Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Effective closed protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-corrosive paint containing epoxy-modified polyurethane emulsion

InactiveCN106811064AImprove water resistanceStrong cohesionAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEpoxy

The invention discloses anti-corrosive paint containing epoxy-modified polyurethane emulsion. The anti-corrosive paint is prepared from the following raw materials by mass percent: 60-80% of the epoxy-modified aliphatic polyurethane emulsion, 5-10% of silica sol, 2-5% of titanium dioxide, 3-5% of mica, 1-3% of water-based silicone oil, 0.1-0.5% of sodium dodecyl benzene sulfonate, 0.5-1% of an alkali-swelling acrylic thickener, 0.3-0.6% of polyether-modified dimethyl siloxane, 0.1-0.5% of acrylic copolymer potassium salt, 0.1-0.5% of polyether modified polysiloxane and the balance of distilled water, wherein the epoxy-modified aliphatic polyurethane emulsion is prepared from the following raw materials in parts by mass: 40-80% of isophorone diisocyanate, 25-40 parts of polypropylene glycol, 25-80 parts of polyethylene glycol, 3-10 parts of dimethylolpropionic acid, 5-12 parts of epoxy resin, 50-80 parts of butanone, 4-10 parts of diethylenetriamine, 3-11 parts of triethylamine, 1-3 parts of dibutyltin dilaurate and 40-80 parts of distilled water. Polyurethane is modified by using epoxy resin, so that the water resistance and mechanical property of a formed film are improved.

Owner:重庆市共赢包装制品有限公司

Strippable temporary package film composition

InactiveCN106811085AEffective closed protectionAvoid corrosionPolyurea/polyurethane coatingsDiethylenetriamineDimethyl siloxane

The invention discloses a strippable temporary package film composition. The composition is prepared from the following raw materials in percentage by mass: 60-80 percent of aliphatic waterborne polyurethane emulsion, 5-10 percent of silica sol, 2-5 percent of titanium dioxide, 3-5 percent of mica, 1-3 percent of waterborne silicone oil, 0.1-0.5 percent of sodium dodecyl benzene sulfonate, 0.5-1 percent of alkali-swelled acrylic acid thickener, 0.3-0.6 percent of polyether modified dimethyl siloxane, 0.1-0.5 percent of acrylic copolymer sylvine, 0.1-0.5 percent of polyether modified organic silicon and the balance of distilled water; and the aliphatic waterborne polyurethane emulsion is prepared from the following raw materials in parts by mass: 40-80 parts of isophorone diisocyanate, 25-40 parts of polypropylene glycol, 25-80 parts of polyethylene glycol, 3-10 parts of dimethylolpropionic acid, 50-80 parts of butanone, 5-12 parts of diethylenetriamine, 3-9 parts of triethylamine, 1-3 parts of dibutyltin dilaurate and 40-80 parts of distilled water. The strippable temporary package film composition is prepared by selecting aliphatic waterborne polyurethane emulsion and silica sol as film-forming substances to improve the mechanical strength and strippable performance of coating and the durability for acid, alkali and salt solutions.

Owner:重庆市共赢包装制品有限公司

Preparation method of freeze-tolerant packaging film composition

InactiveCN106893474AEffectively control the reaction rateStrong cohesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention discloses a preparation method of a freeze-resistant packaging film composition, which includes the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding two Methylolpropionic acid, and then carry out vacuum distillation to obtain secondary products; 3) Disperse the secondary products in the second reaction kettle, add diethylenetriamine aqueous solution to prepare aliphatic water-based polyurethane emulsion; 4) Add to the second reaction kettle Add silica sol and aliphatic water-based polyurethane emulsion to the third reaction kettle to obtain a mixed emulsion for later use; 5) Add an appropriate amount of potassium salt of acrylic acid copolymer to the fourth reaction kettle to obtain a mixed bottom liquid; 6) Add it to the mixed bottom liquid The mixed emulsion is added to obtain a freeze-resistant packaging film composition. The packaging film composition prepared by the invention has strong cohesive force, good peelability, high coating film strength and good safety and environmental protection performance.

Owner:杨富元

Method for preparing water-based aliphatic polyurethane emulsion type strippable coating

InactiveCN106810986AEffectively control the reaction rateImprove water resistanceCoatingsWater basedPolymer science

The invention discloses a method for preparing a water-based aliphatic polyurethane emulsion type strippable coating. The method comprises the following procedures: (1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product to prepare acrylate modified aliphatic polyurethane emulsion; (3) adding silica sol and the acrylate modified aliphatic polyurethane emulsion into a third reaction kettle at room temperature to obtain mixed emulsion; (4) adding a proper amount of an acrylate copolymer potassium salt and the like into a fourth reaction kettle in which distilled water is contained to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution to obtain the water-based aliphatic polyurethane emulsion type strippable coating. By the prepared coating, a protected object can be effectively sealed and protected, and can be prevented from being polluted, corroded and damaged. In addition, the coating is also high in water resistance and strippability and stronger in cohesive force and coating film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-strength protective film composition coated film

InactiveCN106810708AEffectively control the reaction rateHigh strengthAntifouling/underwater paintsPaints with biocidesTectorial membraneWater based

The invention discloses a preparation method of a high-strength protective film composition coated film. The preparation method comprises the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product to obtain an aliphatic water-based polyurethane emulsion; 3) adding the aliphatic water-based polyurethane emulsion into a third reaction kettle to obtain a mixed emulsion for later use; 4) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; 5) adding the mixed emulsion into the mixed substrate to obtain a high-strength protective film composition; 6) wiping and airing the plastic film, and diluting the high-strength protective film composition for later use; and 7) spraying the high-strength protective film composition onto the plastic film, and airing to obtain the high-strength protective film composition coated film. The coated film is convenient for testing the tensile property, corrosion resistance, moisture permeability, peel strength and other properties of the protective film composition.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-stability protective coating

InactiveCN106810658AImprove stabilityStrong cohesionPolyurea/polyurethane coatingsDistillationPotassium

The invention discloses a preparation method of a high-stability protective coating. The preparation method comprises the following processes: (1) dewatering and drying raw materials; (2) adding isophorone diisocyanate and the like into a first reaction kettle at the room temperature to obtain a primary product; (3) adding dimethylolpropionic acid into the primary product, and then carrying out reduced pressure distillation to obtain a secondary product; (4) preparing aliphatic waterborne polyurethane emulsion; (5) preparing modified silica sol; (6) adding the aliphatic waterborne polyurethane emulsion and the modified silica sol into a third reaction kettle at the room temperature to obtain mixed emulsion; (7) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (8) adding the mixed emulsion into the mixed base solution to obtain the high-stability protective coating. The high-stability protective coating prepared by the method has stronger cohesion, good strippable property, higher coating strength, better safety and environmental protection performance and higher stability.

