High temperature steaming strippable membrane

A high-temperature cooking and easy-peeling technology, used in flexible coverings, packaging, layered products, etc., can solve problems such as the inability to meet the technical requirements of sterilization at 121°C for 30 minutes, and achieve good heat-sealability, wide application range, Fast heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

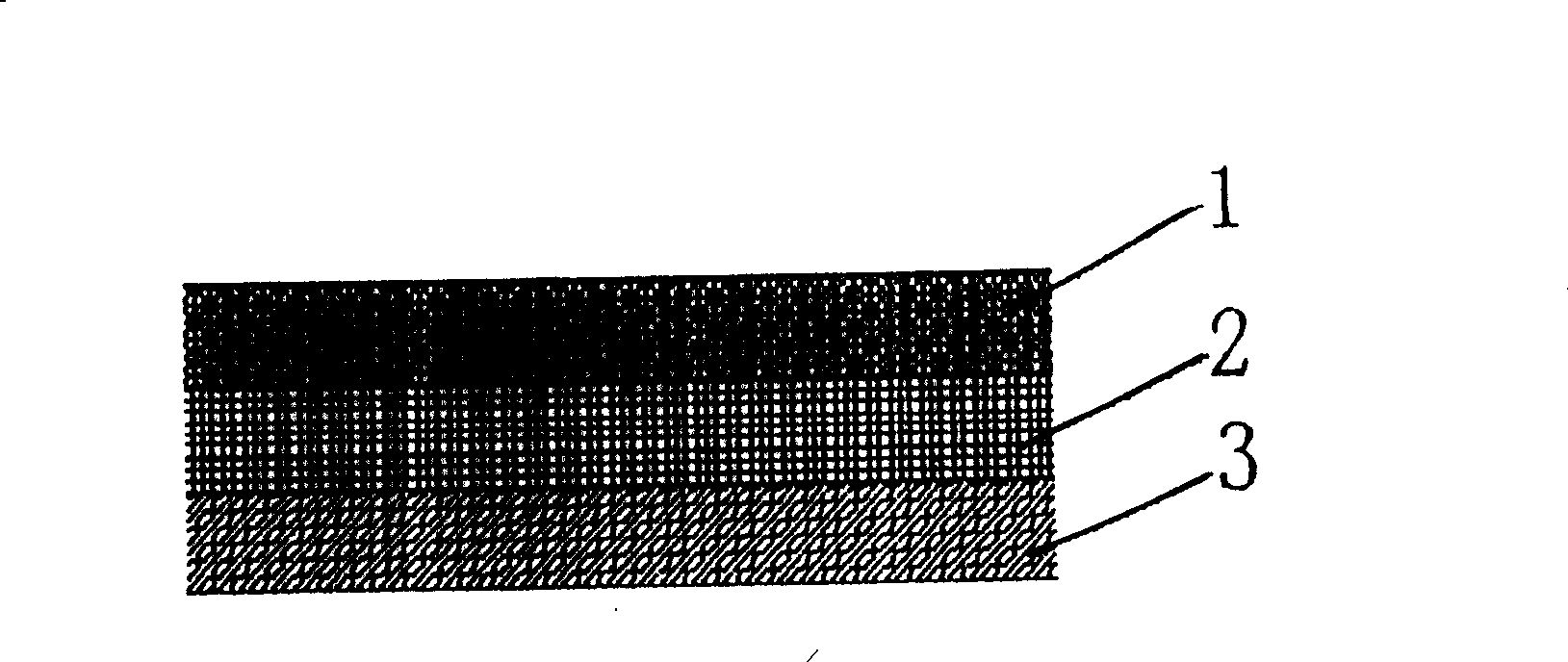

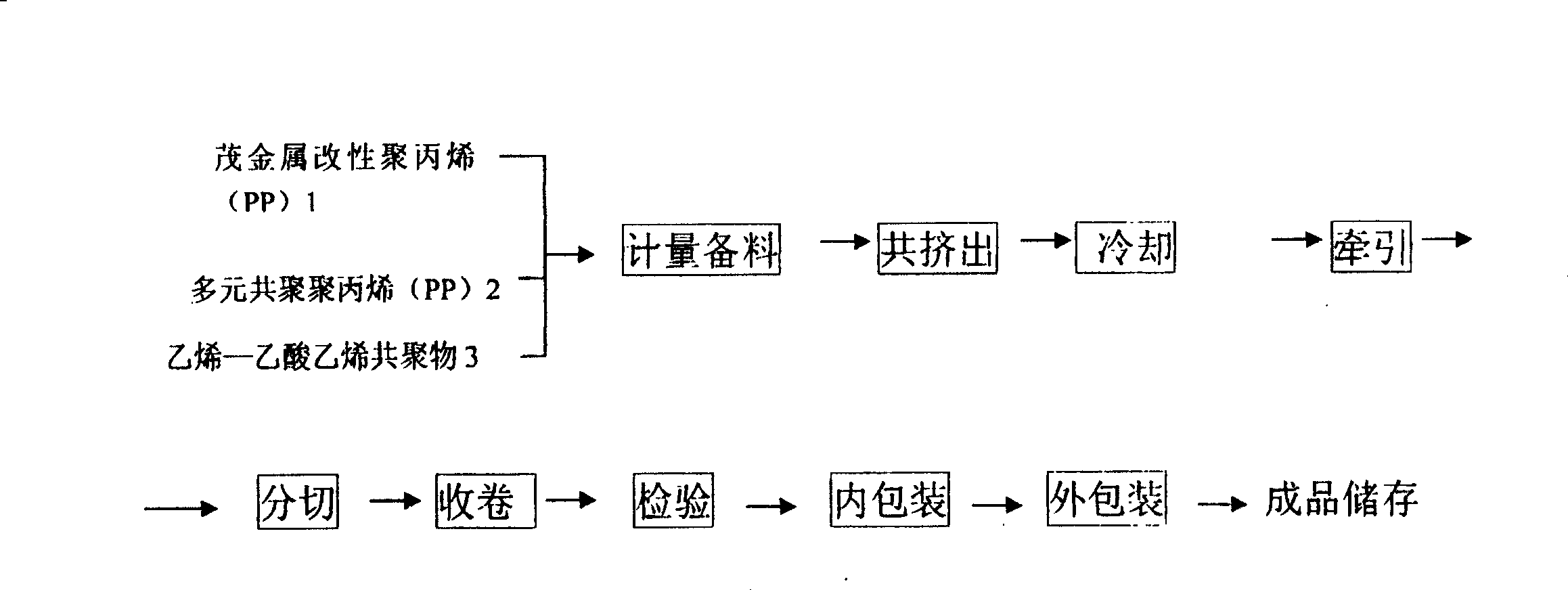

[0012] The invention is a high-temperature cooking easy-peeling film, which is composed of three layers of polymer materials, and the outer layer is modified polypropylene (PP) 1, which is a heat-sealing layer with high strength, high transparency and high temperature resistance; The middle layer is multi-component copolymerized polypropylene (PP) 2, which is an enhanced layer with toughening function, adhesive function and heat-sealing strength; the inner layer is ethylene-vinyl acetate copolymer 3, which is an easy-peeling layer with high temperature resistance and stable chemical properties. layer. When packaging jelly or soft canned food, the inner layer of the present invention, that is, the three layers of ethylene-vinyl acetate copolymer, is in contact with the packaged food, so that the release film can be easily separated from the food when the food is taken out. It adopts the world's most advanced modified polypropylene (PP) polymer material and ethylene-vinyl acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com