Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about "Shaft repair/replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

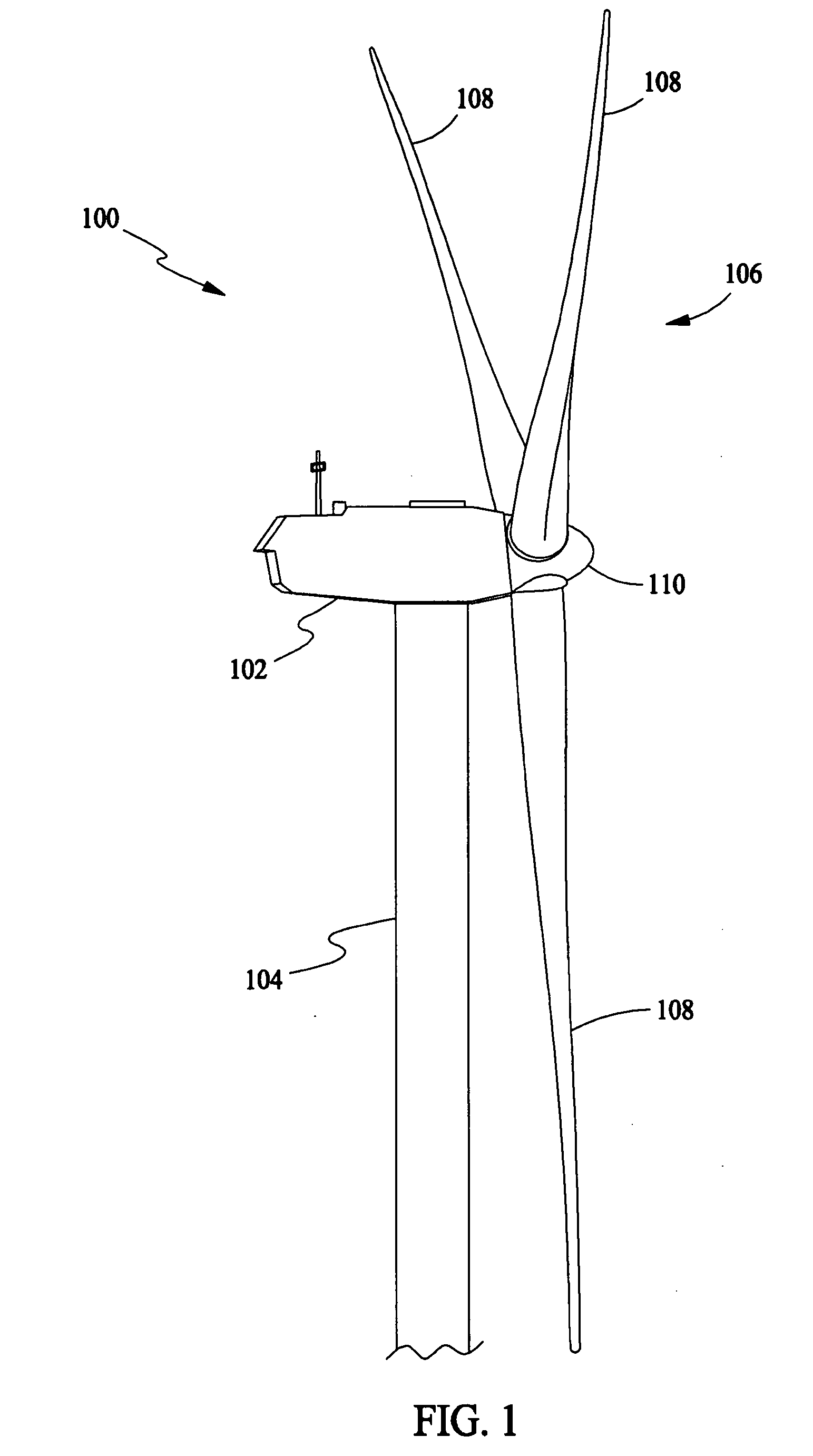