Owner:重庆市共赢包装制品有限公司

Preparation method of strippable coating for protection

InactiveCN106811061AEffectively control the reaction rateImprove stabilityPolyurea/polyurethane coatingsPotassiumDistilled water

The invention discloses a preparation method of a strippable coating for protection. The preparation method comprises the following processes: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature to obtain a primary product; (2) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (4) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution to obtain the strippable coating for protection. The coating prepared by the method can be used for effectively sealing and protecting an object to be protected so as to prevent the object from being contaminated, corroded and damaged. Furthermore, the coating also has higher stability, stronger cohesion, good strippable property and higher coating strength.

Owner:重庆市共赢包装制品有限公司

Modified silica sol/polyurethane emulsion compound peelable protective paint

InactiveCN106811048AHigh mechanical strengthExcellent peelabilityAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterWater based

The invention discloses a modified silica sol / polyurethane emulsion compound peelable protective paint which is prepared from the following raw materials in percentage by mass: 60-80% of aromatic water-based polyurethane emulsion, 5-10% of silica sol, 3-8% of talcum powder, 1-3% of emulsified silicone oil, 0.1-0.5% of acrylate copolymer ammonium salt solution, 0.5-1% of alkali-swellable acrylic thickener, 0.3-0.6% of polyether polyester modified organosiloxane, 0.1-0.5% of acrylic acid copolymer potassium salt, 0.1-0.5% of polyether-modified organic silicon and the balance of distilled water. The aromatic water-based polyurethane emulsion and silica sol are compounded as the film forming matter, thereby enhancing the mechanical strength, peelability and acid / alkali / salt solution resistance of the paint. By using the talcum powder as the filler, thereby preventing the paint coating from cracking, and enhancing the leveling property, scrub resistance, water resistance and the like of the paint. The adopted alkali-swellable acrylic thickener can enhance the viscosity of the disperse system, increase the thickness of the paint and enhance the stability of the paint.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-water-resistance packaging paint coated film

InactiveCN106811092AEffectively control the reaction rateImprove stabilityLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedToluene diisocyanate

The invention discloses a preparation method of a high-water-resistance packaging paint coated film. The preparation method comprises the following steps: 1) adding toluene diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product to obtain an aromatic water-based polyurethane emulsion; 3) adding a silica sol and the aromatic water-based polyurethane emulsion into a third reaction kettle to obtain a mixed emulsion; 4) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; 5) adding the mixed emulsion into the mixed substrate to obtain a high-water-resistance packaging paint; 6) wiping and airing the plastic film, and diluting the high-water-resistance packaging paint for later use; and 7) spraying the high-water-resistance packaging paint onto the plastic film, and airing to obtain the high-water-resistance packaging paint coated film. The coated film is convenient for testing the tensile property, corrosion resistance, moisture permeability, peel strength and other properties of the paint.

Owner:重庆市共赢包装制品有限公司

High-stability protective paint

InactiveCN106811073AHigh mechanical strengthExcellent peelabilityAntifouling/underwater paintsPaints with biocidesEthylenediamineWater based

The invention discloses a high-stability protective paint which is prepared from the following raw materials in percentage by mass: 60-80% of aromatic water-based polyurethane emulsion, 5-10% of silica sol, 3-8% of talcum powder, 1-3% of emulsified silicone oil, 0.1-0.5% of acrylate copolymer ammonium salt solution, 0.5-1% of alkali-swellable acrylic thickener, 0.3-0.6% of polyether polyester modified organosiloxane, 0.1-0.5% of acrylic acid copolymer potassium salt, 0.1-0.5% of polyether-modified organic silicon and the balance of distilled water. The aromatic water-based polyurethane emulsion is prepared from the following raw materials in parts by mass: 40-80 parts of toluene diisocyanate, 40-80 parts of polypropylene glycol, 3-10 parts of dimethylolpropionic acid, 50-80 parts of butanone, 5-12 parts of ethylenediamine, 3-11 parts of triethylamine, 1-3 parts of dibutyltin dilaurate and 40-80 parts of distilled water. The paint prepared by the method can effectively perform sealed protection on the protected object, thereby preventing the protected object from pollution, corrosion and damage. Meanwhile, the paint has the advantages of higher stability, higher cohesive force, favorable peelability and higher coated film strength.

Owner:重庆市共赢包装制品有限公司

Water-tolerant coating based on epoxy resin modified polyurethane emulsion

InactiveCN106811086AImprove water resistanceExcellent peelabilityAntifouling/underwater paintsPaints with biocidesPolyesterEpoxy

The invention discloses a water-tolerant coating based on an epoxy resin modified polyurethane emulsion. The water-tolerant coating is prepared from the following raw materials in mass fraction: 60%-80% of an epoxy-modified aliphatic waterborne polyurethane emulsion, 5%-10% of modified silica sol, 3%-8% of talcum powder, 1%-3% of emulsified silicone oil, 0.1%-0.5% of an acrylate copolymer ammonium salt solution, 0.5%-1% of an alkali-swelling acrylate thickener, 0.3%-0.6% of polyether polyester modified organic siloxane, 0.1%-0.5% of acrylic copolymer sylvite, 0.1%-0.5% of polyether modified organosilicone and the balance of distilled water, wherein the epoxy-modified aliphatic waterborne polyurethane emulsion is prepared from the following raw materials in parts by mass: 40-80 parts of toluene diisocynate, 25-40 parts of polypropylene glycol, 25-60 parts of polyethylene glycol, 3-10 parts of dimethylolpropionic acid, 5-12 parts of epoxy resin, 50-80 parts of butanone, 4-10 parts of diethylenetriamine, 3-11 parts of triethylamine, 1-3 parts of dibutyltin dilaurate and 40-80 parts of distilled water. The coating disclosed by the invention has excellent water tolerance, relatively high stability, relatively strong cohesion, good peelable property and relatively high paint film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of modified silica sol/polyurethane emulsion compound peelable protective paint

