Support device for processing complicated shape punched piece and its producing method

A technology with complex shapes and supporting devices, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to form mass production, low precision, low efficiency, etc., to avoid over-positioning phenomenon, good accuracy retention, search Positive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

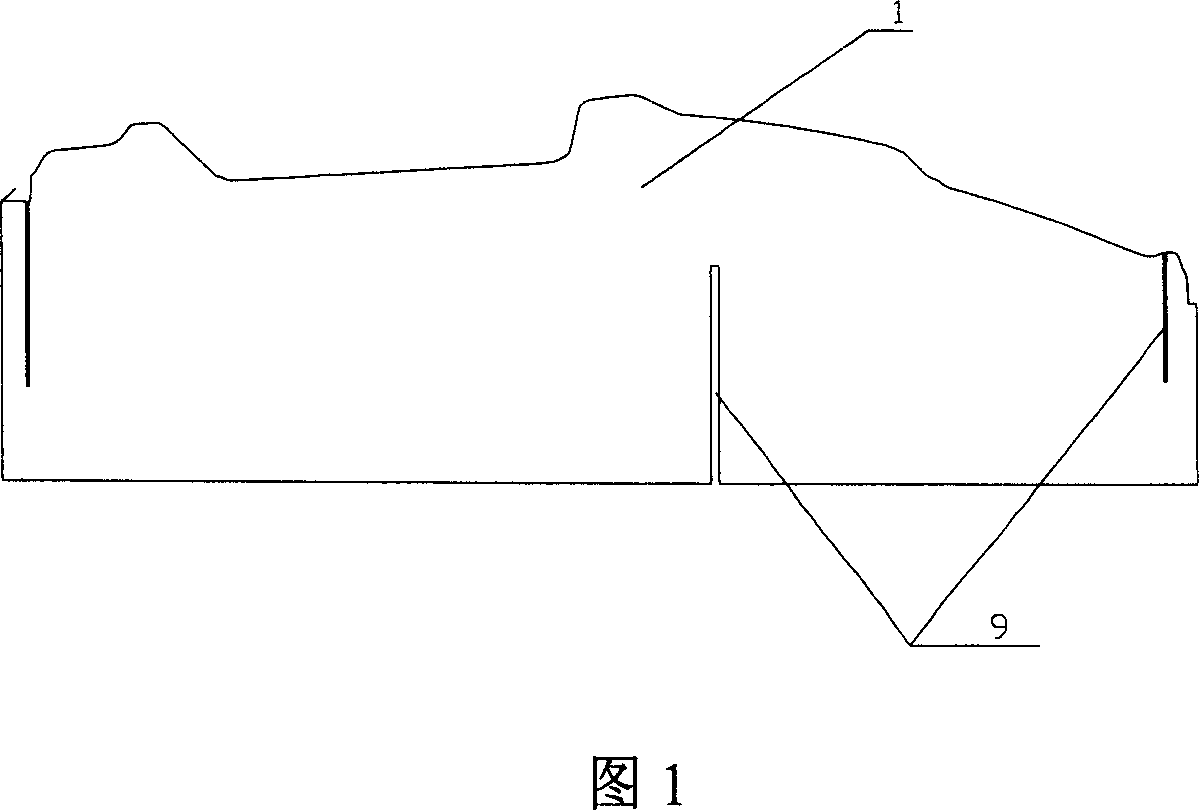

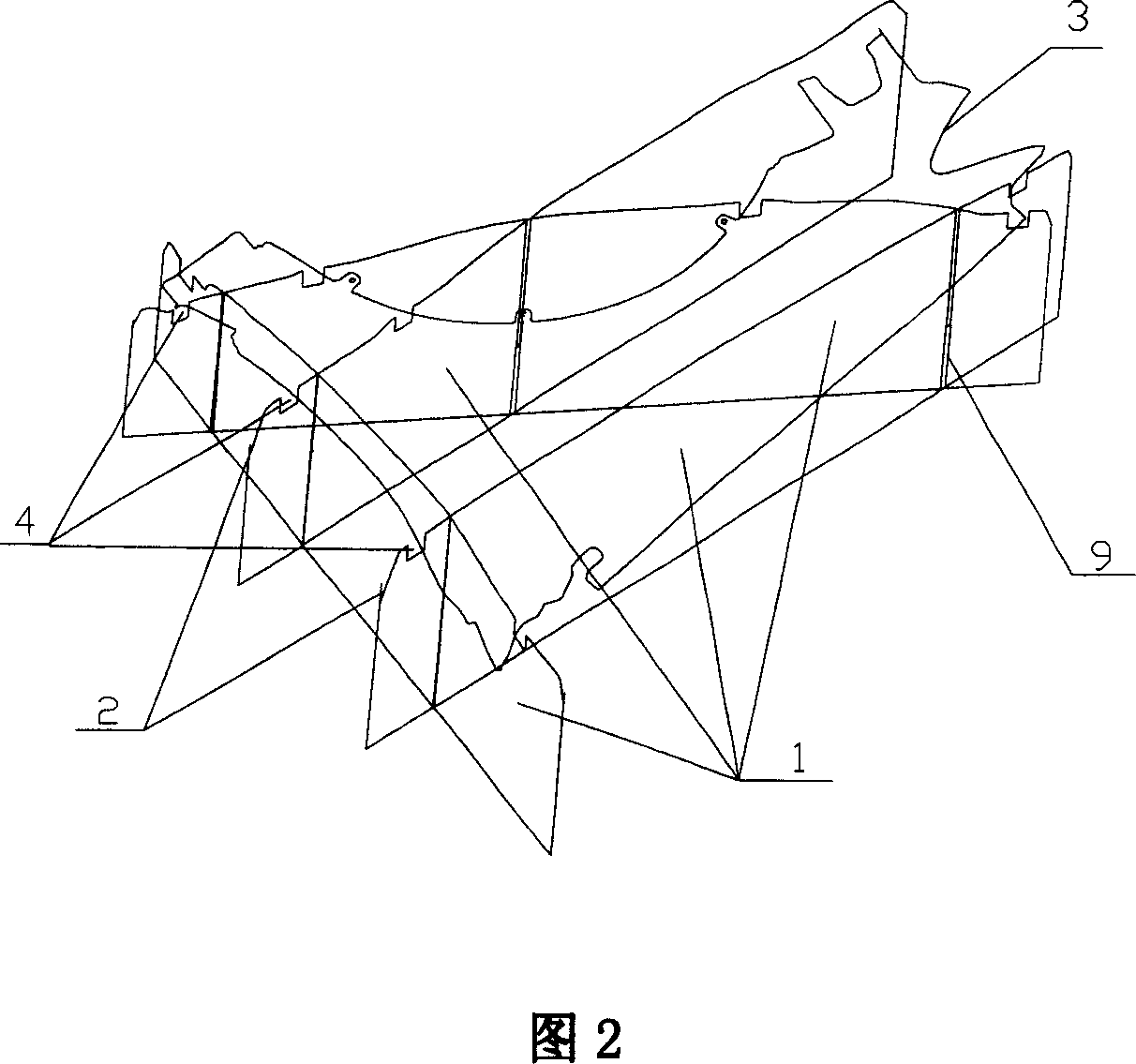

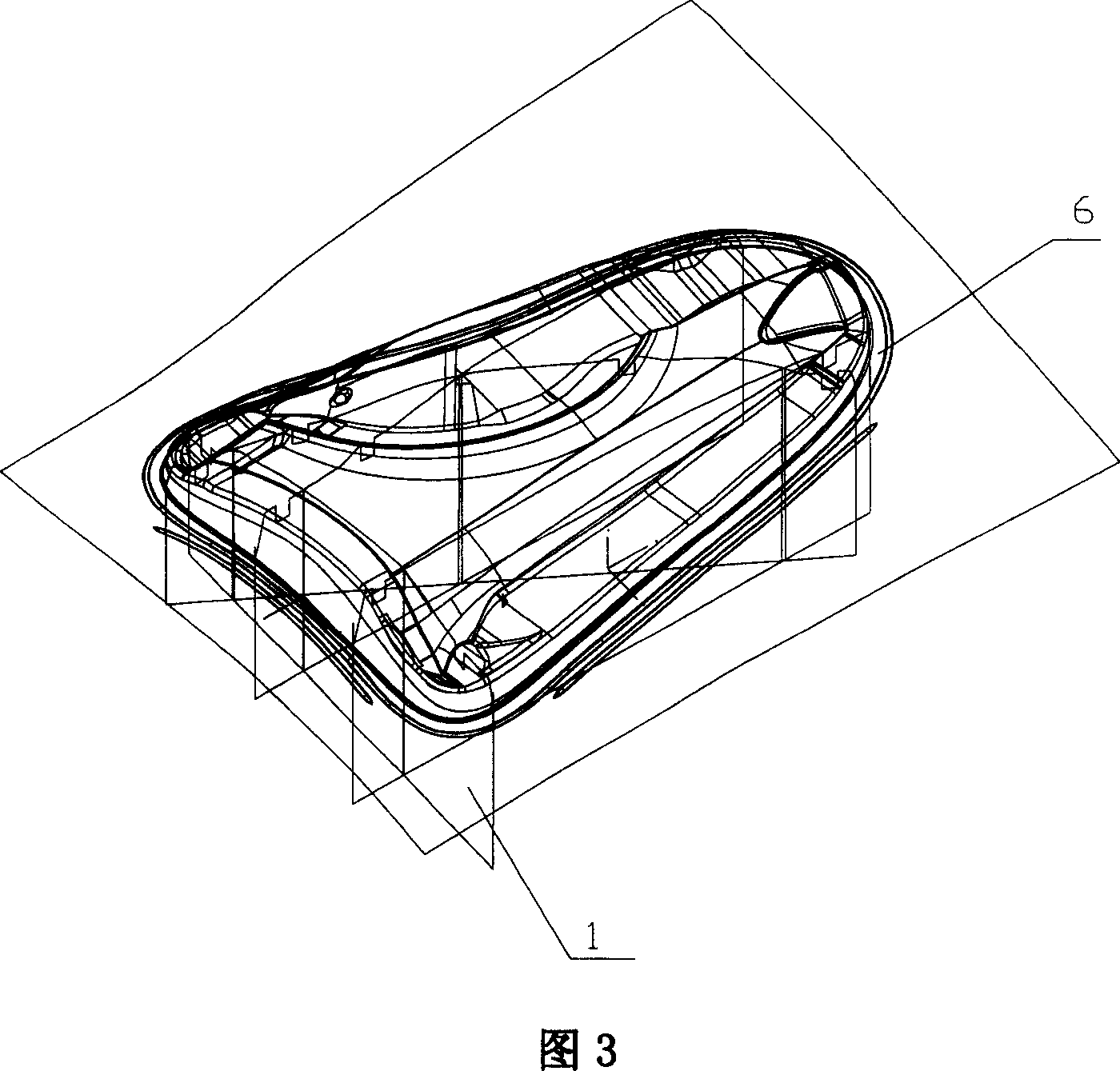

[0029] The present invention makes different support devices according to the different shape features of the workpiece, as shown in Figure 3, completes the positioning of the workpiece 6 by the support device, the manufacturing process of this support device is simple and easy, and its steps are as follows:

[0030] As shown in Figure 6, the shape and position of the support line 5 are determined according to the computer digital model of the workpiece 6, and the digital models of each support line 5 are produced, and the digital model is prepared for cutting the support plate 1 according to the actual situation. . Among them, the material thickness gap s represents the gap between the upper and lower dies of the mold to accommodate the sheet material, because the actual support plate has thickness, and the number in the computer has no thickness, so when processing the mold, it is necessary to use the punch or die One is the surface reference, and the other is the fixed gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com