Glue conveying and glue coating mechanism

A technology for conveying glue and rubber wheels, applied in transportation and packaging, paper/cardboard containers, containers, etc., can solve problems such as low efficiency and achieve the effect of uniform transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

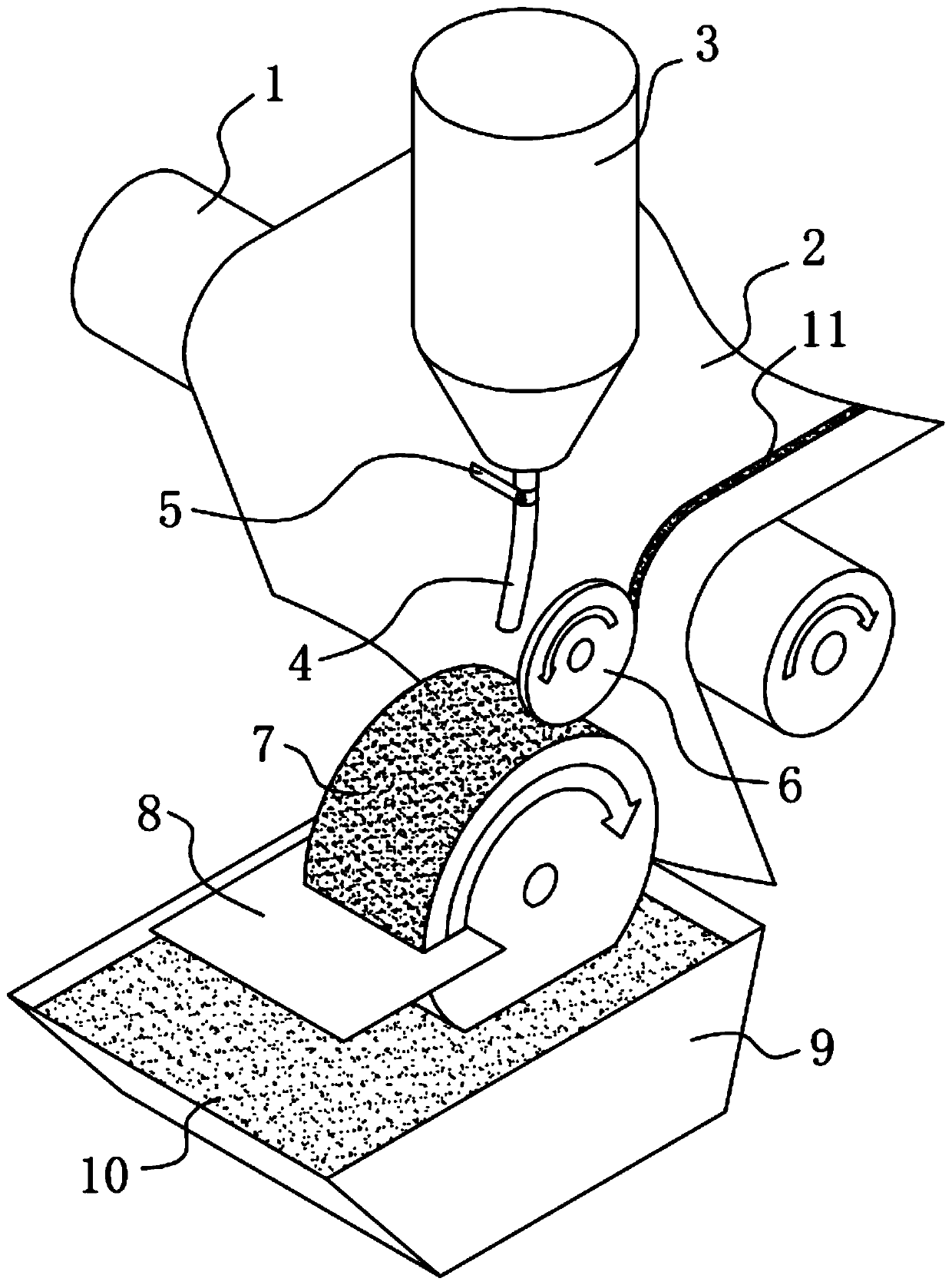

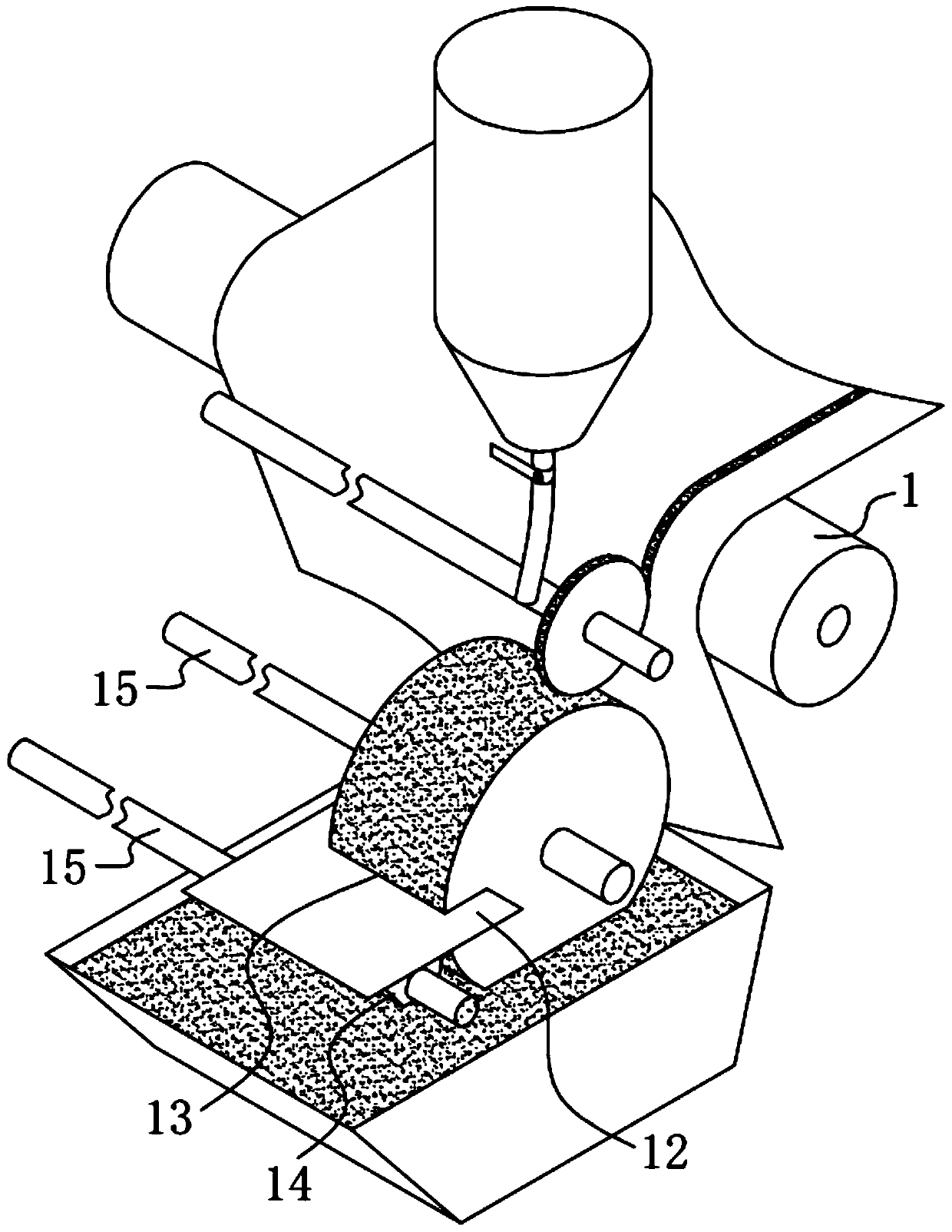

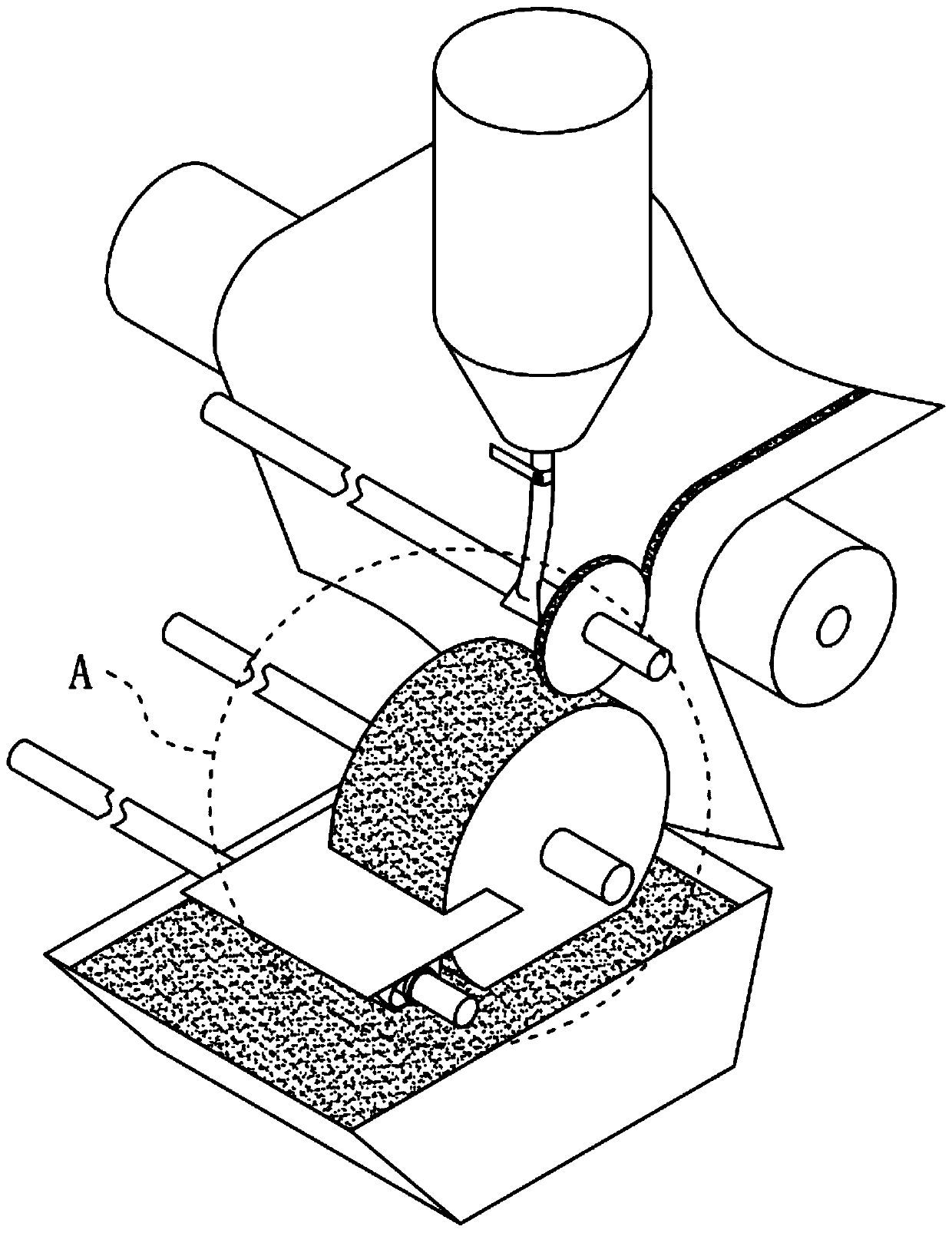

[0034] In order to achieve the purpose of the present invention, a glue delivery mechanism includes: a glue delivery mechanism, including a rubber barrel 3 and a glue bucket 9 arranged up and down respectively, and the bottom of the glue barrel 3 is equipped with a glue dripping tube 4 with an on-off valve 5 , the glue bucket 9 has an upper opening, and there are glue liquid 10 in the glue bucket 3 and the glue bucket 9; the glue spreading mechanism is arranged between the glue bucket 3 and the glue bucket 9, and the glue spreading mechanism includes mutually circumscribed Rubber roller 6, glue roller 7, rubber roller 6 is also cut with paper 2, paper 2 is conveyed by roller 1, the axes of roller 1, rubber roller 6, and glue roller 7 are all horizontal, and glue The wheel 6 has a submerged part buried under the liquid surface of the glue solution 10 in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com