Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Good speed performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

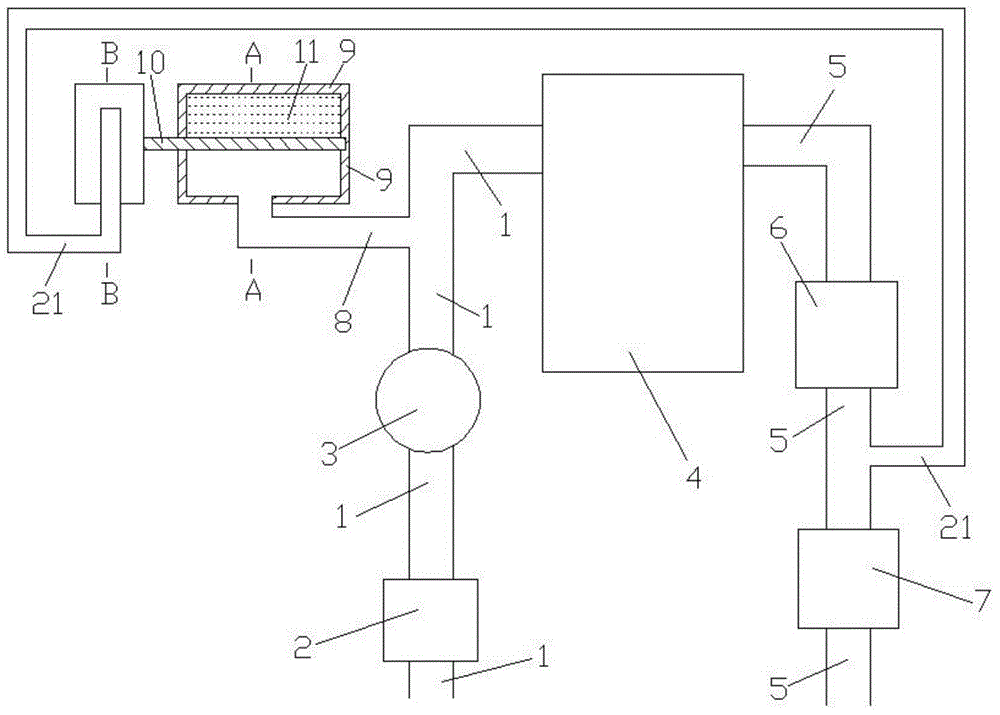

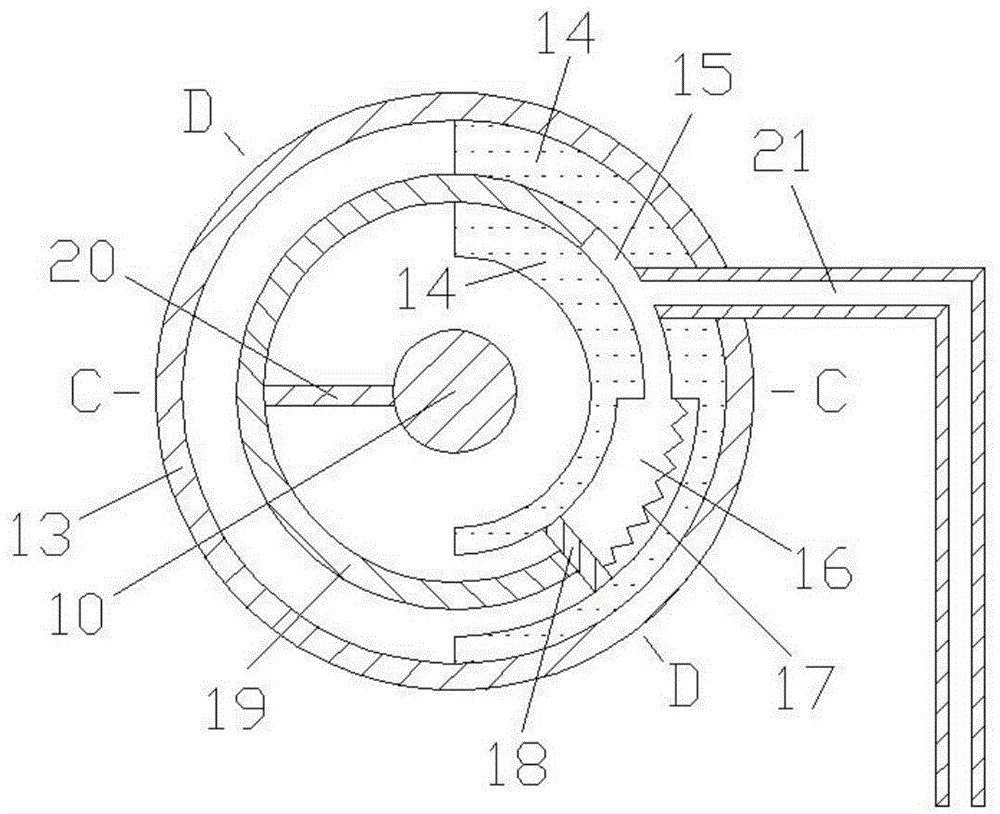

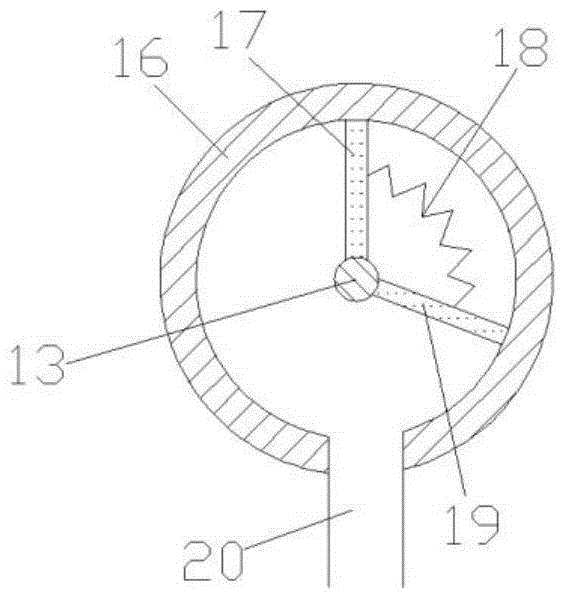

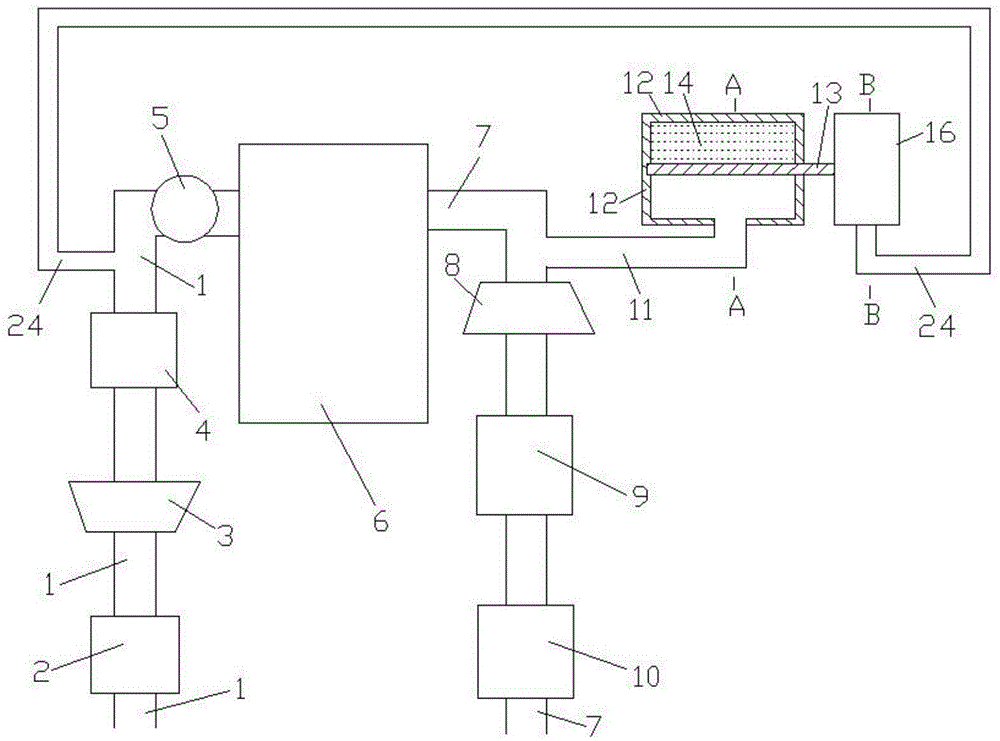

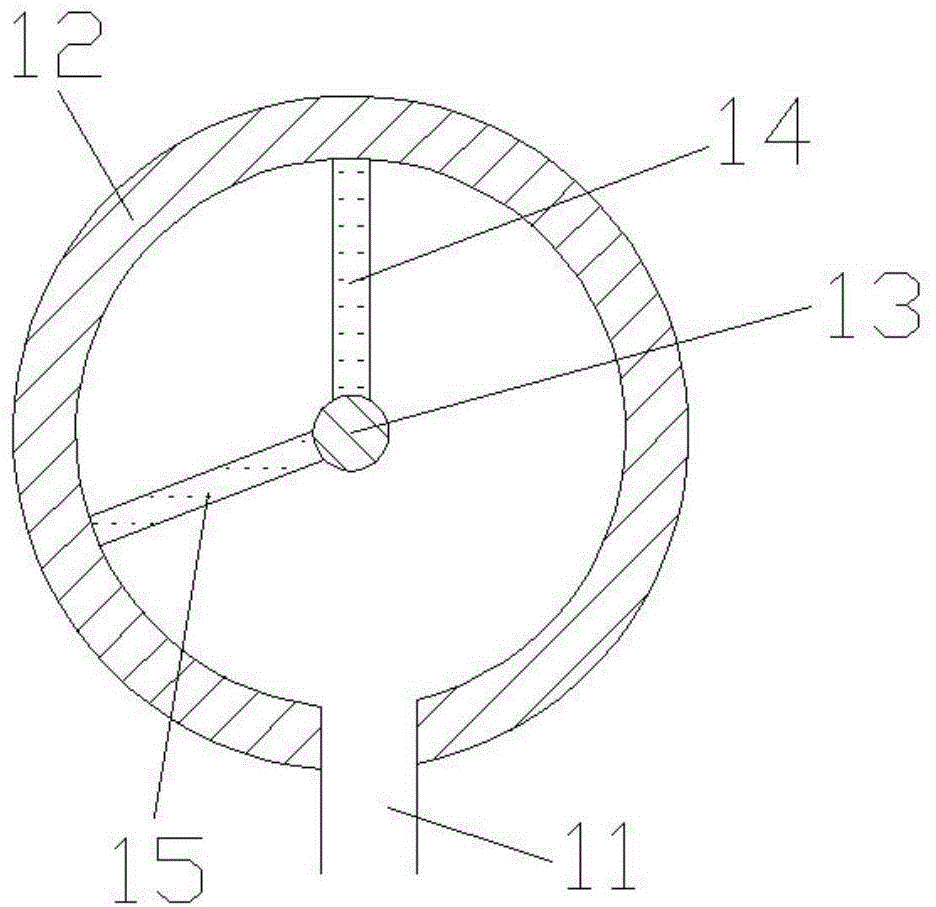

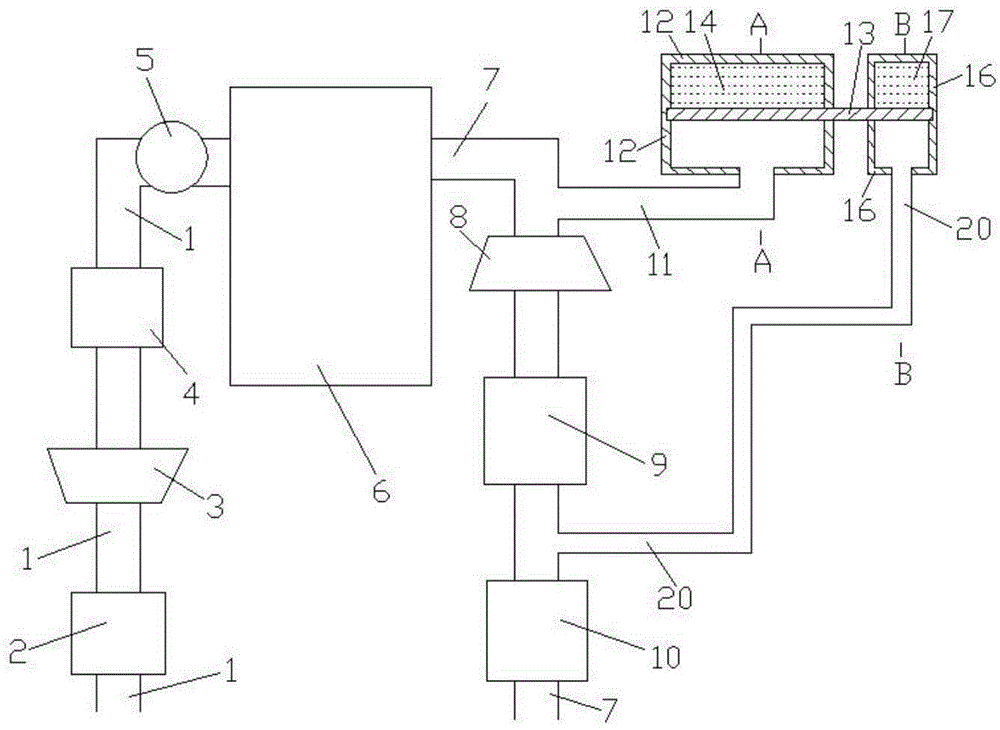

Pipeline expansion mechanism

InactiveCN104358612AContinuously variable volumeGood speed performanceInternal combustion piston enginesCombustionLow speed