InactiveCN106811075AImprove stabilityImprove cohesionPolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsWater basedToluene diisocyanate

The invention discloses a preparation method of a modified silica sol / polyurethane emulsion compound peelable protective paint. The preparation method comprises the following steps: 1) adding toluene diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product, and adding triethylamine to obtain an aromatic water-based polyurethane emulsion; 3) preparing a modified silica sol; 4) adding the modified silica sol and aromatic water-based polyurethane emulsion into a third reaction kettle at room temperature to obtain a mixed emulsion for later use; 5) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; and 6) adding the mixed emulsion into the mixed substrate to obtain the modified silica sol / polyurethane emulsion compound peelable protective paint. The protective paint prepared by the method can effectively perform sealed protection on the protected object, thereby preventing the protected object from pollution, corrosion and damage.

Owner:重庆市共赢包装制品有限公司

Preparation method of protective packaging film composition

InactiveCN106928835AEffectively control the reaction rateEffective closed protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceRoom temperature

The invention discloses a preparation method of a protective packaging film composition. The preparation method comprises the following procedures: 1) dehydrating and drying the raw material; 2) adding toluene diisocynate and the like into a first reaction kettle at the room temperature to obtain a primary product; 3) adding dimethylolpropionic acid into the primary product, then adding triethylamine to obtain an aromatic waterborne polyurethane emulsion; 4) adding a silica solution and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature to obtain a mixed emulsion; 5) adding proper amount of acrylic copolymer sylvite and the like into the mixed emulsion to obtain a crude product; and 6) adding talcum powder into the crude product to obtain the protective packaging film composition. The prepared packaging film composition can effectively protect a protected article in a closed manner, and the protected article is prevented from being polluted, corroded or damaged. Meanwhile, a coating is further higher in stability, stronger in cohesion, excellent in peeling performance, and higher in coating strength.

Owner:蒋正红

Preparation method of waterproof packaging film composition

InactiveCN106893471AEffectively control the reaction rateStrong cohesionAntifouling/underwater paintsPaints with biocidesDistillationDiethylenetriamine

The invention discloses a preparation method of a water-resistant packaging film composition, comprising the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding diisocyanate into the primary product; Methylolpropionic acid, and then carry out vacuum distillation to obtain secondary products; 3) Disperse the secondary products in the second reaction kettle, add diethylenetriamine aqueous solution to prepare aliphatic water-based polyurethane emulsion; 4) Add to the second reaction kettle Add silica sol and aliphatic water-based polyurethane emulsion to the third reaction kettle to obtain a mixed emulsion for later use; 5) Add an appropriate amount of potassium salt of acrylic acid copolymer to the fourth reaction kettle to obtain a mixed bottom liquid; 6) Add it to the mixed bottom liquid The mixed emulsion is added to obtain a water-resistant packaging film composition. The packaging film composition prepared by the invention has strong cohesive force, good peelability, high coating film strength and good safety and environmental protection performance.

Owner:彭忠芳

Protecting film composition based on modified silica sol emulsion

InactiveCN106811078AAvoid pollutionStrong cohesionAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionSODIUM DODECYL BENZENE SULFONATE

The invention discloses a protecting film composition based on a modified silica sol emulsion. The protecting film composition is prepared from the following raw materials in mass fraction: 60%-80% of an aliphatic waterborne polyurethane emulsion, 5%-10% of modified silica sol, 2%-5% of titanium dioxide, 3%-5% of mica, 1%-3% of waterborne silicone oil, 0.1%-0.5% of sodium dodecyl benzene sulfonate, 0.5%-1% of an alkali-swelling acrylate thickener, 0.3%-0.6% of polyether modified dimethyl siloxane, 0.1%-0.5% of acrylic copolymer sylvite, 0.1%-0.5% of polyether modified organosilicone and the balance of distilled water. According to the protecting film composition, the aliphatic waterborne polyurethane emulsion and the modified silica sol are compounded to form a film forming matter, so that the mechanical strength, peelable property and acid-base salt solution resistance of a coating can be improved; and the mica is taken as a filling, so that the properties such as hardness, strength, wear resistance and base material adhesive force of a coating paint film can be improved.

Owner:重庆市共赢包装制品有限公司

Preparation method of waterborne polyurethane coating

InactiveCN106811066AStrong cohesionExcellent peelabilityPolyurea/polyurethane coatingsPropanoic acidEmulsion

The invention discloses a preparation method of waterborne polyurethane coating. The preparation method comprises the following procedures: 1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding dihydromethyl propionic acid into the primary product and adding triethylamine to prepare aliphatic waterborne polyurethane emulsion; 3) preparing modified silica sol; 4) adding the aliphatic waterborne polyurethane emulsion and the modified silica sol into a third reaction kettle at room temperature to obtain mixed emulsion; 5) adding a proper amount of an acrylic copolymer potassium salt and the like into a fourth reaction kettle containing distilled water to obtain a mixed base solution; 6) adding the mixed emulsion into the mixed base solution to obtain the waterborne polyurethane coating. The coating prepared by the preparation method can be used for carrying out effective sealed protection on a protected object and preventing the protected object from being polluted, corroded and damaged. Meanwhile, the coating also has the advantages of good strippable property, high film coating strength, high cohesive force and high stability.

