Epitaxial thin films

An epitaxial thin film and thin film technology, applied in the field of epitaxial thin films of dielectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

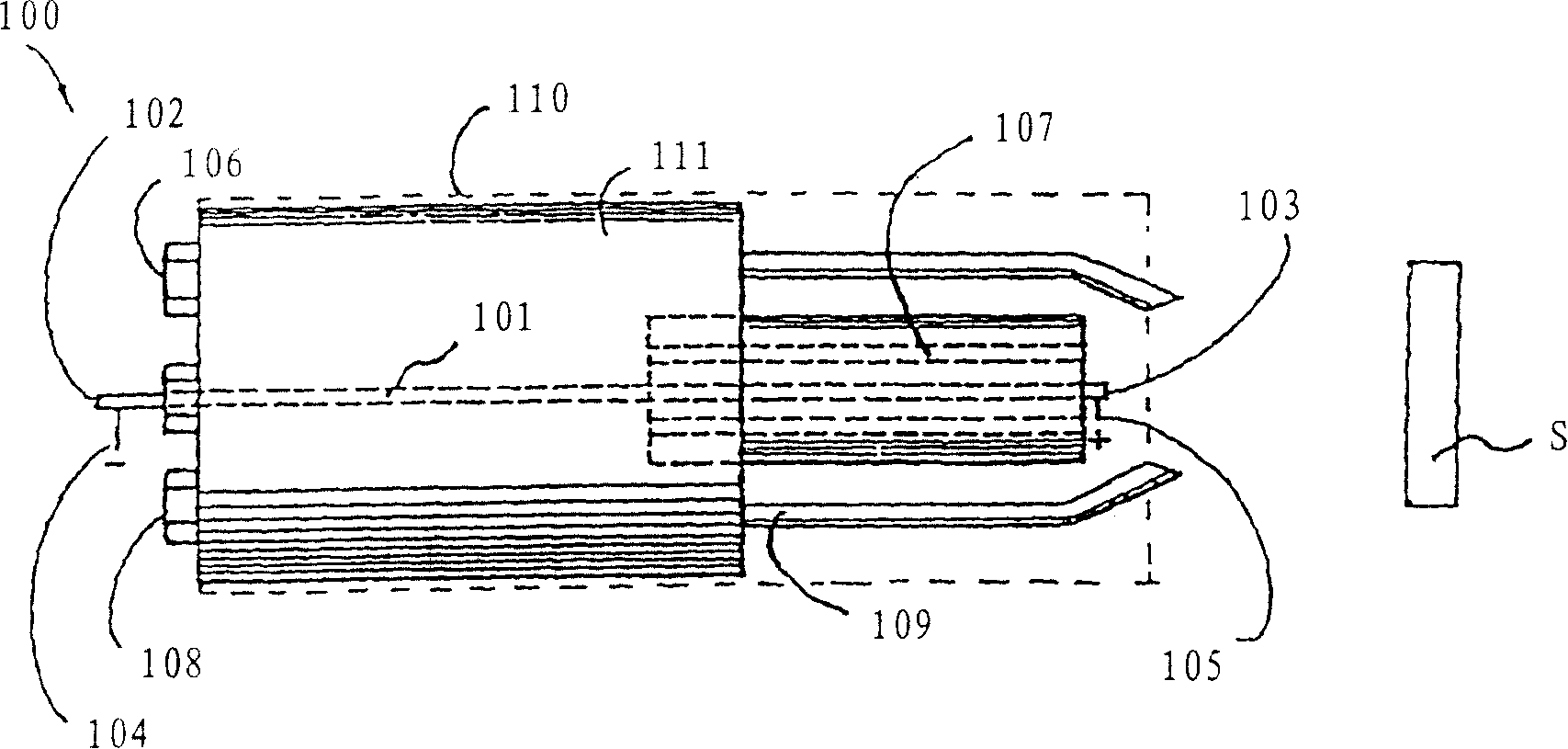

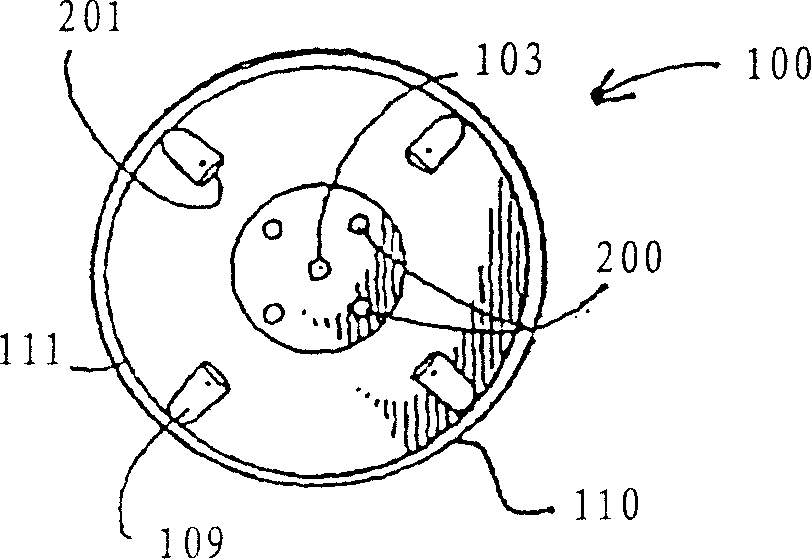

Method used

Image

Examples

Embodiment 1

[0050] In this example, the SrTiO 3 (STO) deposited on rolled textured nickel. The precursor solution included 1.26 g strontium 2-ethylhexanoate (2eh) (diluted with toluene to 1.5 wt.% strontium), 1.11 g titanium diisopropoxybisacetylacetonate (diluted to 0.94 wt. %), 51ml denatured ethanol and 300g propane. The solution was added to the needle at a rate of 3 ml / min while a heating current of 1.75A was applied to the needle. Nozzle oxygen at 3 lpm at 80 psi, hydrogen pilot gas at 15 psi at 18 lpm, and argon at 32 lpm at 50 psi as shielding gas. Deposition was carried out for 10 minutes at a substrate temperature of 950°C.