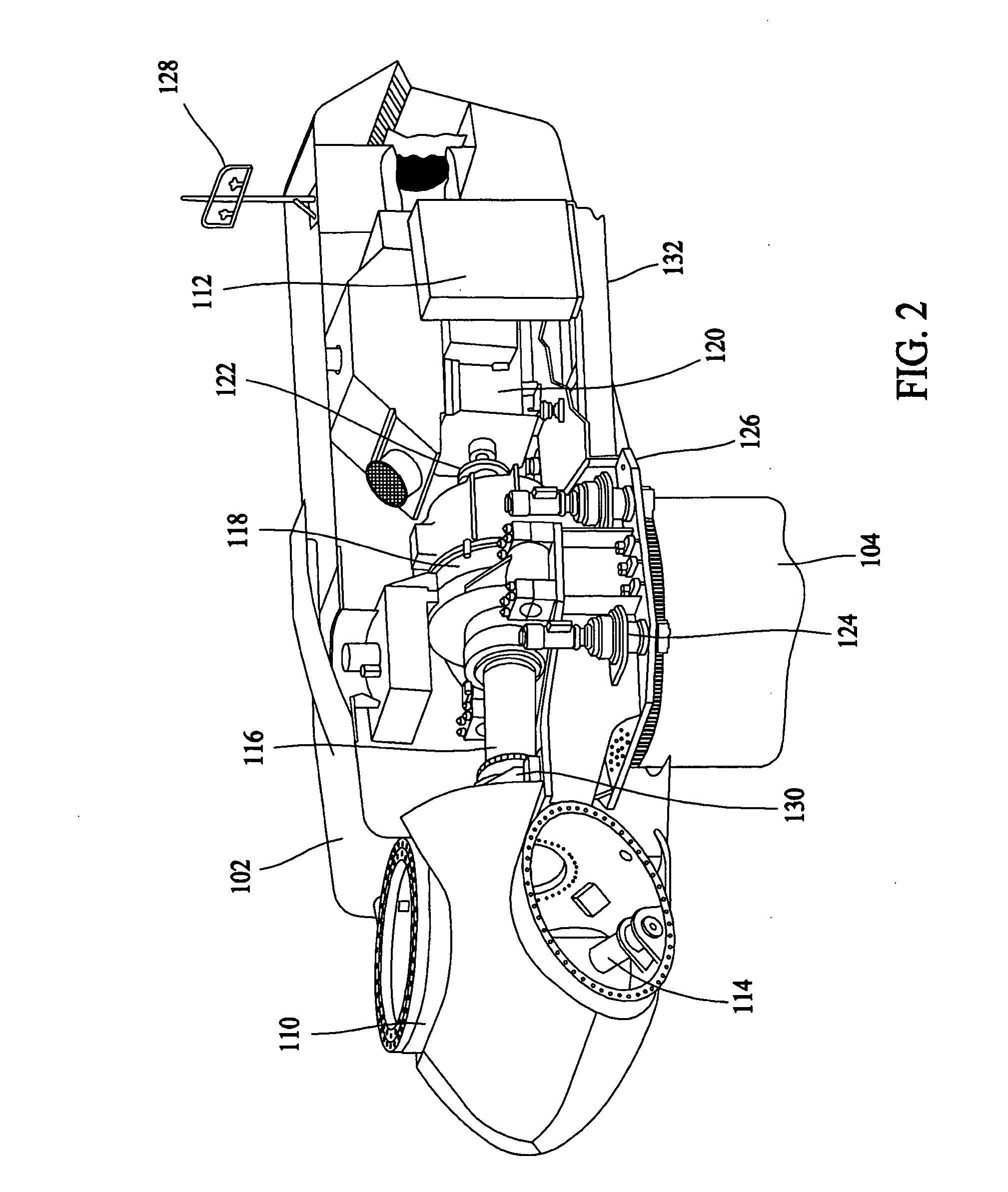