Owner:重庆市共赢包装制品有限公司

Method for preparing powder coating

InactiveCN106893479AStrong cohesionExcellent peelabilityAnti-corrosive paintsPolyurea/polyurethane coatingsDistilled waterRoom temperature

The invention discloses a method for preparing a powder coating. The method comprises the following steps: 1) adding isophorone diisocyanate and the like into a first reactor at room temperature so as to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product, and adding triethylamine so as to prepare aliphatic powder emulsion; 3) preparing modified silica sol; 4) adding the aliphatic powder emulsion and the modified silica sol into a third reactor at room temperature so as to obtain mixed emulsion; 5) adding a proper amount of acrylic copolymer potassium salt and the like into a fourth reactor filled with distilled water so as to obtain a mixed base solution; and 6) adding the mixed emulsion into the mixed base solution, thereby obtaining the powder coating. According to the coating prepared by the invention, a protected object can be subjected to effective enclosed protection, and is prevented from being polluted, corroded and damaged. Meanwhile, the coating has the advantages of strippable property, high coating strength, high cohesion and high stability.

Owner:宋容

Preparation method of mixed emulsion type packaging protective film composition

InactiveCN106811059AEffective closed protectionAvoid pollutionPolyurea/polyurethane coatingsPolymer sciencePotassium

The invention discloses a preparation method of a mixed emulsion type packaging protective film composition. The preparation method comprises the following processes: adding toluene diisocynate and the like into a first reaction kettle at the room temperature to obtain a primary product; (2) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (4) adding right amount of acrylic copolymer potassium salt and the like into the mixed emulsion to obtain a crude product; (5) adding talcum powder into the crude product to obtain the mixed emulsion type packaging protective film composition. The mixed emulsion type packaging protective film composition prepared by the method has the advantages of being simple and convenient to operate and high in production efficiency, and can be used for effectively and temporarily sealing and protecting an object to be protected.

Owner:重庆市共赢包装制品有限公司

Preparation method of water-tolerant packaging film composition

InactiveCN106811070AEffectively control the reaction rateEffective closed protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceDistilled water

The invention discloses a preparation method of a water-tolerant packaging film composition. The preparation method comprises the following procedures: (1) adding isophorone diisocyanate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) sequentially adding dimethylolpropionic acid and triethylamine into the primary product, so as to prepare an aliphatic waterborne polyurethane emulsion; (3) adding silica sol and the aliphatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion for later use; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the water-tolerant packaging film composition. By utilizing the water-tolerant packaging film composition prepared by virtue of the preparation method, a protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. Meanwhile, the water-tolerant packaging film composition further has relatively strong cohesion, good peelable property and relatively high film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of aromatic polyurethane emulsion water-based paint

InactiveCN106811069AEffectively control the reaction rateImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyWater based

The invention discloses a preparation method of an aromatic polyurethane emulsion water-based paint. The preparation method comprises the following steps: 1) preparing an epoxy resin-butanone solution; drying raw materials; 2) adding toluene diisocyanate and the like into a first reaction kettle to obtain a primary product; 3) adding dimethylolpropionic acid into the primary product, and adding triethylamine to obtain an epoxy modified aromatic polyurethane emulsion; 4) adding a silica sol and the epoxy modified aromatic polyurethane emulsion into a third reaction kettle at room temperature to obtain a mixed emulsion for later use; 5) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; and 6) adding the mixed emulsion into the mixed substrate to obtain the aromatic polyurethane emulsion water-based paint. The paint disclosed by the invention has the advantages of excellent water resistance, higher stability, higher cohesive force, favorable peelability and higher coated film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of environment-friendly packaging material

InactiveCN106810987AEffectively control the reaction rateHigh peel strengthAnti-corrosive paintsRoom temperatureDistilled water

The invention discloses a preparation method of an environment-friendly packaging material. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution, so as to obtain the environment-friendly packaging material; (6) carrying out wiping and air-drying on a plastic film, and diluting the environment-friendly packaging material; and (7) spraying the environment-friendly packaging material to the plastic film, so as to obtain an environment-friendly packaging material paint film. By utilizing the environment-friendly packaging material prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented.