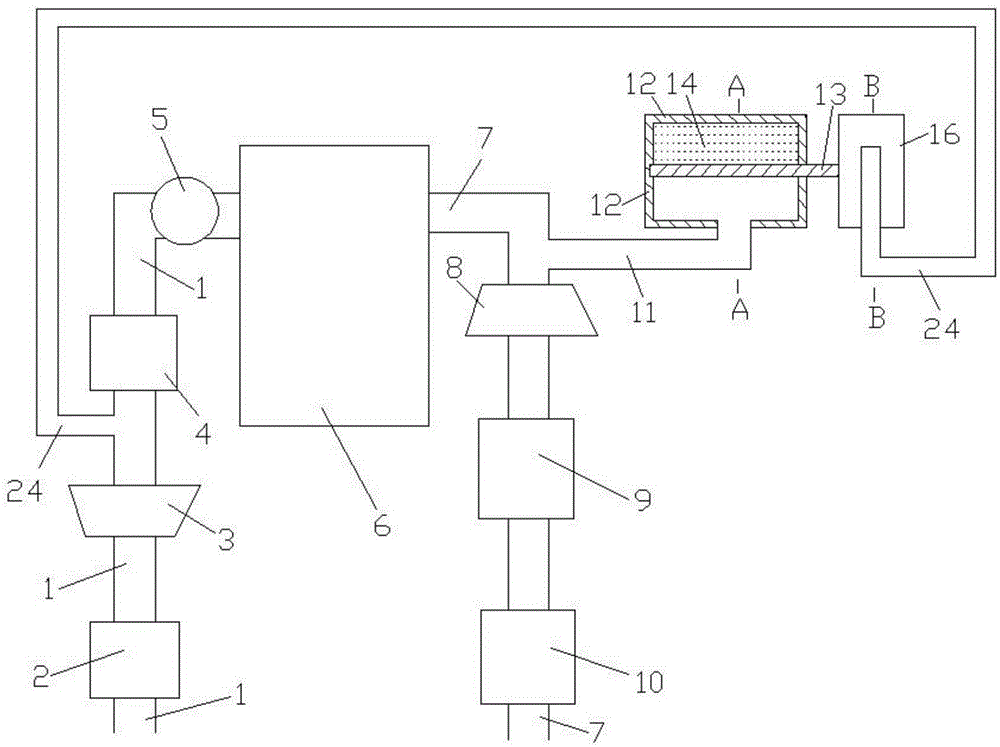

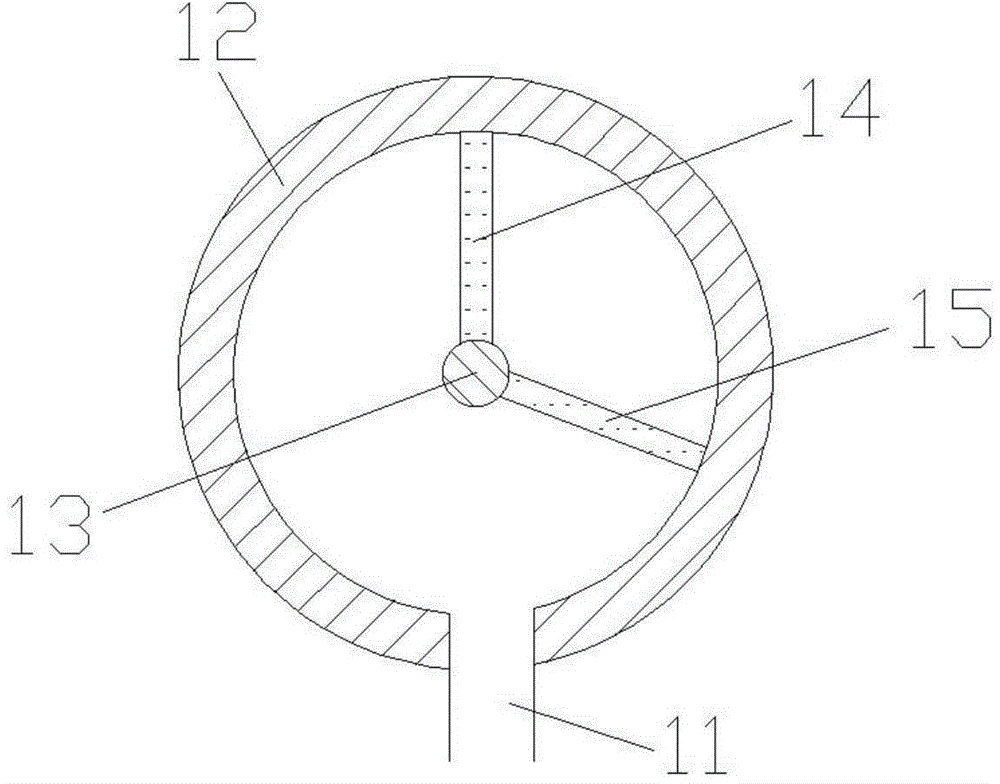

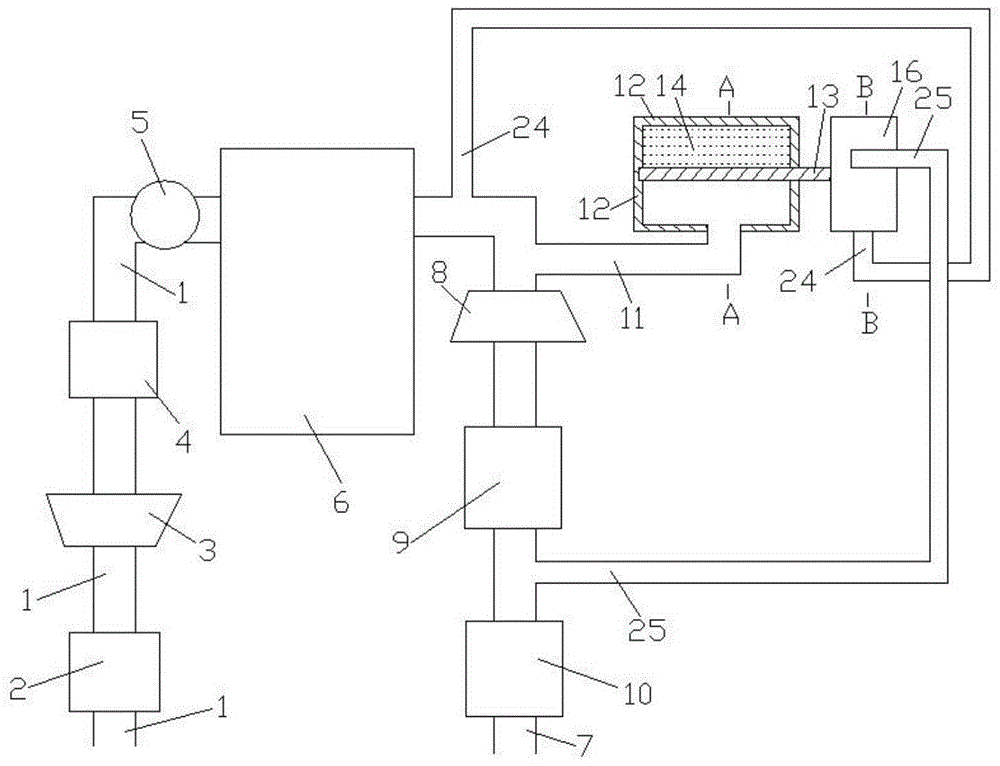

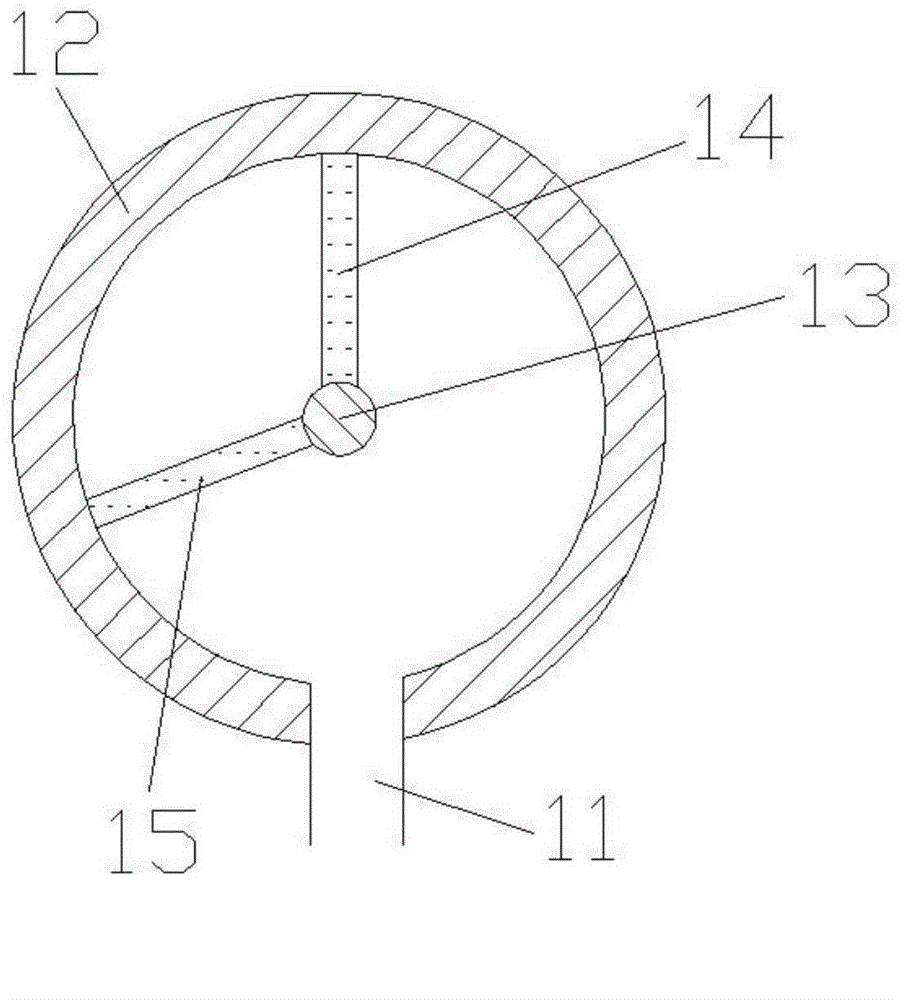

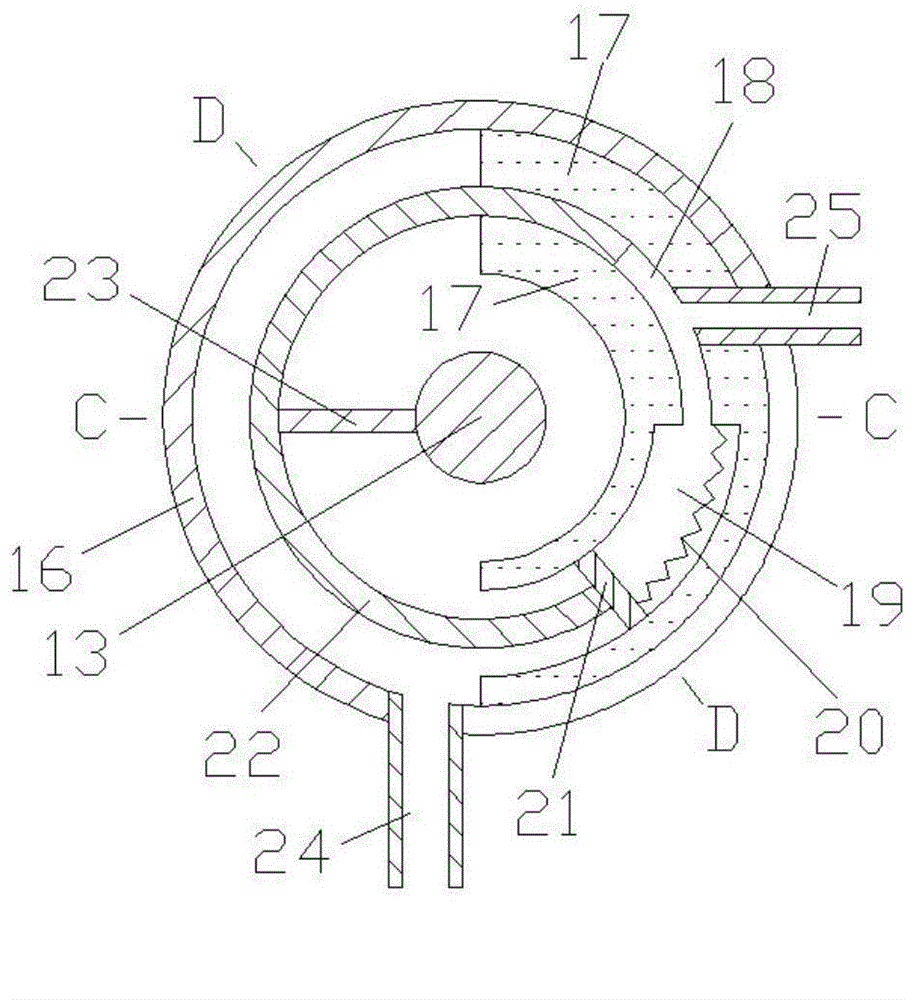

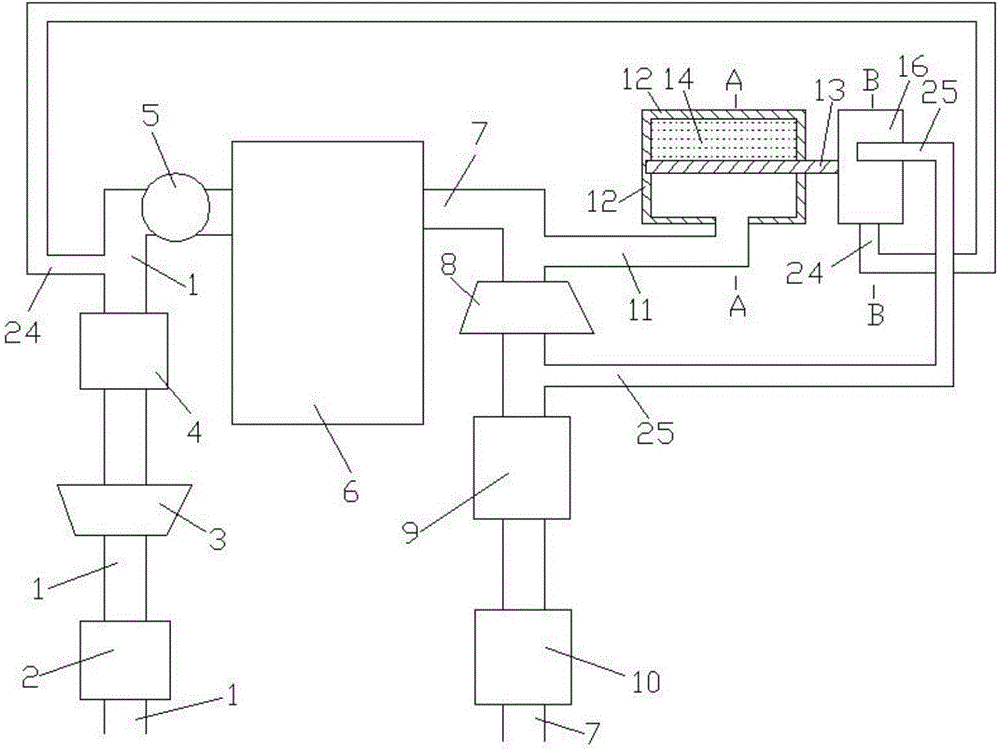

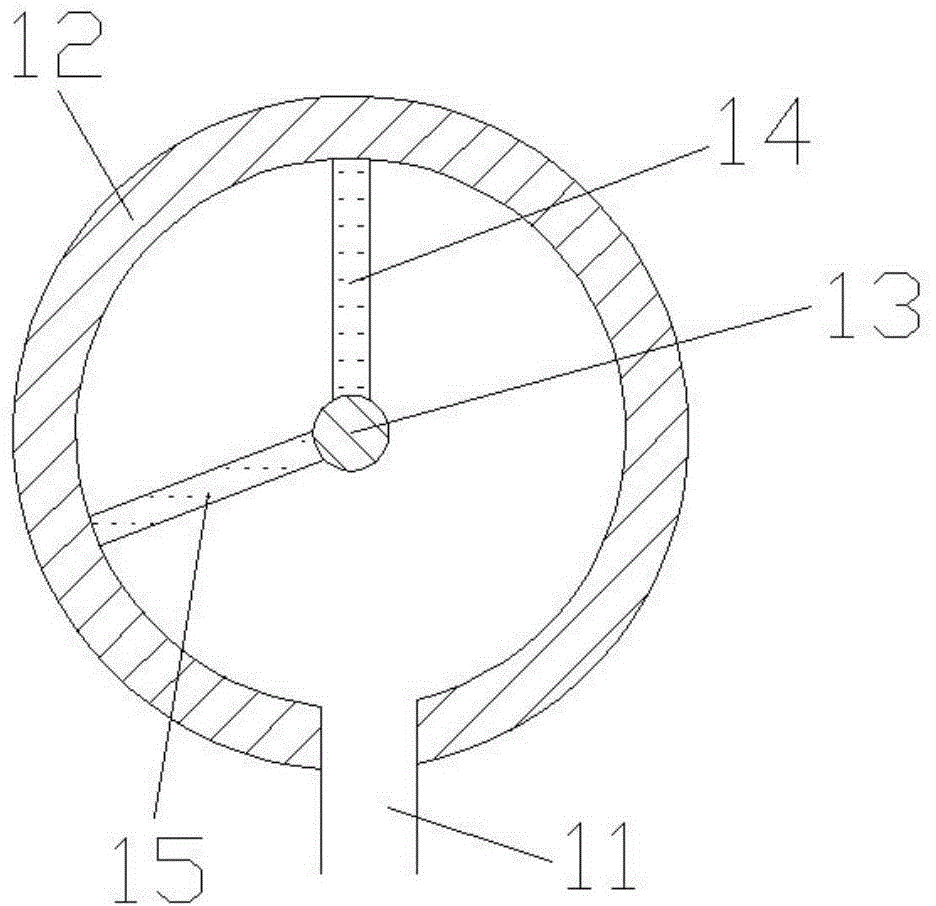

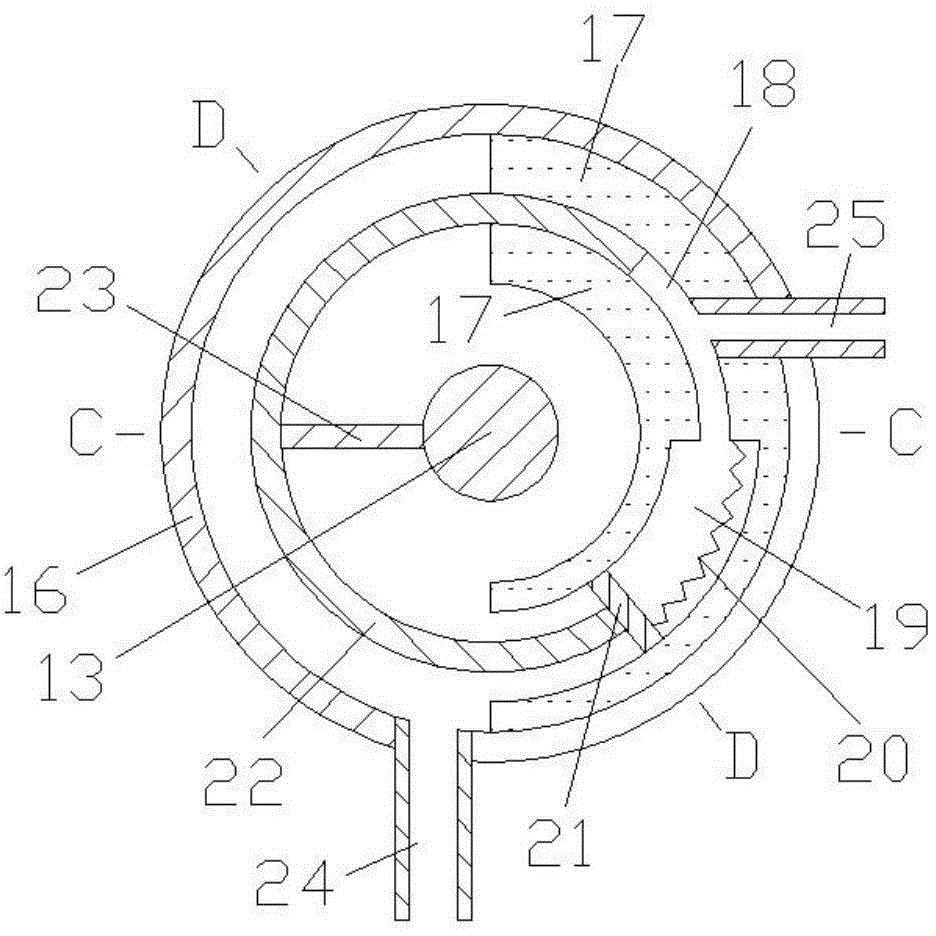

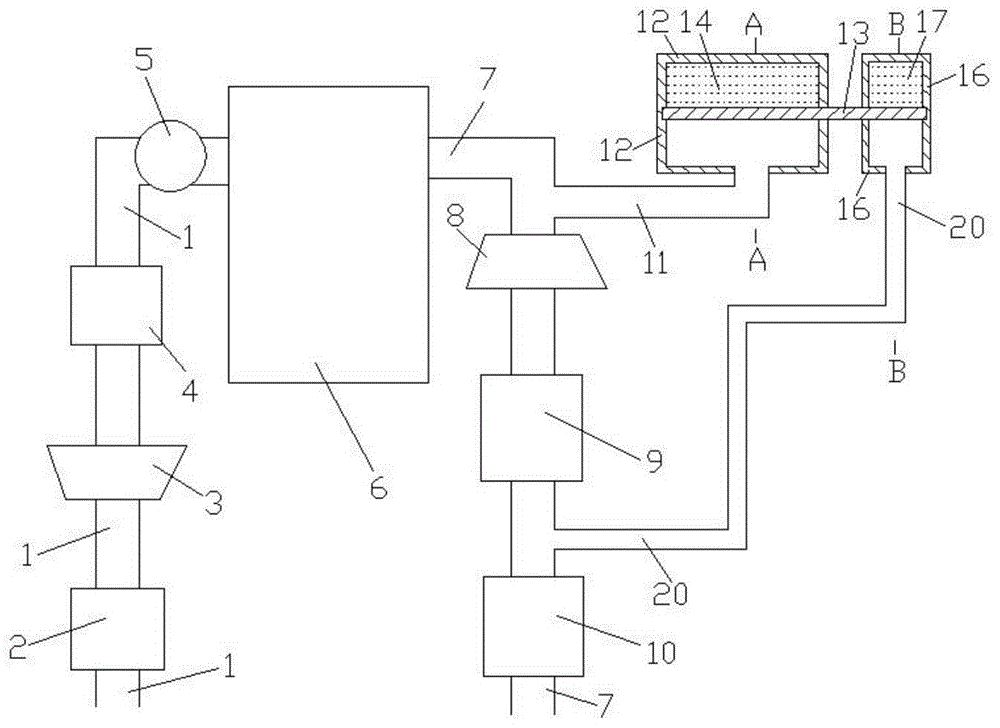

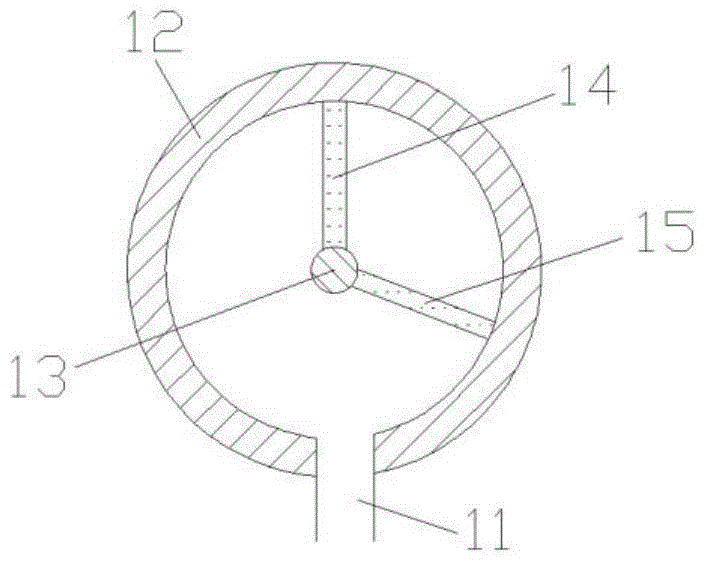

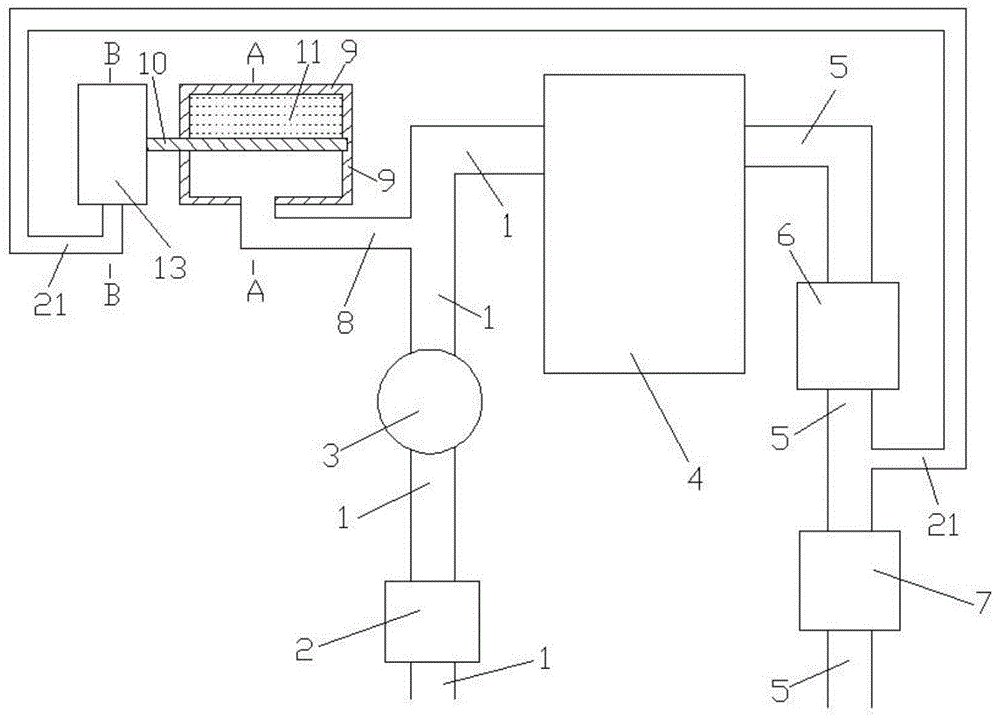

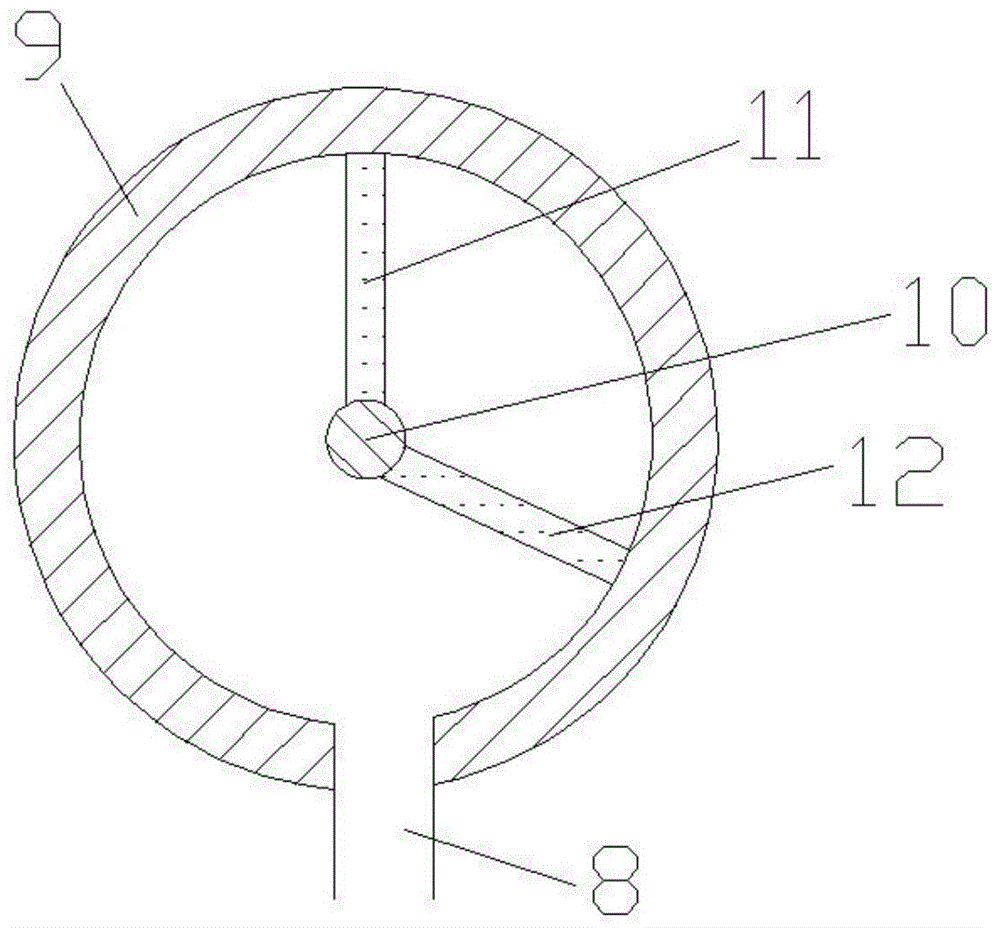

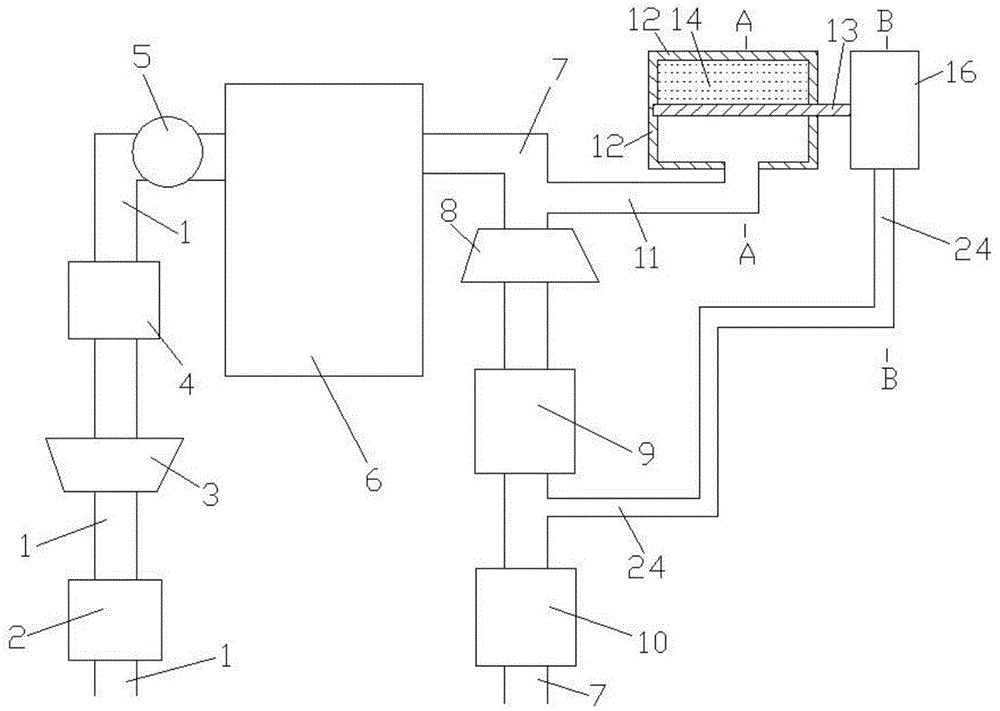

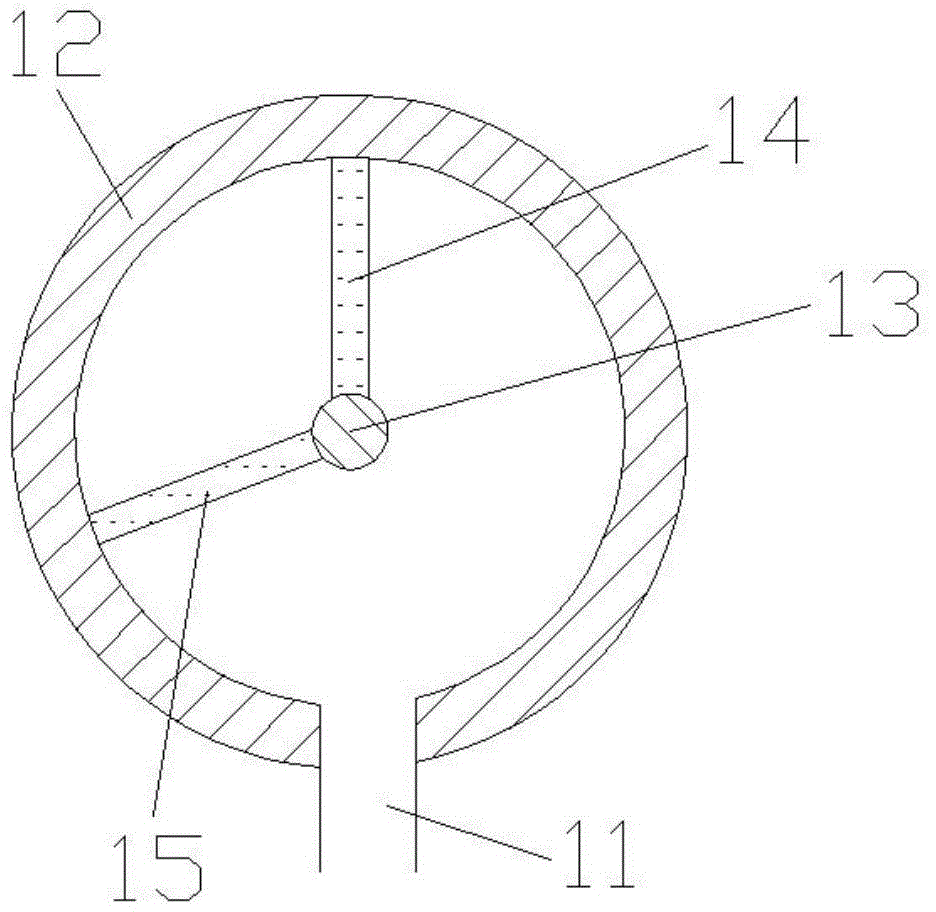

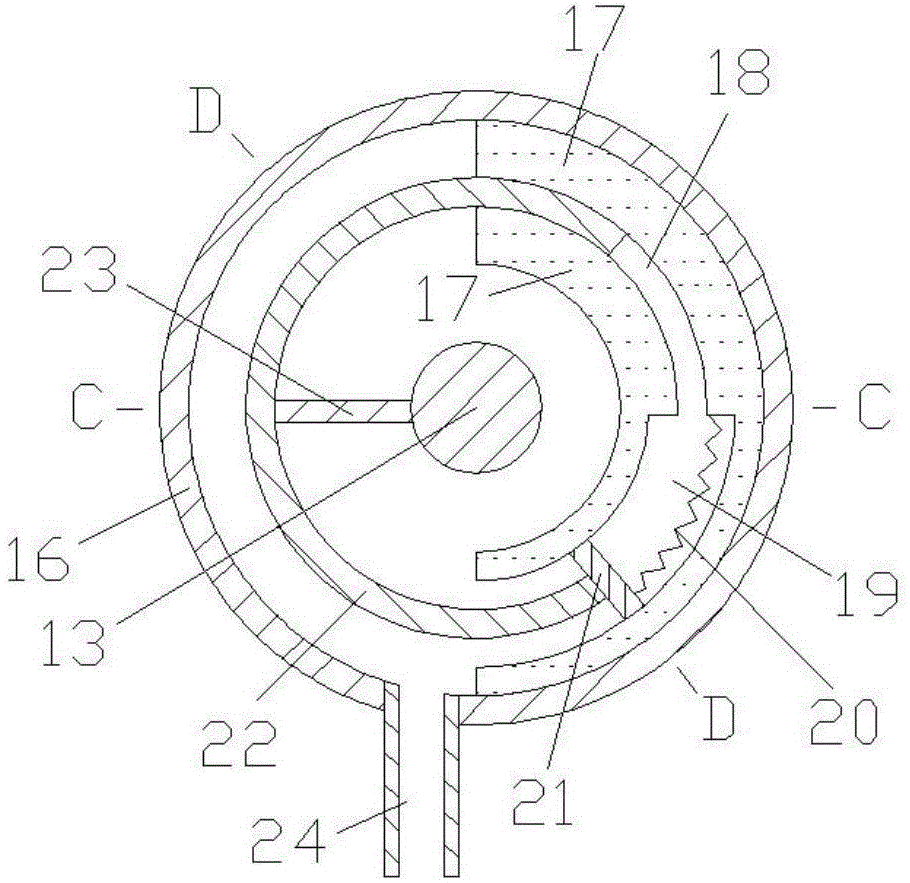

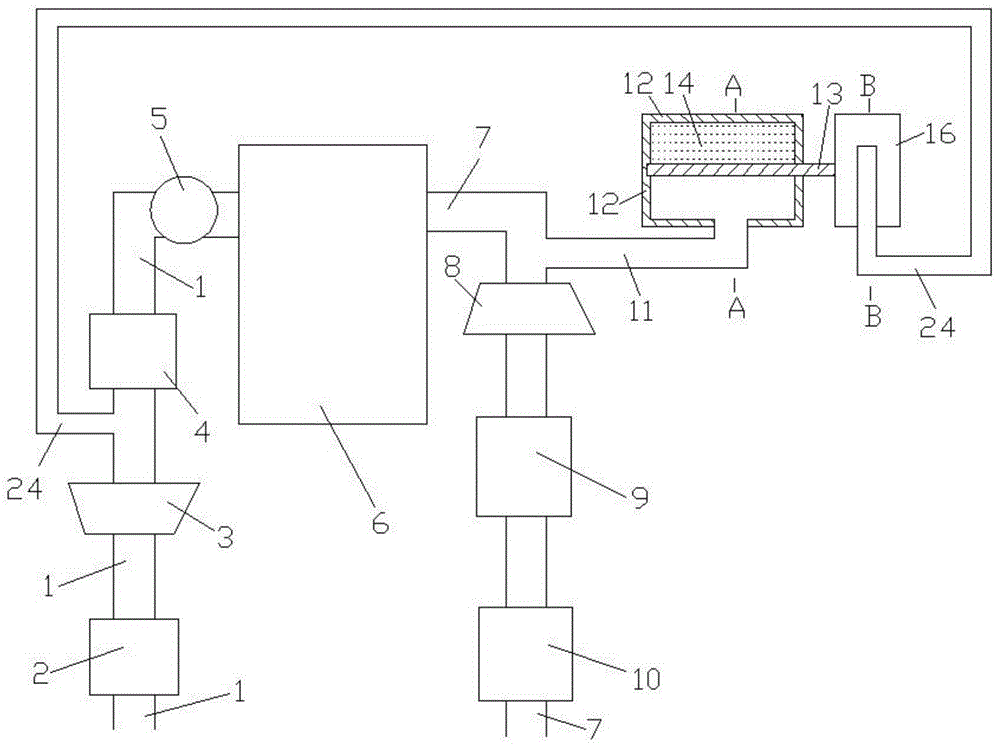

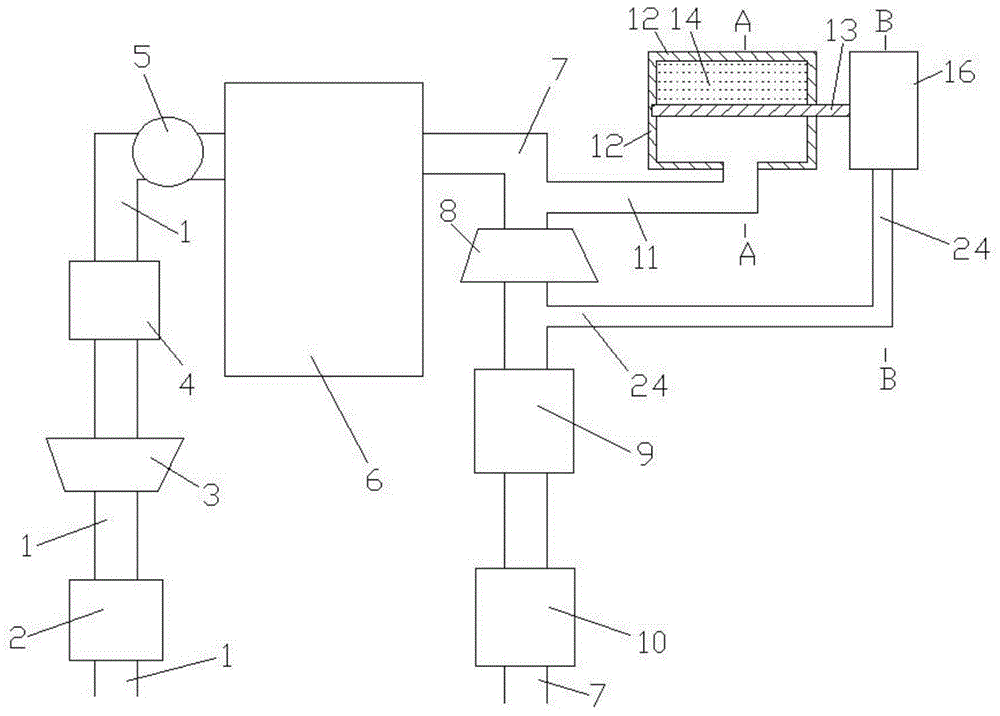

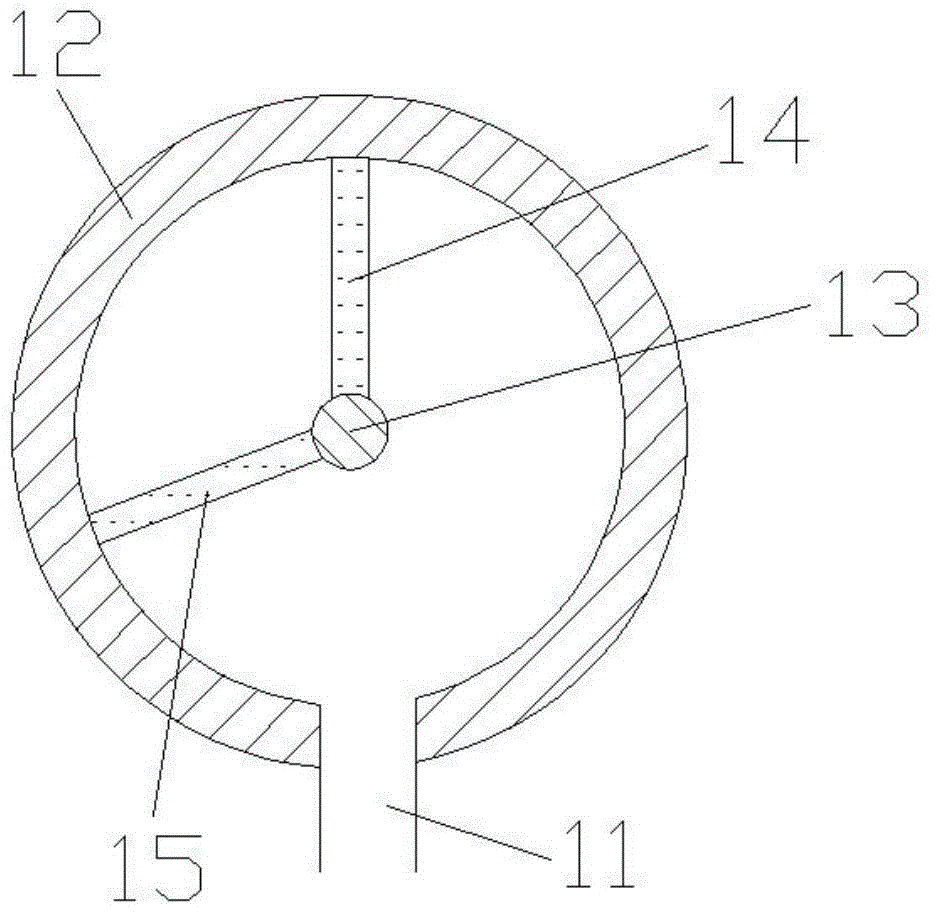

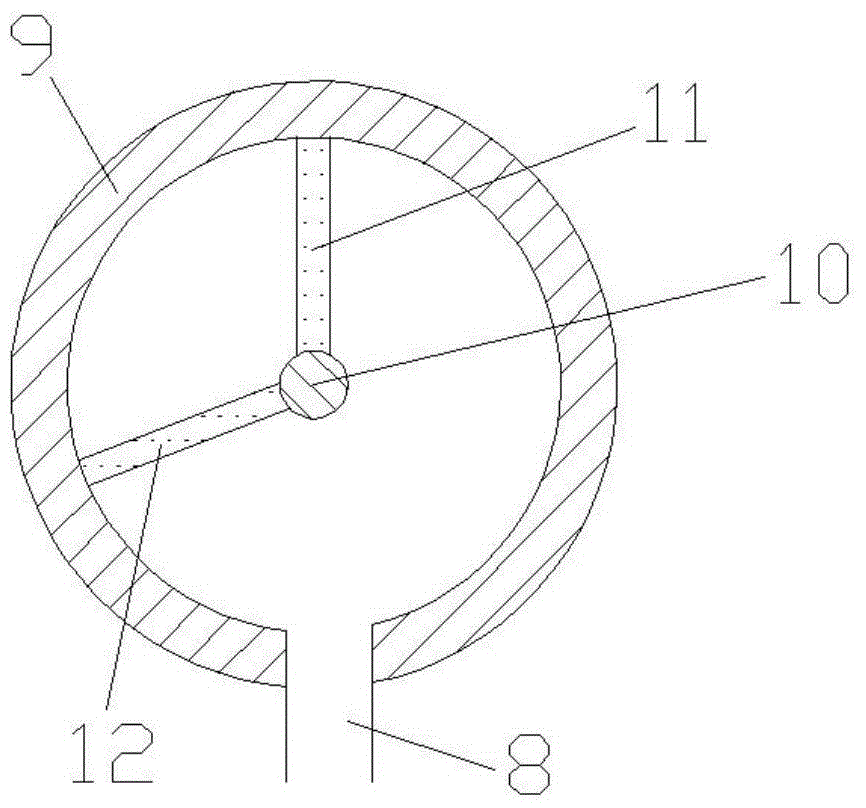

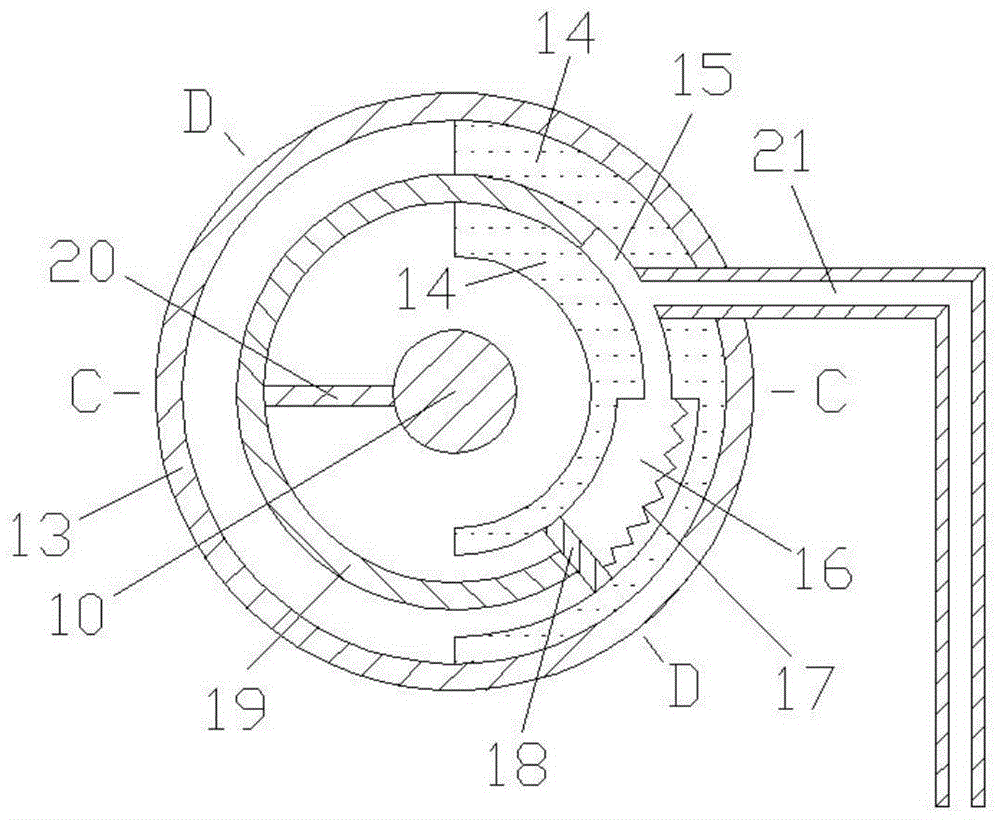

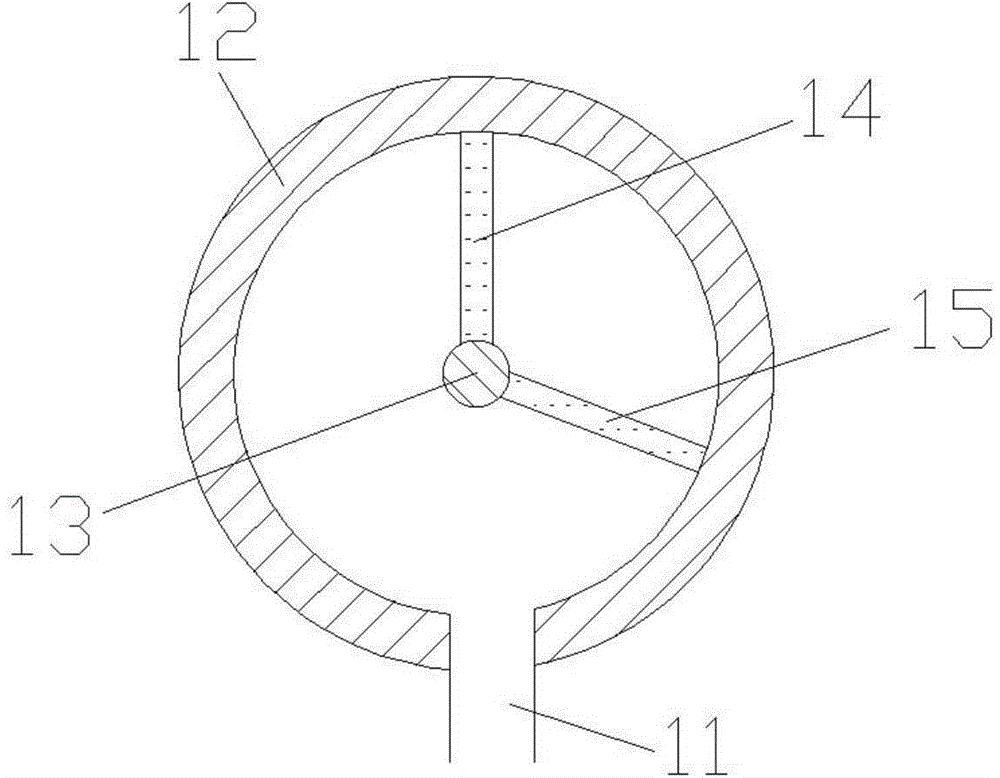

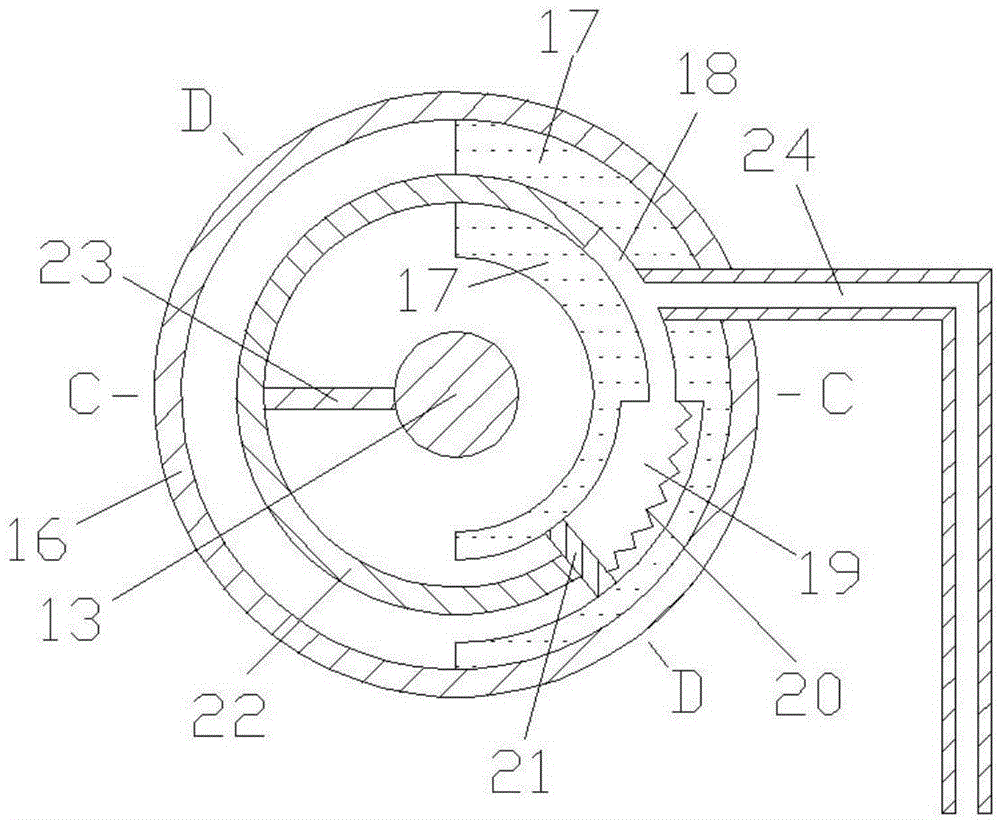

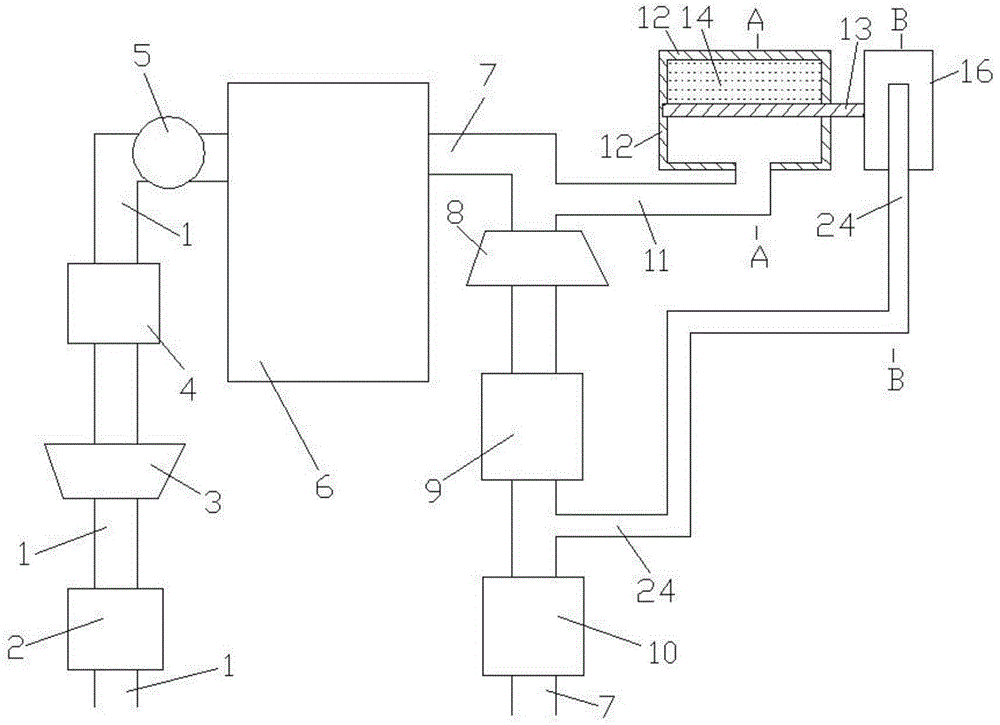

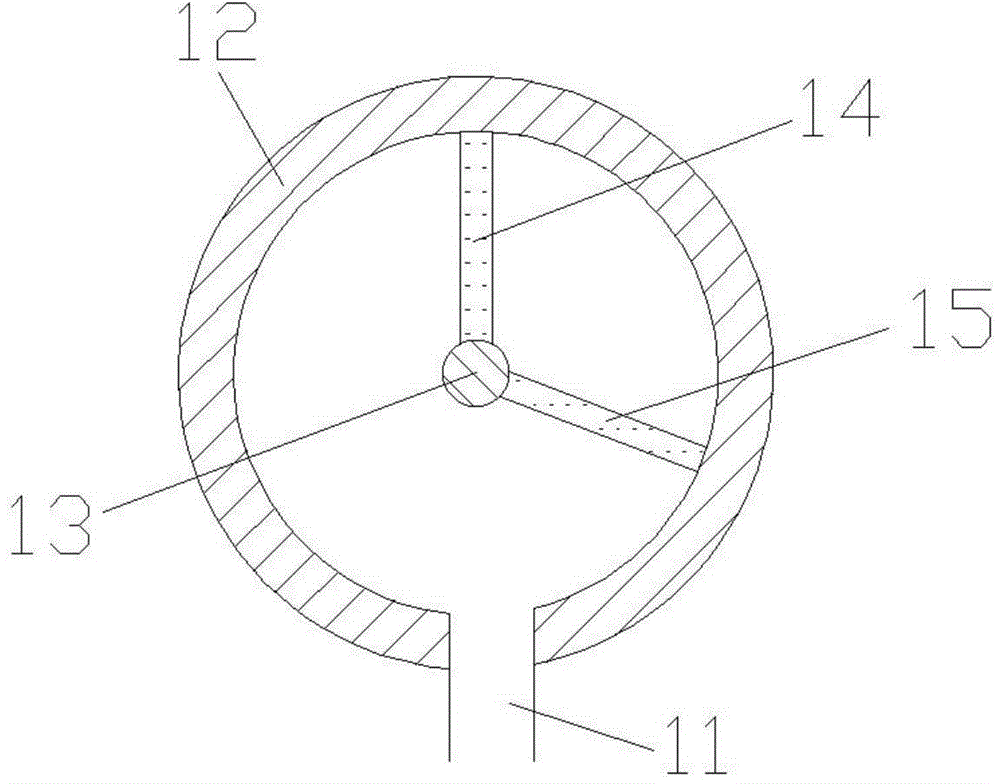

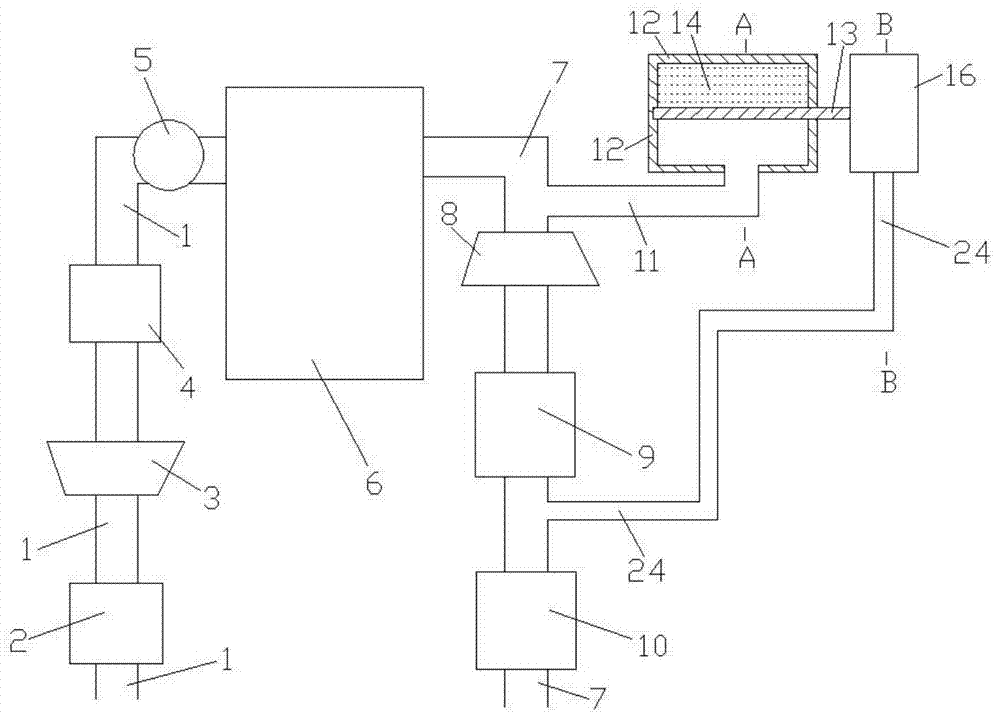

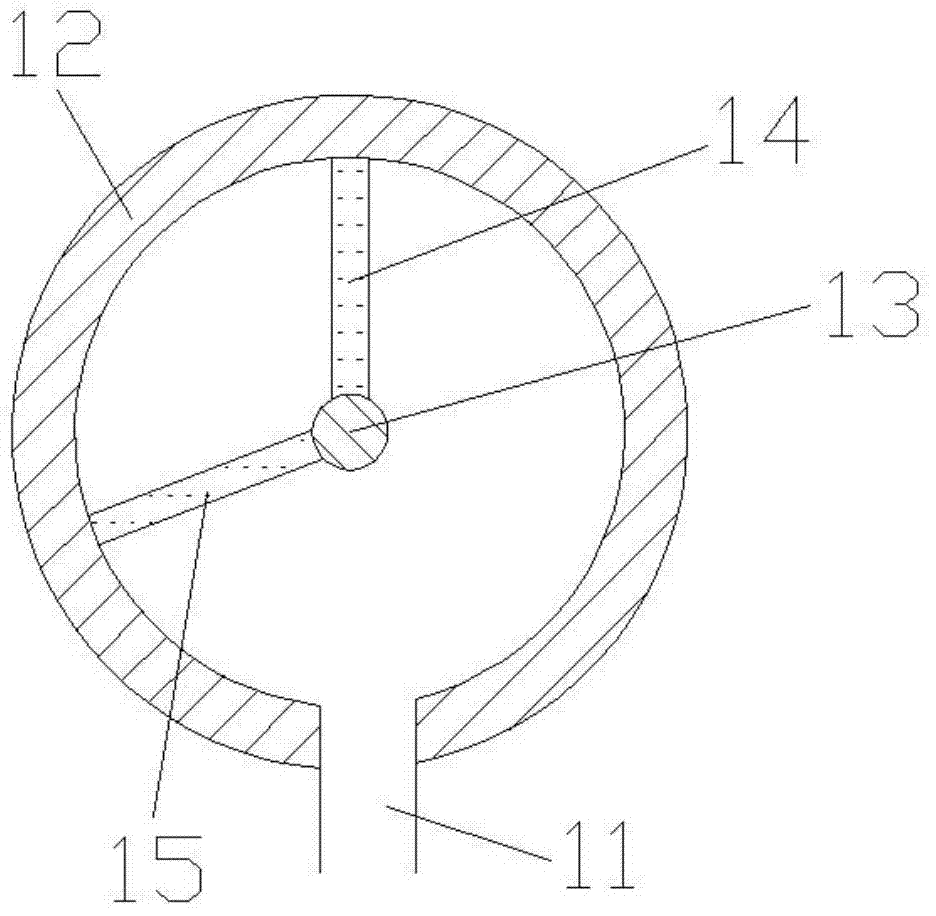

The invention discloses a pipeline expansion mechanism belonging to the technical field of internal combustion engines. The pipeline expansion mechanism comprises an engine air inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, a regulating cavity, a rotating shaft, a rotating plate, a control cavity, inner pipes, a spring and a rotator, wherein the regulating cavity and the control cavity are coaxially connected through the rotating shaft; the upper wall surface of the second inner pipe is connected together with a partition plate through the spring; and one end of the second connecting pipe is communicated with the first inner pipe after passing through a fixation body, and the other end of the second connecting pipe is connected with the engine air inlet pipe located between a compressor and an intercooler. According to the pipeline expansion mechanism, when the engine operates at a high