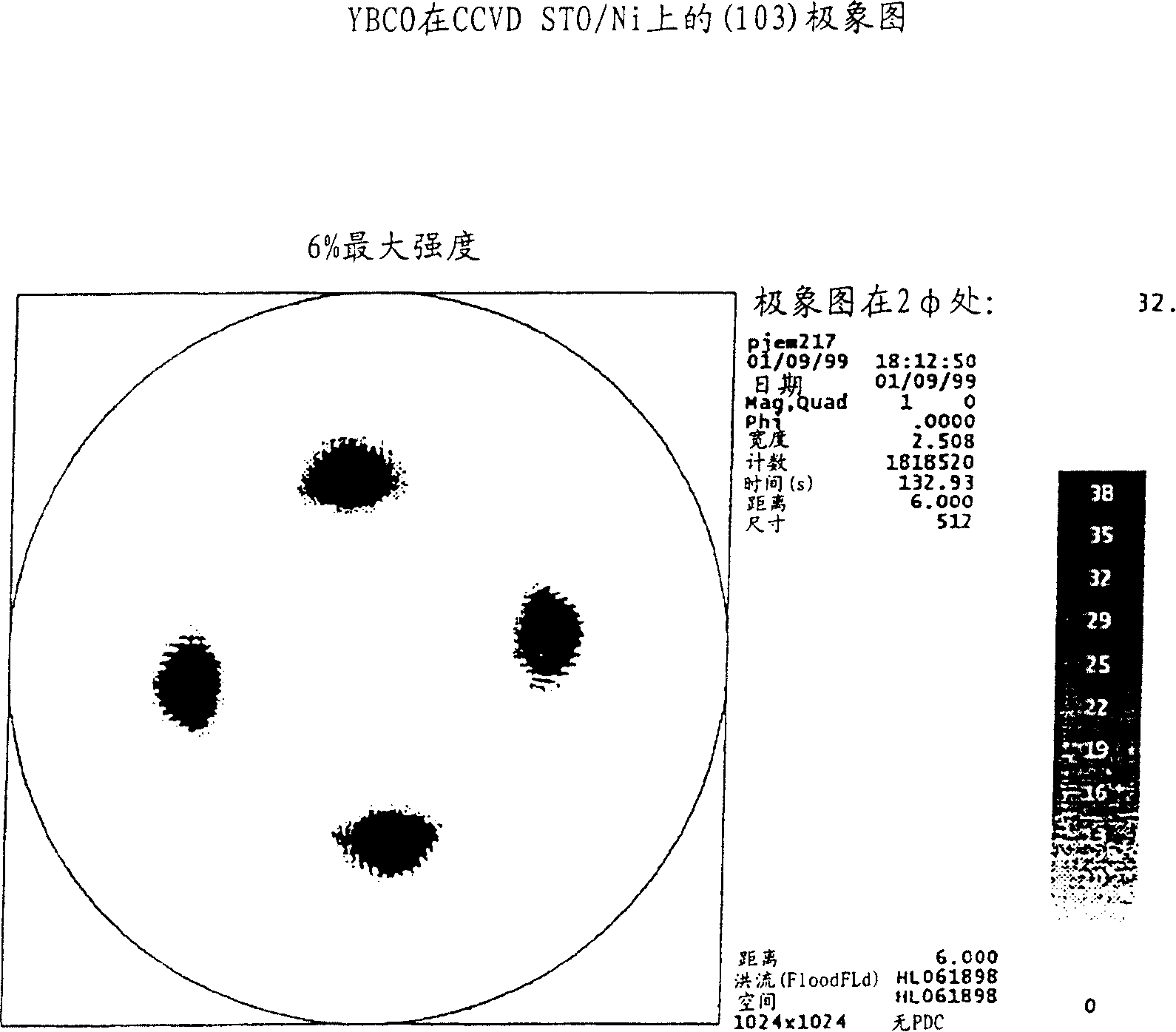

[0051] Such as image 3 As shown, the deposited buffer layer is highly epitaxial, exhibiting a single cubic in-plane orientation. image 3 is SrTiO deposited on nickel by CCVD 3 YBa deposited on the surface of the buffer layer 2 Cu 3 o x Pole image diagram of (YBCO) superconductor. The polar image of the YBCO layer exhibits the same uniplane in-pl...

Embodiment 2

[0061] In this example, LSM was deposited on a-plane sapphire using CCVD. The precursor solution included 0.21g Mn-2eh (diluted to 6% by weight of Mn with mineral spirits), 1.96g of La-2eh (diluted to 2% by weight of La with mineral spirits), 0.97g of Sr-2eh (10% by weight of %Sr in 2-ethylhexanoic acid, further diluted with toluene to a Sr of 1.25% by weight). This solution was added to toluene to make a total volume of 10 ml, then added to 60 g of propane. The solution was added at a rate of 3 ml / min for a total deposition time of 30 minutes. A 2.42A current was applied to the needle, and the nozzle oxygen flow rate was 3500ml / min. The nozzle oxygen pressure is 60 psi (no hydrogen or argon). The flame temperature is maintained at 1200-1400°C. exist Figure 8 , SEM micrographs of LSM on sapphire showing a porous and columnar microstructure. The electrode layer must have sufficient porosity to transport gaseous species or ions to the electrolyte while collecting electron...

Embodiment 3

[0063] In this example, YSB was deposited on a-plane sapphire by CCVD. The precursor solution included 2.88g Ba-2eh (8.5 wt% Ba in xylene, further diluted with toluene to 2 wt% Ba), 0.08g Y-2eh (diluted to 0.69 wt% Y with toluene). This solution was added to toluene to make a total volume of 10 ml, then added to 60 g of propane. The solution was added at a rate of 3 ml / min for a total deposition time of 29 minutes. A current of 2.50A was applied to the needle, and the nozzle oxygen flow rate was 3300ml / min. The flame temperature was maintained at 1200°C. The nozzle oxygen pressure is 60 psi (no hydrogen or argon).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com