Silion carbide substrate gallium nitride high electronic transport ratio transistor and producing method

A technology with high electron mobility and silicon carbide substrates, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. In order to achieve the effect of reducing electron scattering, improving channel electron mobility, and effectively limiting leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

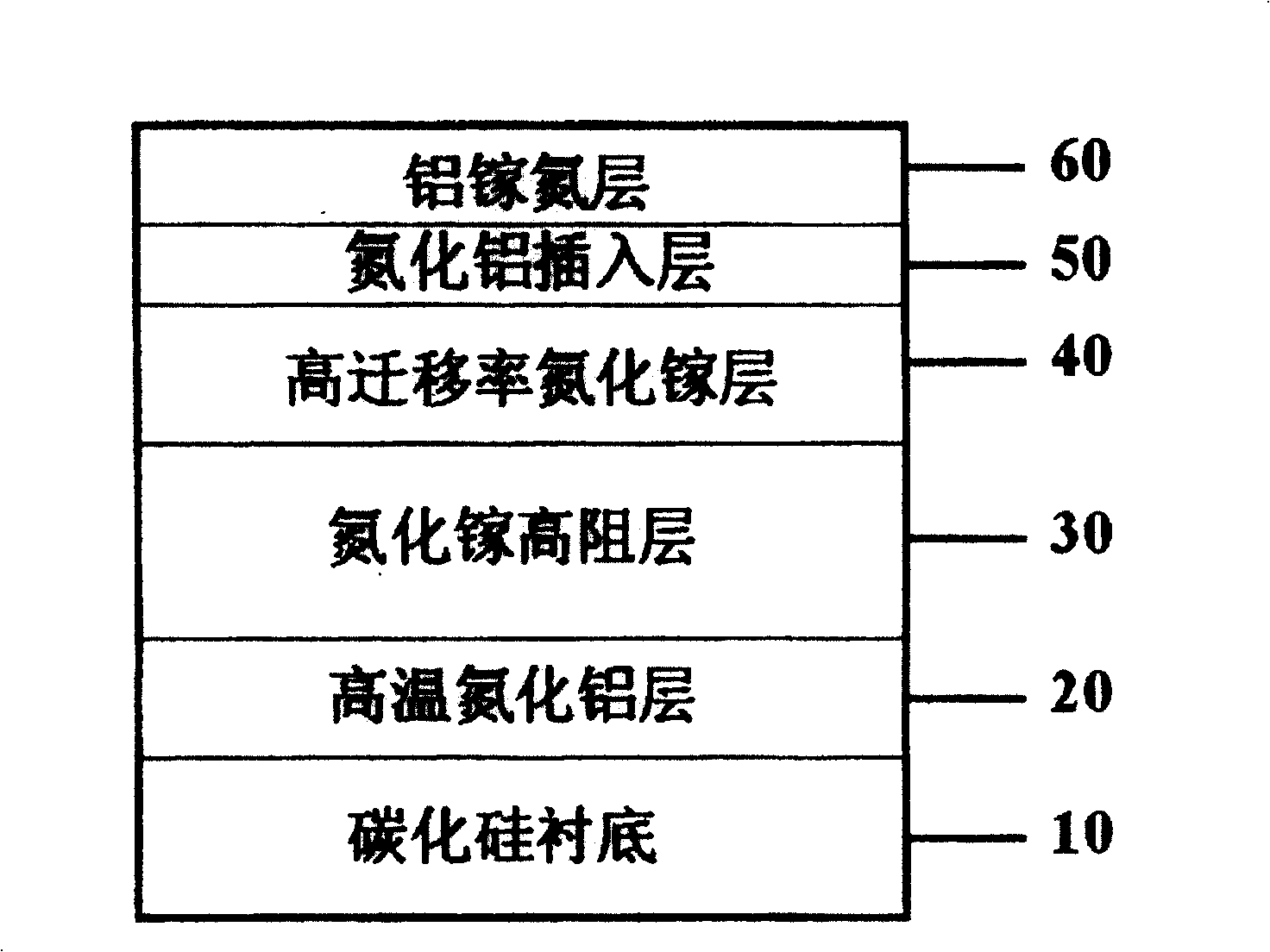

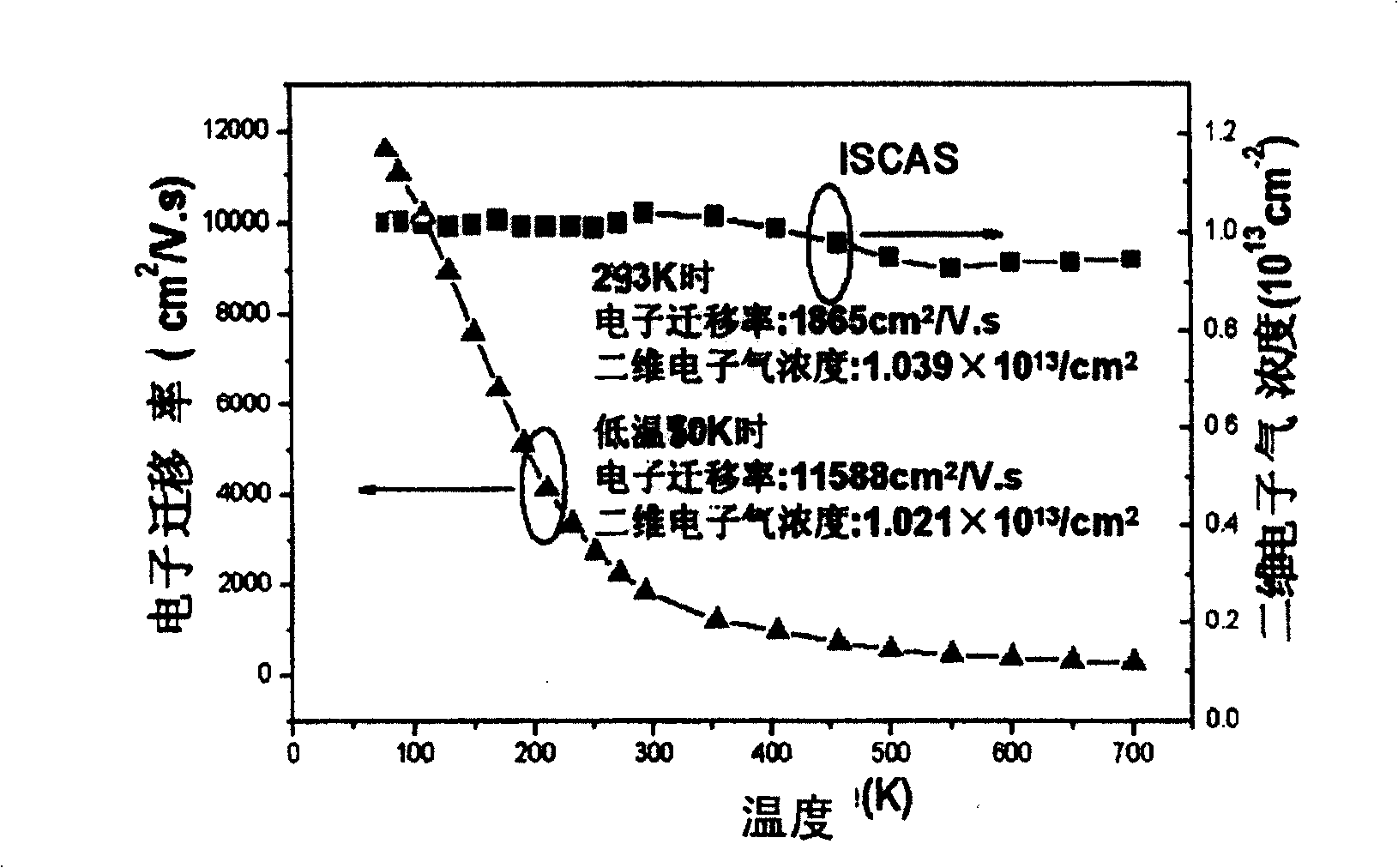

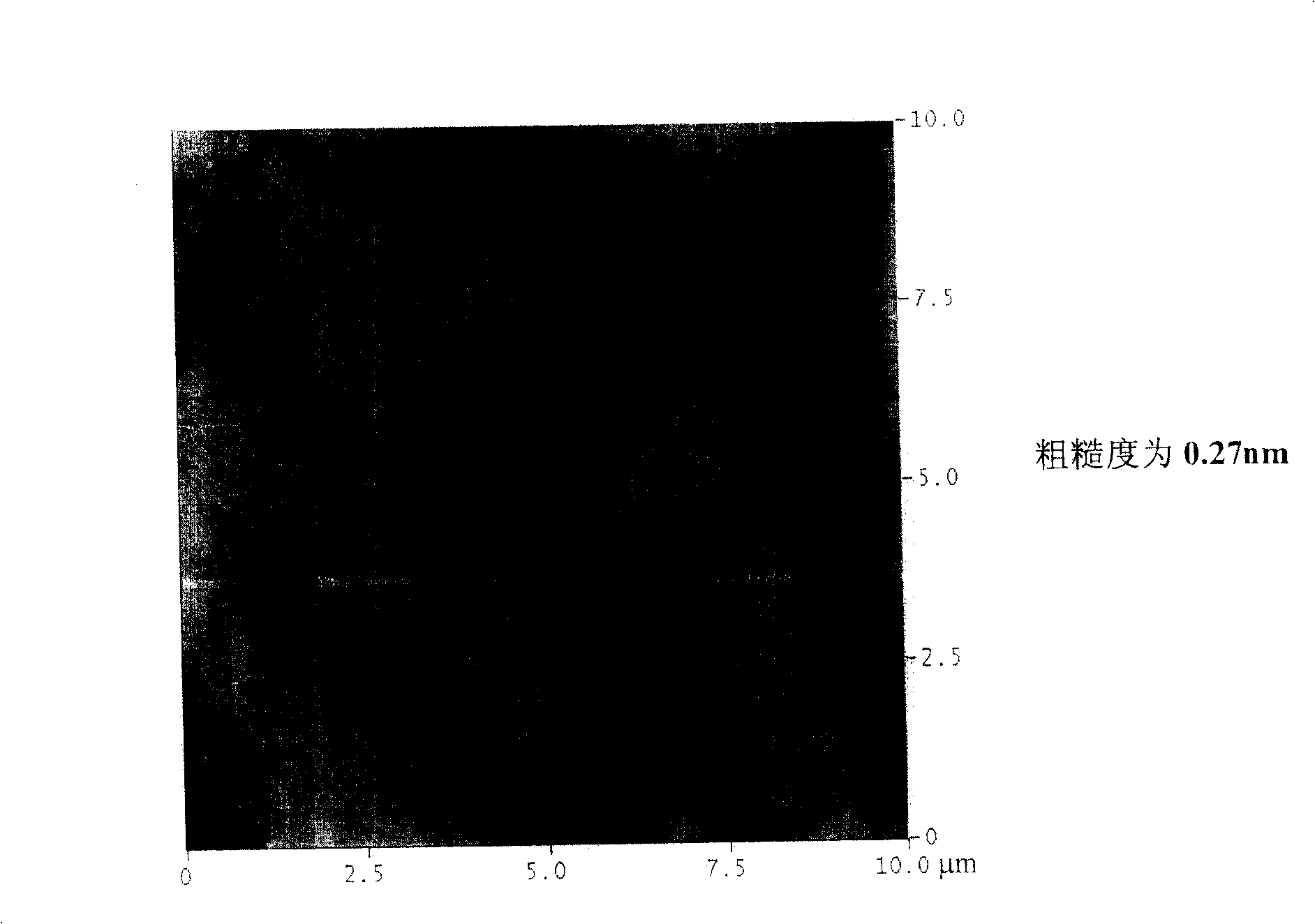

[0031] The key of the present invention is to use a new type of high-mobility gallium nitride thin layer as the channel layer in structure, and introduce a thin layer of aluminum nitride insertion layer between the gallium nitride channel layer and the aluminum gallium nitride barrier layer. By precisely controlling the growth conditions, such as temperature, pressure, and V / III ratio, the stress caused by lattice mismatch can be effectively relieved and the crystal quality of the channel layer can be improved, so as to epitaxially grow high-quality silicon carbide substrate nitride Gallium transistor structural material. The high-mobility GaN channel layer provides a good channel for the two-dimensional electron gas, which significantly improves the channel mobility and crystal quality. One of the functions of the aluminum nitride insertion layer is to use the binary compound to separate the channel electrons from the ternary compound aluminum gallium nitrogen barrier layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com