Composite mineral fibre reinforced brake liner and preparation process and special device therefor

A composite mineral fiber and reinforced technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of brake pad expansion and cracking, large temperature gradient, uneven heat transfer, etc., to avoid expansion and cracking, thermal stress The effect of uniform distribution and uniform internal heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of the first steel back

[0042] That is, the tailoring of the steel back: use a punch to make a formed brake pad steel back, clean and polish the surface, and apply a layer of phenolic resin 2123 adhesive;

[0043] Preparation of lining material in the second step

[0044]Weigh 20 kg of sepiolite fiber, 10 kg of wollastonite needle fiber, 10 kg of modified slag wool, 2 kg of cellulose fiber, 8 kg of modified phenolic resin 2123 as binder, 20 kg Graphite as a lubricant and 15 kg of barium sulfate as a filler, drying and crushing processes were carried out, and then 0.01 kg of r- Aminopropyltriethoxysilane is used as coupling agent and 0.02 kg of phosphate ester amine salt as antistatic agent and other pretreatment procedures are prepared into required powder;

[0045] The third step cold pressing

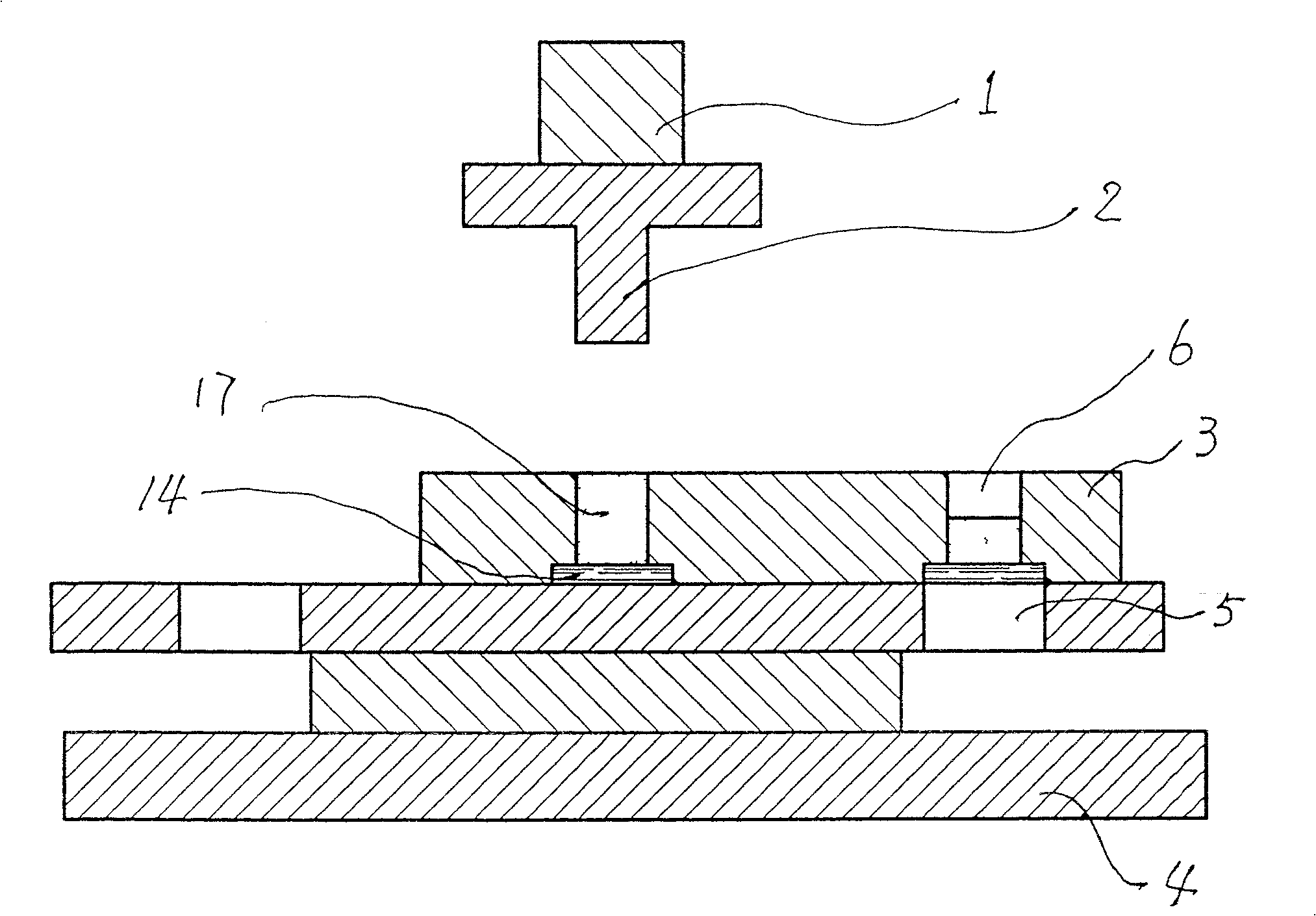

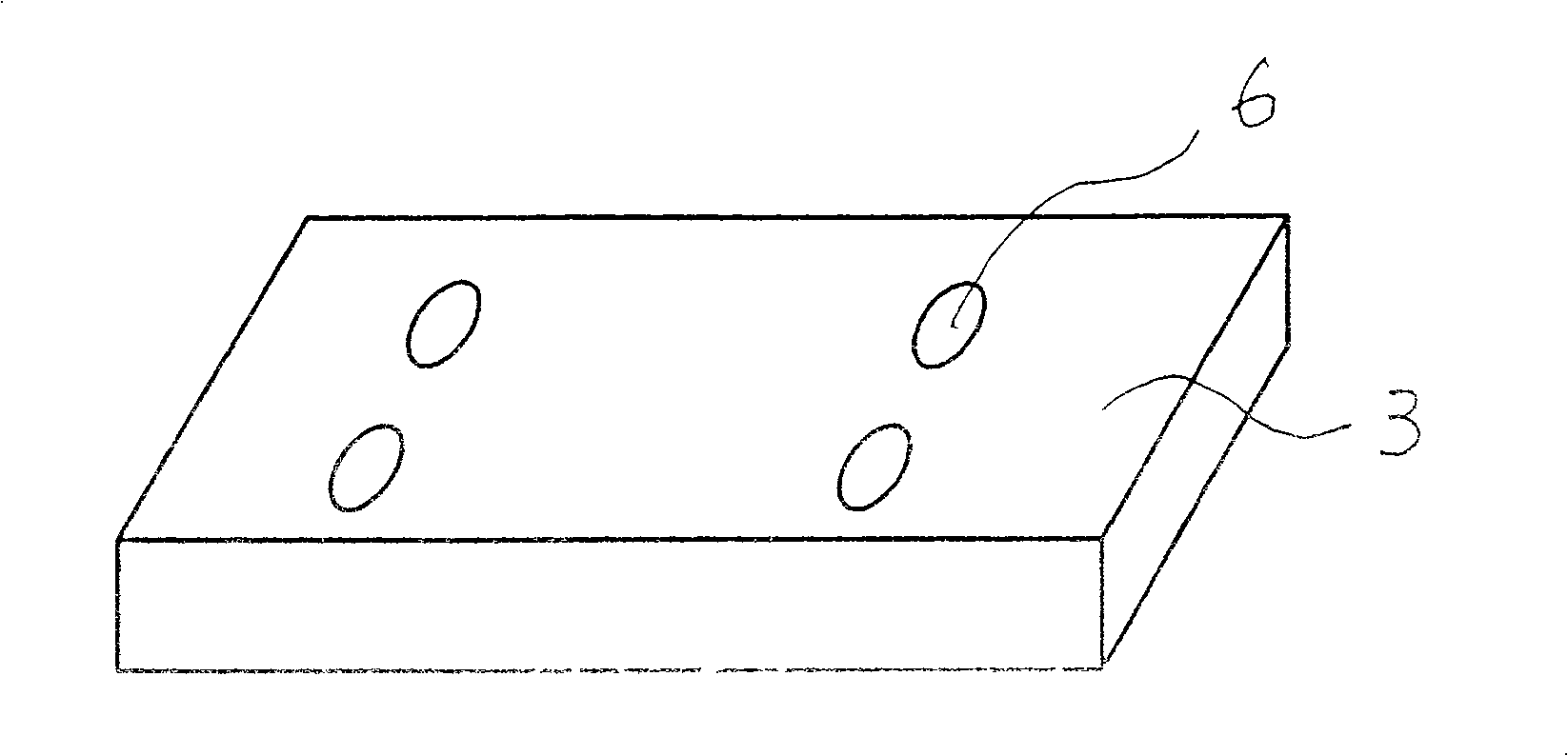

[0046] Fill the steel back 14 and the weighed powdery lining material 17 (the steel back 14 is below) into such as figure 1 and figure 2 In the mold cavity ...

Embodiment 2

[0056] Preparation of the first steel back

[0057] That is, the tailoring of the steel back: use a punch to make a formed brake pad steel back, clean and polish the surface, and apply a layer of phenolic resin J04 adhesive;

[0058] Preparation of lining material in the second step

[0059] Weigh 10 kg of sepiolite fiber, 5 kg of wollastonite needle fiber, 5 kg of modified slag wool, 8 kg of paper fiber, 12 kg of nano-modified phenolic resin as adhesive, 5 kg Graphite and 5 kg of friction agent are used as lubricant and 20 kg of heavy calcium as filler, which are dried and pulverized respectively, and then separated into sepiolite fiber, wollastonite needle fiber, modified slag wool and paper fiber Add 0.06 kg of anilinomethyltriethoxysilane as coupling agent and 0.05 kg of antistatic agent TM to mix and other pretreatment processes to prepare required powder;

[0060] The third step cold pressing

[0061] With embodiment 1;

[0062] The fourth step is hot pressing curing...