Owner:重庆市共赢包装制品有限公司

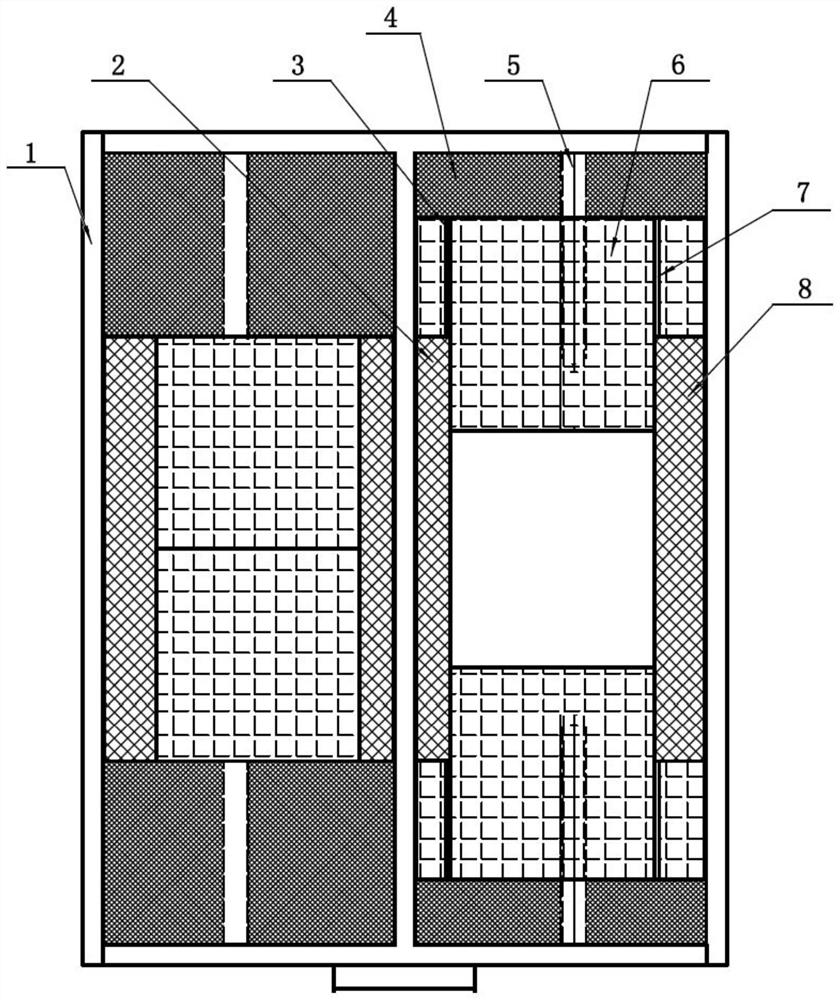

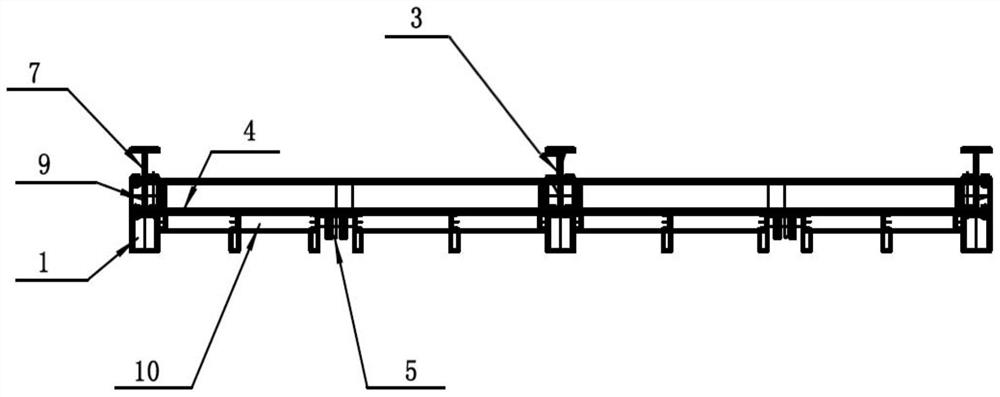

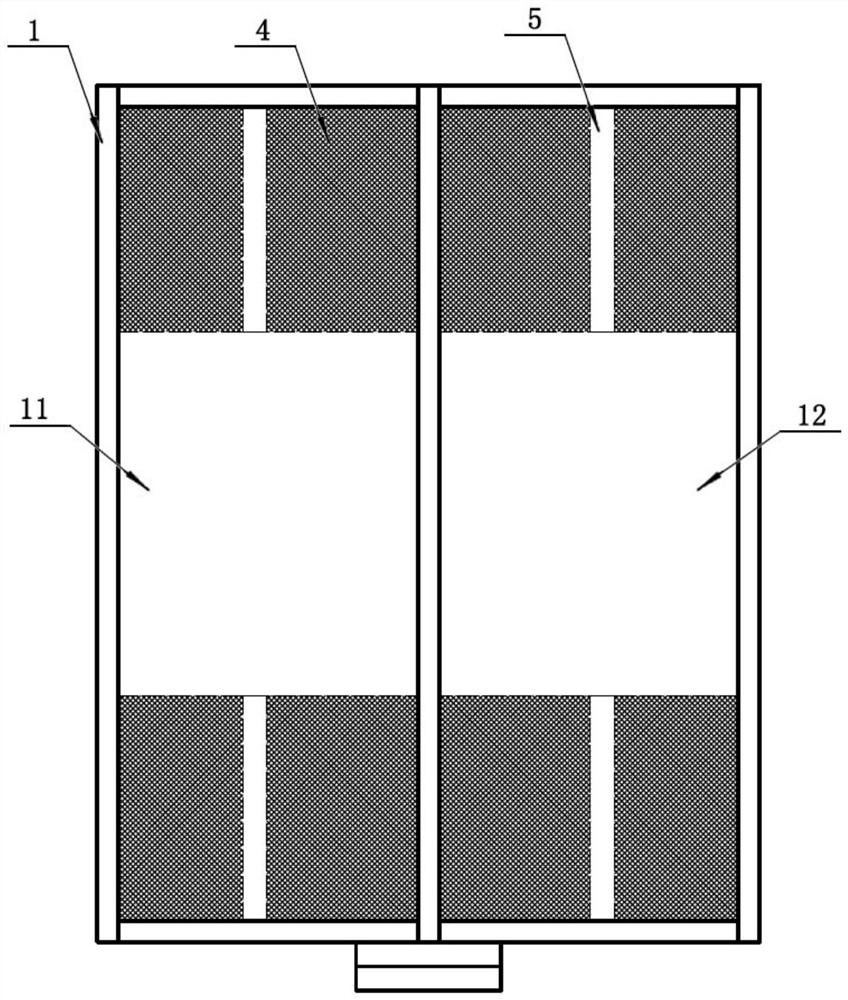

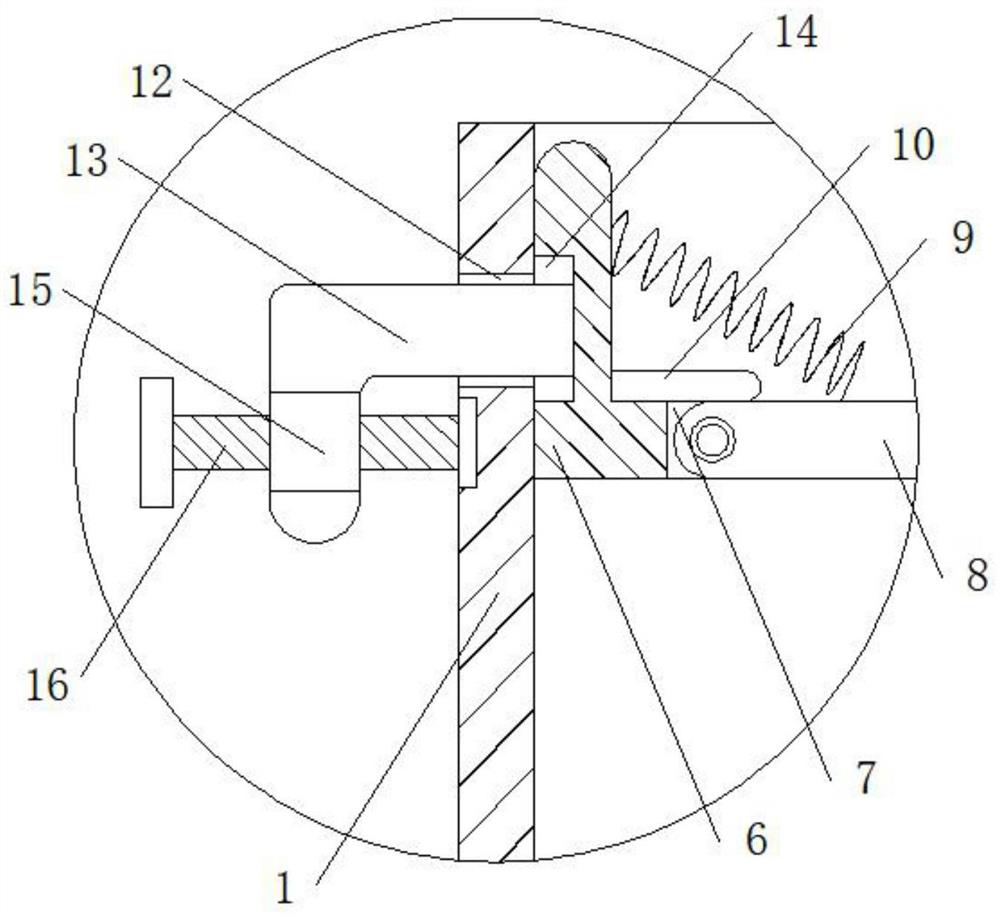

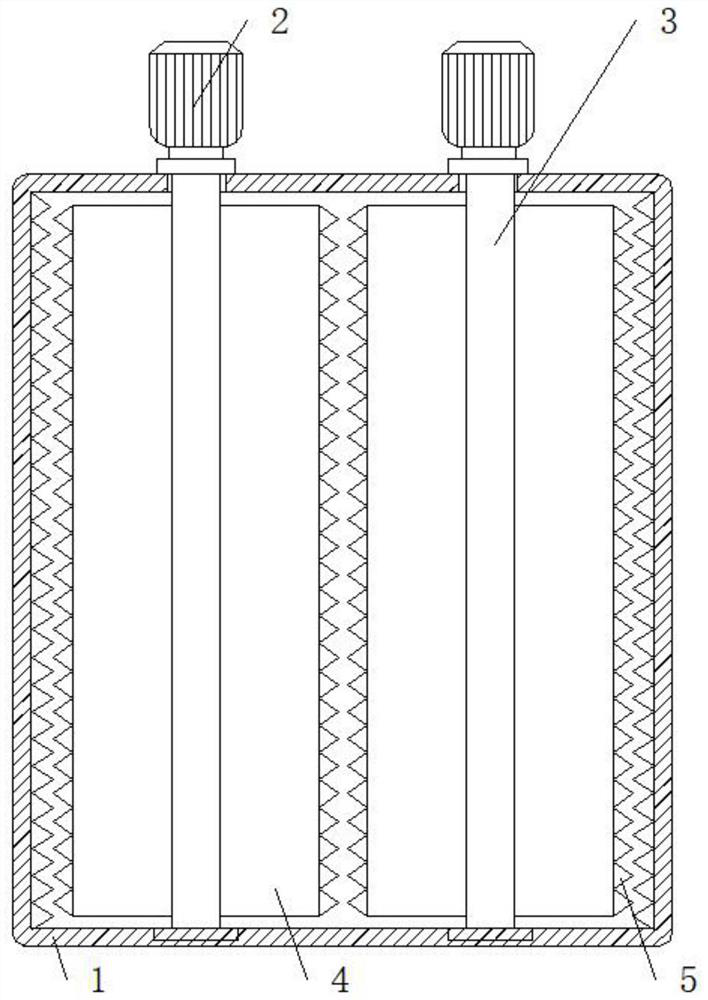

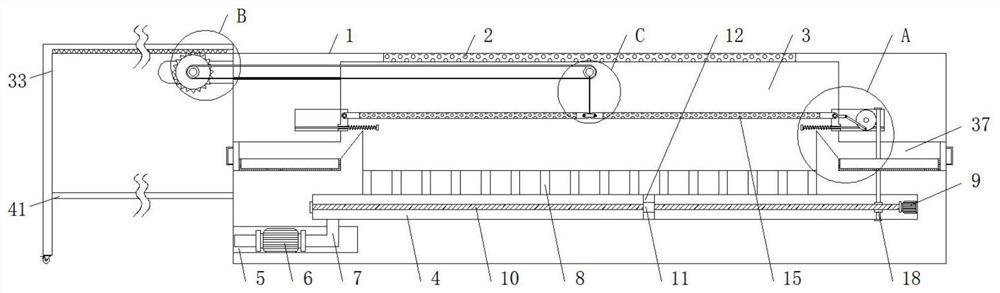

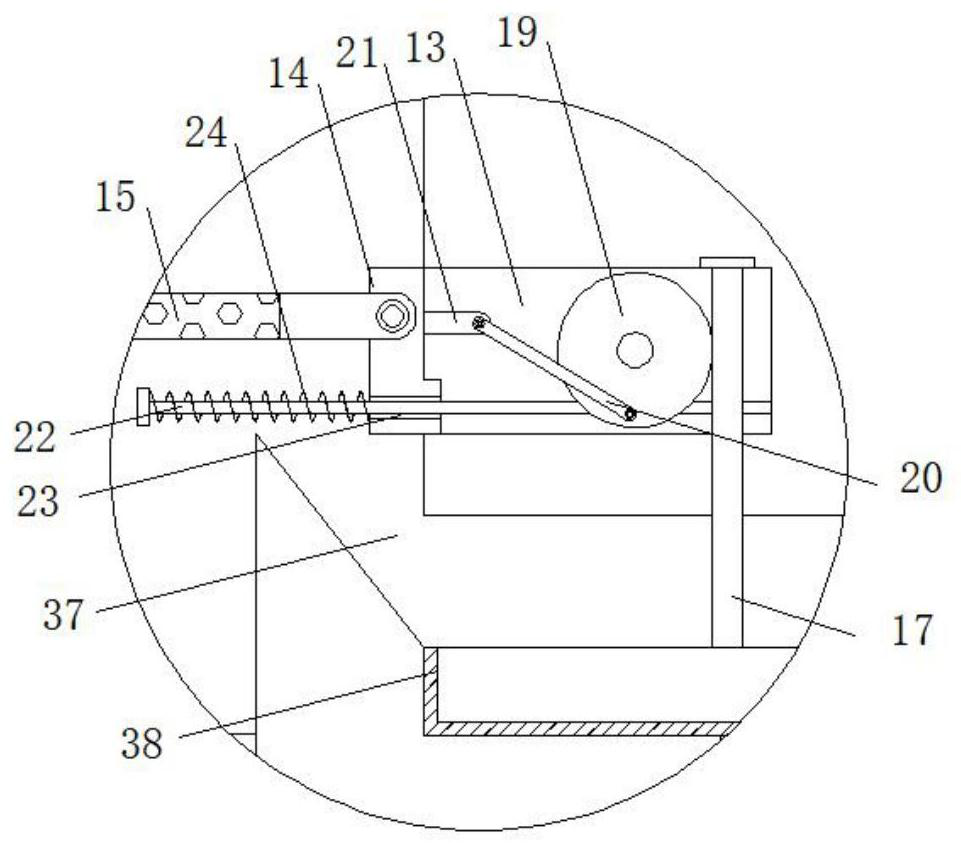

Skip bucket vertical shaft wellhead sealing maintenance platform

The invention provides a skip bucket vertical shaft wellhead sealing maintenance platform. The skip bucket vertical shaft wellhead sealing maintenance platform comprises a main support, and further comprises two bottom sealing platforms, two middle sealing platforms and two top sealing platforms which are sequentially installed on the main support from bottom to top; and each bottom sealing platform comprises two bottom layer platform supports and two bottom layer sealing plates. According to the skip bucket vertical shaft wellhead sealing maintenance platform, a hydraulic oil cylinder can push a plurality of main platform sealing plates to oppositely move on a main platform