Lactescent gunite material for supports of mine and construction method for guniting supports

A construction method and spraying technology, applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve the problems of high rebound rate of sprayed concrete materials, easy cracking, falling off, affecting the health of operators, etc., to eliminate workers Occupational diseases, fast construction speed, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

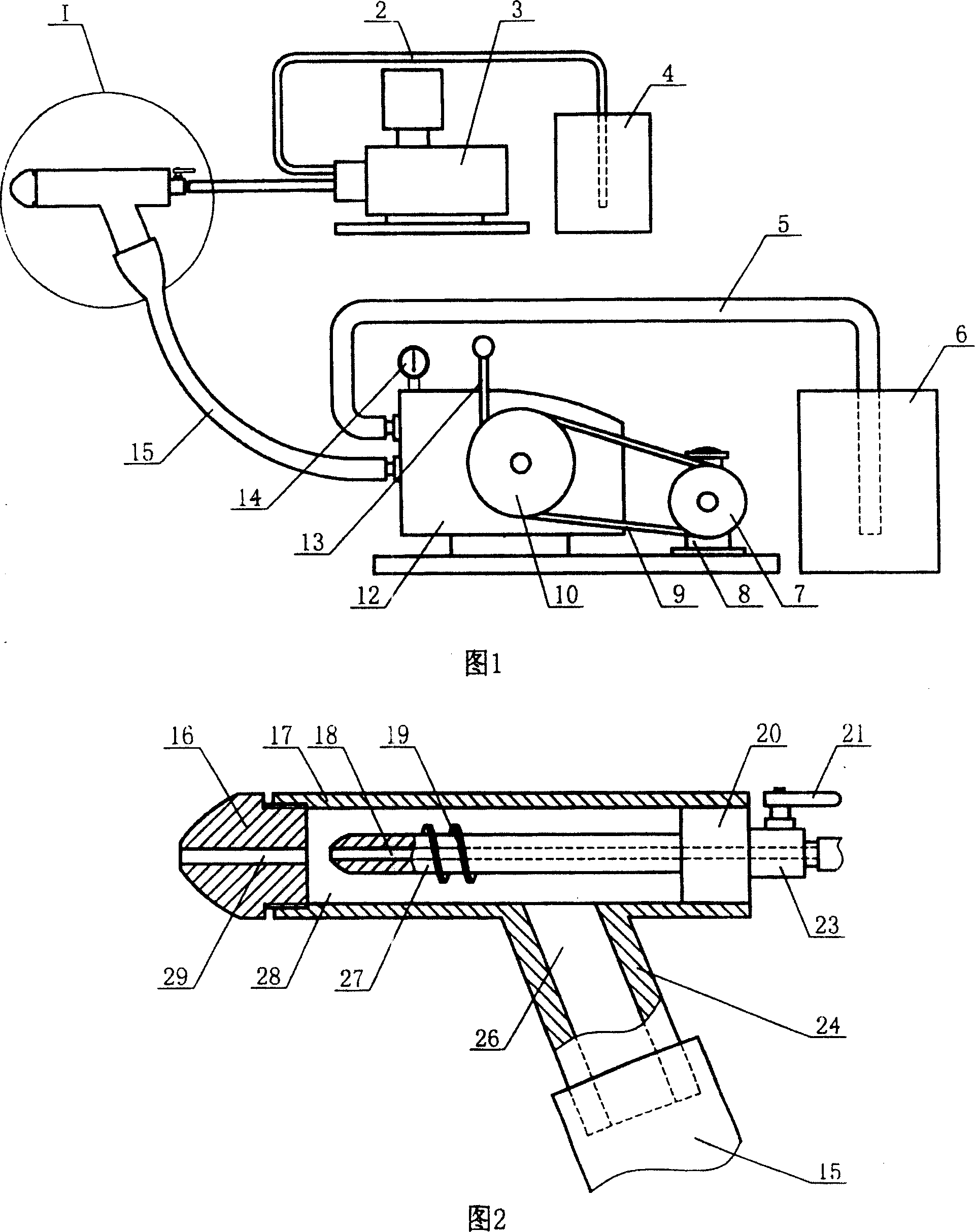

Image

Examples

Embodiment Construction

[0014] 1. The base material of the mine support emulsion shotcrete material of the present invention has the following various embodiments:

[0015] 1. The weight ratio of water glass and talc is 1:0.4.

[0016] 2. The weight ratio of water glass and talc is 1:0.45.

[0017] 3. The weight ratio of water glass and talc is 1:0.6.

[0018] 4. The weight ratio of water glass and talc is 1:1.2.

[0019] 5. The weight ratio of water glass and talc is 1:1.15.

[0020] 6. The weight ratio of water glass and talc is 1:1.1.

[0021] 7. The weight ratio of water glass and talc is 1:0.7.

[0022] 8. The weight ratio of water glass and talc is 1:0.9.

[0023] 9. The weight ratio of water glass and talc is 1:0.8.

[0024] 10. The weight ratio of water glass and talc is 1:1.0.

[0025] 11. The weight ratio of water glass and talc is 1:0.2.

[0026] 12. The weight ratio of water glass and talc is 1:0.3.

[0027] 13. The weight ratio of water glass and quartz powder is 1:0.2.

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com