speed, the exhaust capacity of the front of the turbine is relatively high, the pumping loss is relatively low, and the oil consumption is relatively low; and when the engine operates at a low speed, the exhaust capacity of the front of the turbine is relatively low, the pulse energy can be sufficiently utilized, and the oil consumption is relatively low. The pipeline expansion mechanism is reasonable in design, simple in structure and suitable for optimal design of an exhaust system of a turbocharged engine.

Owner:王春海

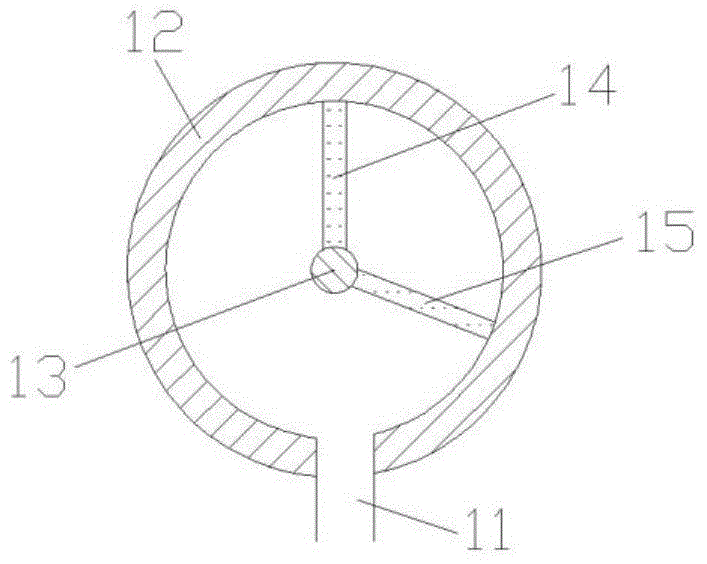

Air inlet system for naturally aspirated engine

InactiveCN104595071AReasonable designSimple structureAir intakes for fuelInternal combustion engineCombustion

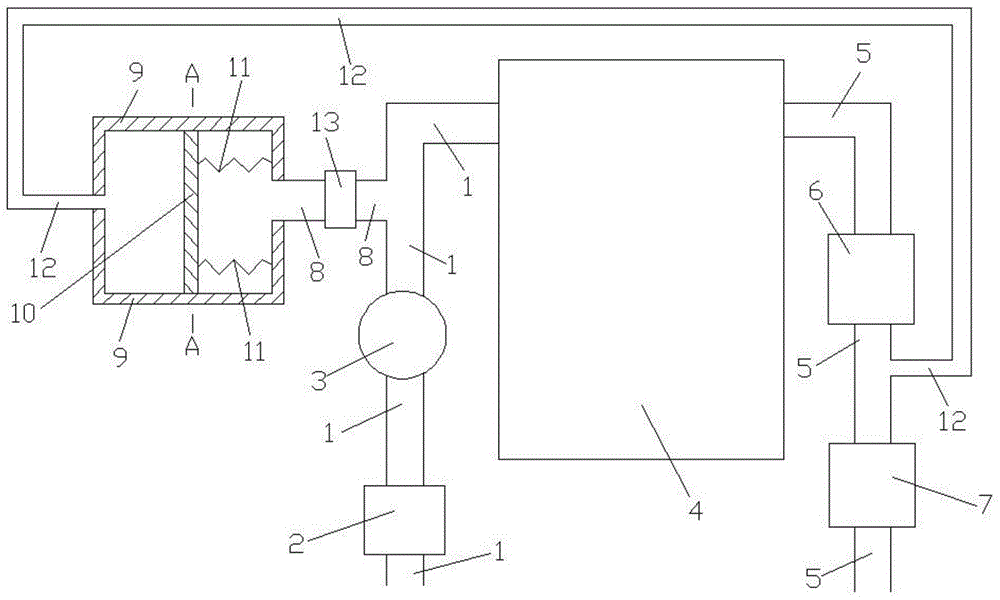

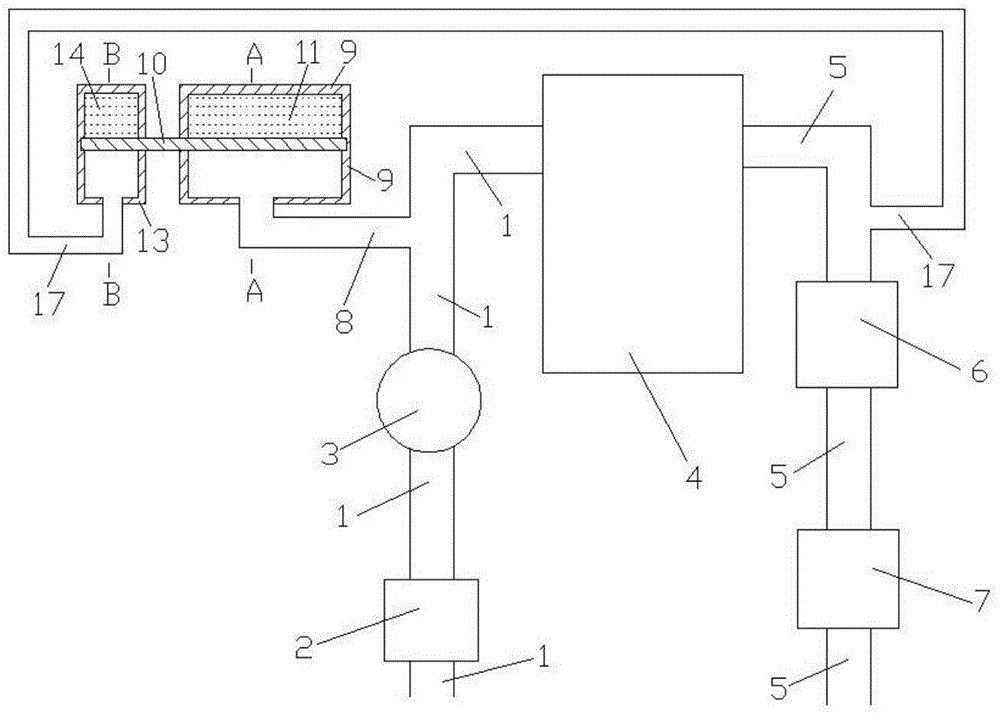

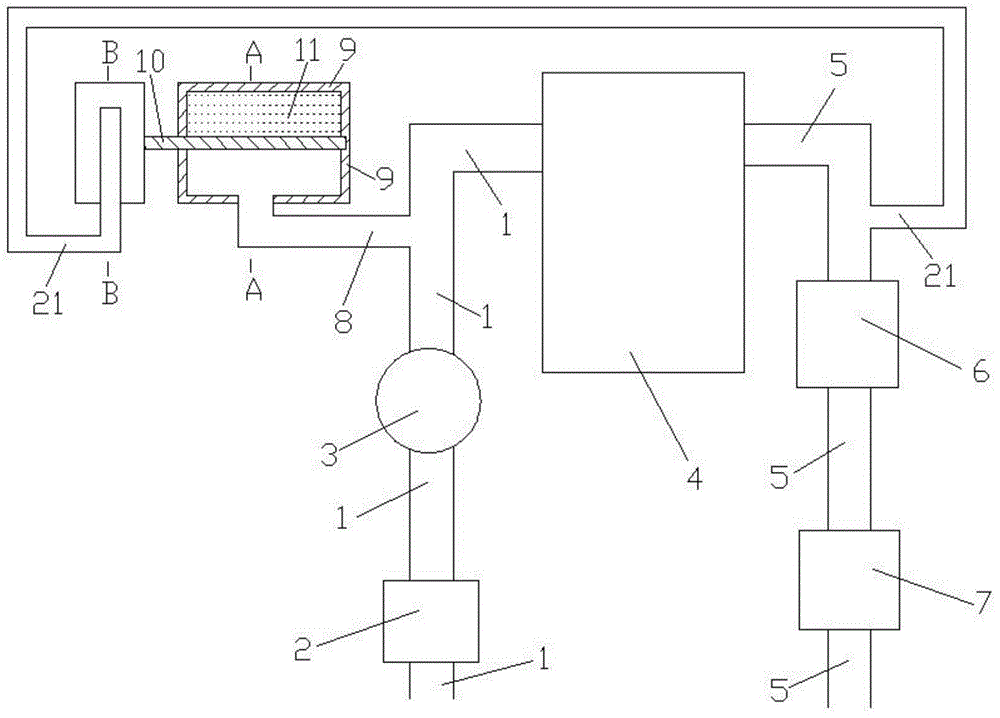

The invention discloses an air inlet system for a naturally aspirated engine and belongs to the technical field of internal combustion engines. The system comprises an air inlet pipe of the engine, the engine, an exhaust pipe of the engine, a connecting pipe, an adjusting cavity, a movable plate, a spring and a control valve, wherein the movable plate is arranged in the adjusting cavity and is in sealed contact with the inner wall of the adjusting cavity, the movable plate is connected with the right wall of the adjusting cavity through a spring, one end of the second connecting pipe is communicated with the left wall of the adjusting cavity, the other end of the second connecting pipe is communicated with the exhaust pipe, between a catalyzing bag and a silencer, of the engine, and the control valve is arranged on a first connecting pipe. The volume of the air inlet pipe is large when the engine operates at a low speed and small when the engine operates at a high speed, and in other words, the volume of the air inlet pipe can be adjusted automatically. The system is reasonable in design, simple in structure and optimal in design.