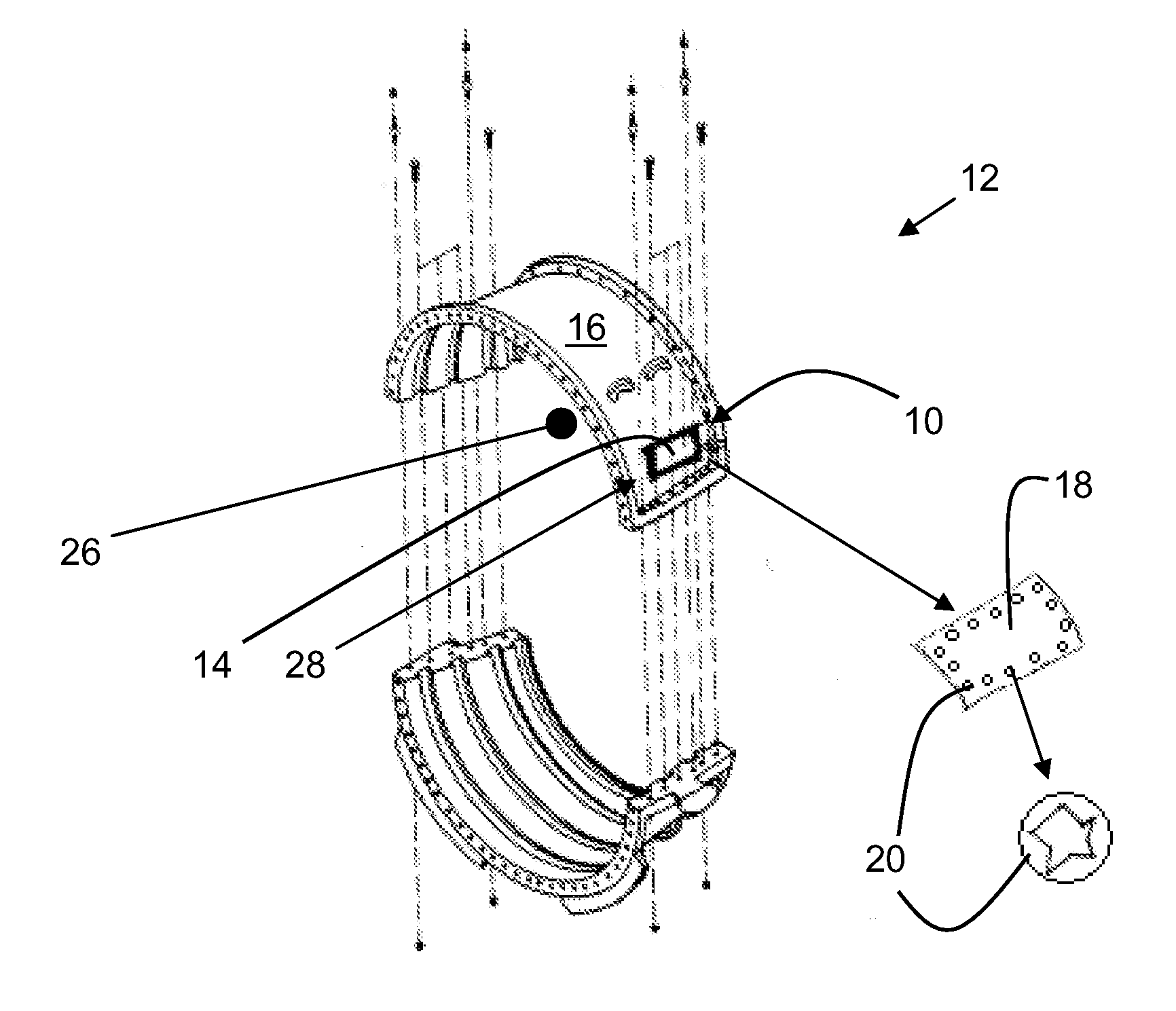

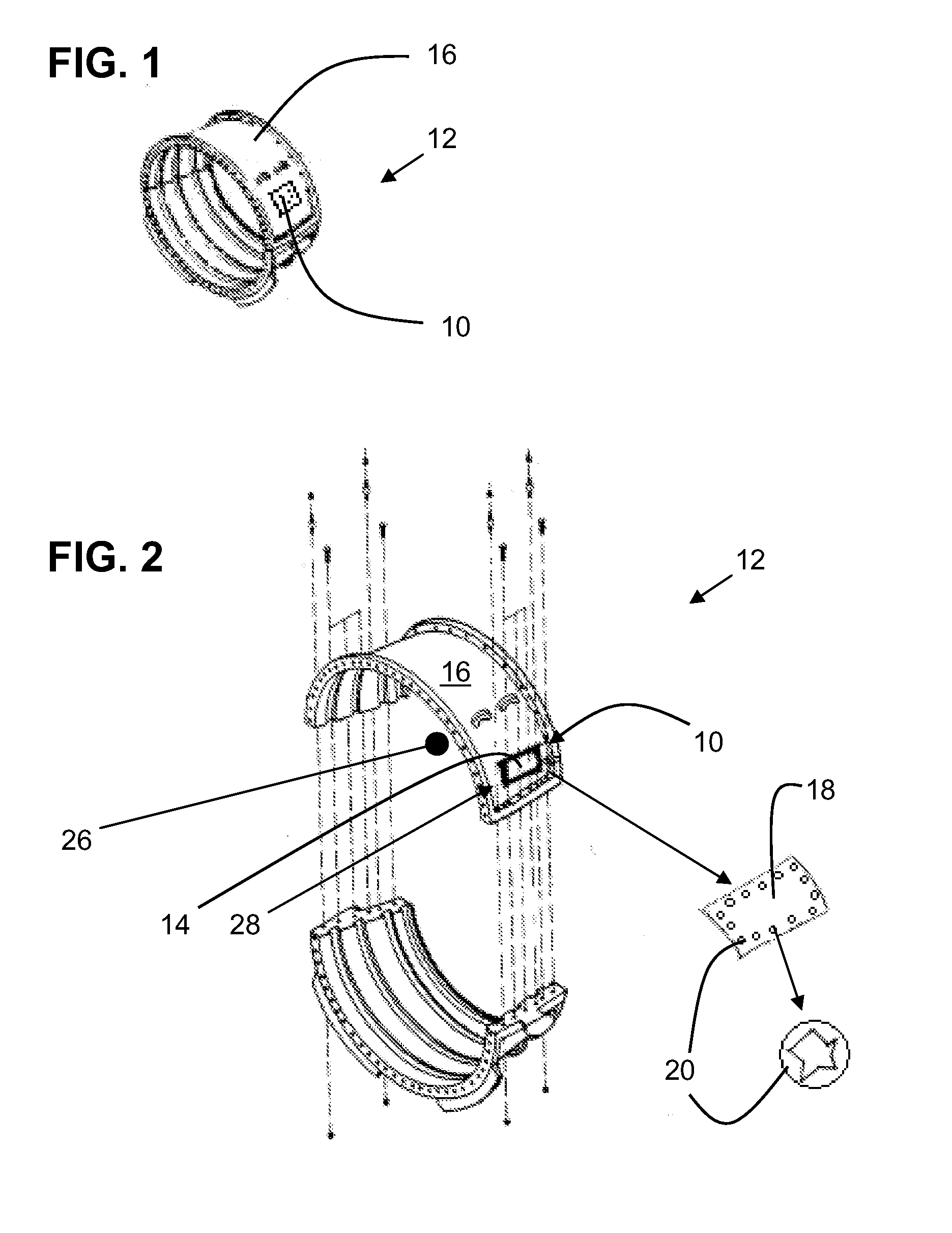

