Method for preparing nano strontium titanate by lactic acid adjuvant process

A technology of nanometer strontium titanate and lactic acid, applied in chemical instruments and methods, crystal growth, self-gel state and other directions, can solve the problems of less strontium titanate, combustion and explosion, etc., to reduce dosage, reduce production cost, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

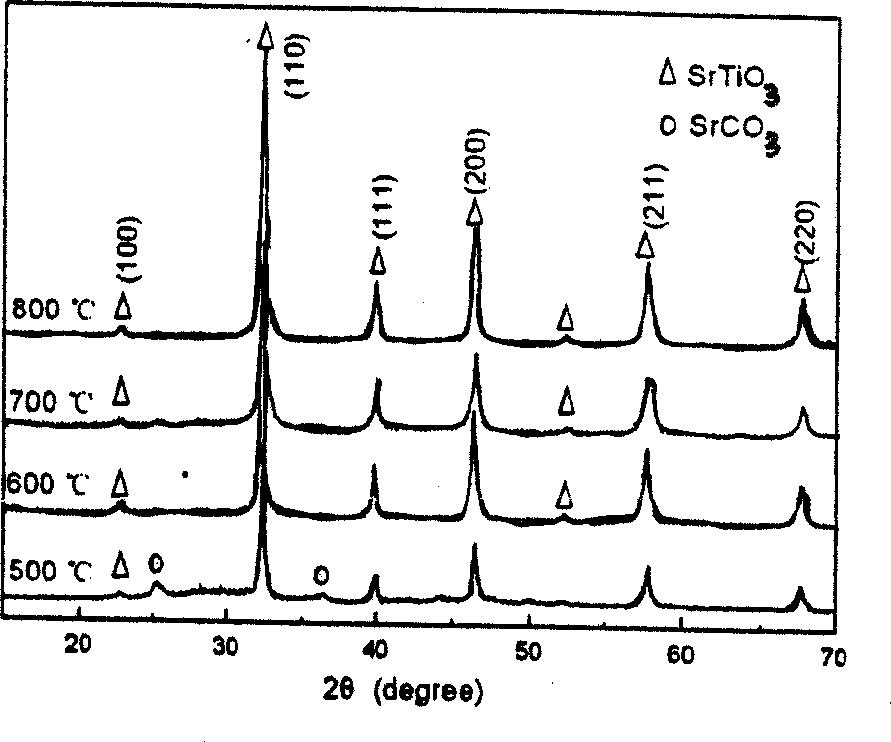

Embodiment 1

[0026] Weigh 0.1 mol of strontium carbonate and dissolve it in 0.8 mol of lactic acid, add 10 ml of deionized water, stir on a magnetic constant temperature stirrer at 80°C for 3 hours until uniform and transparent, and obtain solution A. Then weigh 0.1 mol of butyl titanate, slowly drop it into solution A, and stir at a speed of 200 rpm. After mixing, continue stirring for 30 minutes to obtain a uniform and transparent sol. Nitric acid and ammonia water were added to adjust the pH of the sol to 5. The sol was placed in an oven at 50°C for 23 hours to obtain a uniform and transparent gel. The gel was vacuum-dried at 120° C. for 11 hours to obtain a xerogel, and the xerogel was ground and then heat-treated at 600° C. and then ground to obtain strontium titanate nanopowder.

Embodiment 2

[0028] Weigh 0.15 mol of strontium carbonate and dissolve it in 1.2 mol of lactic acid, add 30 ml of deionized water, and stir on a magnetic constant temperature stirrer at 90°C for 3 hours until uniform and transparent to obtain solution A. Then weigh 0.15 mol of butyl titanate, slowly add it dropwise into solution A, and stir at a speed of 250 rpm. After mixing, continue stirring for 45 minutes to obtain a uniform and transparent sol. Nitric acid and ammonia water were added to adjust the pH of the sol to 4. The sol was placed in an oven at 70°C for 24 hours to obtain a uniform and transparent gel. The gel was vacuum-dried at 130° C. for 10 hours to obtain a xerogel, and the xerogel was ground and then heat-treated at 700° C. and then ground to obtain strontium titanate nanopowder.

Embodiment 3

[0030] Weigh 0.2 mol of strontium carbonate and dissolve it in 1.4 mol of lactic acid, add 50 ml of deionized water, and stir on a magnetic constant temperature stirrer at 70°C for 3 hours until uniform and transparent to obtain solution A. Then weigh 0.2 mol of butyl titanate, slowly add it dropwise into solution A, and stir at a speed of 300 rpm. After mixing, continue stirring for 30 minutes to obtain a uniform and transparent sol. Nitric acid and ammonia water were added to adjust the pH of the sol to 4. The sol was placed in an oven at 60°C for 23 hours to obtain a uniform and transparent gel. The gel was vacuum-dried at 120° C. for 11 hours to obtain a xerogel, and the xerogel was ground and then heat-treated at 600° C. and then ground to obtain strontium titanate nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com