Owner:苏皓

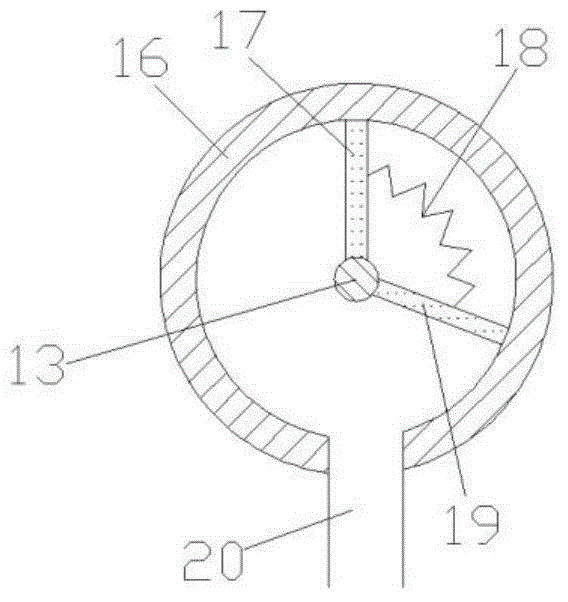

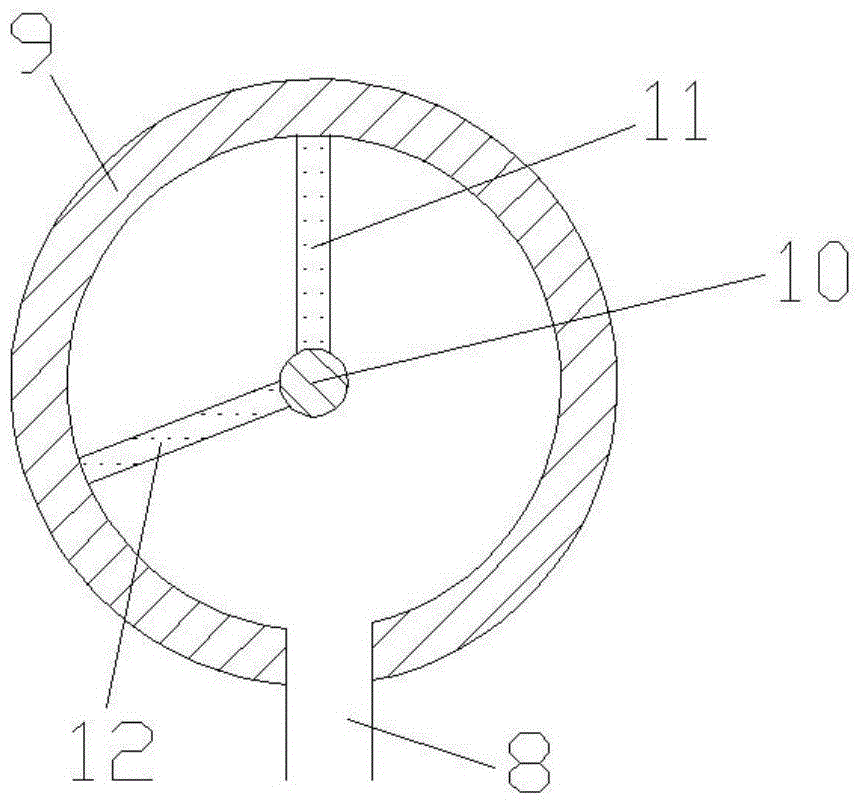

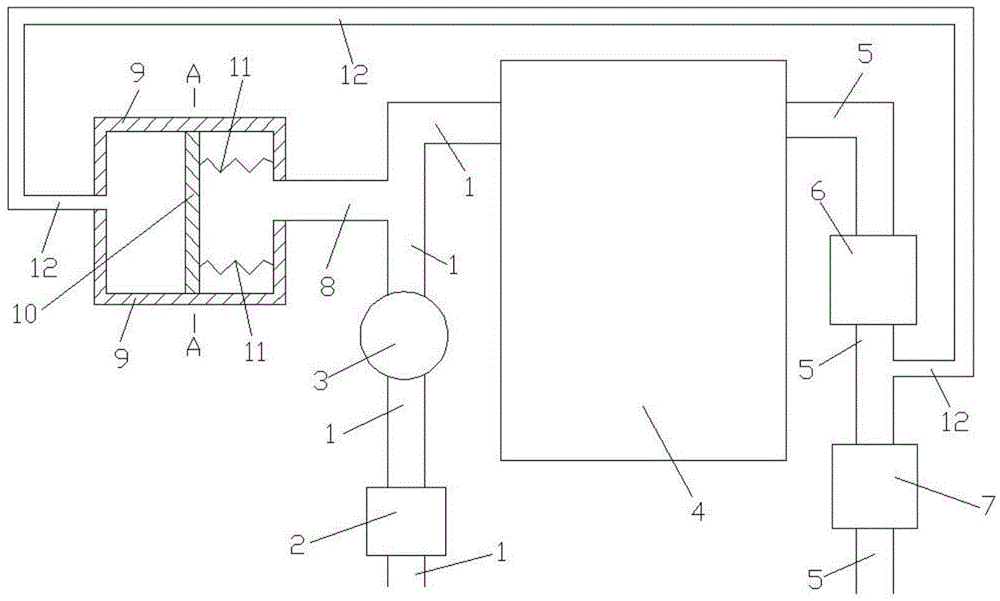

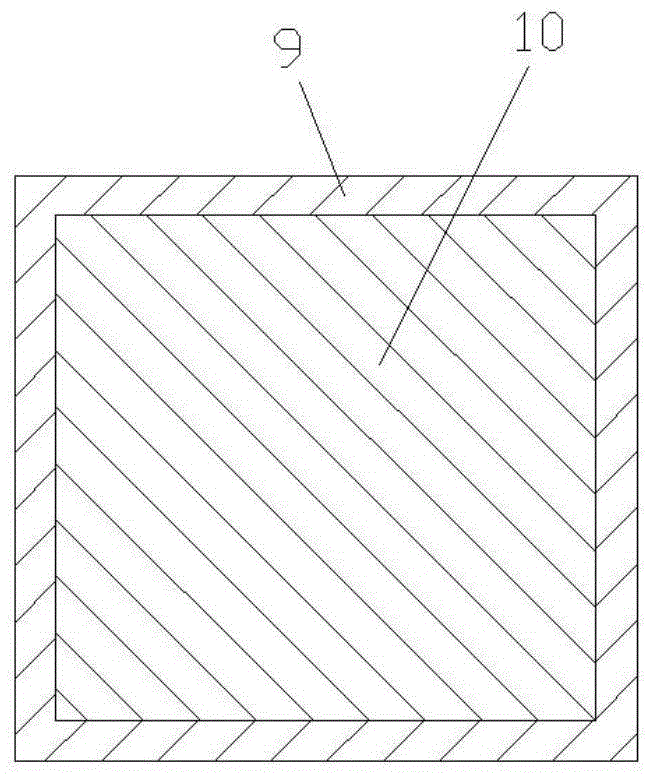

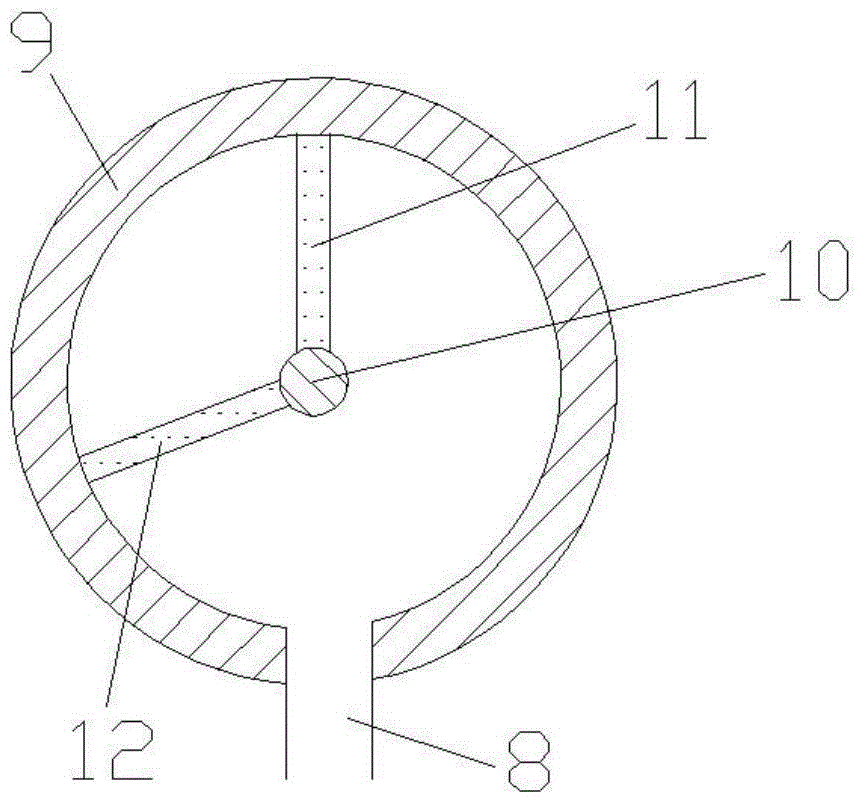

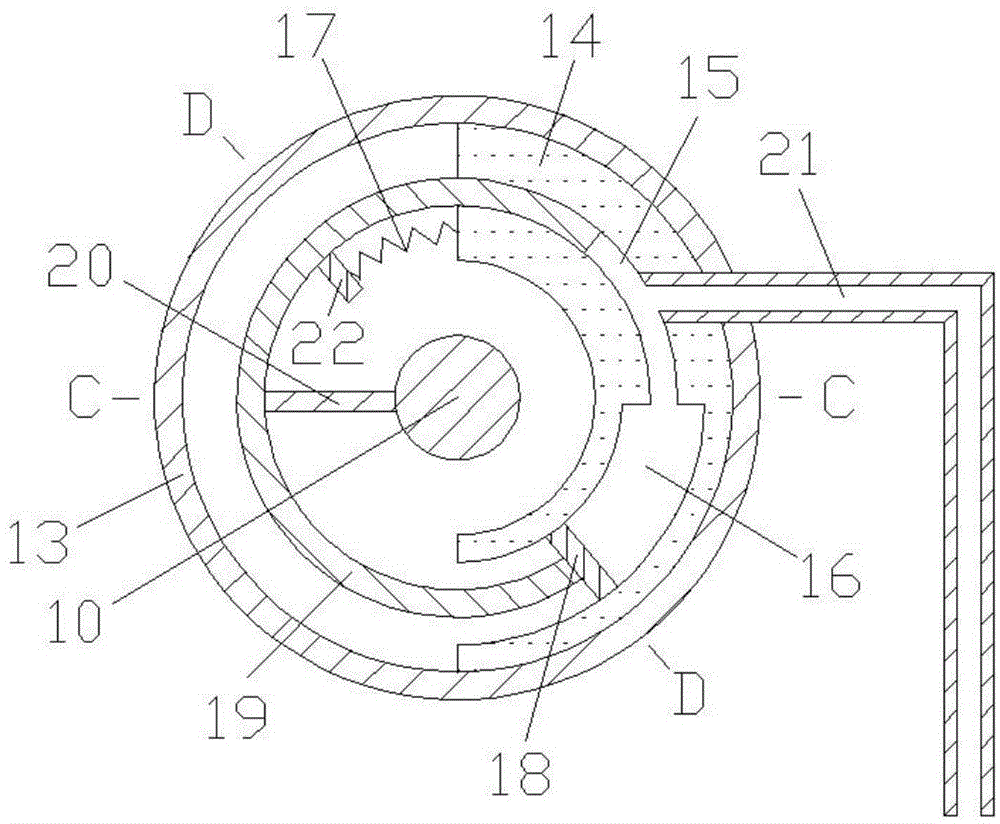

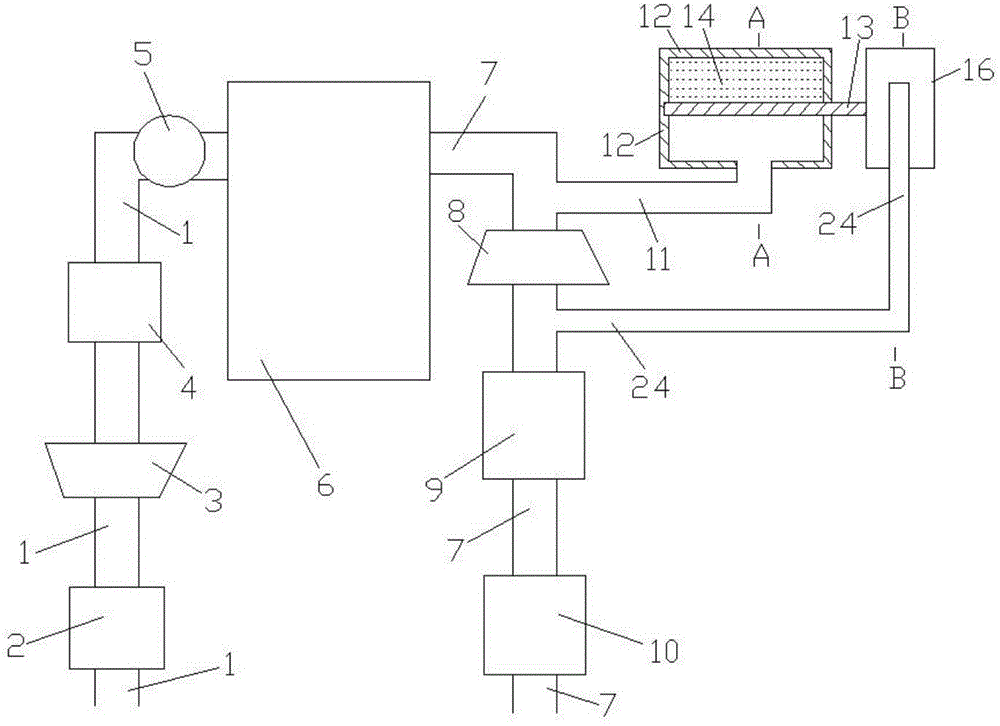

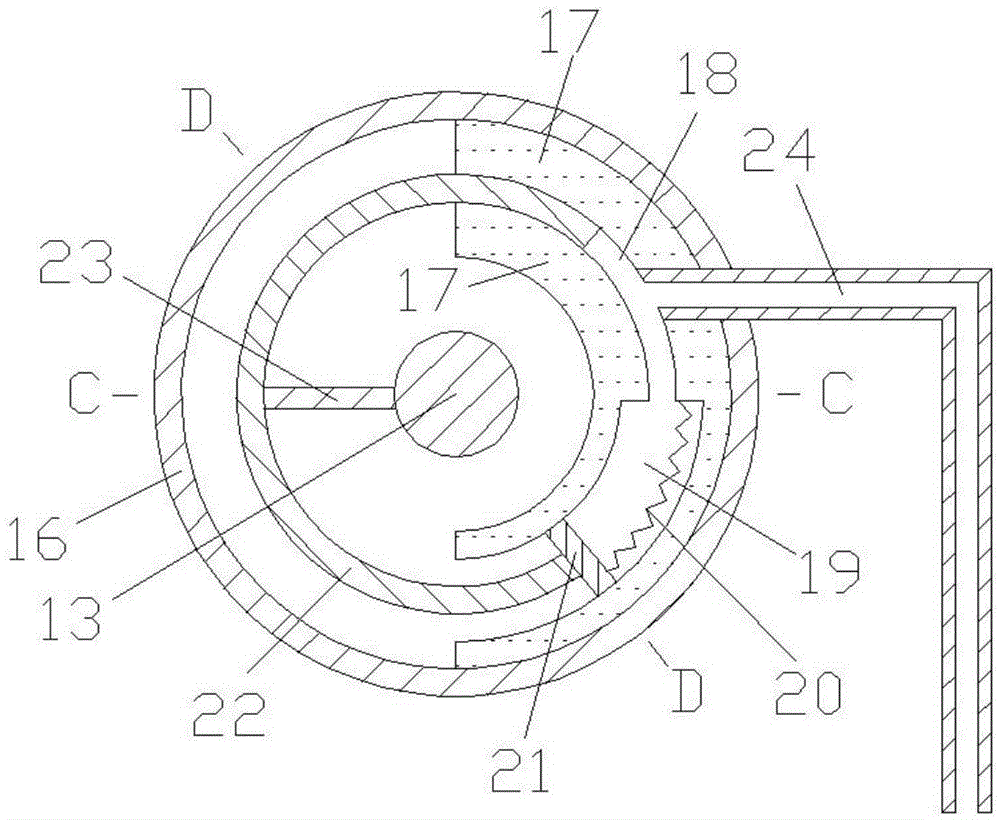

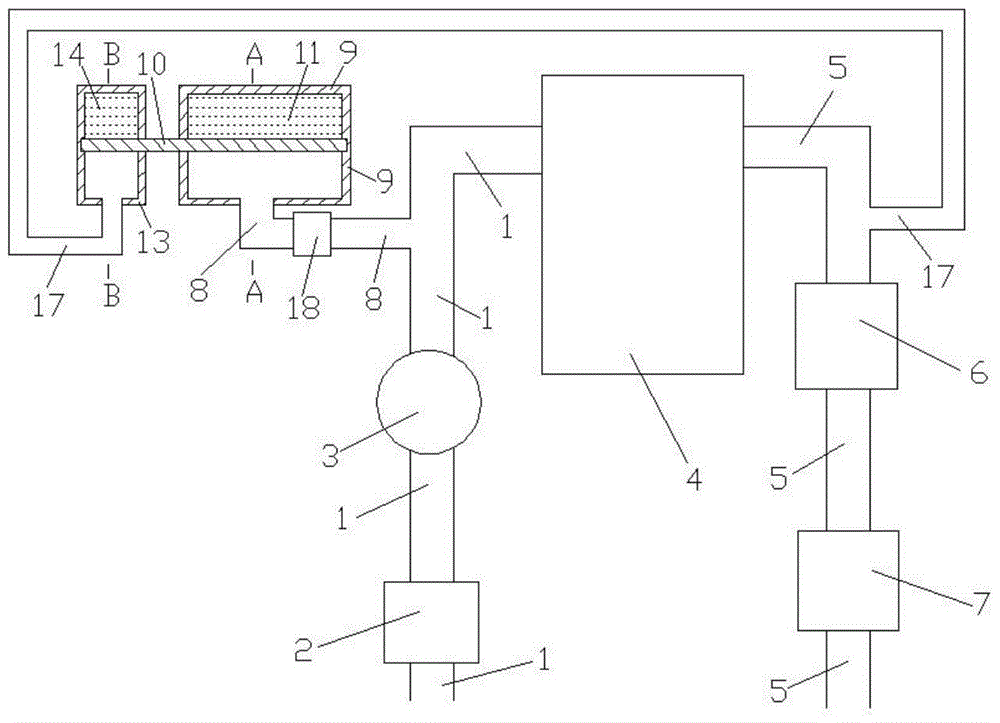

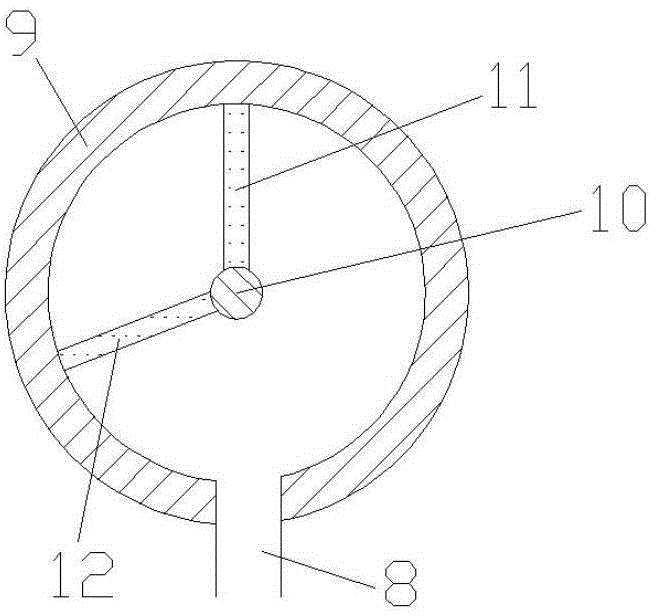

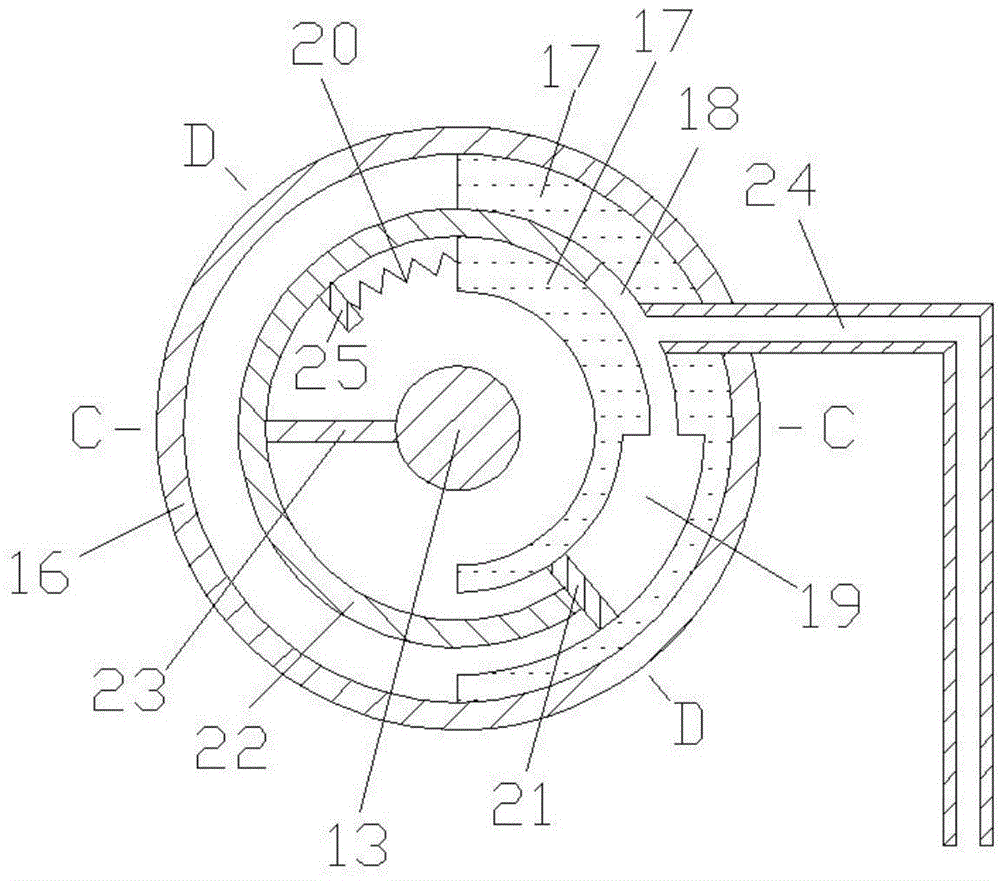

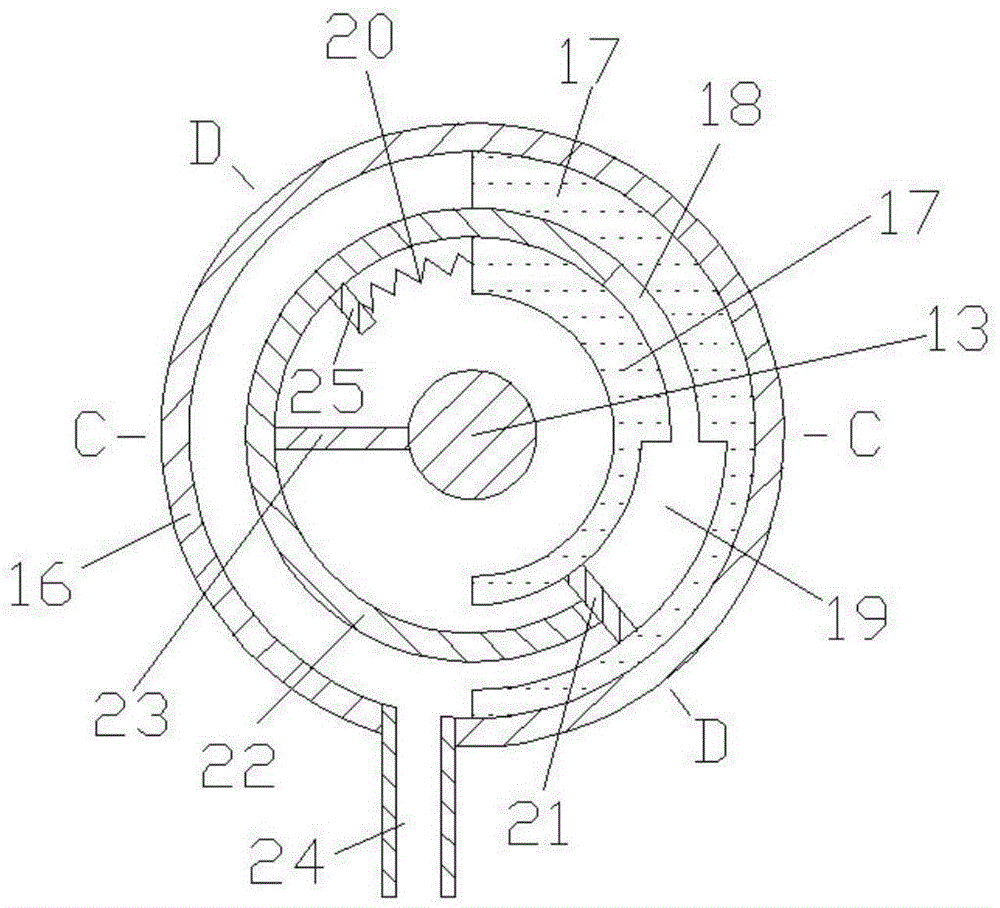

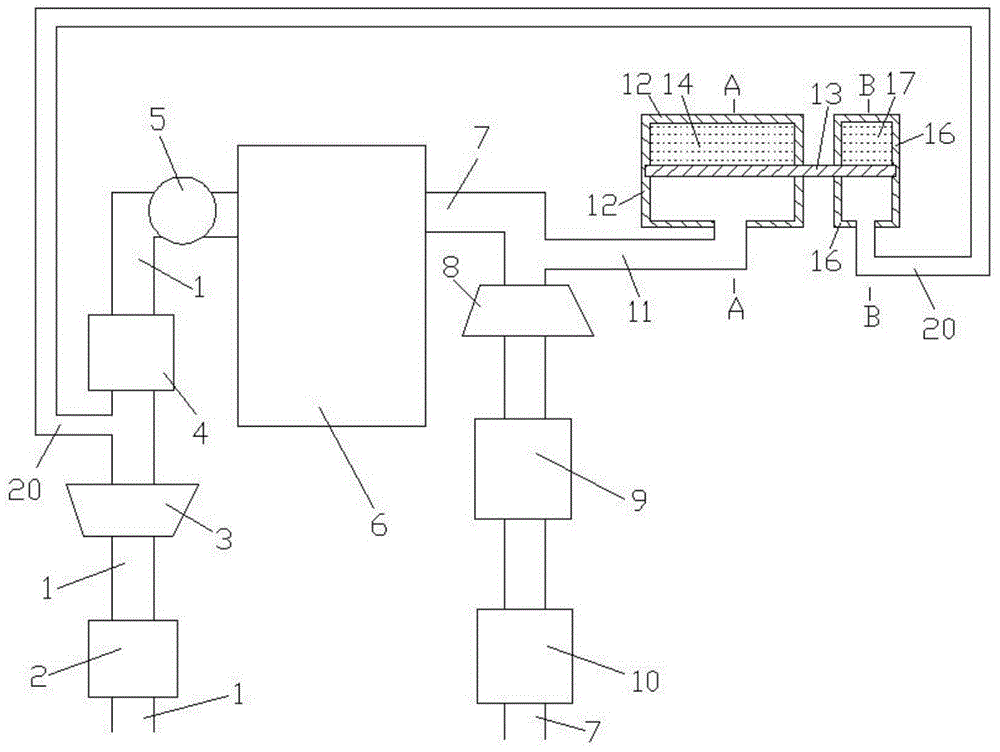

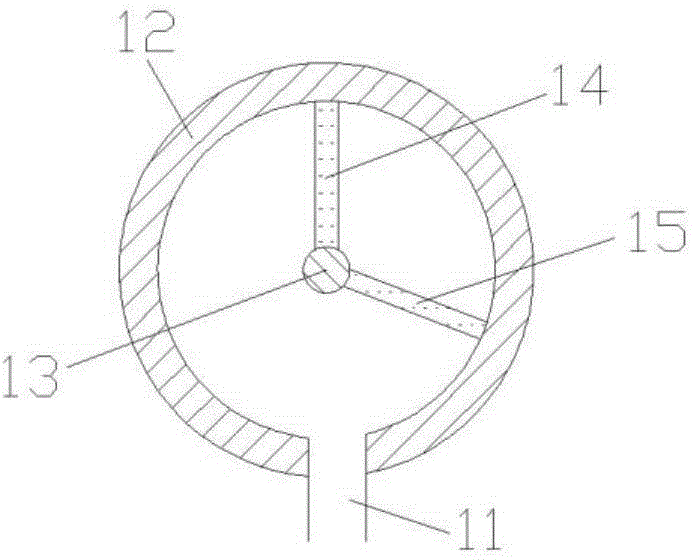

Piston exhaust pressure controller

InactiveCN104481672AContinuously variable volumeGood speed performanceInternal combustion piston enginesLow speedExternal combustion engine

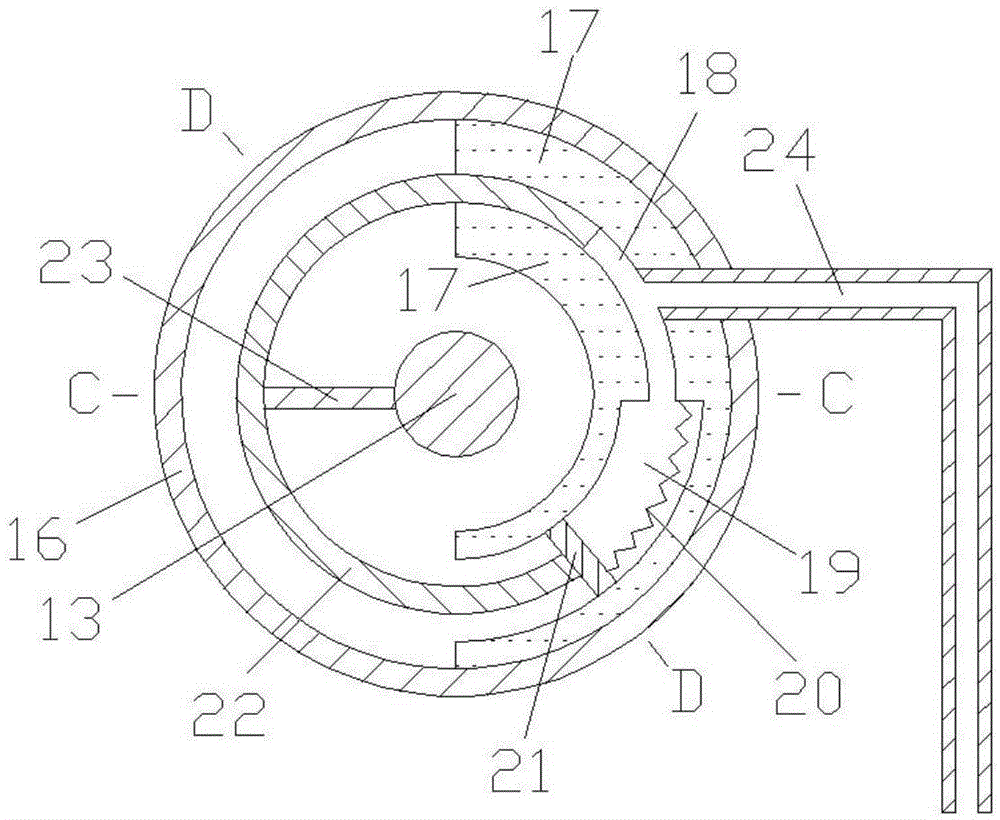

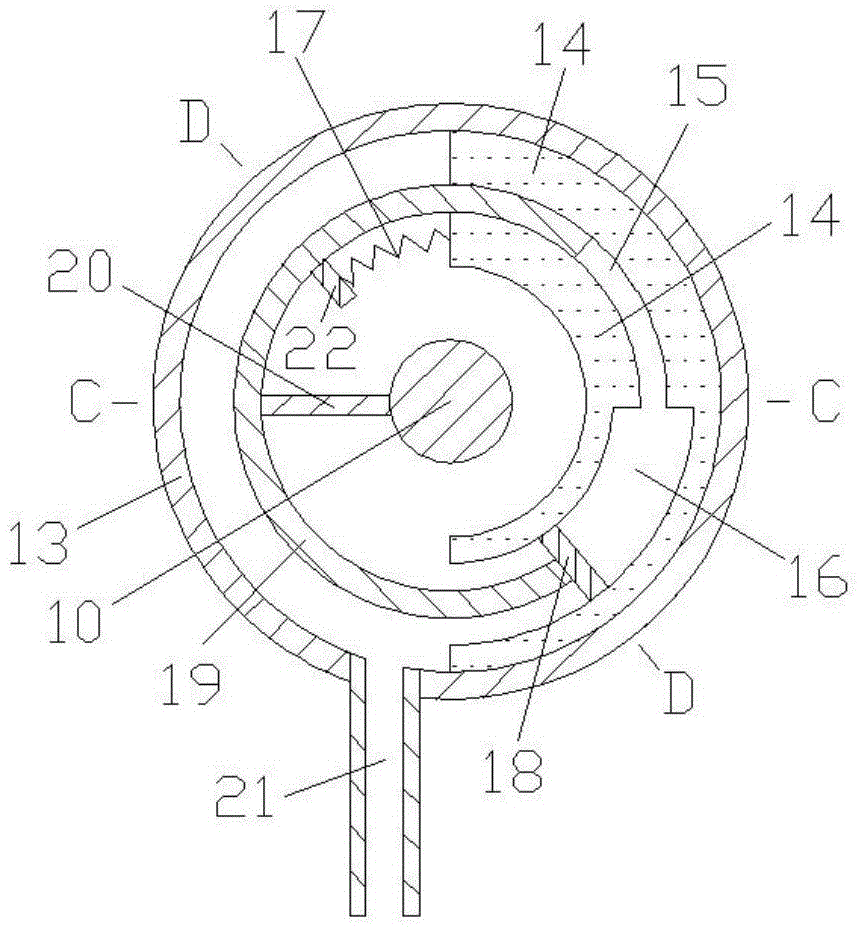

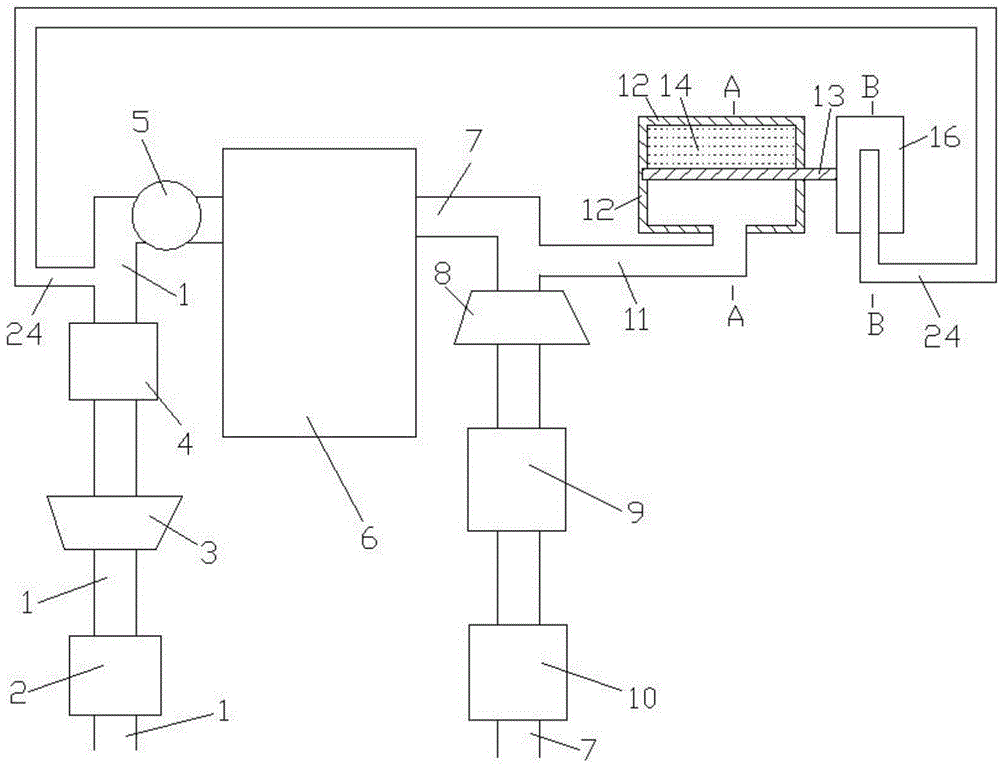

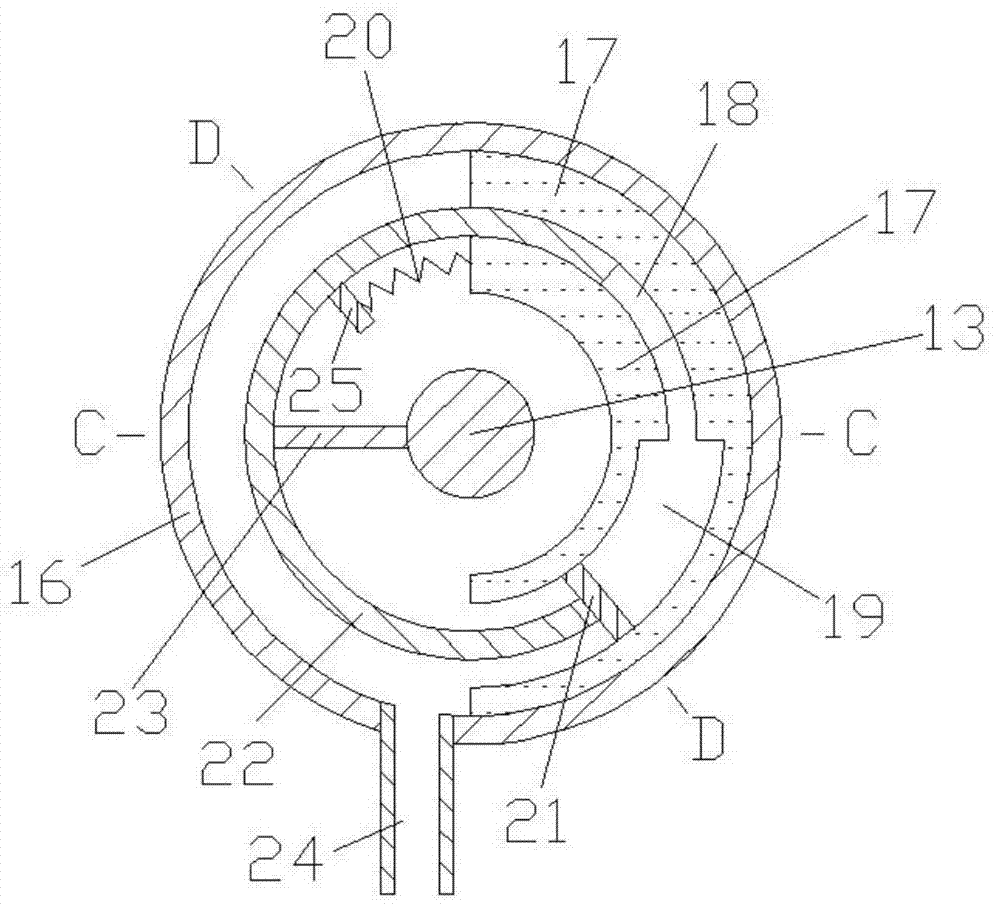

The invention belongs to the technical field of internal combustion engines, and discloses a piston exhaust pressure controller which comprises air inlet pipes of an engine, a supercharger, the engine, exhaust pipes of the engine, a turbine, connecting pipes, a regulating cavity, a rotary shaft, a rotary plate, a control cavity, internal pipes, a spring and a rotator. The regulating cavity and the control cavity are coaxially connected with each other by the rotary shaft, one end of the second connecting pipe is communicated with an internal cavity of the control cavity, the other end of the second connecting pipe is connected with the certain exhaust pipe of the engine, and the certain exhaust pipe of the engine is arranged between the engine and the turbine. The piston exhaust pressure controller has the advantages that the turbine is high in forward exhaust volume when the engine runs under high-speed working conditions, and accordingly pumping loss and oil consumption are low; the turbine is low in forward exhaust volume when the engine runs under low-speed working conditions, accordingly, pulse energy can be sufficiently utilized, and the oil consumption is low; the piston exhaust pressure controller is reasonable in design, simple in structure and applicable to optimally designing exhaust systems of turbine supercharged engines.