Embodiment 3

[0068] Preparation of the first steel back

[0069] Same as Example 1

[0070] Preparation of lining material in the second step

[0071] Weigh 10 kg of wollastonite needle-like fiber, 10 kg of modified slag wool, 8 kg of cellulose fiber, 10 kg of nitrile rubber modified phenolic resin as adhesive, 5 kg of mica, 5 kg of Talc powder and 5 kg of friction material are used as lubricant, 15 kg of barite, 10 kg of wollastonite as filler, and 8 kg of ferrochrome powder are used to increase the friction coefficient. Prepared by adding 0.015 kg of r-aminopropyltriethoxysilane as coupling agent and 0.02 kg of phosphate amine salt as antistatic agent to stone needle-shaped fibers, modified slag wool and cellulose fibers. into the desired powder form;

[0072] The third step cold pressing

[0073] With embodiment 1;

[0074] The fourth step is hot pressing curing

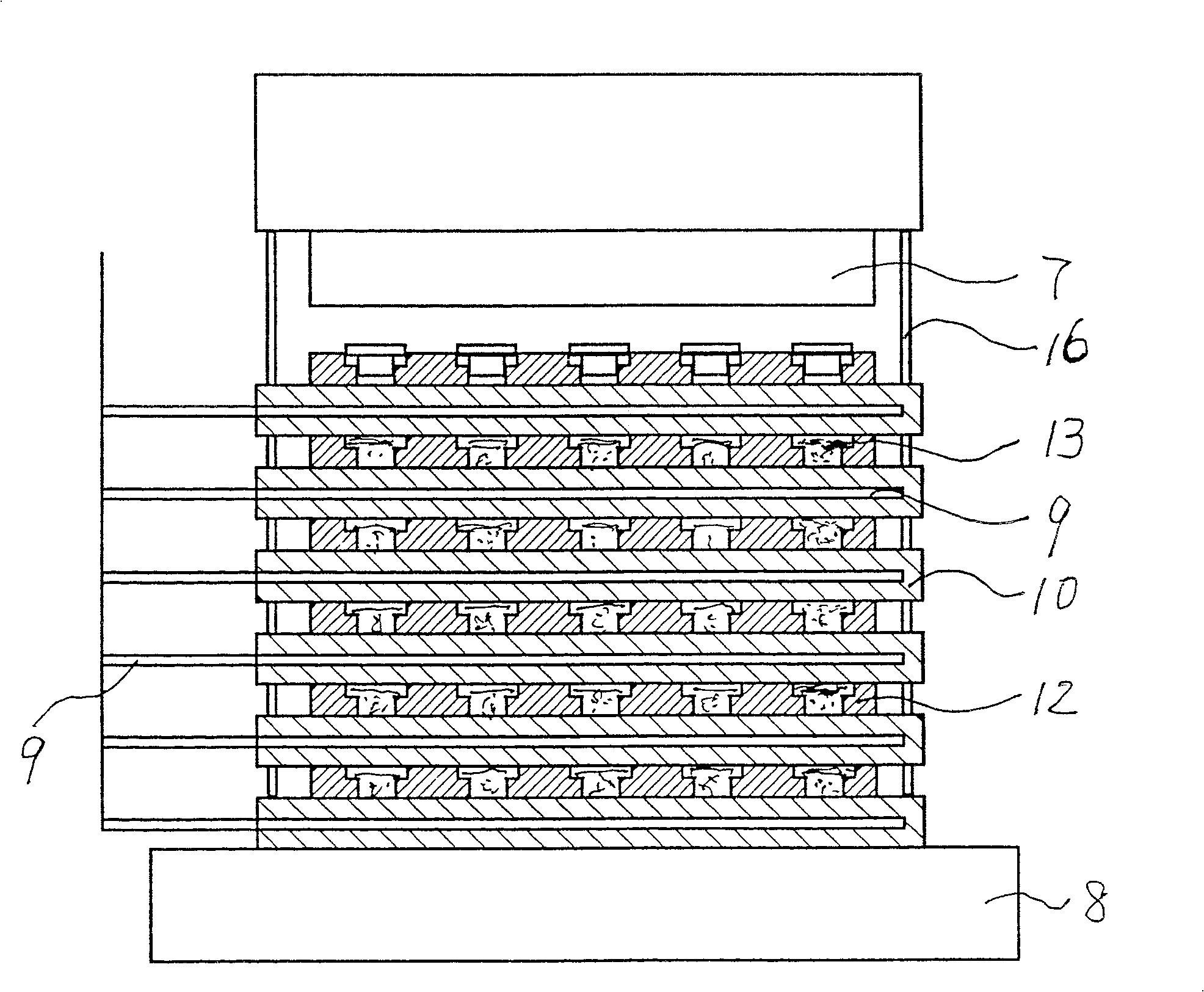

[0075] Arrange the cold-formed brake pad blanks into the Figure 4 In the second cavity 11 of the vulcanized plate 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com