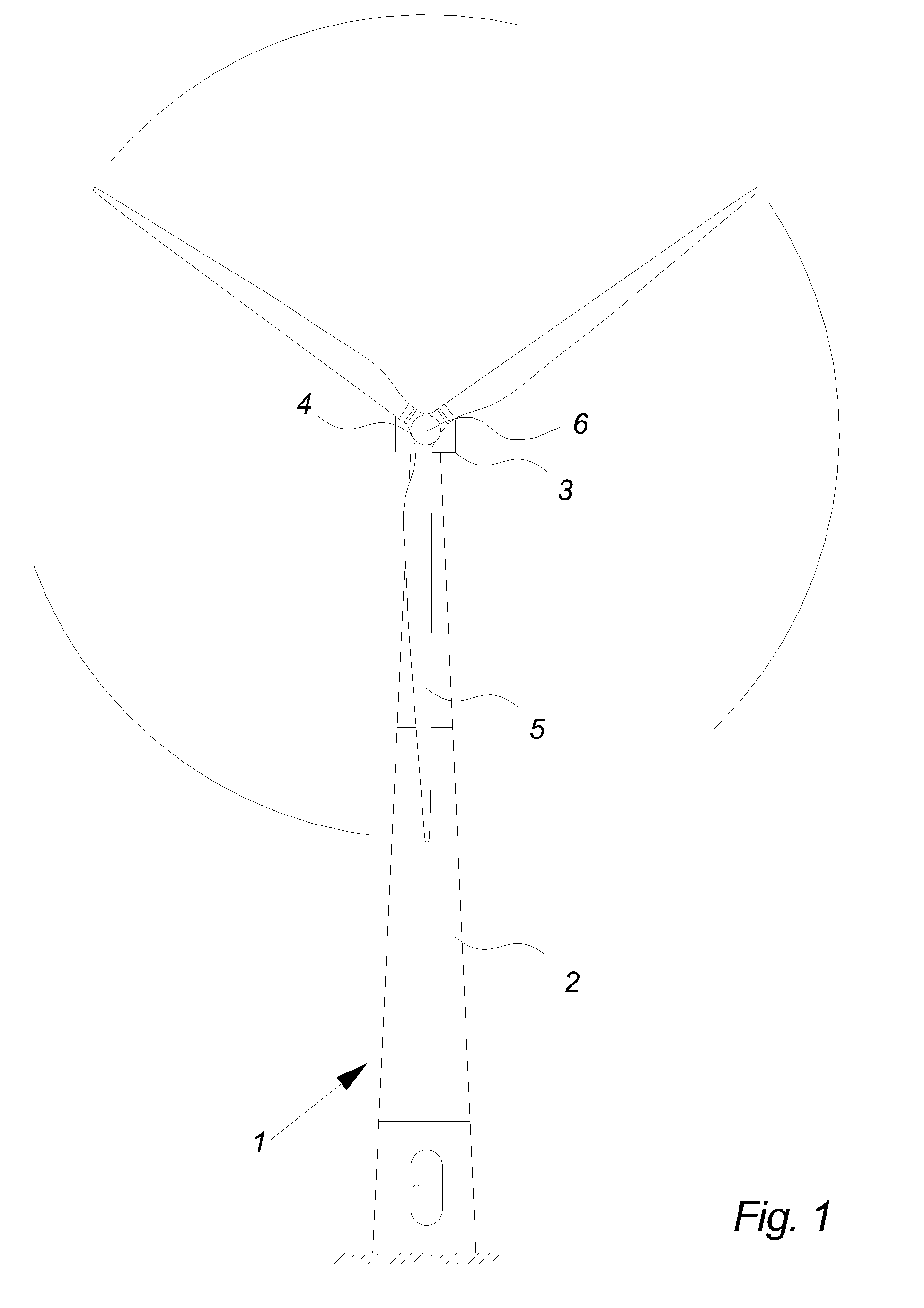

