Nickel base alloy

A technology of nickel-based alloys and alloys, used in machines/engines, stators, mechanical equipment, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

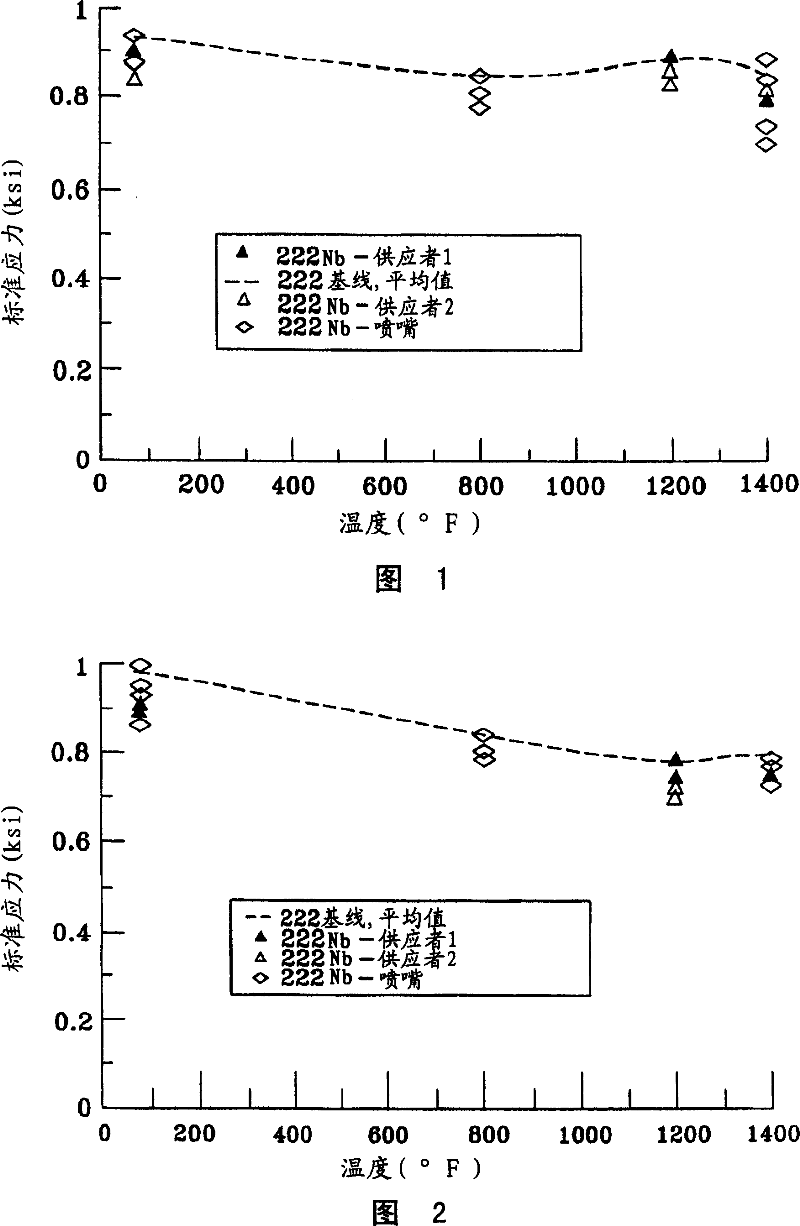

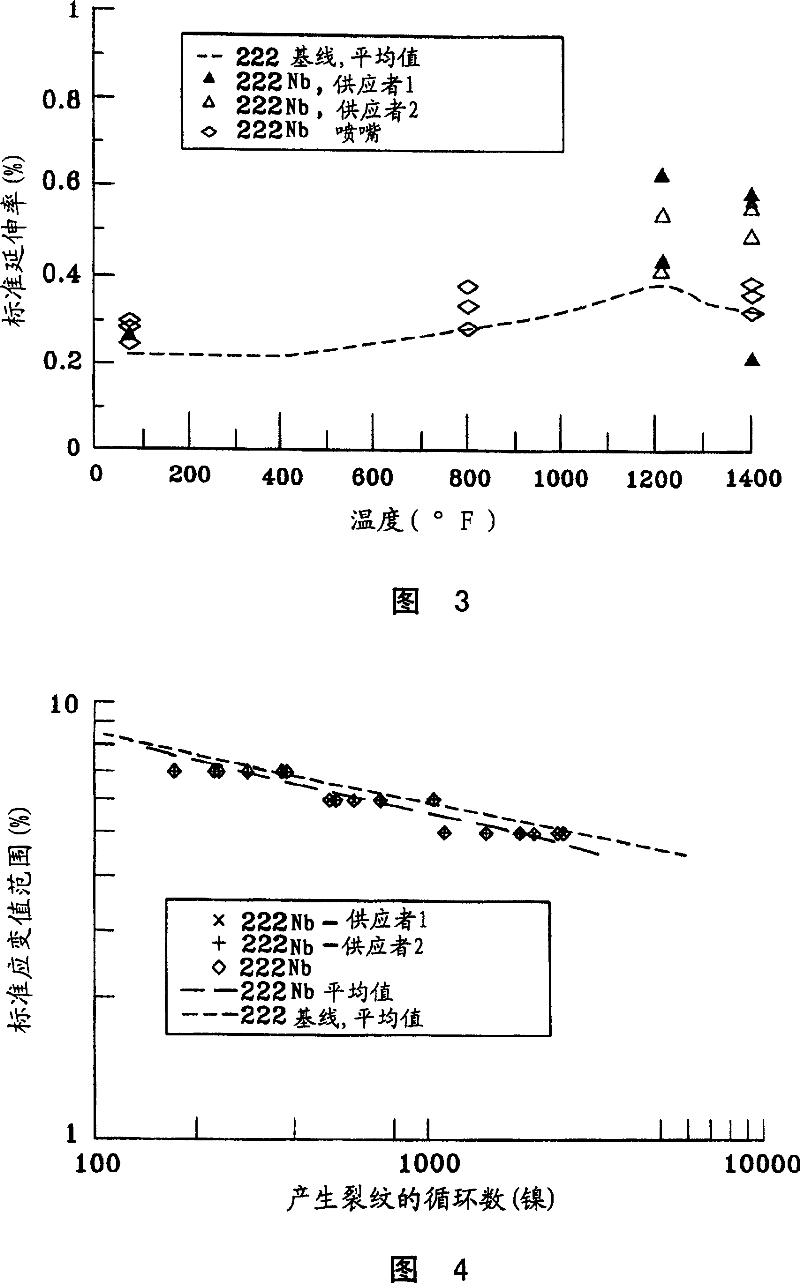

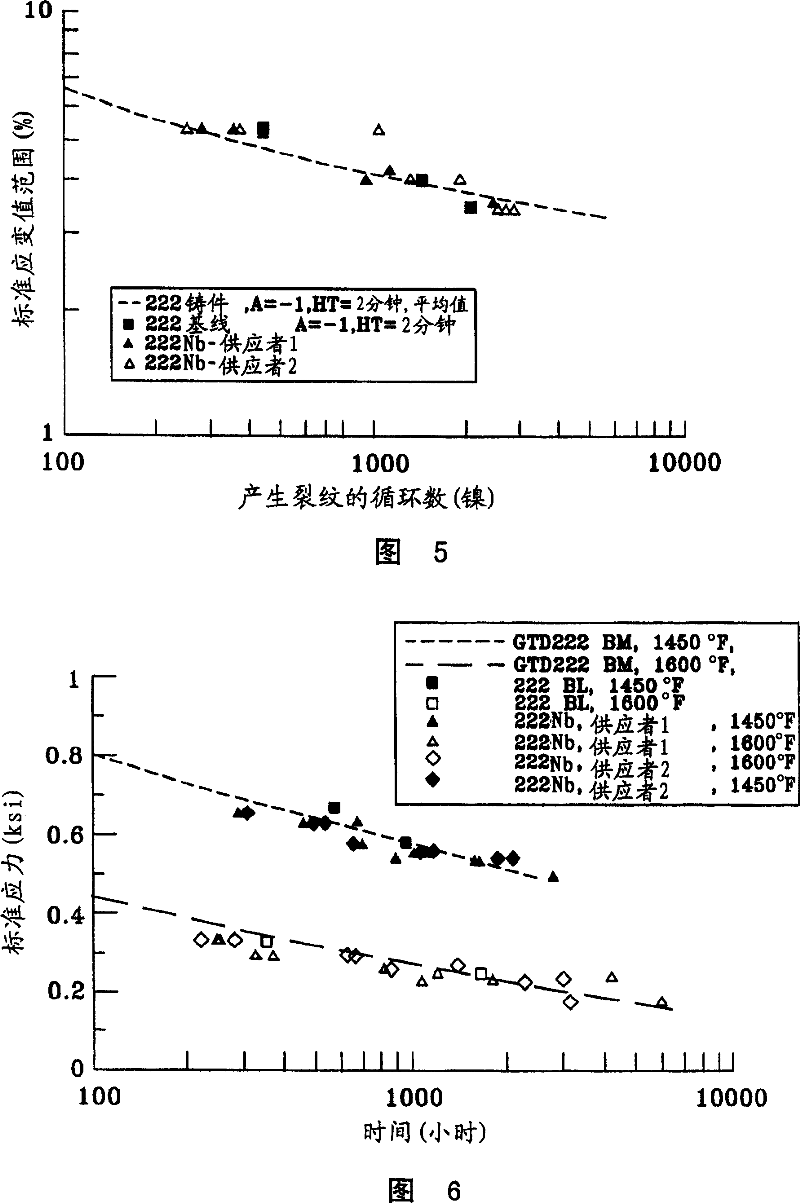

[0012] The present invention is the result of an effort to develop a nickel-based alloy with properties comparable to that marketed as GTD-222 and disclosed in U.S. Patent No. 4,810,467, which is disclosed here For reference, but its chemical composition is carefully balanced to reduce or completely eliminate tantalum. This research led to the development of nickel-based alloys with properties particularly suited to nozzles used in the second or third turbine stages of gas turbine engines. Therefore, specific properties of interest include creep strength, weldability, fatigue life, castability, metallurgical stability and oxidation resistance. As a result of this study, the niobium content was increased to replace the absence of tantalum, thus fundamentally altering the two trace alloying elements in GTD-222 known to affect the gamma primary dispersion strengthening phase.

[0013] The high-temperature strength of nickel-based superalloys is directly related to the volume fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com