Rare earth-iron-boron based magnet and method for production thereof

一种磁铁、稀土的技术,应用在高性能磁铁领域,能够解决磁铁表面层富Nd相受损、磁铁表面部分磁性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

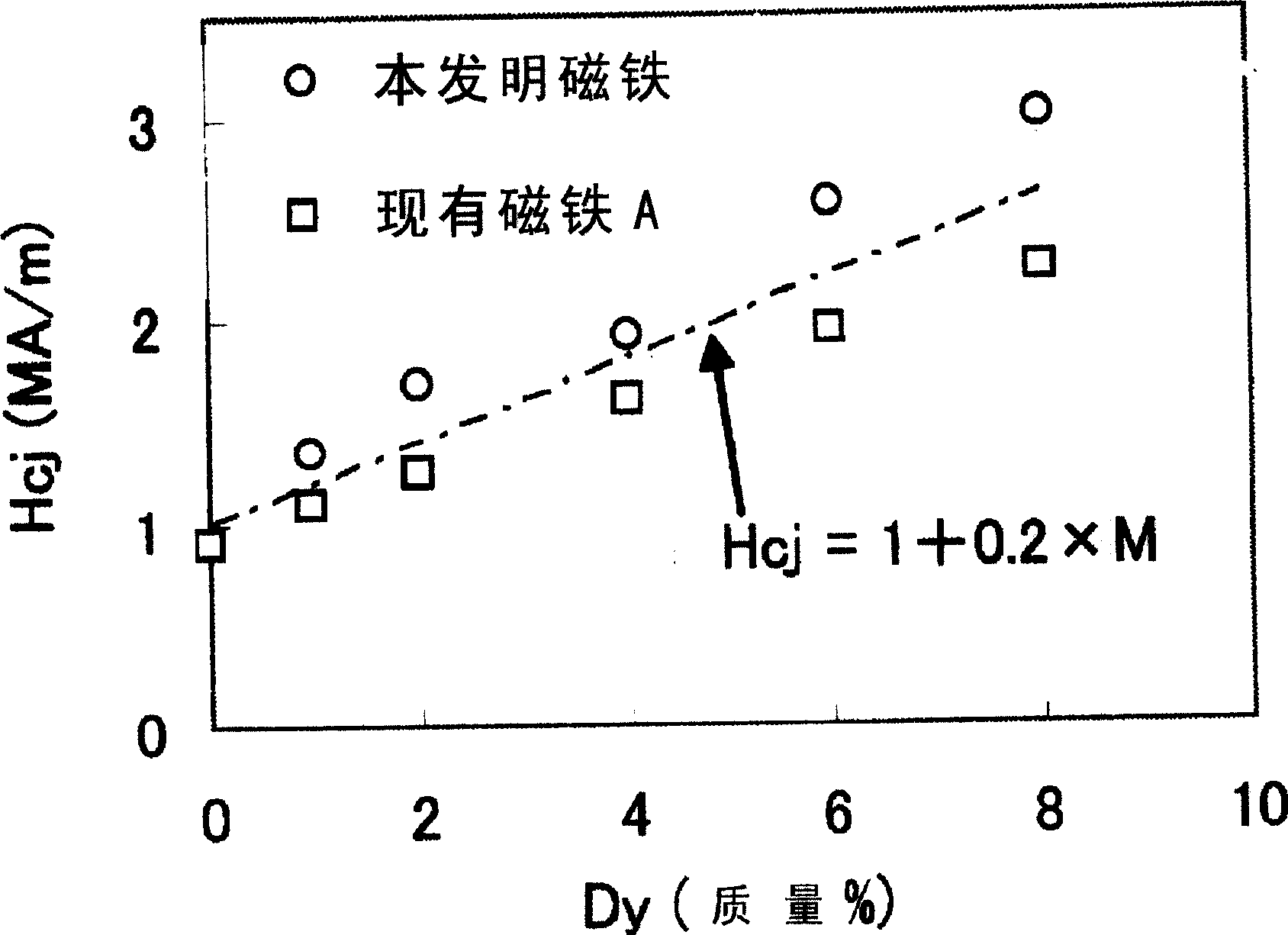

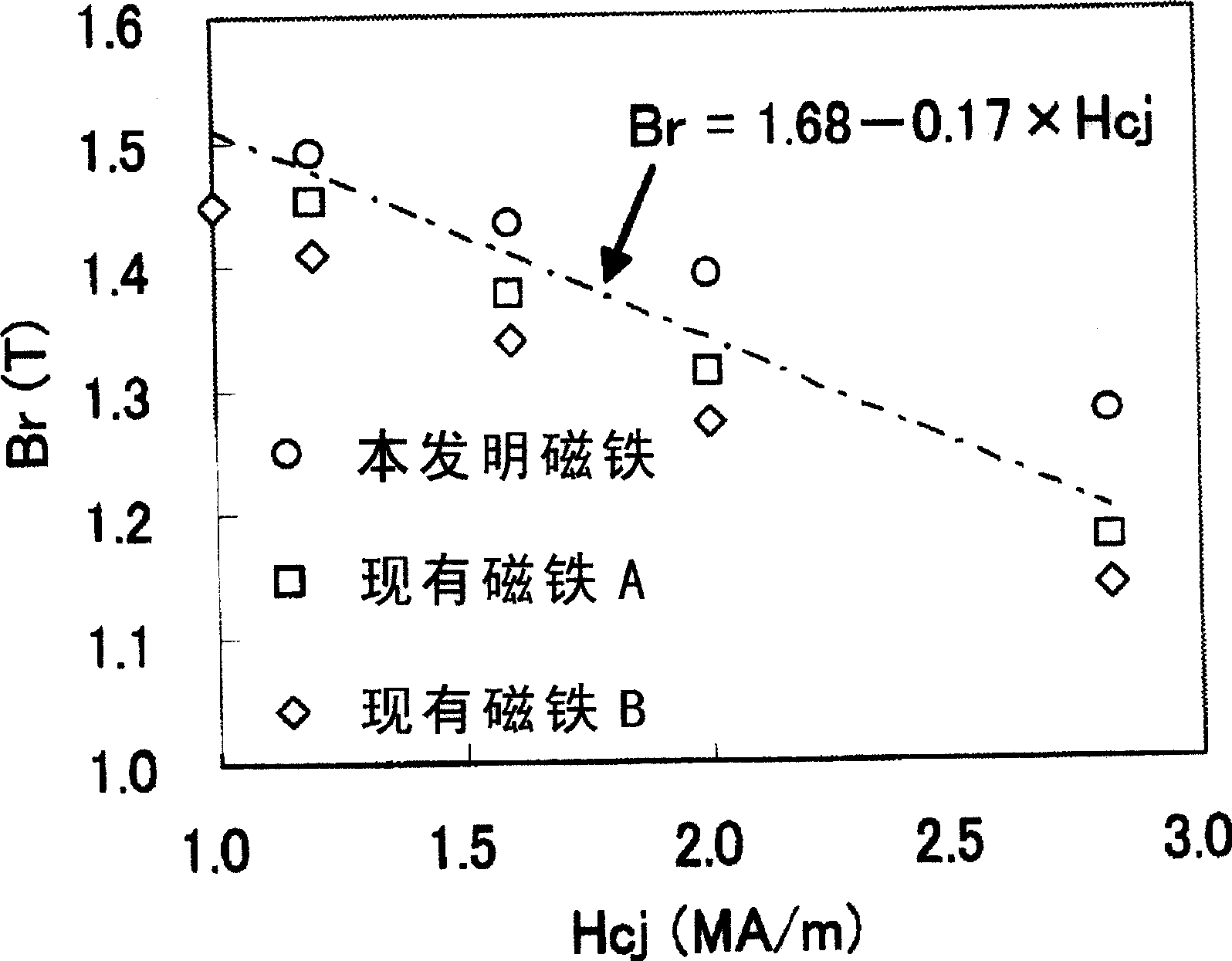

[0071] From Nd 12.5 Fe 78.5 co 1 B 8 The formed alloy ingot is manufactured into an alloy flake with a thickness of about 0.3mm according to the single-roll rapid cooling solidification method. Then, the flakes were filled in a container and released after absorbing 500 kPa of hydrogen at room temperature to obtain an amorphous powder with a size of 0.1 to 0.2 mm, which was then pulverized by a jet mill to produce a fine powder of about 3 μm.

[0072] After adding and mixing 0.05% by mass of calcium stearate to the fine powder, fill it into a mold, extrude it in a magnetic field, fill it into a vacuum furnace, and sinter it at 1080°C for 1 hour, then cut, open holes, Cylindrical grinding and other mechanical processing to manufacture a volume of 11.2mm with an outer diameter of 2.4mm, an inner diameter of 1mm, and a length of 3mm 3 cylindrical magnets. Let this be a comparative example sample (1).

[0073] Next, use Figure 4 In the three-dimensional sputtering apparatu...

Embodiment 2

[0082] Same as Example 1, with Nd 12.5 Fe 78.5 co 1 B 8 The composed alloy is used as the starting material to manufacture a sintered magnet block with a side length of 24mm, which is cut and ground with a grindstone and subjected to electrical discharge machining, thereby manufacturing an outer diameter of 4mm, a thickness of 1mm, and a volume of 12.6mm 3 disc magnet. After mounting the metal targets of Dy and Tb in the