Sulphurs phase-change material chemically machinery polished non-abrasive polishing liquid and its use

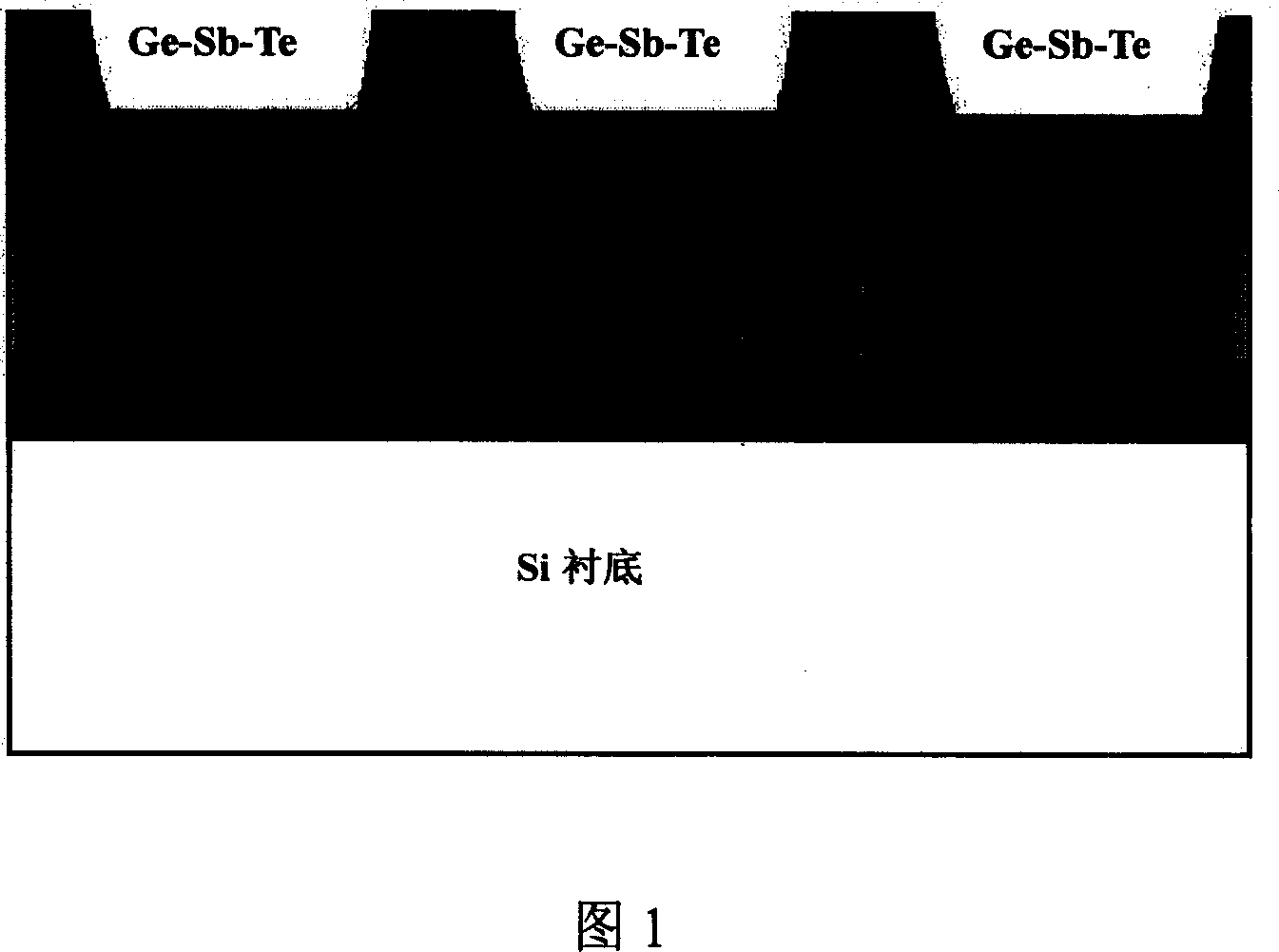

A non-abrasive polishing liquid, chemical mechanical technology, applied in the direction of polishing composition, chemical instruments and methods, can solve the problems of Ge-Sb-Te thin film material CMP work that has not been reported in the literature, and achieve the effect required by high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of abrasive-free polishing fluid A: the polishing fluid contains 6.0wt% hydrogen peroxide; 0.3wt% ammonium hydroxyethyl ethylenediamine tetraacetate; 0.3wt benzotriazole; dodecyl alcohol polyoxyethylene ether 0.2wt%; 1.0wt% ammonium chloride, 50ppm polydimethylsilane, 10ppm isomeric thiazolinone, tetramethylammonium hydroxide is the pH regulator, the pH value is 10.8, and the rest is deionized water.

Embodiment 2

[0044] Preparation of abrasive-free polishing liquid B: the polishing liquid contains 10.0 wt% of urea hydrogen peroxide; 0.5 wt% of ammonium ethylenediamine tetraacetate; 0.1 wt% of 1,2,4-triazole; Ammonium bromide 0.1wt%, lauryl alcohol polyoxyethylene ether 0.1wt%; ammonium chloride 1.5wt%, polydimethylsilane 50ppm, isomeric thiazolinone 10ppm, hydroxylamine as pH regulator, pH value 9.8, the rest is deionized water.

