Production of isolating column of organic electroluminescent device

A technology of electroluminescence devices and isolation columns, applied in the field of optoelectronics, can solve the problems of unsuitability for large-scale production, complicated preparation process, and high requirements of photolithography process, so as to save production time, simplify process flow, and reduce equipment cost. The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

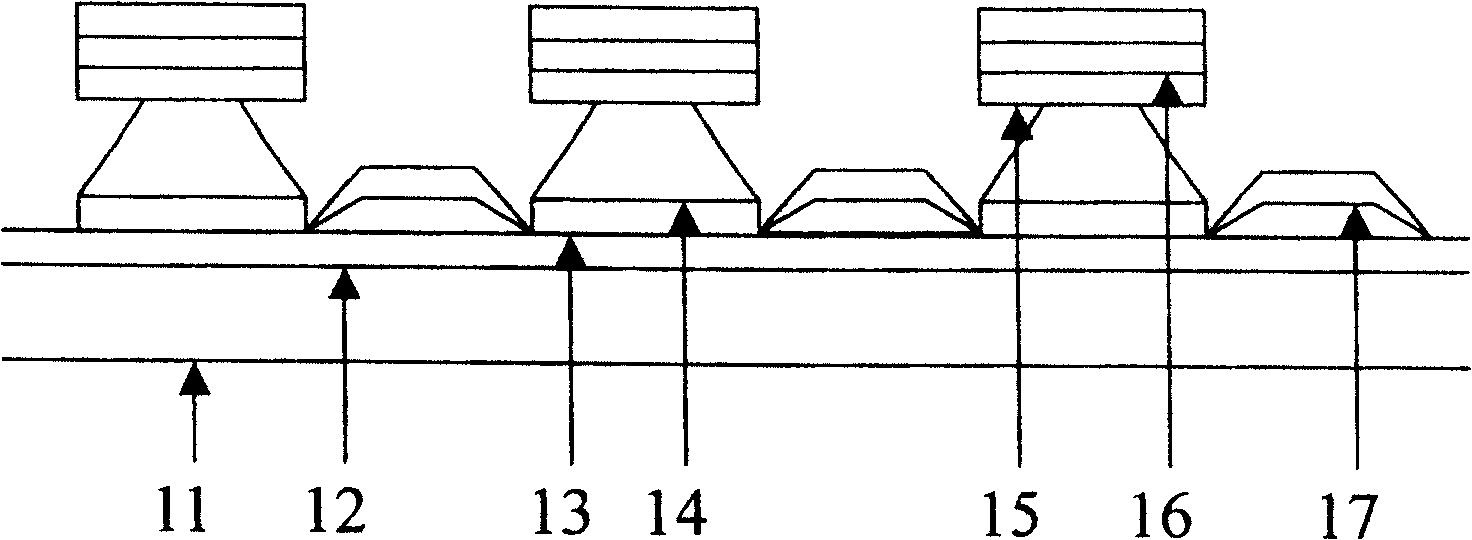

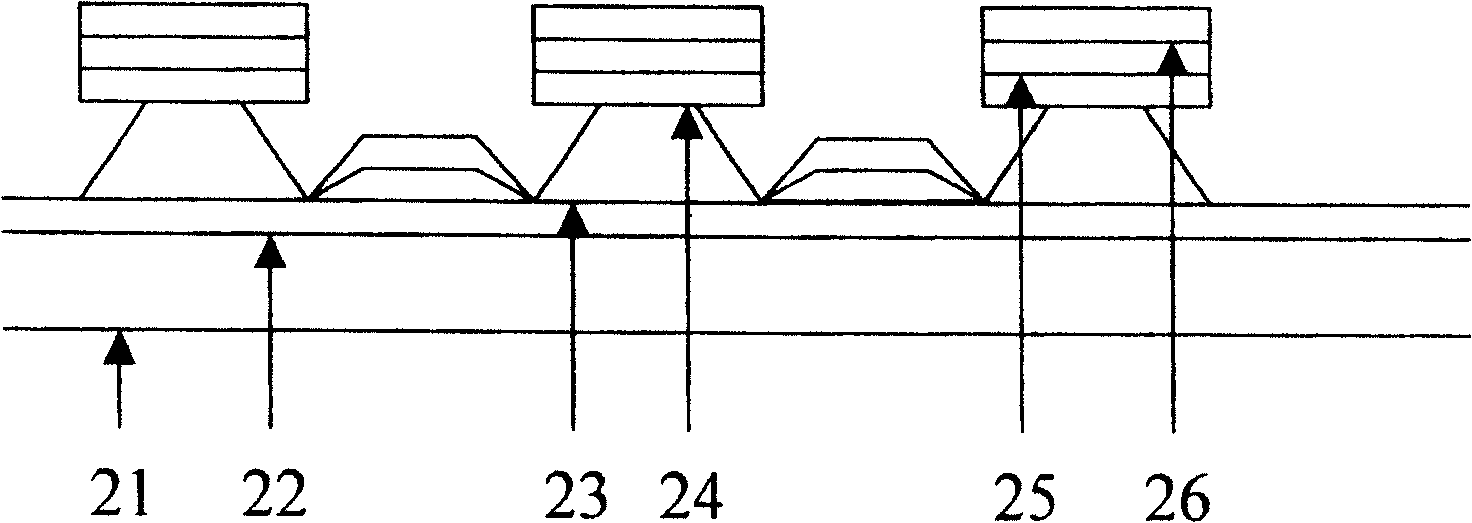

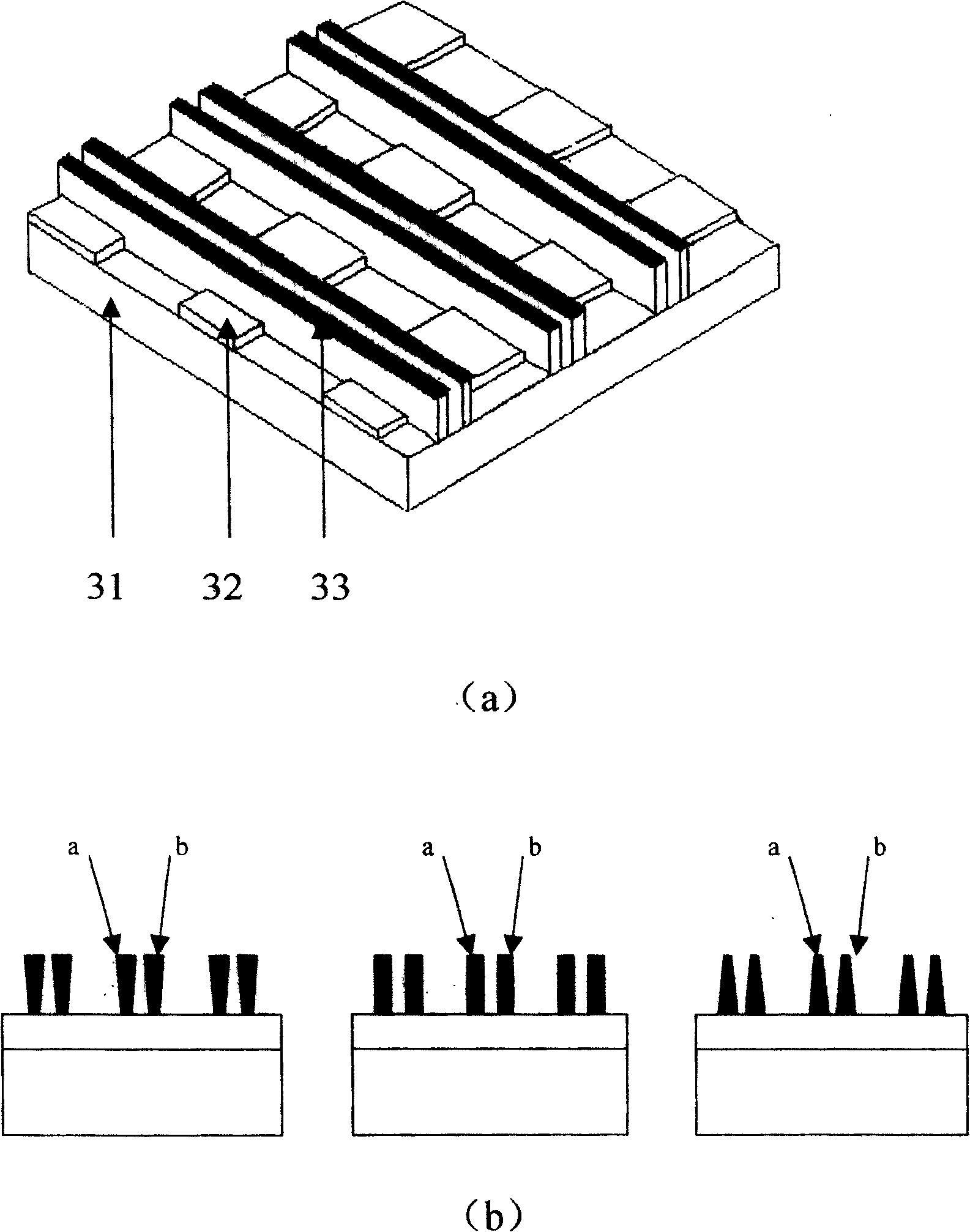

[0040] According to the method for preparing a cathode isolation column in an organic electroluminescent device proposed by the present invention, an effective cathode isolation column is prepared, and the specific preparation steps are as follows:

[0041] Step 1, pretreatment: Clean the glass substrate (area 50mm*50mm, thickness 1mm) with decontamination powder, acetone, ethanol, and deionized water respectively, remove impurities and organic matter on the glass surface, and dry in an oven after cleaning.

[0042] Step 2, prepare the first electrode indium tin oxide (ITO) film: on the glass substrate processed in step 1, use DC magnetron sputtering method to evaporate the ITO film, the sputtering power is 300W, the sputtering pressure is 0.2mTorr, Simultaneous access to Ar / O 2 The mixed gas ratio was 15:1, and the thickness of the ITO film obtained by sputtering was 150 nm. Then, a photolithography process is performed to produce the required electrode pattern, and the patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com