track so that the four main platform sealing plates can be all pushed to the position above a wellhead, effective sealing protection is formed on the wellhead, foreign matters are prevented from entering the wellhead, an inner side sealing plate and an outer side sealing plate are moved to be close to a skip bucket, then positioning pins are used for fixing the inner side sealing plate and the outer side sealing plate so that a worker can stand on the inner side sealing plate and the outer side sealing plate to check and maintain the skip bucket, and the maintenance becomes simple and convenient.

Owner:云南悦真机械设备有限公司

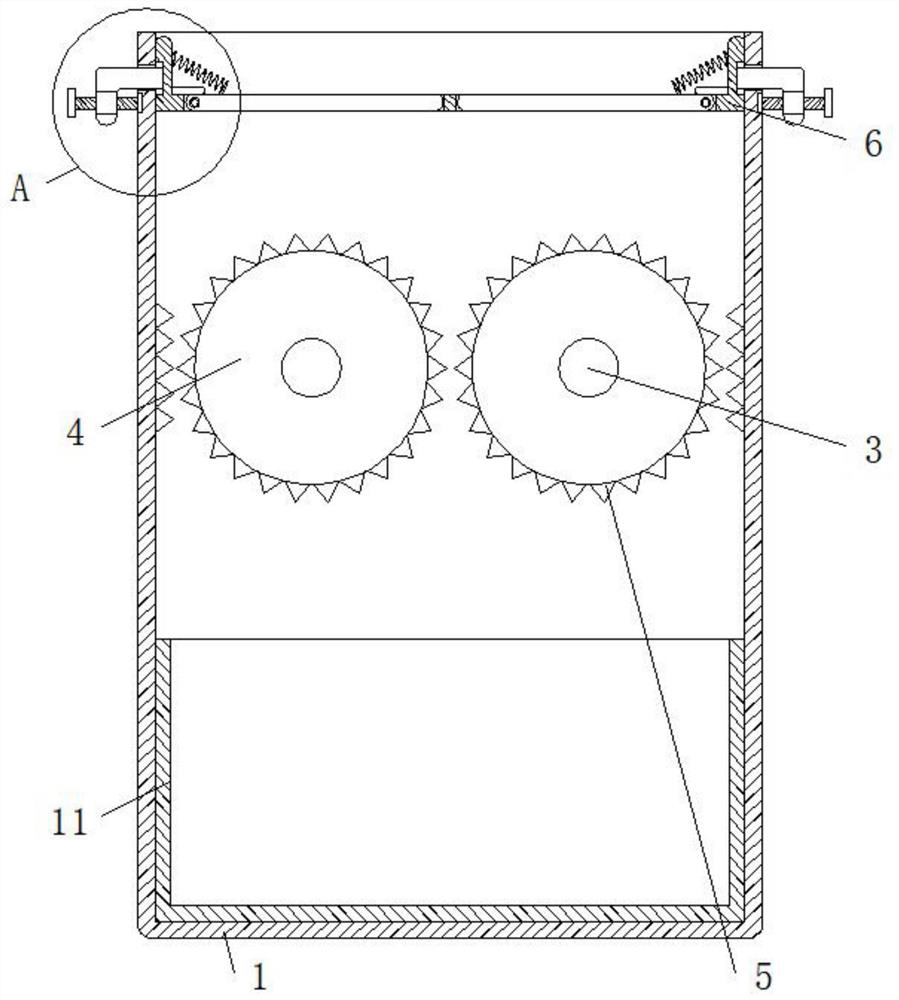

Cement kiln solid waste treatment device and treatment method

PendingCN113102018ARapid crushingEasy to put inIncinerator apparatusGrain treatmentsThermodynamicsProcess engineering

The invention discloses a cement kiln solid waste treatment device and a treatment method and relates to the technical field of waste treatment. Aiming at the problem that an existing cement kiln is low in solid waste treatment efficiency, the following scheme is provided; the cement kiln solid waste treatment device comprises a shell, a crushing mechanism is arranged in the shell, a stop block is connected to the interior of the shell in a sliding mode, a connecting mechanism is arranged on the shell, the stop block is connected to the interior of the shell through the connecting mechanism, the stop block is located below the crushing mechanism, and feeding grooves are formed in the two ends of the stop block. According to the cement kiln solid waste treatment device, solid waste can be quickly crushed, so that a user can conveniently throw the solid waste into a combustion furnace of a cement kiln, and therefore, the treatment efficiency of the solid waste is effectively improved; and moreover, a feeding part of the treatment device can be effectively sealed and protected, the user can conveniently take out the treated solid waste, and therefore, the treatment progress of the solid waste is effectively improved, and the working performance is high.