three-dimensional sputtering device, the magnet was placed inside the coiled tungsten electrode wire, and the targets were sequentially exchanged to form a film for each metal. The film forming operation is to remove the oxide film on the surface of the magnet by reverse sputtering in the same manner as in Example 1, then apply 60W of RF output and 200W of DC output, and perform normal sputtering for 5 to 50 minutes to form a film of 2 to 18 μm.

[0083] Then, one of the two magnets was packed into an electric furnace in a closed operation box, and heat-tr...

Embodiment 3

[0089] From Nd 12 Dy 0.5 Fe 80 B 7.5 Composition of raw material alloys, disk-shaped magnets having an outer diameter of 4 mm and a thickness of 0.2 mm, 0.4 mm, 1 mm, 2 mm, or 4 mm were produced by the same procedure as in Example 2. Next, put these magnets into a three-dimensional sputtering device, perform reverse sputtering, remove the oxide film on the surface of the magnet, apply 100W of RF output and 120W of DC output, and perform ordinary sputtering for 15 minutes to form 2μm on the surface of the magnet. Dy metal film. Next, the film-formed magnets were loaded into an electric furnace in a sealed operating box, and heat-treated at 800° C. for 30 minutes to obtain samples (16) to (20) of the present invention. In addition, a sintered magnet having an outer diameter of 4 mm and a thickness of 1 mm without sputtering was used as a comparative sample (8).

[0090] The magnetic properties of each sample were measured by a vibrating sample type magnetometer, and the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diffusion length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com