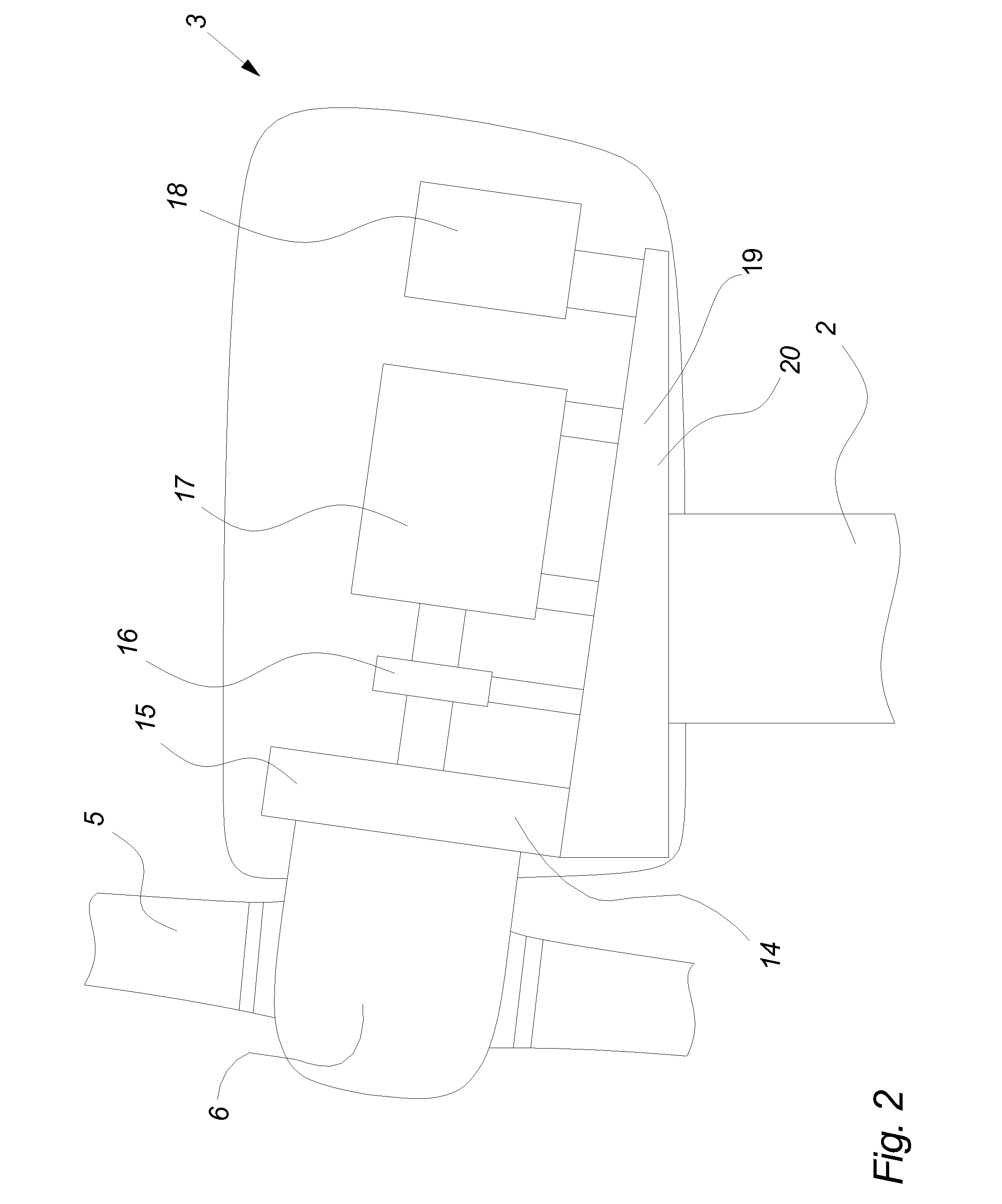

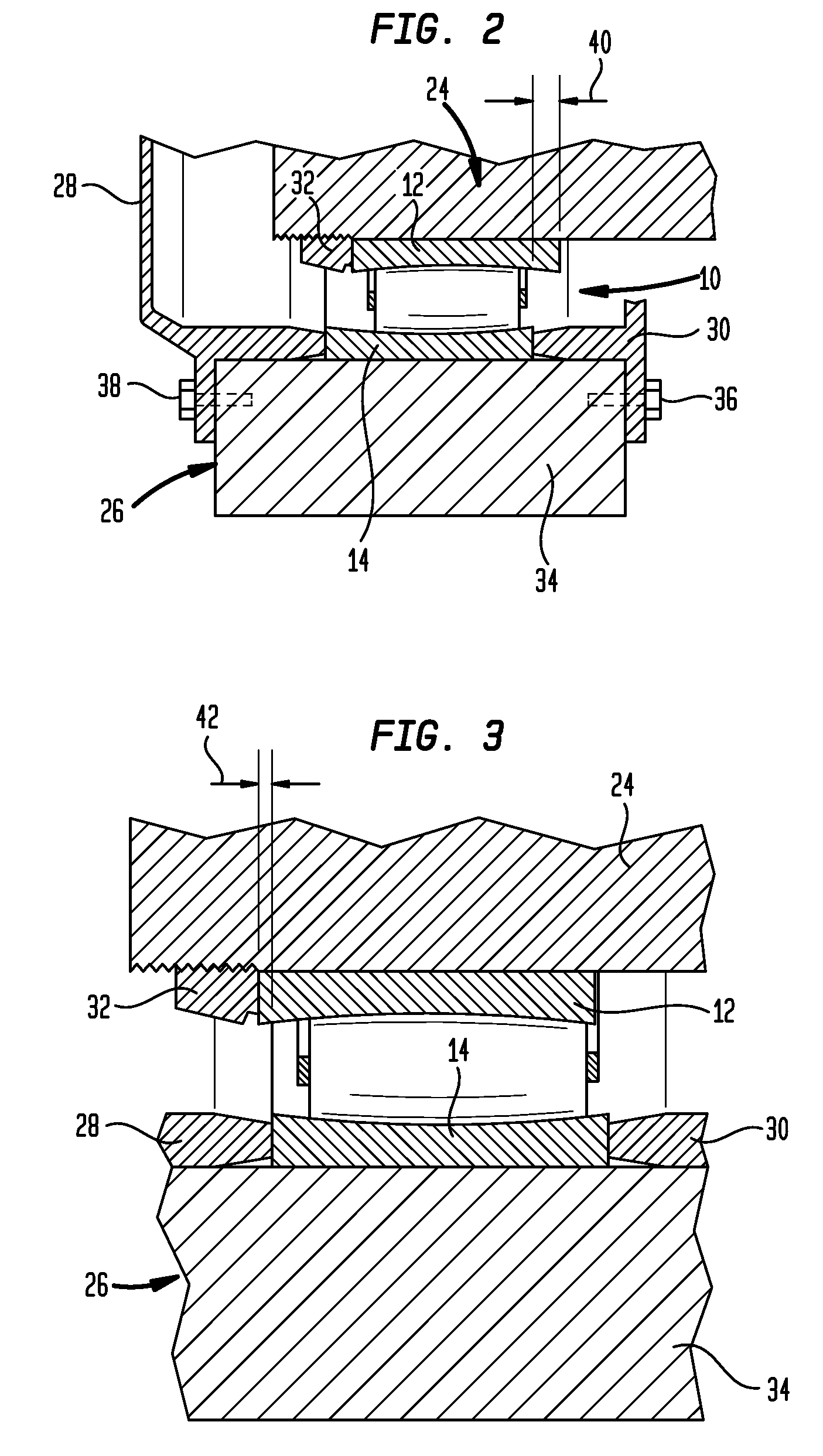

