Marine diesel engine test device

A marine diesel engine and test device technology, which is applied to the test bench of marine diesel engines and the field of test devices for marine diesel engines, can solve problems such as broken mounting feet, elimination of gaps between mounting feet and fixed supports, vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

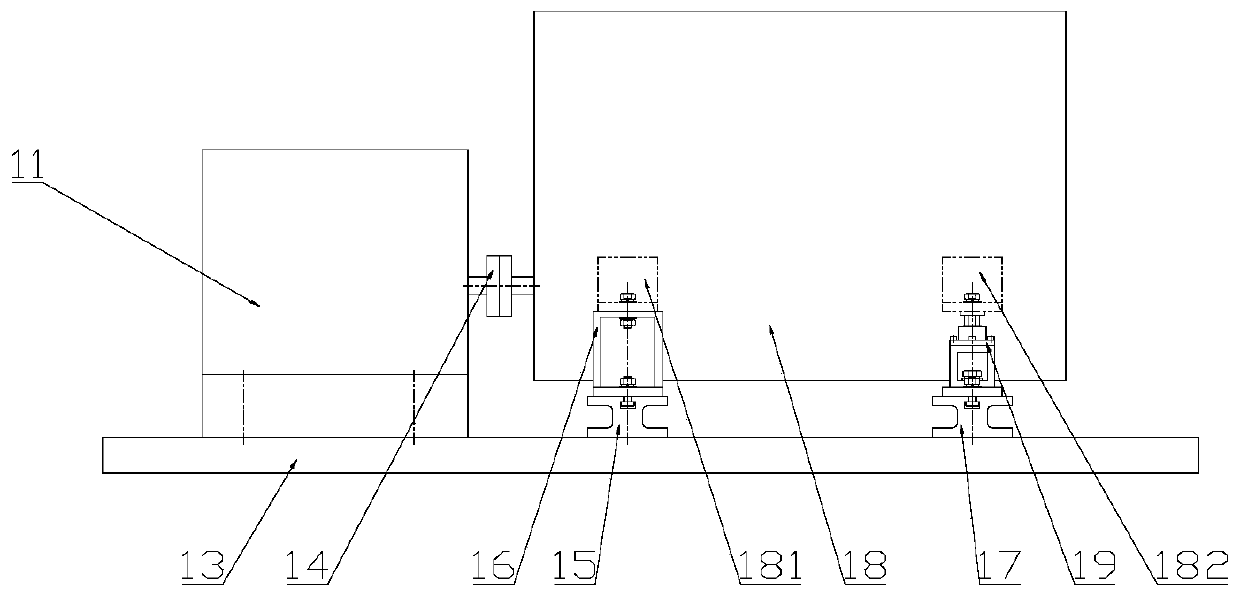

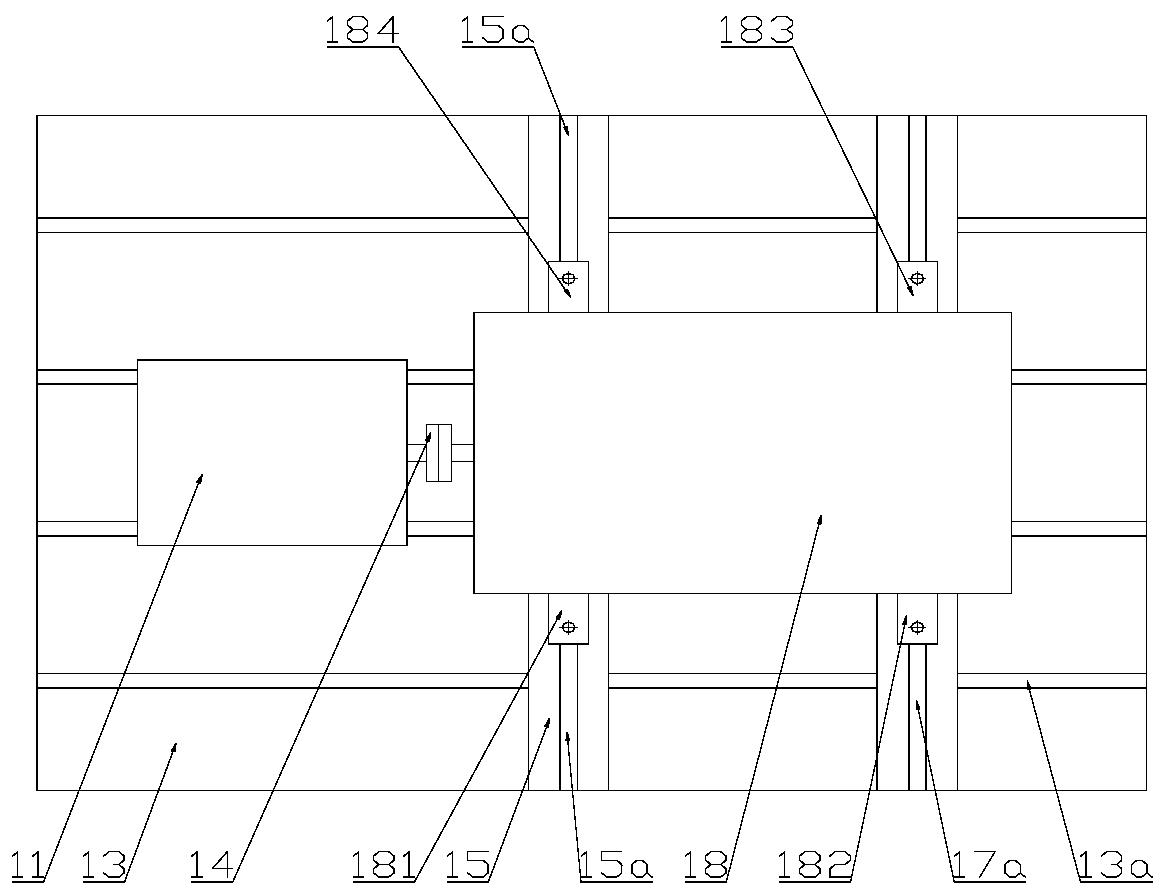

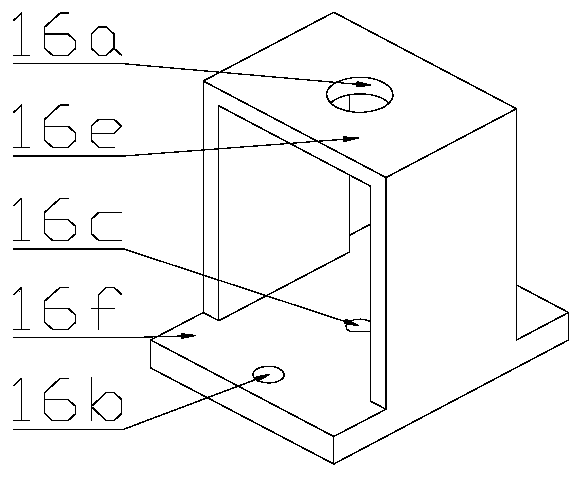

[0026] In order to make the purpose of the present invention and technical scheme statement clearer, the present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0027] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used herein have the same meaning as commonly understood by those of ordinary skill in the art to which this invention belongs.

[0028] The meaning of "left, right, up, down, front, back" mentioned in the present invention means that when the reader is facing the drawings, the left side of the reader is left, the right side of the reader is right, and the reader's right side is right. The upper edge of the reader is the upper edge, the lower edge of the reader is the lower edge, the face in the paper in front of the reader is the front, and the face facing the reader is the back, rather than specific limitations to the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com