Owner:HWASU

Preparation method of waterproof material

InactiveCN106893472AStrong cohesionExcellent peelabilityPolyurea/polyurethane coatingsPotassiumDistilled water

The invention discloses a preparation method of a waterproof coating, which comprises the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding dimethylolpropane into the primary product acid, and then add triethylamine to prepare aliphatic waterproof emulsion; 3) prepare modified silica sol; 4) add aliphatic waterproof emulsion and modified silica sol to the third reaction kettle at room temperature to obtain a mixed emulsion; 5) Adding an appropriate amount of acrylic acid copolymer potassium salt and the like to the fourth reaction kettle filled with distilled water to obtain a mixed bottom liquid; 6) Adding a mixed emulsion to the mixed bottom liquid to obtain a waterproof coating. The paint prepared by the invention can effectively seal and protect the protected object, preventing the protected object from being polluted, corroded and damaged. At the same time, the coating also has the advantages of good peelability, high coating film strength, strong cohesion and high stability.

Owner:彭忠芳

Preparation method of anti-corrosion coating

InactiveCN106811088AEffectively control the reaction rateImprove securityAntifouling/underwater paintsPaints with biocidesMeth-Propanoic acid

The invention discloses a preparation method of the anti-corrosion coating. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) sequentially adding dimethylolpropionic acid and triethylamine into the primary product, so as to obtain an aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion for later use; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the anti-corrosion coating. By utilizing the anti-corrosion coating by prepared by virtue of the preparation method, a protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. Meanwhile, the coating further has relatively high stability, relatively strong cohesion, good peelable property and relatively high film strength.

Owner:重庆市共赢包装制品有限公司

Shaping auxiliary device for module patch machining

ActiveCN113681780AImprove processing efficiencyImprove battery lifeFouling preventionDispersed particle filtrationProcess engineeringMachining

The invention discloses a shaping auxiliary device for module patch machining, and relates to the technical field of module machining. For the following the problem of poor working performance of an existing mold, the following scheme is put forward now; the shaping auxiliary device comprises a mold main body and an installation cavity formed in the mold main body, and the mold main body is provided with an air exhaust assembly for gas exhaust; and the mold main body is further provided with a sealing assembly used for sealing the mold main body, and a filtering assembly is arranged in the installation cavity. According to the shaping auxiliary device, gas suction and adsorption can be conducted on membrane materials on the mold, gaps between the membrane materials are reduced, product fluffiness is avoided, it is ensured that the sizes of mold sets are consistent, then the product quality is effectively improved, the gas suction range can be flexibly adjusted, dust and impurities sucked in the gas suction process can be filtered out, the working performance is high, and use is convenient.

Owner:星源电子科技(深圳)有限公司

Preparation method of waterborne peelable protecting film composition

InactiveCN106811077AEffectively control the reaction rateEffective closed protectionAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

Owner:重庆市共赢包装制品有限公司

Preparation method of high temperature-resistant packaging film composition

InactiveCN106893071AStrong cohesionExcellent peelabilityAnti-corrosive paintsPolyurea/polyurethane coatingsDistillationDiethylenetriamine

The invention discloses a preparation method of a high temperature-resistant packaging film composition. The method comprises the following steps: 1, adding isophorone diisocyanate into a first reaction kettle at room temperature to obtain a primary product; 2, adding dimethylolpropionic acid to the primary product, and carrying out reduced pressure distillation to obtain a secondary product; 3, dispersing the secondary product in a second reaction kettle, and adding an aqueous diethylenetriamine solution to prepare an aliphatic aqueous polyurethane emulsion; 4, adding silica sol and the aliphatic aqueous polyurethane emulsion into a third reaction kettle to prepare a mixed emulsion for later use; 5, adding a proper amount of a potassium salt of an acrylic copolymer into a fourth reaction kettle to obtain a mixed base solution; and 6, adding the mixed emulsion to the mixed base solution to obtain the high temperature-resistant packaging film composition. The high temperature-resistant packaging film composition prepared through adopting the method has the advantages of strong cohesive force, good strippable property, high coating strength and good safety and environmentally-friendly performance.

Owner:张世禄

Preparation method of acrylate modified polyurethane protecting packaging film composition

InactiveCN106811106AEffectively control the reaction rateEffective closed protectionPolyurea/polyurethane coatingsChemistryToluene

The invention discloses a preparation method of an acrylate modified polyurethane protecting packaging film composition. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the acrylate modified polyurethane protecting packaging film composition. By utilizing the packaging film composition prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. The packaging film composition further has excellent water tolerance, relatively high stability, relatively strong cohesion, good peelable property and relatively high paint film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-coating-strength packaging body composition

InactiveCN106811065AImprove securityImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPotassium

The invention discloses a preparation method of a high-coating-strength packaging body composition. The method comprises the following processes: (1) preparing an epoxy resin-butanone solution; dewatering and drying raw materials; (2) adding toluene diisocynate and the like into a first reaction kettle to obtain a primary product; (3) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare epoxy-modified aromatic polyurethane emulsion; (4) adding silica sol and the epoxy-modified aromatic polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (5) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (6) adding the mixed emulsion into the mixed base solution to obtain the high-coating-strength packaging body composition. The high-coating-strength packaging body composition prepared by the method has higher safety, excellent water resistance, higher stability, stronger cohesion, good strippable property and higher coating strength.

Owner:重庆市共赢包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com