[0045] implement

example

Polishing fluid

serial number

Chelating agent

Surfactant

Accelerator

pH

3

C

h 2 o 2

3.0wt%

Ammonium EDTA

2.0wt%

Hexadecyltrimethyl bromide

Ammonium 0.2wt%

0.5wt%

0.1wt%;

Ammonia, Hydroxy

Amine, pH9.2

4

D

h 2 o 2...

Embodiment 8

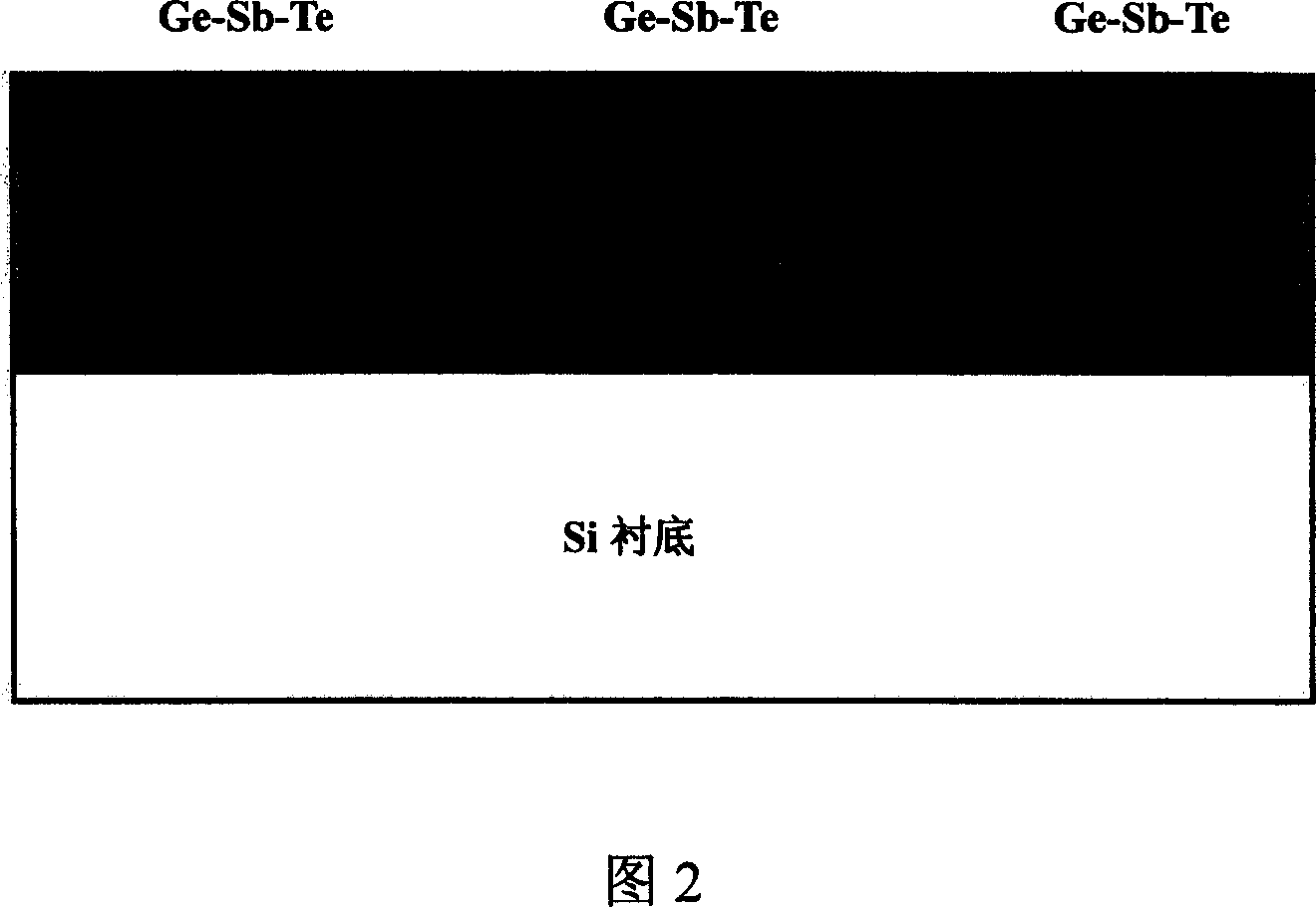

[0049] CMP test: CP-4 polishing machine from CETR Company of the United States is used, the polishing pad is IC1000 / SubaIV, the polishing machine chassis speed is 50rpm, the polishing head speed is 47rpm, the polishing liquid flow rate is 200ml / min, and the pressure is 2psi. Composition provided by 7 embodiments, the polishing pad sample is Si / SiO 2 / Ge 2 Sb 2 Te 5 . The RMS roughness of the polished surface was measured by an atomic force microscope (AFM), and the results are shown in Table 2. It can be seen from the table that after the Ge-Sb-Te compound is CMPed by the abrasive-free polishing solution provided by the present invention, the surface roughness RMS has been reduced to below 1.0 nm, which meets the requirements of high-performance C-RAM.

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com