A vertical axis system of a precision turntable

A vertical shaft and turntable technology, which is applied in the field of similar mechanical equipment and vertical shafting of precision turntables, can solve the problems of poor assembly process, non-unique bearing parts, affecting the stability of shafting, etc., to improve shafting accuracy and bearing capacity. Large, the effect of increasing the stability of the shafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

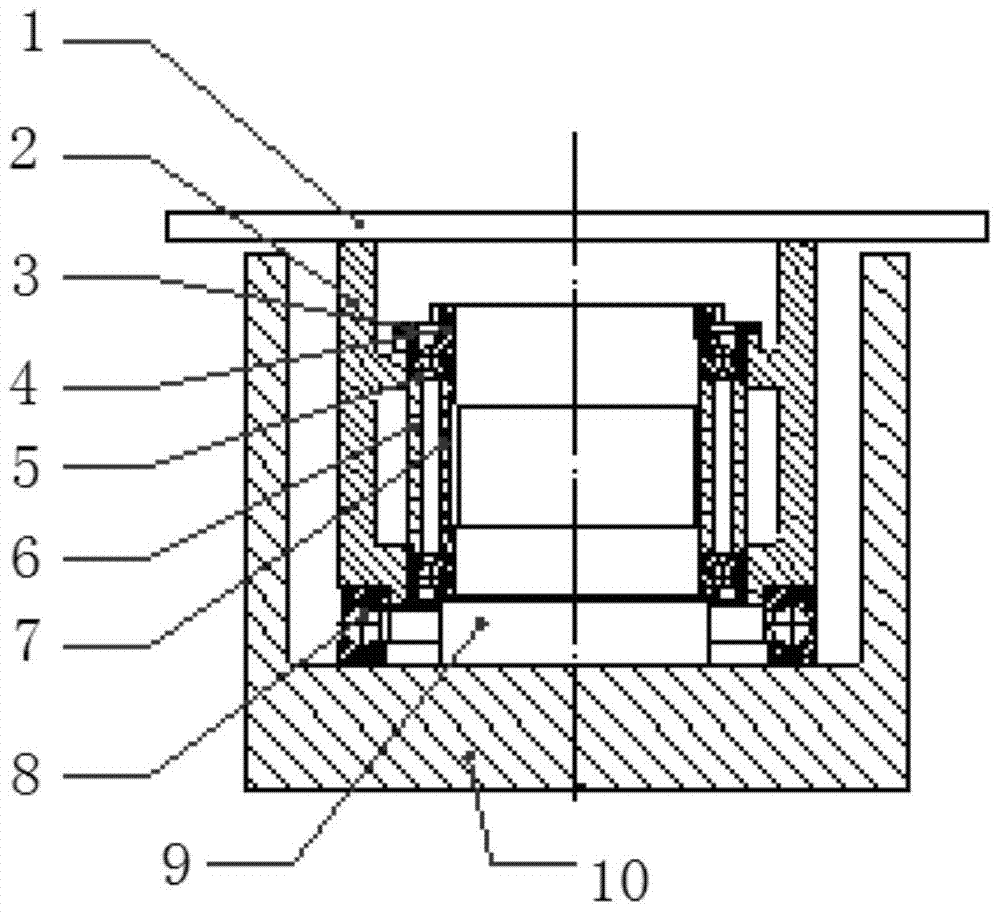

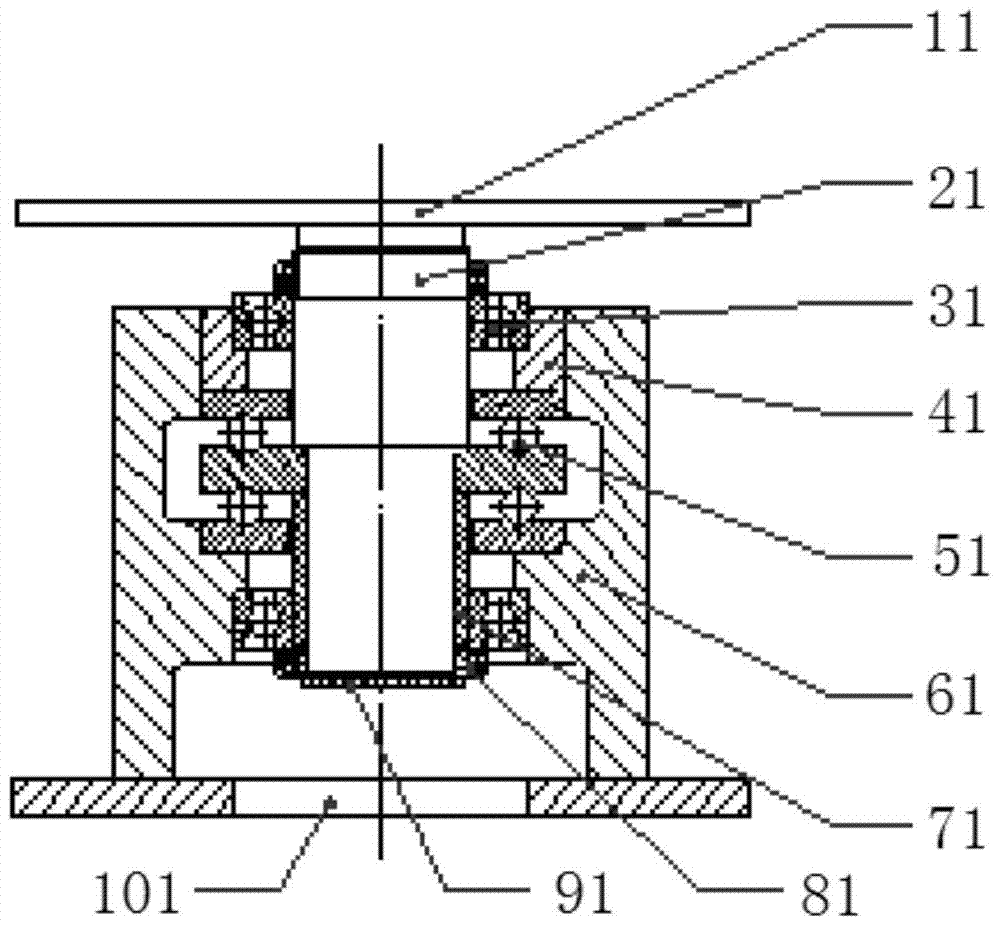

[0031] Such as figure 2 As shown, the present invention provides a vertical axis system of a precision turntable, including a stage 11, an azimuth rotating shaft 21, an angular contact ball bearing 31, a thrust ball bearing 51 and an azimuth fixed box 61,

[0032] Both the azimuth rotation shaft and the angular contact ball bearing are arranged in the azimuth fixed box; the upper end of the azimuth rotation shaft supports the stage 11;

[0033] The angular contact ball bearings are a pair, and the pair of angular contact ball bearings are installed back-to-back at both ends of the azimuth rotation shaft; the angular contact ball bearing at the upper end of the azimuth rotation shaft is the first angular contact ball bearing, and the angular contact ball bearing at the lower end The contact ball bearing is the second angular contact ball bearing;

[0034] A bearing mounting nest is provided between the first angular contact ball bearing and the azimuth-fixed box, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com