Owner:黄昕煜

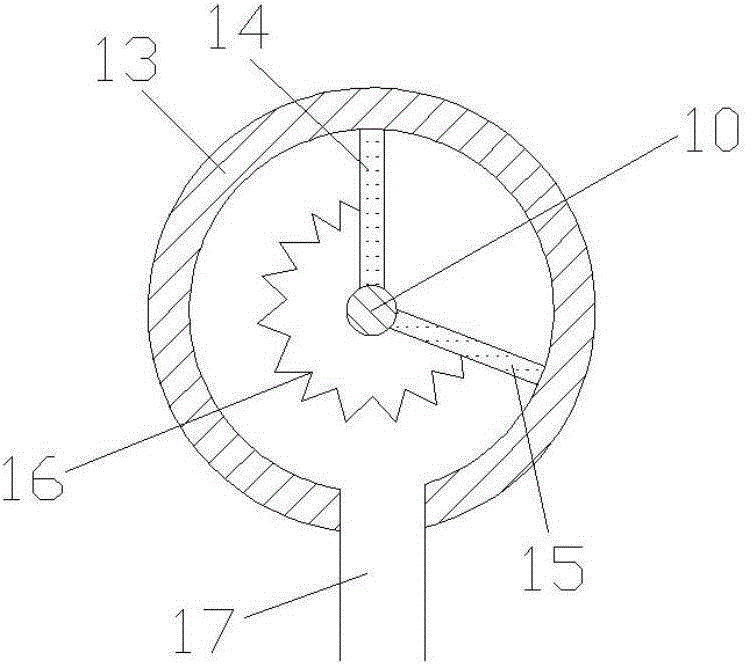

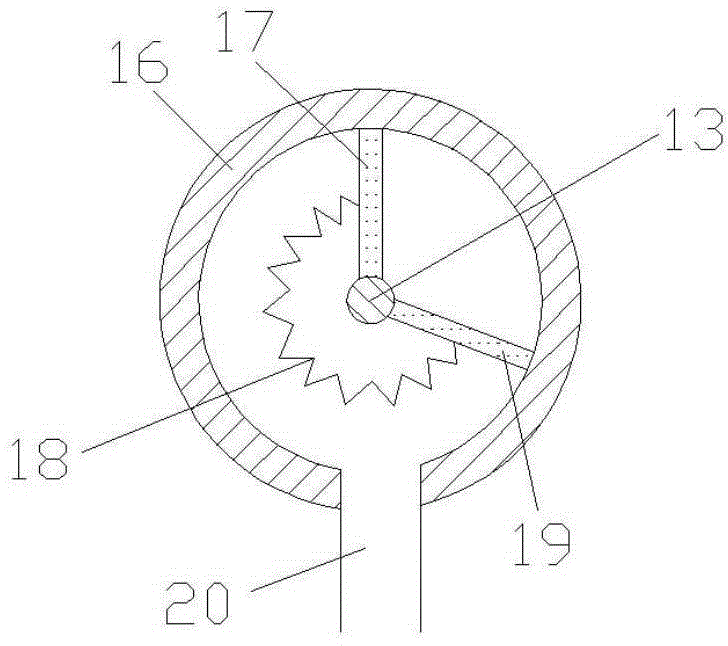

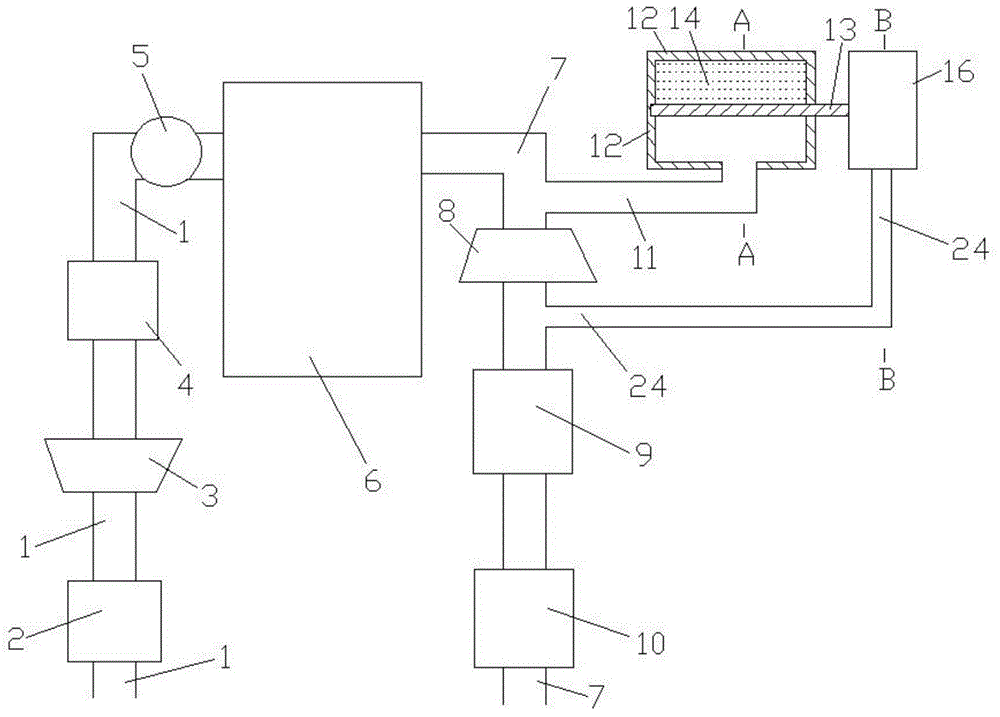

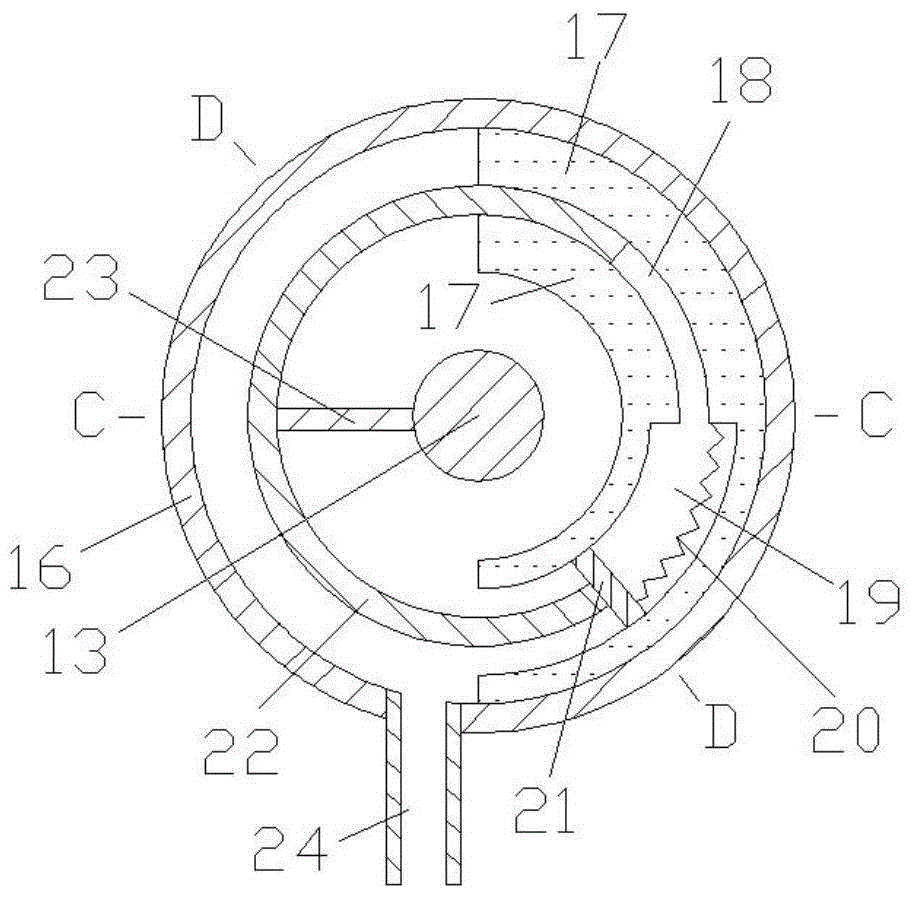

Piston exhaust pressure regulator

InactiveCN104481677AContinuously variable volumeGood speed performanceInternal combustion piston enginesLow speedExternal combustion engine

The invention belongs to the technical field of internal combustion engines, and discloses a piston exhaust pressure regulator which comprises air inlet pipes of an engine, a supercharger, the engine, exhaust pipes of the engine, a turbine, connecting pipes, a regulating cavity, a rotary shaft, a rotary plate, a control cavity, internal pipes, a spring and a rotator. The regulating cavity and the control cavity are coaxially connected with each other by the rotary shaft, one end of the second connecting pipe is communicated with an internal cavity of the control cavity, the other end of the second connecting pipe is connected with the certain air inlet pipe of the engine, and the certain air inlet pipe of the engine is arranged between an inter-cooler and a throttle valve. The piston exhaust pressure regulator has the advantages that the turbine is high in forward exhaust volume when the engine runs under high-speed working conditions, and accordingly pumping loss and oil consumption are low; the turbine is high in forward exhaust volume when the engine runs under low-speed working conditions, accordingly, pulse energy can be sufficiently utilized, and the oil consumption is low; the piston exhaust pressure regulator is reasonable in design, simple in structure and applicable to optimally designing exhaust systems of turbine supercharged engines.

