Large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table

A static pressure turntable, ultra-precise technology, applied in the direction of large fixed members, anti-centrifugal force rotating parts, bearings, etc., can solve the problems that the processing of key parts is difficult to obtain high precision, the moment of inertia of the rotary shaft system is large, and cannot fully meet the processing requirements , to avoid the increase of the moment of inertia, improve the machining accuracy and improve the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

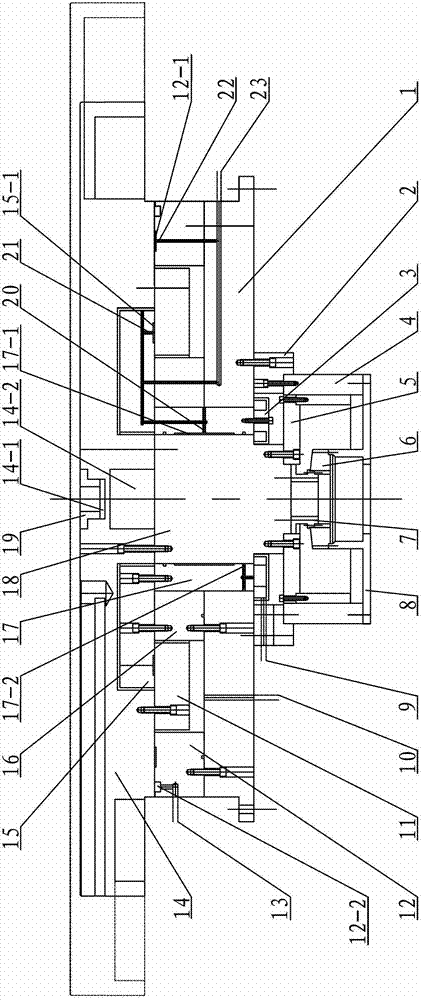

[0017] Specific implementation mode one: as figure 1 As shown, a large-diameter-to-height ratio ultra-precision hydrostatic turntable of this embodiment, the ultra-precision hydrostatic turntable includes a turntable base 1, a motor base 2, an oil receiving plate 3, a torque motor 4, a connection plate 5, Angle encoder 6, connecting shaft 7, encoder seat 8, lower floating plate 11, upper floating thrust plate 12, upper floating plate 14, lower floating thrust plate 15, inner spacer ring 16, radial bearing bush 17, main shaft 18, positioning installation shaft 19. Oil inlet pipeline 23, several radial restrictors 20, several floating restrictors 21 and several floating restrictors 22;

[0018] The upper floating thrust plate 12, the lower floating plate 11, the lower floating thrust plate 15 and the inner spacer ring 16 are all circular, the cross section of the upper floating plate 14 is circular, and the upper plane of the upper floating plate 14 can be used as the working su...

specific Embodiment approach 2

[0019] Specific implementation mode two: as figure 1 As shown, the floating liquid static pressure thrust oil film clearance and the floating liquid static pressure thrust oil film clearance of this embodiment are obtained by grinding the upper and lower surfaces of the inner spacer ring 16 to make it a negative tolerance. In this way, a large-diameter closed circular thrust surface is realized, which is beneficial to improve the machining accuracy, avoid a large moment of inertia and large deformation of the thrust plate, and is beneficial to improve the precision, rigidity and dynamic performance of the turntable. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: as figure 1 As shown, the radial bearing bush 17 of this embodiment is provided with an oil return groove 17-2, and the first oil return pipe 9 is installed on the oil receiving pan 3, and the oil returning groove 17-2 is connected to the first oil return pipe 9 through the oil receiving pan 3 ; The second oil return pipe 10 is installed on the base 1 of the turntable, and the upper plane of the upper floating thrust plate 12 is provided with an annular oil return groove 12-2, which is connected to the third oil return pipe installed on the upper floating thrust plate 12 13. This design is convenient for installation and debugging, and prevents oil leakage. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0021] working principle

[0022] When working, the hydraulic oil first enters several floating throttles 22, several downward floating throttles 21 and seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com