Chromic-nickel-free high-strength high ductility structural steel and manufacturing method thereof

A manufacturing method and technology of structural steel, applied in temperature control, tool manufacturing, heat treatment process control, etc., can solve the problems of high price, poor tempering resistance and poor machinability of chromium-nickel carburizing steel, and achieve heat treatment process Simple, stable anti-tempering ability, easy-to-control quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

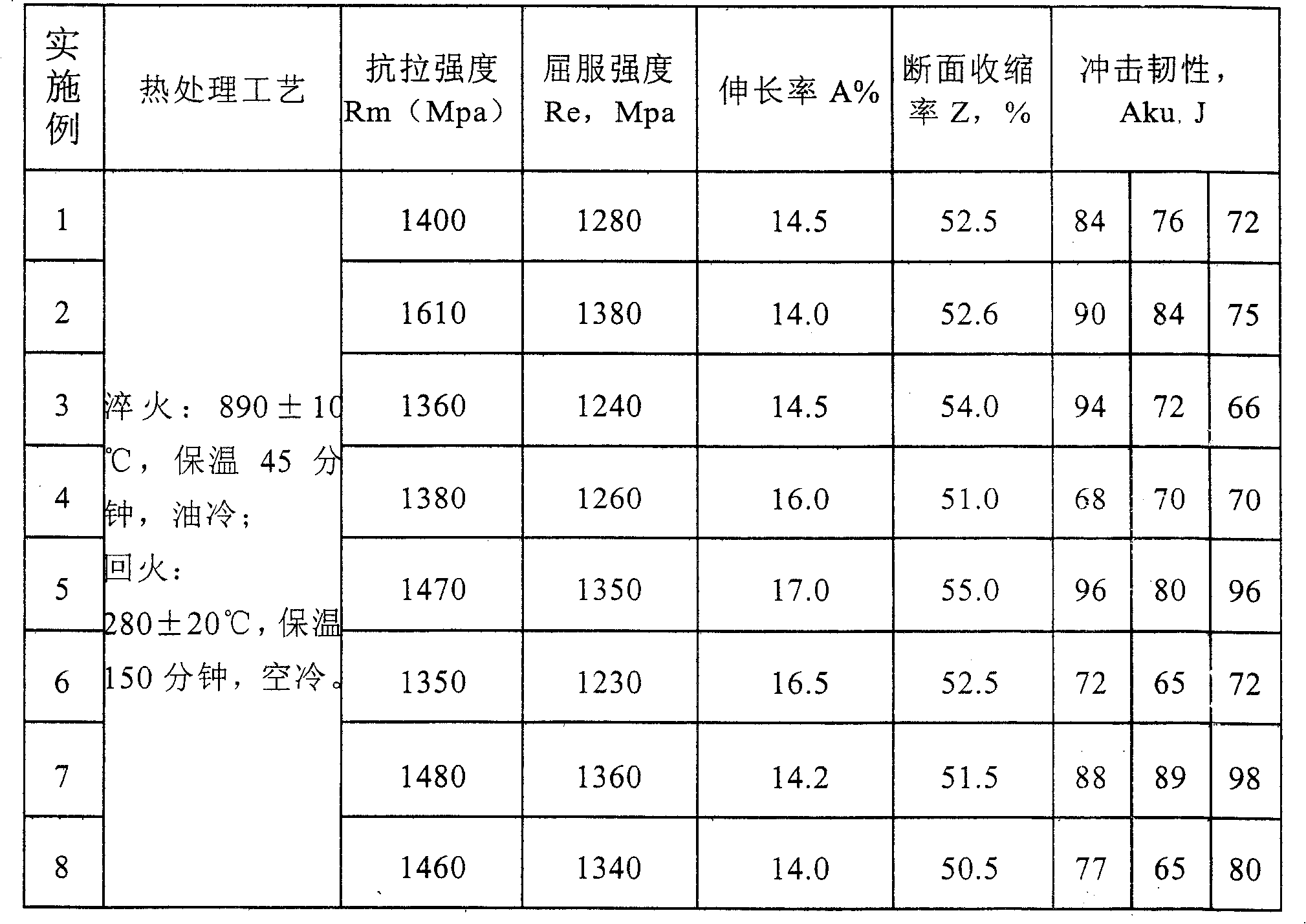

Examples

Embodiment Construction

[0042] A steel company implements the patent of this invention and smelts 26 electroslag furnace numbers. The preparation method adopts a four-step process: the first step: primary smelting in electric arc furnace→vacuum refining in ladle furnace→pouring electrode ingots; the second step: electroslag Remelting; Step 3: Rolling mill (brush mill) thermal processing and rolling into products; Step 4: Annealing of rolled products.

[0043] The first step, electric arc furnace smelting cast ingot

[0044] Using the white slag method, the molten steel is initially smelted in an electric arc furnace with a capacity of 20 to 100 tons, and the steel with basically qualified components is smelted. Harmful gases and inclusions in the steel are vacuumed and degassed; the electrode round ingot is poured, and the electrode round ingot mold is cooled for 16 to 24 hours (the cooling time is controlled according to the size of the steel ingot round ingot), and the demoulding enters the next pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com