Owner:黄昕煜

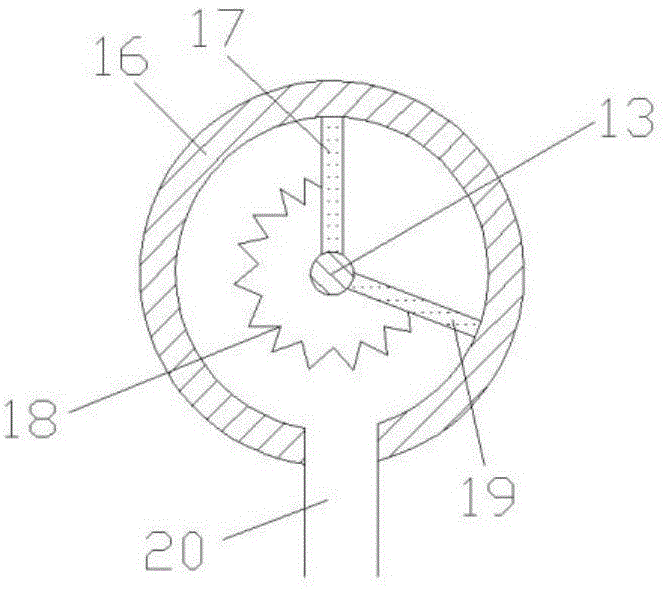

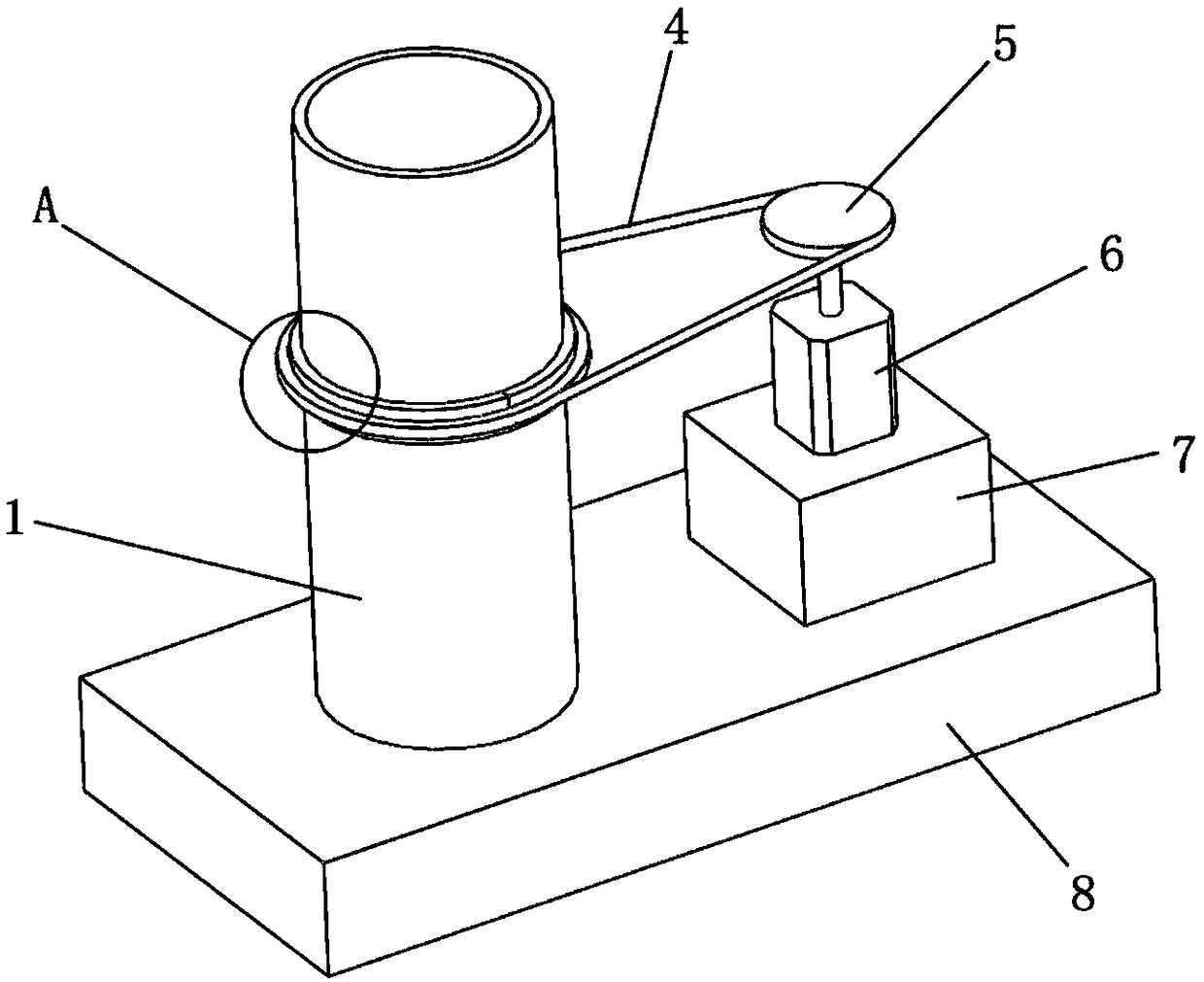

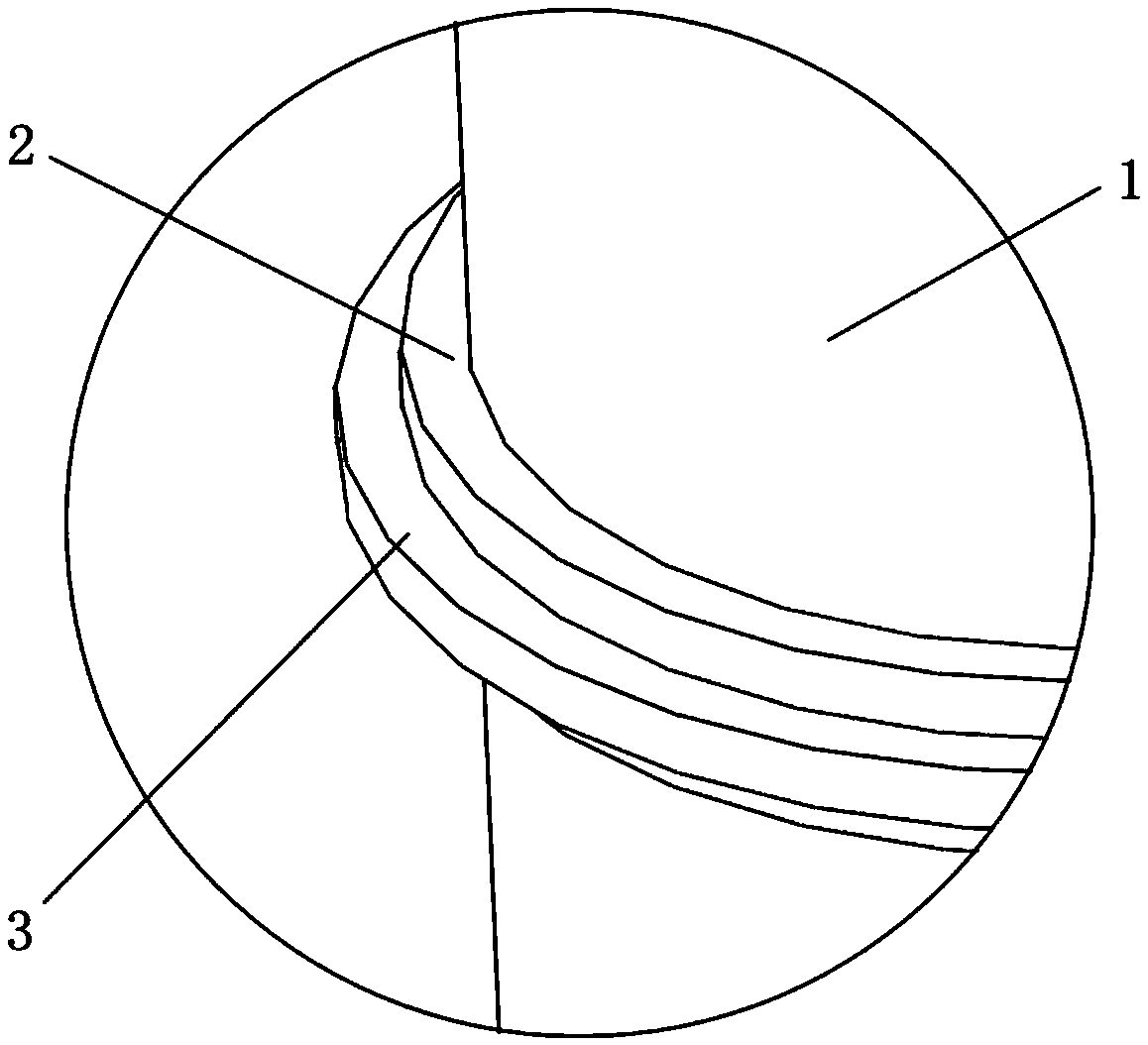

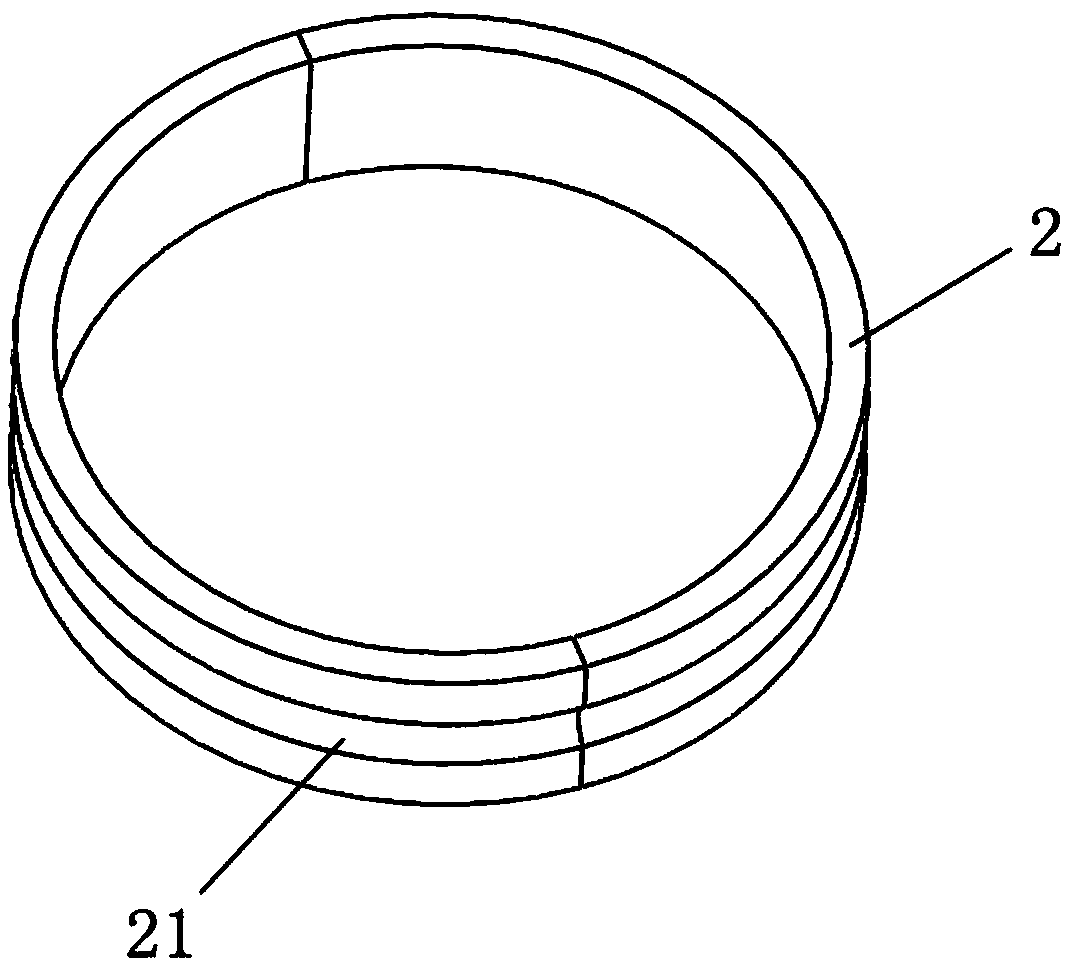

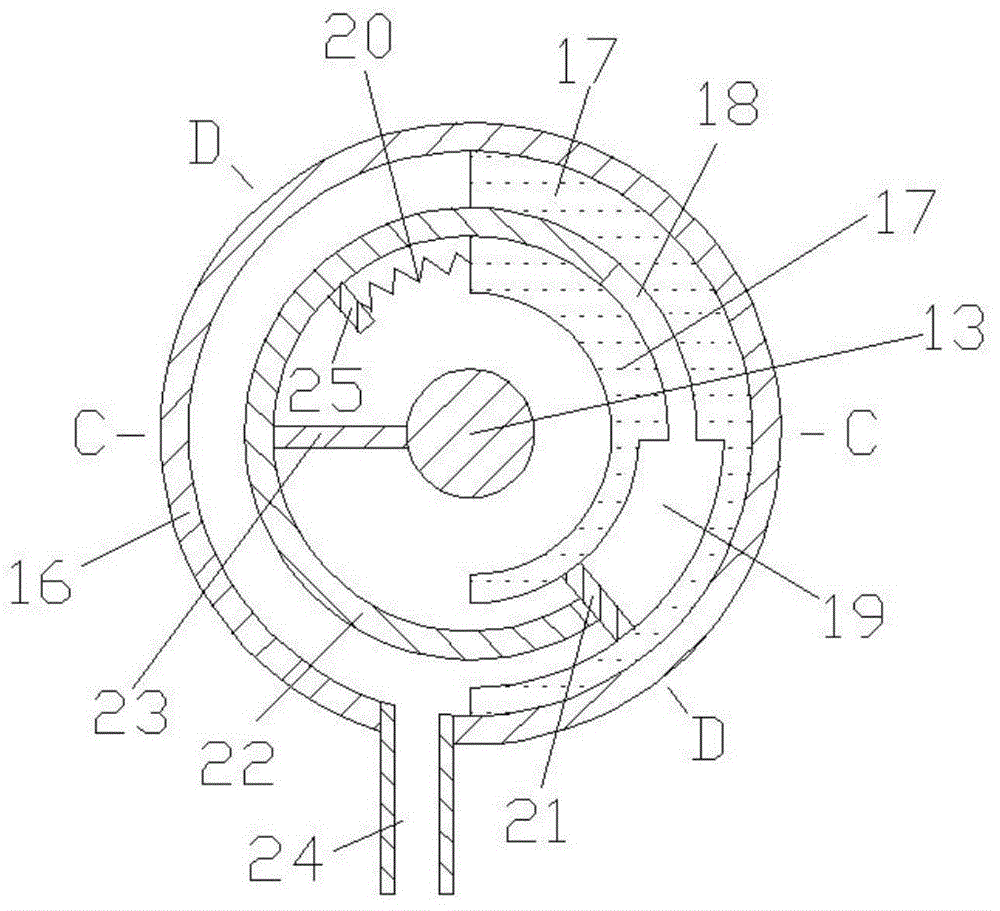

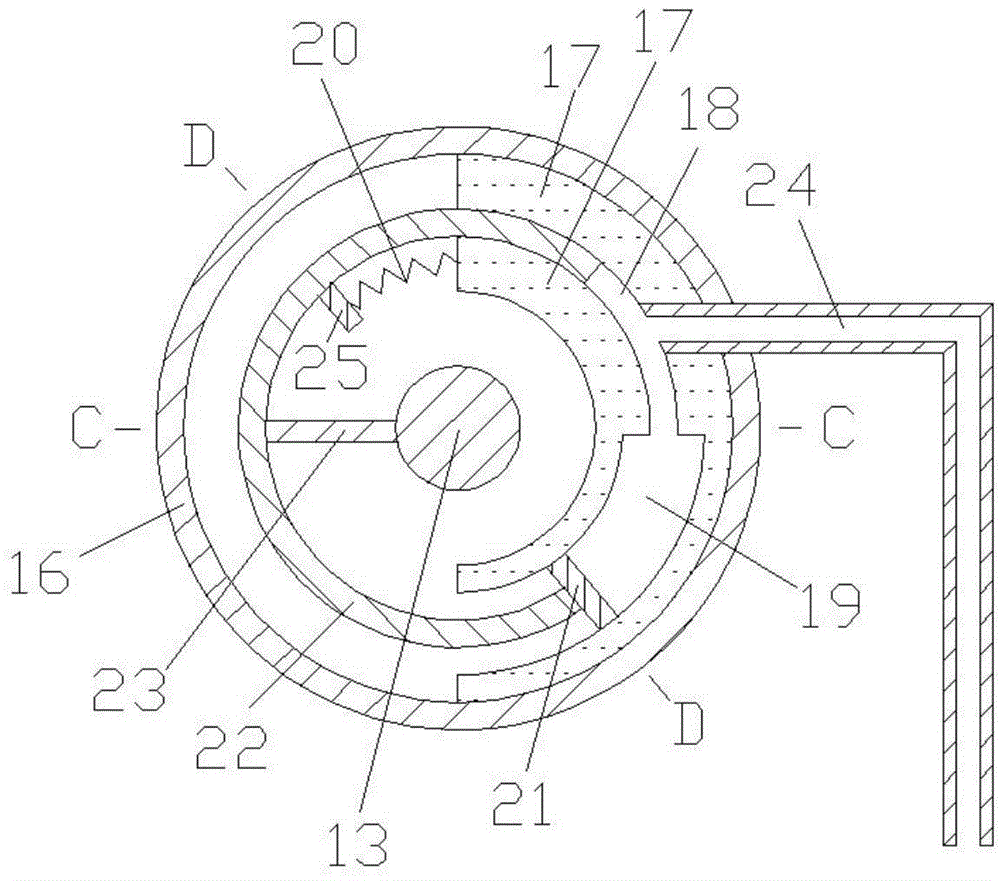

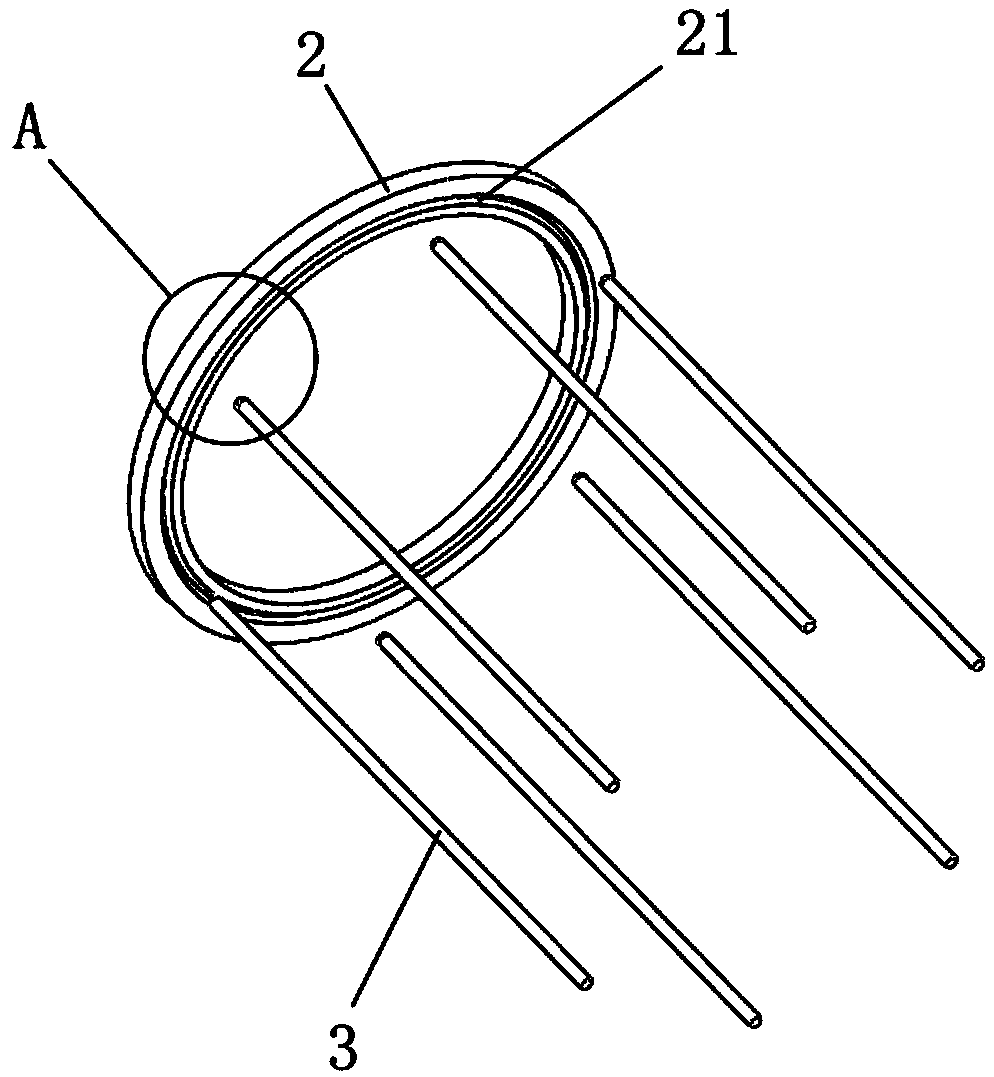

Rust removal device and method for inner wall of metal pipe

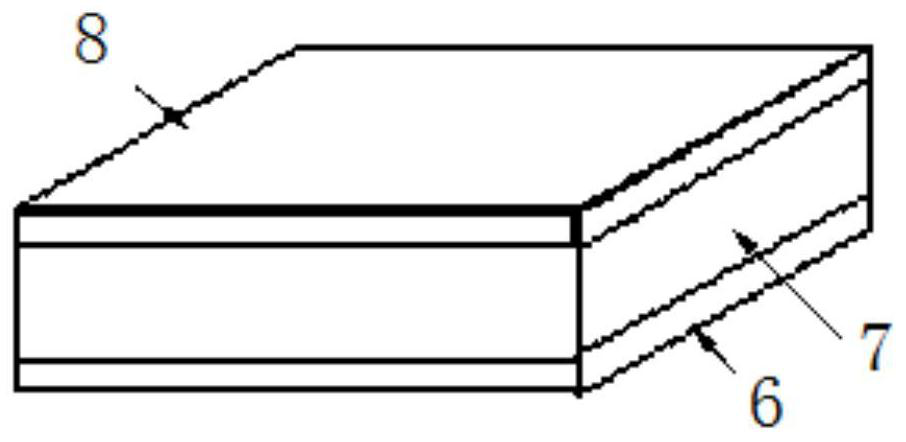

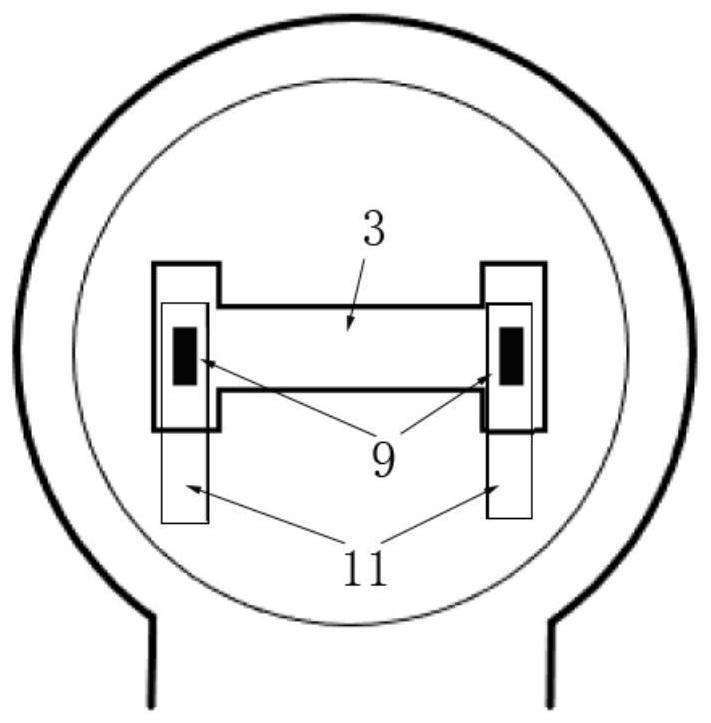

InactiveCN108857846AGuaranteed derusting effectWon't hurtEdge grinding machinesPolishing machinesMetal particleRust

The invention discloses a rust removal device and method for the inner wall of a metal pipe. The device comprises a pipe body and a rotation ring; metal particles are placed in a cavity of the pipe body, the rotation ring is located on the outer surface of the pipe body and connected with the pipe body through a thread track, multiple magnets electrically connected with the exterior are arranged in the rotation ring, and the rotation ring can rotate relative to the pipe body and can move in the length direction of the thread track in the rotation process. The device is easy to operate, the inner wall of the metal pipe can be subjected to dust removal operation, the dust removal effect is guaranteed, and the portions, without rusty layers, of the metal pipe cannot be damaged.

Owner:FOSHAN GAOMING XILUO TECH CO LTD

Independent displacement volume controllable system

InactiveCN104481657AReasonable designSimple structureExhaust apparatusSilencing apparatusPulse energyEngineering

The invention belongs to the technical field of internal combustion engines, and discloses an independent displacement volume controllable system which comprises air inlet pipes of an engine, a supercharger, the engine, exhaust pipes of the engine, a turbine, connecting pipes, adjusting cavities, movable plates, a spring, fixed plates and a rotary shaft. The first adjusting cavity and the second adjusting cavity are coaxially connected with each other by the rotary shaft, the spring is arranged on a clockwise rotation side of the second rotary plate and is connected with the second rotary plate and the second fixed plate, one end of the second connecting pipe is communicated with the second adjusting cavity, the other end of the second connecting pipe is communicated with the certain exhaust pipe of the engine, and the certain exhaust pipe of the engine is arranged between a catalysis pack and a silencer. The independent displacement volume controllable system has the advantages that the turbine is high in forward exhaust volume when the engine runs under high-speed working conditions, and accordingly pumping loss and oil consumption are low; the turbine is low in forward exhaust displacement when the engine runs under low-speed working conditions, accordingly, pulse energy can be sufficiently utilized, and the oil consumption is low; the independent displacement volume controllable system is reasonable in design, simple in structure and applicable to optimally designing exhaust systems of turbine supercharged engines.

Owner:何卓遥

Antiknock chemical additive for lead-free gasoline

InactiveCN103773514AImprove antiknock performanceImprove powerLiquid carbonaceous fuelsFuel additivesXylyleneMethylaniline

An antiknock chemical additive for lead-free gasoline comprises the raw materials in parts by weight: 30-40 parts of industrial ethanol, 10-20 parts of industrial methanol, 5-10 parts of ferrocene, 2-10 parts of monomethyl aniline, 5-10 parts of isobutyl acetate, 20-30 parts of methyl tertiary butyl ether, and 10-15 parts of xylene. The addition amount of the antiknock chemical additive in the lead-free gasoline is 0.2-1.0%. The gasoline octane number can be increased by 20-40 units, and the antiknock property and the dynamic property of the gasoline are enhanced. The antiknock chemical additive has the advantages of easily obtained raw materials, low cost, simple process, and easy popularization; the antiknock chemical additive has obvious using effect, significantly increases the octane number, improves oil product chemical properties, has a catalytic combustion function, can allow mixed gas to be fully burnt, improves the oxidation speed, thereby reducing knocking occurrence and having good speed increasing performance; and emissions of CO, hydrocarbons, NOx and solid particles in exhaust gas are greatly reduced, environmental pollution is reduced, moreover, the lead content is extremely low, and economic benefits and social benefits are substantial.

