts an aluminum material with a thickness of 3 nanometers, and the organic material functional layer 32 selects CuPc that absorbs red light and Alq3 that absorbs UV-blue light, and its thickness is 70 nanometers. The ratio of the two materials is 1:1, image 3 It is the reflectance spectrum curve diagram of the blue light device adopting the above embodiment.

Embodiment 2

[0028] Embodiment 2. The thin metal electrode reflective layer 31 is made of an aluminum material with a thickness of 3.5 nanometers, and the organic material functional layer 32 is made of CuPc and Rubrene with a thickness of 70 nanometers, and the ratio of the two materials is 1:1. , Figure 4 It is the reflectance spectrum curve diagram of the blue light device adopting the above embodiment.

Embodiment 3

[0029] Embodiment 3. The thin metal electrode reflective layer 31 is made of an aluminum material with a thickness of 4 nanometers, and the organic material functional layer 32 is made of CuPc and Rubrene with a thickness of 90 nanometers. Figure 5 The reflectance spectrum curves of the blue light device when the ratio of the above two materials are 90:0, 80:10 and 70:20 are listed in . The reflectivity of the device whose black electrode is mixed with the above two materials is significantly lower than that of the ordinary device, and is also lower than that of the device whose black electrode is only made of one material (CuPc:Rubrene=90:0).

[0030] The organic electroluminescent display with black electrode structure of the present invention is produced by vacuum evaporation using high vacuum coating equipment, and the entire production process is completed at one time without breaking the vacuum. All the following steps:

[0031] A. Clean the anode substrate;

[0032] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com