Owner:XIAN RUNDA CHEM TECH

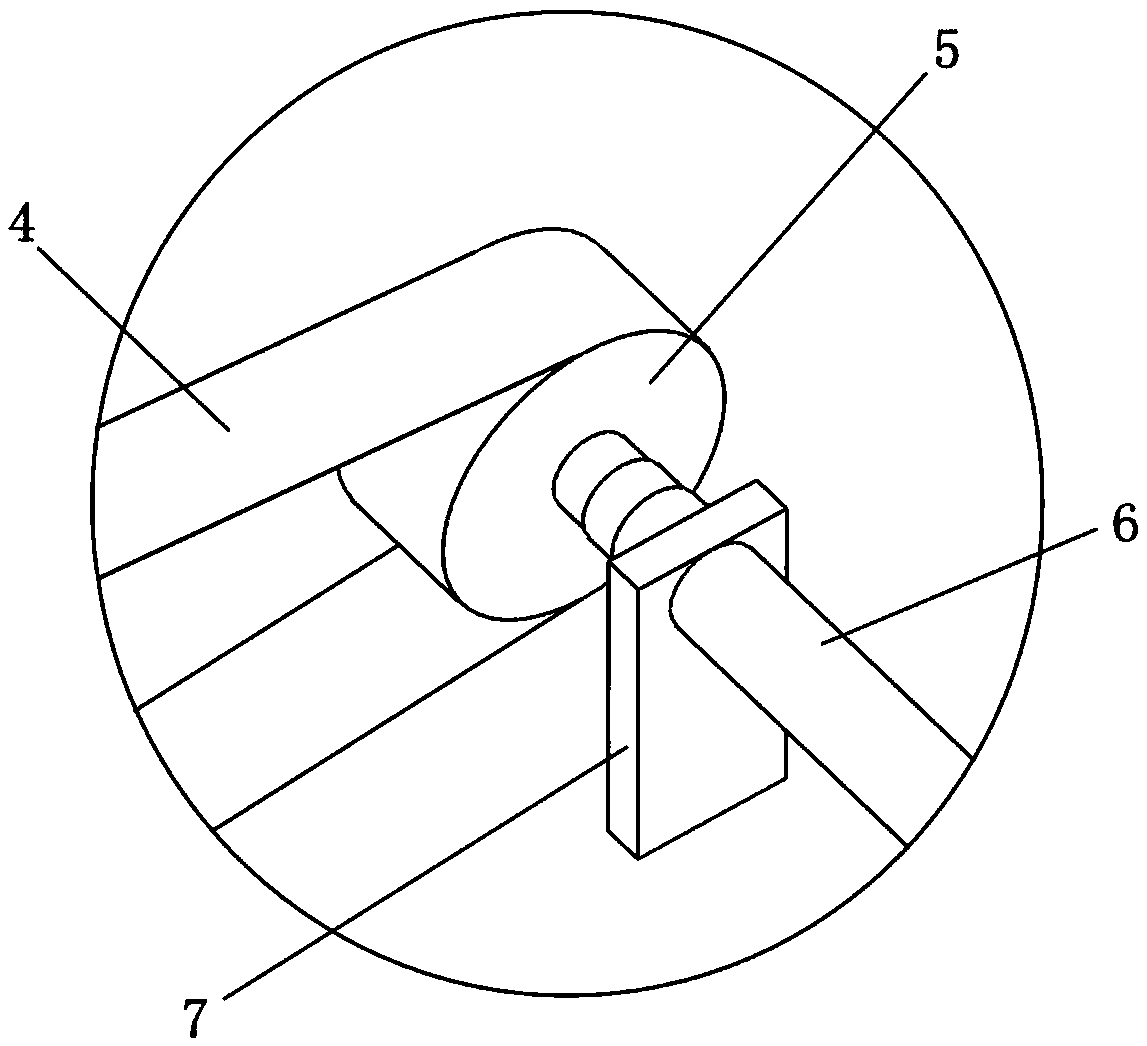

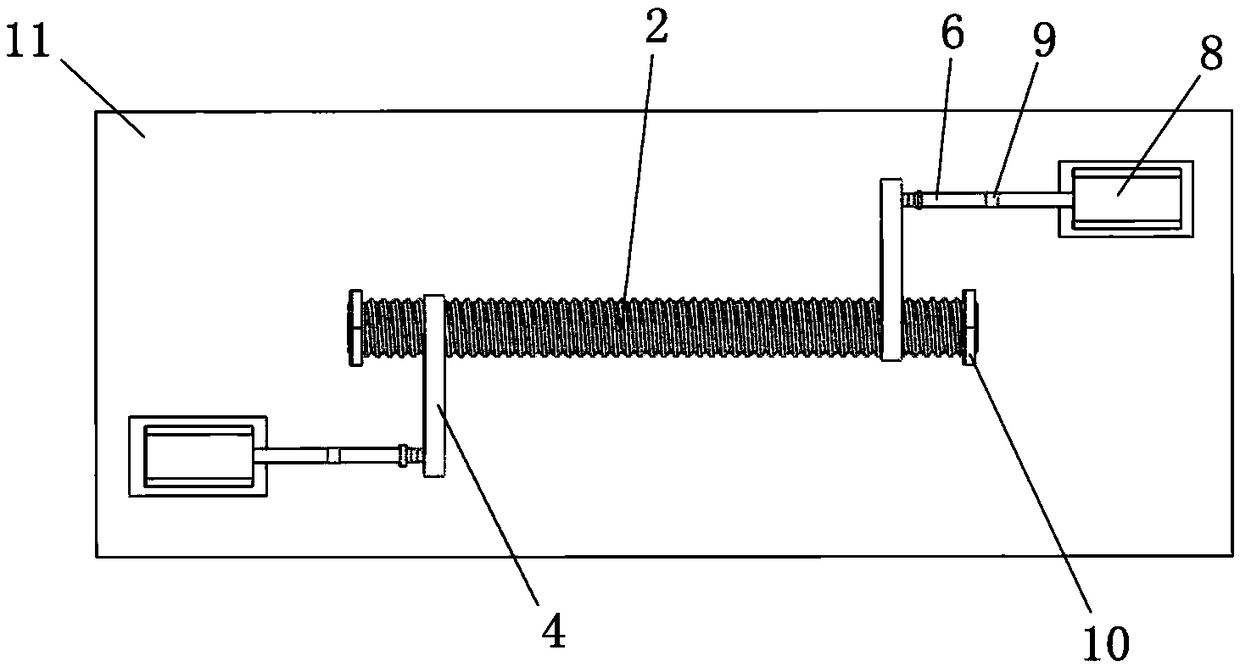

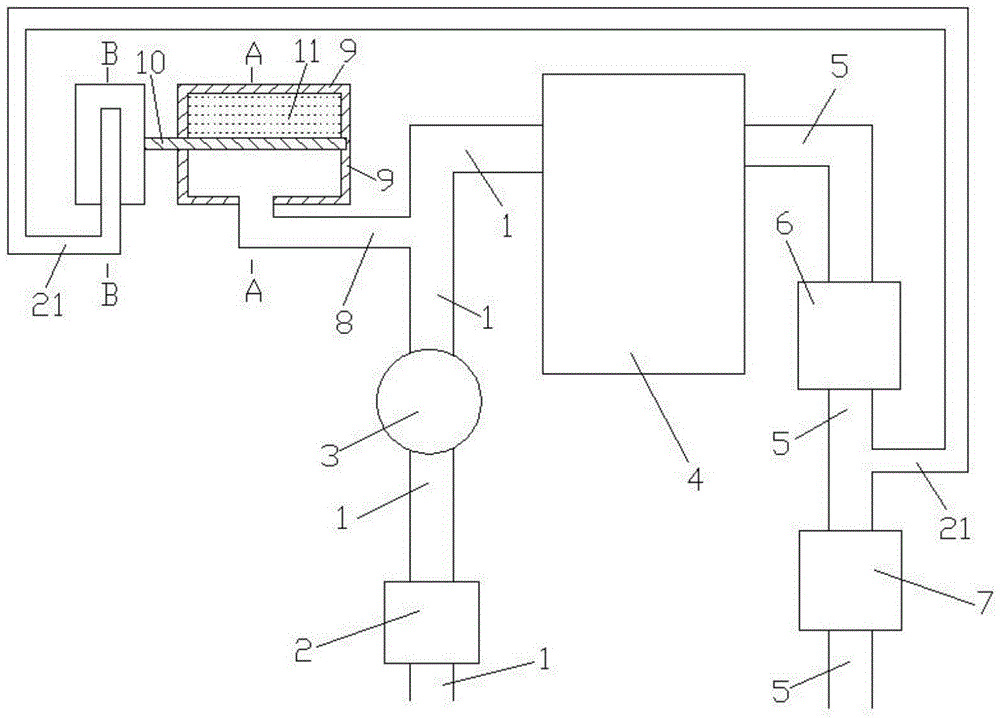

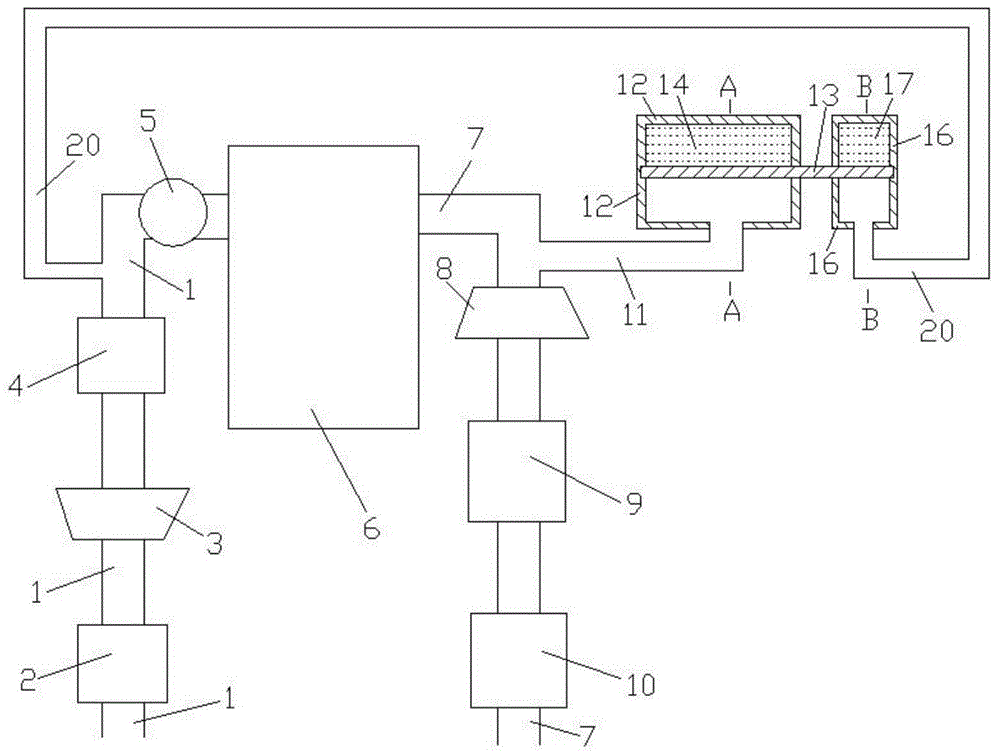

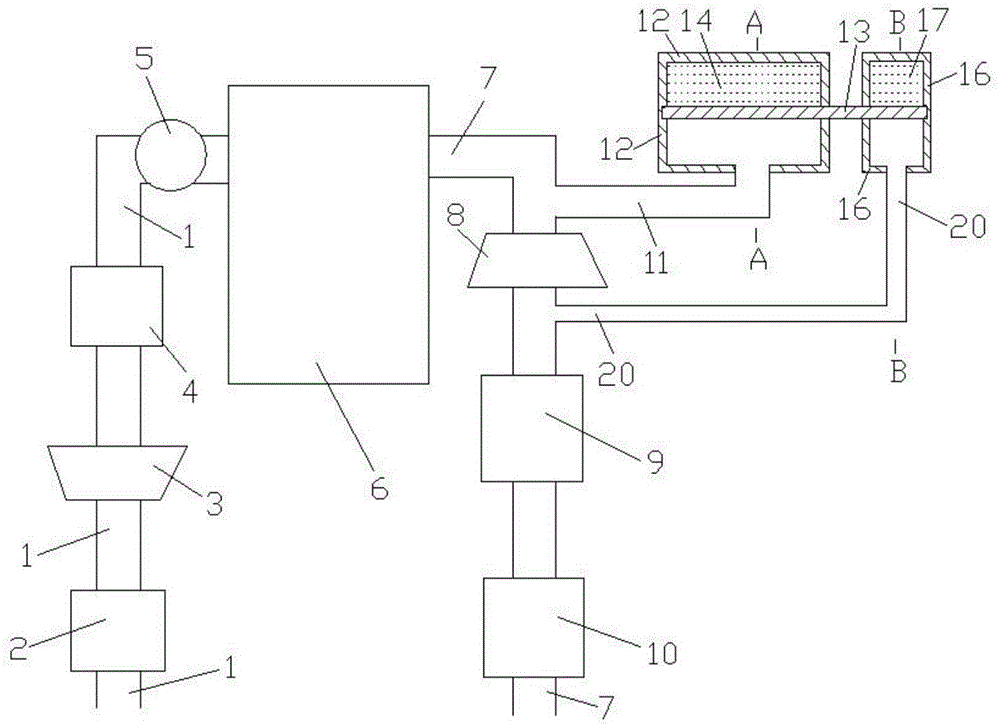

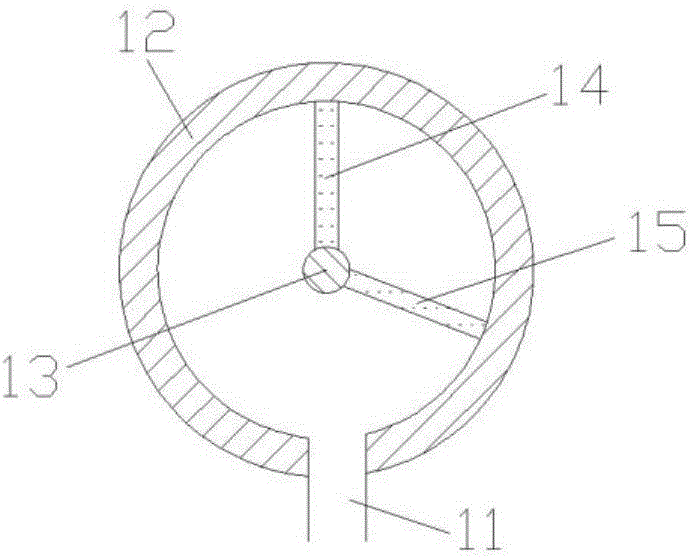

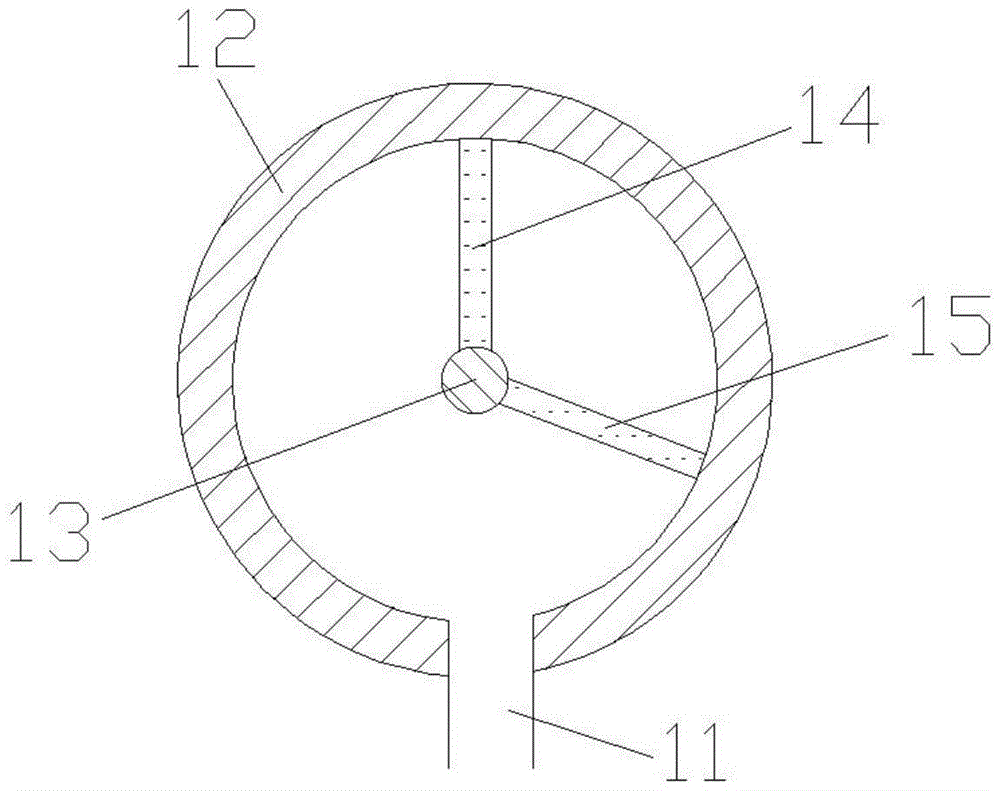

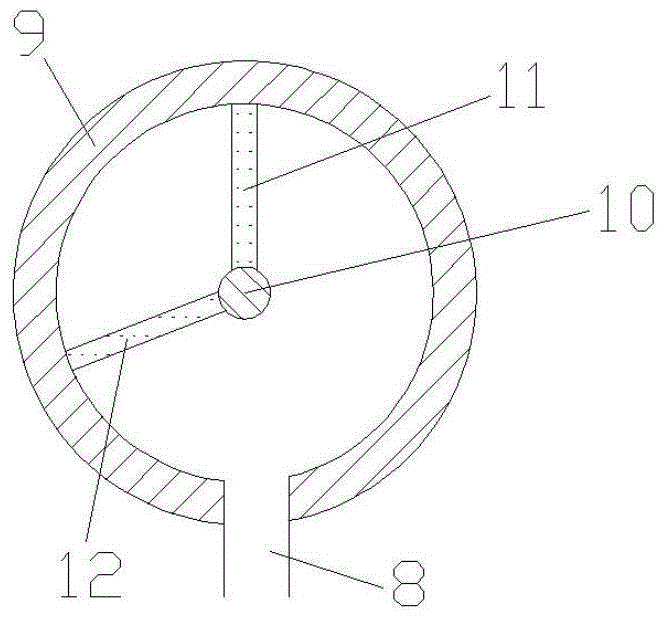

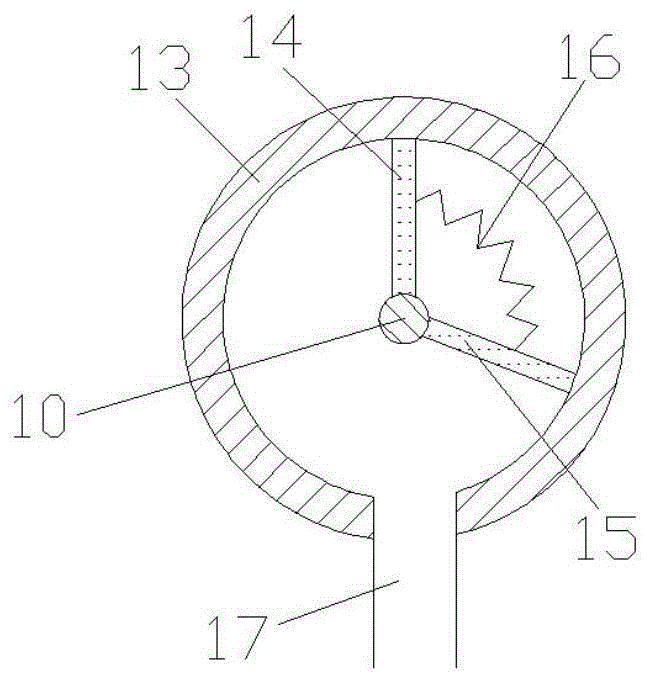

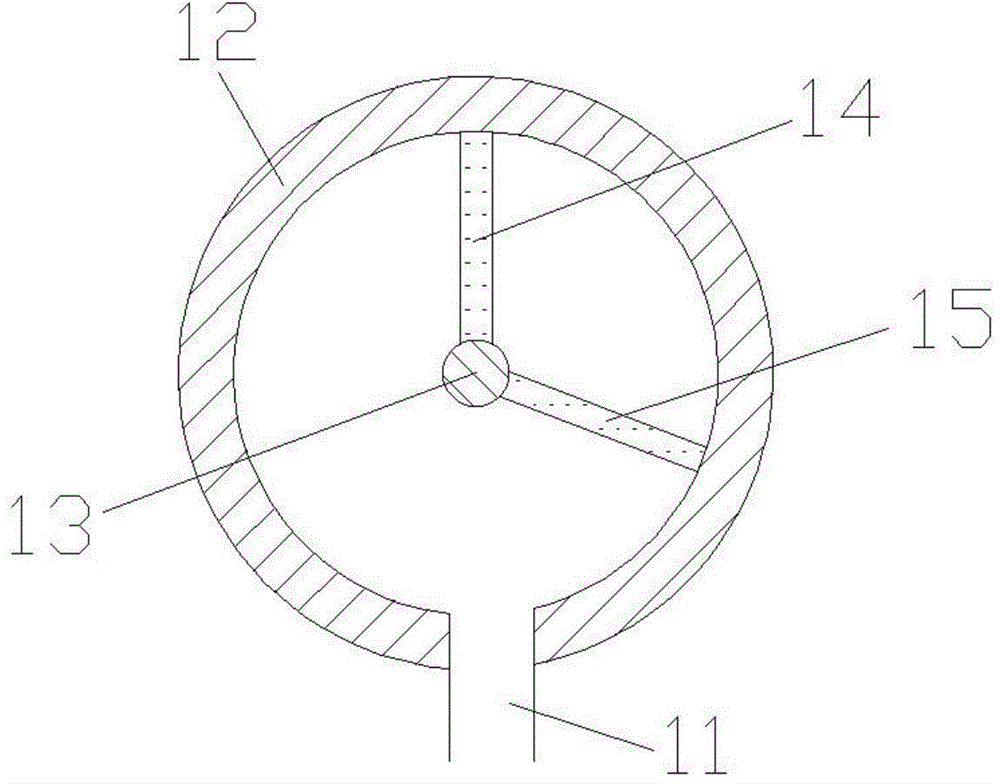

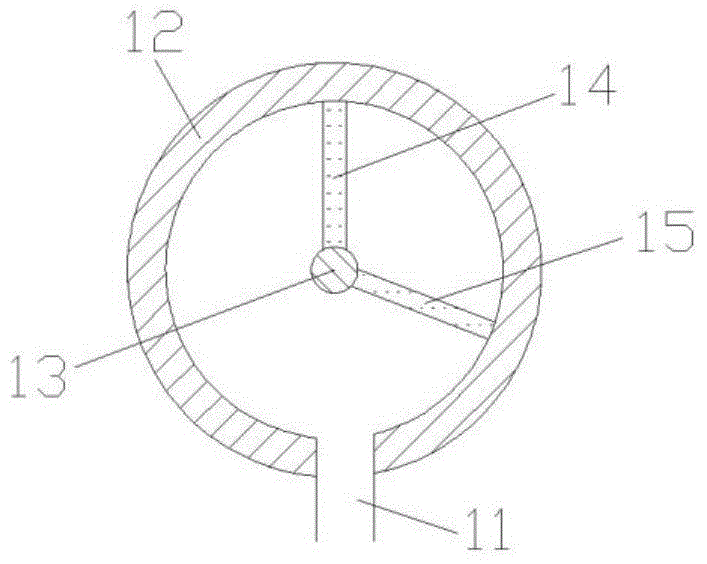

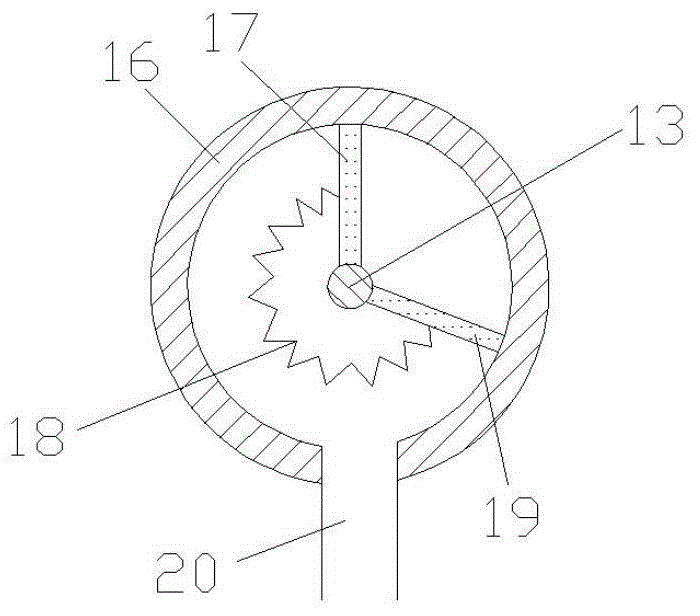

Active-type controlling mechanism

InactiveCN104481670AContinuously variable volumeGood speed performanceInternal combustion piston enginesAir intakes for fuelCombustionLow speed

The invention discloses an active-type controlling mechanism and belongs to the technical field of internal combustion engines. The mechanism comprises an engine intake pipe, an engine, an engine exhaust pipe, a connecting pipe, inner pipes, an adjusting cavity, a controlling cavity and a rotating shaft, the adjusting cavity and the controlling cavity are coaxially connected through the rotating shaft, an upper wall surface of a second inner pipe is connected with a baffle through a spring, one end of a second connecting pipe is communicated with a first inner pipe after penetrating through a fixed object, the other end of the second connecting pipe is communicated with the engine exhaust pipe between a catalyst pack and a silencer. When the engine operates in a low speed condition, the volume of the intake pipe is bigger, and when the engine operates in a high speed condition, the volume of the intake pipe is smaller, and the volume of the intake pipe is self-adjusted. The active-type controlling mechanism is reasonable in design, simple in structure, and suitable for optimizing the design of the intake system of a naturally aspirated internal combustion engine.

Owner:储德新

Inflation efficiency adjusting system

InactiveCN104481753AContinuously variable volumeGood speed performanceCombustion-air/fuel-air treatmentMachines/enginesLow speedExternal combustion engine

An inflation efficiency adjusting system belongs to the technical field of an internal combustion engine. The inflation efficiency adjusting system comprises an engine air inlet pipe, an engine, an engine air exhausting pipe, a connection pipe, an adjusting cavity, a movable plate and a spring, wherein the movable plate is arranged in an adjusting cavity and is in sealed contact with an inner wall surface of the adjusting cavity; the movable plate is connected with a right wall surface of the adjusting cavity by the spring; one end of a second connection pipe is communicated with a left wall surface of the adjusting cavity and the other end of the second connection pipe is communicated with the engine air exhausting pipe between a catalyzing bag and a silencer. According to the inflation efficiency adjusting system, when the engine is operated at a low speed working station, the capacity of an air pipe is larger; when the engine is operated at a high speed working station, the capacity of the air pipe is smaller, so that the capacity of the air inlet pipe can be automatically adjusted. The inflation efficiency adjusting system is reasonable in design and simple in structure, and is suitable for an optimized design of an air inlet system of a natural air suction internal combustion engine.

Owner:苏皓

Continuous control mechanism

InactiveCN104632354AReasonable designSimple structureInternal combustion piston enginesEngineeringExternal combustion engine

The invention provides a continuous control mechanism and belongs to the technical field of internal combustion engines. The continuous control mechanism comprises an engine air inlet pipe, an engine, an engine exhaust pipe, connection pipes, internal pipes, an adjustment cavity, a control cavity and a rotation shaft. The adjusting cavity and the control cavity are coaxially connected through the rotation shaft. A baffle is fixedly connected with a rotation body. The left wall of a fixing body is connected with the baffle through a spring. One end of the second connection pipe penetrates through the fixing body to be communicated with the first internal pipe. The other end of the second connection pipe is communicated with the portion, located between a catalysis pack and a silencer, of the engine exhaust pipe. When the engine works at a low speed, the volume of the engine air inlet pipe is large, and when the engine works at a high speed, the volume of the engine air inlet pipe is small. The volume of the engine air inlet pipe can be self-adjusted. The continuous control mechanism is reasonable in design, simple in structure, and suitable for optimization design of naturally aspirated internal combustion engine air inlet systems.

Owner:储德新

Drawing-in type exhaust volume-controllable system

InactiveCN104454142AReasonable designSimple structureInternal combustion piston enginesIntercoolerPulse energy

The invention relates to a drawing-in type exhaust volume-controllable system and belongs to the technical field of internal combustion engines. The system comprises an engine gas inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting tubes, adjusting cavities, rotating plates, a spring, fixed plates and a rotary shaft. The first adjusting cavity and the second adjusting cavity are coaxially connected through the rotary shaft. The spring is disposed on the clockwise rotation side of the second rotating plate and connected with the second rotating plate and the second fixed plate. One end of the second connecting tube is communicated with the second adjusting cavity. The other end of the second connecting tube is communicated with the engine gas inlet pipe between an intercooler and a throttle valve. The drawing-in type exhaust volume-controllable system has the advantages that when the engine operates at a high speed, the front exhaust volume of the turbine is large, pump gas loss is small, and oil consumption is low; when the engine operates at a low speed, the front exhaust volume of the turbine is small, pulse energy can be fully utilized, and oil consumption is low; the system is reasonable in design, simple in structure, and applicable to optimization design of the exhaust system of a turbocharged engine.

Owner:何卓遥

Actuator controller series system

InactiveCN104358639AContinuously variable volumeGood speed performanceCombustion-air/fuel-air treatmentMachines/enginesLow speedExternal combustion engine

The invention relates to an actuator controller series system belonging to the technical field of internal combustion engines, which comprises an engine intake pipe, an engine, an engine exhaust pipe, connecting pipes, internal pipes, a regulating chamber, a control chamber and a rotary shaft, the regulating chamber and the control chamber are coaxially connected through the rotary shaft, a baffle and a rotor are fixedly bonded together, the left wall of a stator is connected with the baffle through a spring, one end of the second connecting pipe communicates with the internal cavity of the control chamber, and the other end of the second connecting pipe communicates with the engine exhaust pipe between a catalysis package and a muffler. In the actuator controller series system, the volume of the intake pipe is large when the engine operates under a low-speed condition, and is small when the engine operates under a high-speed condition, so the volume of the intake pipe can be self-regulated. The actuator controller series system is reasonably designed, has a simple structure, and is applicable to the optimization design of an intake system of a naturally aspirated engine.

Owner:桑元俊

Modified pulse turbo-charged system

InactiveCN104481671AContinuously variable volumeGood speed performanceInternal combustion piston enginesCombustionExternal combustion engine

The invention belongs to the technical field of internal combustion engines and relates to a modified pulse turbo-charged system comprising an engine intake pipe, a turbocharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, adjusting cavities, a moving plate, a spring, fixed plates and a rotating shaft. The first adjusting cavity and the second adjusting cavity are coaxially connected through the rotating shaft. The spring is disposed on the anticlockwise rotatable side of a second rotating plate and connected to the second rotating plate and the second fixed plate. One end of the second connecting pipe is communicated with the second adjusting cavity. The other end of the second adjusting pipe is communicated with the engine exhaust pipe arranged between the turbine and a catalyst capsule. When the engine runs at high speed, before-the-turbine displacement volume is high, pumping loss is low, and oil consumption is low; when the engine runs at low speed, the before-the-turbine displacement volume is low, pulse energy is made full use, and oil consumption is low. The modified pulse turbo-charged system is reasonable in design and simple in structure and is applicable to optimal design of an exhaust system of a turbo-charged engine.

Owner:李鹏飞

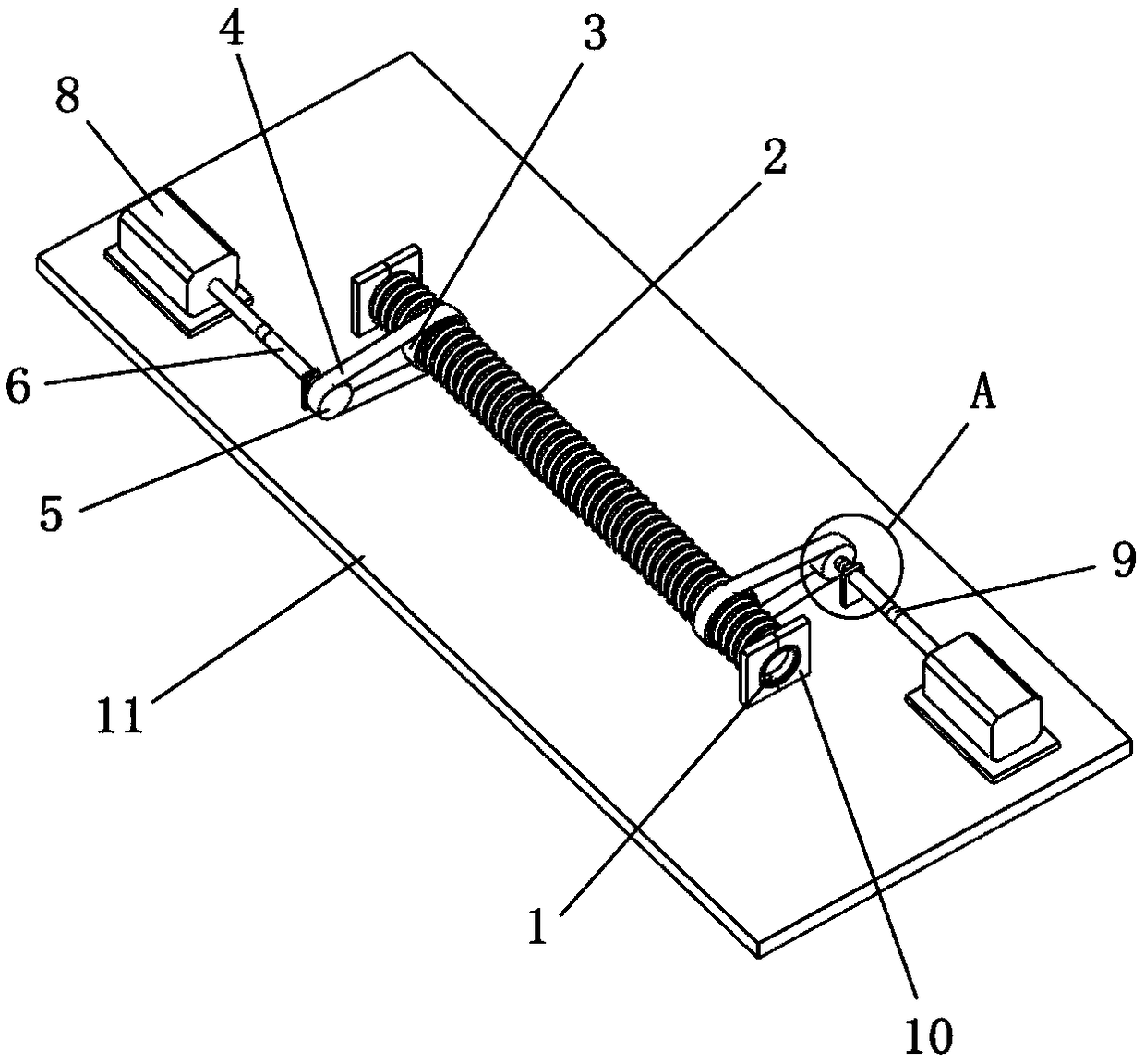

Tensile deformation pipeline

InactiveCN104358640AReasonable designSimple structureCombustion-air/fuel-air treatmentMachines/enginesOptimal designPulse energy

The invention discloses a tensile deformation pipeline belonging to the technical filed of internal combustion engines. The tensile deformation pipeline comprises an engine air inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, a regulating cavity, a rotating shaft, a rotating plate, a control cavity, inner pipes, a spring and a rotator, wherein the regulating cavity and the control cavity are coaxially connected through the rotating shaft; the upper wall surface of the second inner pipe is connected together with a partition plate through the spring; and one end of the second connecting pipe is communicated with the first inner pipe after passing through a fixation body, and the other end of the second connecting pipe is connected with the engine exhaust pipe located between the turbine and a catalysis bag. According to the tensile deformation pipeline, when the engine operates at a high speed, the exhaust capacity of the front of the turbine is relatively high, the pumping loss is relatively low, and the oil consumption is relatively low; and when the engine operates at a low speed, the exhaust capacity of the front of the turbine is relatively low, the pulse energy can be sufficiently utilized, and the oil consumption is relatively low. The tensile deformation pipeline is reasonable in design, simple in structure and suitable for optimal design of an exhaust system of a turbocharged engine.

Owner:王春海

Mechanical double plate rotation device

ActiveCN104612811BContinuously variable volumeGood speed performanceInternal combustion piston enginesCombustionEngineering

Owner:浙江和夏科技股份有限公司

Pre-turbine fluid compression and release system

InactiveCN104595015AContinuously variable volumeGood speed performanceInternal combustion piston enginesLow speedCombustion

The invention belongs to the technical field of internal combustion engines and provides a pre-turbine fluid compression and release system. The pre-turbine fluid compression and release system comprises an engine air inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, an adjusting cavity, a rotary shaft, a rotary plate, a control cavity, internal pipes, a spring and a rotating body. The adjusting cavity and the control cavity are coaxially connected through the rotary shaft. The upper wall face of the second internal pipe is connected with a partition board through the spring. One end of the second connecting pipe is communicated with an inner cavity of the control cavity. The other end of the second connecting pipe is connected with the engine exhaust pipe between a catalysis bag and a silencer. When the engine operates on a high-speed working condition, the pre-turbine exhaust volume is large, pumping loss is small, and oil consumption is low; when the engine operates on a low-speed working condition, the pre-turbine exhaust volume is small, pulse energy can be fully utilized, and oil consumption is low. The pre-turbine fluid compression and release system is reasonable in design, simple in structure and applicable to optimization design of a turbine supercharged engine exhaust system.

Owner:范光鑫

Rotary plate and fixed plate matching device

InactiveCN104481755AReasonable designSimple structureCombustion-air/fuel-air treatmentMachines/enginesEngineeringLow speed

The invention belongs to the technical field of internal combustion engines, and discloses a rotary plate and fixed plate matching device. The rotary plate and fixed plate matching device comprises air inlet pipes of an engine, the engine, exhaust pipes of the engine, connecting pipes, adjusting cavities, movable plates, a spring, fixed plates and a rotary shaft. The first adjusting cavity and the second adjusting cavity are coaxially connected with each other by the rotary shaft, the spring is arranged on an anticlockwise rotation side of the second rotary plate and is connected with the second rotary plate and the second fixed plate, one end of the second connecting pipe is communicated with the second adjusting cavity, the other end of the second connecting pipe is communicated with the certain exhaust pipe of the engine, and the certain exhaust pipe of the engine is positioned at the front of a catalysis pack. The rotary plate and fixed plate matching device has the advantages that the air inlet pipes are large in volume when the engine runs under low-speed working conditions and are low in volume when the engine runs under high-speed working conditions, and accordingly the volumes of the air inlet pipes can be automatically adjusted; the rotary plate and fixed plate matching device is reasonable in design, simple in structure and applicable to optimally designing air inlet systems of naturally aspirated internal combustion engines.

Owner:孙松

Intercooler front engine inlet air leading-out equipment

InactiveCN104358613AReasonable designSimple structureInternal combustion piston enginesIntercoolerPulse energy

The invention discloses intercooler front engine inlet air leading-out equipment belonging to the technical field of internal combustion engines. The intercooler front engine inlet air leading-out equipment comprises an engine air inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, a regulating cavity, a rotating shaft, a rotating plate, a control cavity, inner pipes, a spring, a rotator and a stressed plate, wherein the regulating cavity and the control cavity are coaxially connected through the rotating shaft; the stressed plate is connected together with the left wall surface of a fixation body through the spring; and one end of the second connecting pipe is communicated with the first inner pipe after passing through the fixation body, and the other end of the second connecting pipe is connected with the engine air inlet pipe located between a compressor and an intercooler. According to the intercooler front engine inlet air leading-out equipment, when the engine operates at a high speed, the exhaust capacity of the front of the turbine is relatively high, the pumping loss is relatively low, and the oil consumption is relatively low; and when the engine operates at a low speed, the exhaust capacity of the front of the turbine is relatively low, the pulse energy can be sufficiently utilized, and the oil consumption is relatively low. The intercooler front engine inlet air leading-out equipment is reasonable in design, simple in structure and suitable for optimal design of an exhaust system of a turbocharged engine.

Owner:朱坤旭

High-speed working condition pumping reducing device

InactiveCN104533602AContinuously variable volumeGood speed performanceInternal combustion piston enginesLow speedCombustion

A high-speed working condition pumping reducing device belongs to the technical field of internal combustion engines. The high-speed working condition pumping reducing device comprises an engine air inlet pipe, a pressurizer, an engine, an engine exhausting pipe, a turbine, a connection pipe, an adjusting cavity, a rotating shaft, a rotating plate, a control cavity, an inner pipe, a spring, a rotating body and a stressing plate, wherein the adjusting cavity and the control cavity are coaxially connected by the rotating shaft; the stressing plate is connected with the left wall surface of a fixed body by the spring; one end of a second connection pipe is communicated with an inner cavity of the control cavity; the other end of the second connection pipe is connected with the engine air inlet pipe between an intercooler and a throttle valve. According to the high-speed working condition pumping reducing device, when the engine is operated under a high-speed working condition, the front exhausting volume of the turbine is larger, the pumping loss is lower and the oil consumption is lower; when the engine is operated under a low-speed working condition, the front exhausting volume of the turbine is smaller, pulse energy can be sufficiently utilized and the oil consumption is lower. The high-speed working condition pumping reducing device has a reasonable design and a simple structure, and is suitable for an optimal design of a turbine pressurizing engine exhausting system.

Owner:魏江山

Laminar flow stirring device and stirring method

InactiveCN108905838AGuaranteed stirring effectShorten the timeTransportation and packagingMixer accessoriesElectricityEngineering

Owner:FOSHAN GAOMING XILUO TECH CO LTD

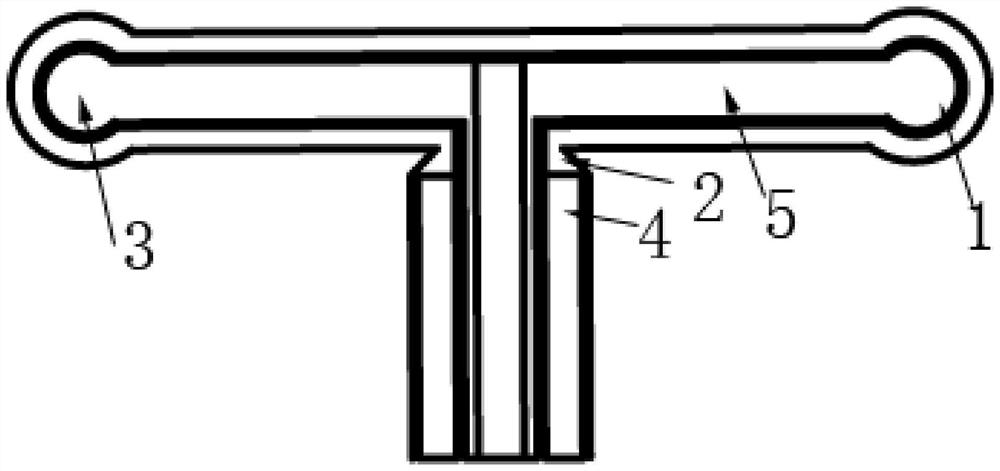

Wind speed sensor and preparation method thereof

ActiveCN111707844AGood speed performanceImprove stabilityAcceleration measurement using interia forcesFluid speed measurement using thermal variablesEngineeringResistor

The invention relates to a wind speed sensor, which comprises a speed measurement unit positioned in a closed space, and the speed measurement unit comprises a T-shaped heater and a temperature measurement sensor which are positioned in the closed space; and the T-shaped heater is of a T-shaped structure, and the two ends of the transverse portion of the T-shaped structure are each provided with two heating resistors. The temperature measuring sensor is arranged around the outer side of the T-shaped structure, and two temperature measuring resistors are arranged at the positions, located on the two sides of the middle vertical part of the T-shaped structure, of the temperature measuring sensor respectively; with the middle vertical part of the T-shaped structure as the symmetry axis, the two heating resistors are symmetrically arranged, and the two temperature measuring resistors are symmetrically arranged. Compared with the prior art, the sensor has the advantages of being small in size, high in sensitivity, high in practicability and the like.

Owner:SHANGHAI INST OF TECH

Pumping loss adjusting system

InactiveCN104481659AContinuously variable volumeGood speed performanceExhaust apparatusSilencing apparatusLow speedCombustion

The invention provides a pumping loss adjusting system, and belongs to the technical field of internal combustion engines. The pumping loss adjusting system comprises an engine air feeding tube, a supercharger, an engine, an engine exhaust tube, a turbine, a connecting tube, an adjusting cavity, a rotating shaft, a rotating plate, a control cavity, an internal tube, a spring, a rotating body and a stress plate, wherein the adjusting cavity is coaxially connected with the control cavity through the rotating shaft; the stress plate is connected with a left wall surface of a fixed body through the spring; one end of a second connecting tube is connected with an internal cavity body of the control cavity; and the other end of the second connecting tube is connected with the engine exhaust tube between the turbine and a catalyzing pack. In the pumping loss adjusting system, when the engine runs under the working condition of high speed, the front exhaust volume of the turbine is large, pumping loss is low, and oil consumption is low; and when the engine runs under the working condition of low speed, the front exhaust volume of the turbine is small, pulse energy can be used sufficiently, and the oil consumption is low. The pumping loss adjusting system is reasonable in design and simple in structure, and is suitable for the optimization design of an exhaust system of a turbocharged engine.

Owner:魏江山

Two-pressurization-system combination device

InactiveCN104595014AContinuously variable volumeGood speed performanceInternal combustion piston enginesCombustionLow speed

The invention belongs to the technical field of internal combustion engines and provides a two-pressurization-system combination device. The two-pressurization-system combination device comprises an engine intake pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, adjusting cavities, a moving plate, a spring, fixed plates and a rotating shaft, wherein the first adjusting cavity is coaxially connected with the second adjusting cavity through the rotating shaft, the spring is arranged on the counterclockwise rotation side of a second rotating plate and connected with the second rotating plate and the second fixed plate, one end of the second connecting pipe is communicated with the second adjusting cavity, and the other end of the second connecting pipe is communicated with the engine intake pipe between an air compressor and an intercooler. According to the two-pressurization-system combination device, when the engine runs under a high speed working condition, the front exhaust capacity of the turbine is large, pumping loss is small, and oil consumption is low; when the engine runs under a low speed working condition, the front exhaust capacity of the turbine is small, pulse energy can be used sufficiently, and oil consumption is low. The two-pressurization-system combination device is reasonable in design, simple in structure and suitable for optimization design of turbo supercharged engine exhaust systems.

Owner:李鹏飞

Drive type control system

InactiveCN104358638AContinuously variable volumeGood speed performanceCombustion-air/fuel-air treatmentMachines/enginesLow speedControl system

The invention relates to a drive type control system, and belongs to the technical field of an internal combustion engine. The drive type control system comprises an engine air inlet pipe, an engine, an engine exhaust pipe, connecting pipes, inside pipes, a regulating cavity, a control cavity and a rotating shaft, wherein the regulating cavity and the control cavity are coaxially connected through the rotating shaft, the upper wall surface of the second inside pipe is connected with a separation plate through a spring, one end of the second connecting pipe passes through a fixing body and is then communicated with the first inside pipe, and the other end of the second connecting pipe is communicated with the engine exhaust pipe arranged in front of a catalyzing bag. According to the drive type control system, when the engine operates under the low-speed work condition, the volume of the air inlet pipe is greater; when the engine operates under the high-speed work condition, the volume of the air inlet pipe is smaller, and in addition, the volume of the air inlet pipe can be automatically regulated. The driven type control system has the advantages that the design is reasonable, the structure is simple, and the driven type control system is applicable to the optimized design of a natural air suction internal combustion engine air inlet system.

Owner:储德新

Pipe permitted extending mechanism

InactiveCN104594998AContinuously variable volumeGood speed performanceExhaust apparatusSilencing apparatusLow speedCombustion

The invention provides a pipe permitted extending mechanism, and belongs to the technical field of internal combustion engines. The pipe permitted extending mechanism comprises an engine air inlet pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connection pipes, an adjusting cavity, a rotating shaft, a rotating plate, a control cavity, internal pipes, a spring and a rotating body. The adjusting cavity and the control cavity are coaxially connected through the rotating shaft. The upper wall face of a second internal pipe is connected with a partition plate through the spring. One end of a second connection pipe penetrates through a fixed body and then is communicated with a first internal pipe, and the other end of the second connection pipe is connected with the engine air inlet pipe between an intercooler and an air damper. According to the pipe permitted extending mechanism, when the engine operates under a high-speed working condition, the exhaust volume before the turbine is larger, the air pumping loss is smaller, and oil consumption is lower; when the engine operates under a low-speed working condition, the exhaust volume before the turbine is smaller, the pulse energy can be fully utilized, and oil consumption is lower. The pipe permitted extending mechanism is reasonable in design, simple in structure and suitable for optimal design of a turbocharged engine exhaust system.

Owner:王春海

Exhaust leading-out equipment for rear engine of catalytic converter

InactiveCN104481675AContinuously variable volumeGood speed performanceInternal combustion piston enginesLow speedCombustion

The invention provides exhaust leading-out equipment for a rear engine of a catalytic converter, and belongs to the technical field of internal combustion engines. The exhaust leading-out equipment for the rear engine of the catalytic converter comprises an engine air feeding tube, a supercharger, the engine, an engine exhaust tube, a turbine, connecting tubes, an adjusting cavity, a rotating shaft, a rotating plate, a control cavity, internal tubes, a spring, a rotating body and a stress plate, wherein the adjusting cavity is coaxially connected with the control cavity through the rotating shaft; the stress plate is connected with a left wall surface of a fixed body through the spring; one end of the second connecting tube penetrates in the fixed body and is connected with the first internal tube; and the other end of the second connecting tube is connected with the engine exhaust tube between the catalytic converter and a silencer. In the exhaust leading-out equipment for the rear engine of the catalytic converter, when the engine runs under the condition of high speed, the front exhaust volume of the turbine is large, pumping loss is low, and oil consumption is low; and when the engine runs under the working condition of low speed, the front exhaust volume of the turbine is small, pulse energy can be utilized sufficiently, and the oil consumption is low. The exhaust leading-out equipment for the rear engine of the catalytic converter is reasonable in design and simple in structure and is suitable for the optimization design of an exhaust system of a turbocharged engine.

Owner:朱坤旭

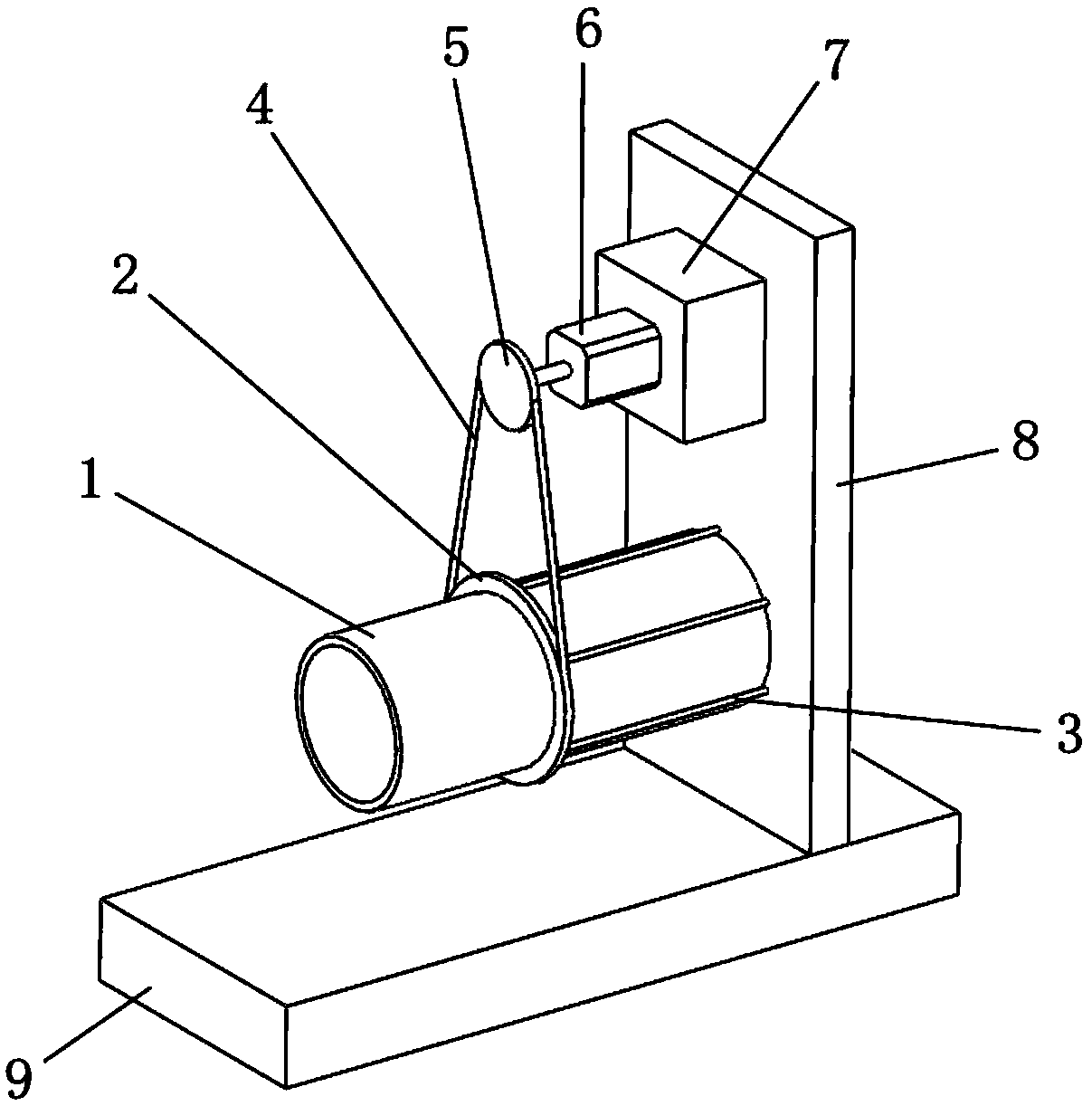

Pipe cutting device and using method of device

InactiveCN109015829AWon't hurtGuaranteed cutting effectMetal working apparatusEngineeringMetal particle

The invention discloses a pipe cutting device and a using method of the device. The pipe cutting device comprises a pipe body and a rotating ring positioned on the outer surface of the pipe body. Thepipe body is a hollow flexible pipe, angular metal particles are placed in the pipe body, the rotating ring is positioned on the outer surface of the pipe body, a cavity is formed in the rotating ring, a plurality of electromagnets electrically connected with the outside are arranged in the cavity of the rotating ring, the rotating ring can rotate relative to the pipe body, and the rotating ring is positioned at a position where the pipe body needs to be cut. According to the pipe cutting device and the using method of the device, flexible pipes can be quickly and stably cut, the cutting effect is ensured, safety accidents are avoided, and no damage is brought to operators.

Owner:FOSHAN GAOMING XILUO TECH CO LTD

Modified constant-pressure charging system

InactiveCN104632360AReasonable designSimple structureInternal combustion piston enginesPulse energyLow speed

The invention provides a modified constant-pressure charging system and belongs to the technical field of internal combustion engines. The modified constant-pressure charging system comprises an engine intake pipe, a supercharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, adjusting cavities, a moving plate, a spring, fixing plates and a rotary shaft, wherein the first adjusting cavity and the second adjusting cavity are coaxially connected through the rotary shaft, the spring is arranged on the counter-clockwise rotating side of a second rotating plate and is connected with the second rotating plate and the second fixing plate, one end of the second connecting pipe is communicated with the second adjusting cavity, and the other end of the second connecting pipe is communicated with the engine exhaust pipe between a catalyst pack and a silencer. In the modified constant-pressure charging system, when the engine operates under the high-speed working condition, the front exhaust volume of the turbine is larger, pumped gas loss is low, and oil consumption is lower. When the engine operates under the low-speed working condition, the front exhaust volume of the turbine is smaller, pulse energy can be fully utilized, and oil consumption is lower. The modified constant-pressure charging system is reasonable in design, simple in structure and suitable for optimization design of a turbo-charging engine exhaust system.

Owner:李鹏飞

Before-the-turbine fluid self-control unit

InactiveCN104481658AReasonable designSimple structureExhaust apparatusSilencing apparatusPulse energyExternal combustion engine

The invention belongs to the technical field of internal combustion engines and relates to a before-the-turbine fluid self-control unit comprising an engine intake pipe, a turbocharger, an engine, an engine exhaust pipe, a turbine, connecting pipes, an adjusting cavity, a rotating shaft, a rotating plate, a control cavity, internal pipes, a spring and a rotator. The adjusting cavity and the control cavity are coaxially connected through the rotating shaft. The upper wall face of the second internal pipe is connected to a partition through the spring. One end of the second connecting pipe is communicated with an inner cavity of the control cavity. The other end of the second connecting pipe is connected to the engine exhaust pipe arranged between the turbine and a catalyst capsule. When the engine runs at high speed, volume of before-the-turbine displacement is high, pumping loss is low, and oil consumption is low; when the engine runs at low speed, volume of before-the-turbine displacement is low, pulse energy can be made full use, and oil consumption is low. The before-the-turbine fluid self-control unit is reasonable in design and simple in structure and is applicable to optimal design of an exhaust system of a turbocharged engine.

Owner:范光鑫

Pulse energy increasing device in low-speed working condition

InactiveCN104500217AContinuously variable volumeGood speed performanceInternal combustion piston enginesCombustionLow speed

The invention discloses a pulse energy increasing device in a low-speed working condition and belongs to the technical field of internal combustion engines. The pulse energy increasing device in the low-speed working condition comprises an engine gas feeding pipe, a supercharger, an engine, an engine gas discharging pipe, a turbine, a connection pipe, a regulation cavity, a rotation shaft, a rotation plate, a control cavity, an inner pipe, a spring, a rotation body and a stressed plate, wherein the regulation cavity and the control cavity are coaxially connected with each other through the rotation shaft; the stressed plate is connected with the left wall surface of a fixing body through the spring; one end of a second connection pipe is communicated with an inner cavity of the control cavity; the other end of the second connection pipe is connected with the engine gas discharging pipe between a catalyst pack and a silencer. According to the pulse energy increasing device, when the engine runs under the high-speed working condition, the turbine is relatively large in front gas discharging capacity, the pumping loss is relatively low, and the oil consumption is relatively low; when the engine runs under the low-speed working condition, the turbine is relatively small in front gas discharging capacity, the pulse energy can be fully used, and the oil consumption is relatively low. The pulse energy increasing device is reasonable in design, simple in structure and suitable for optimization design of a gas discharging system of a turbo supercharged engine.

Owner:魏江山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com