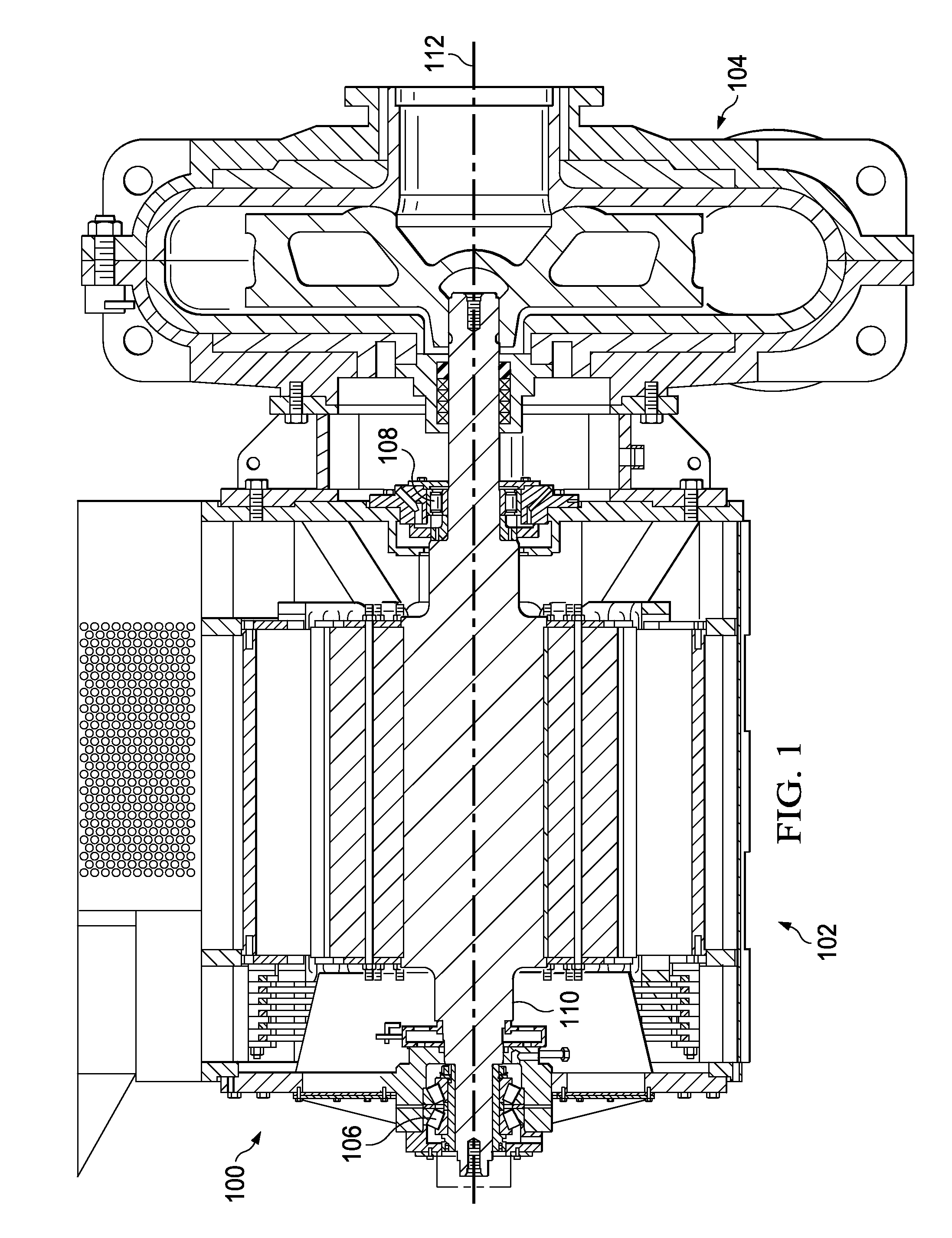

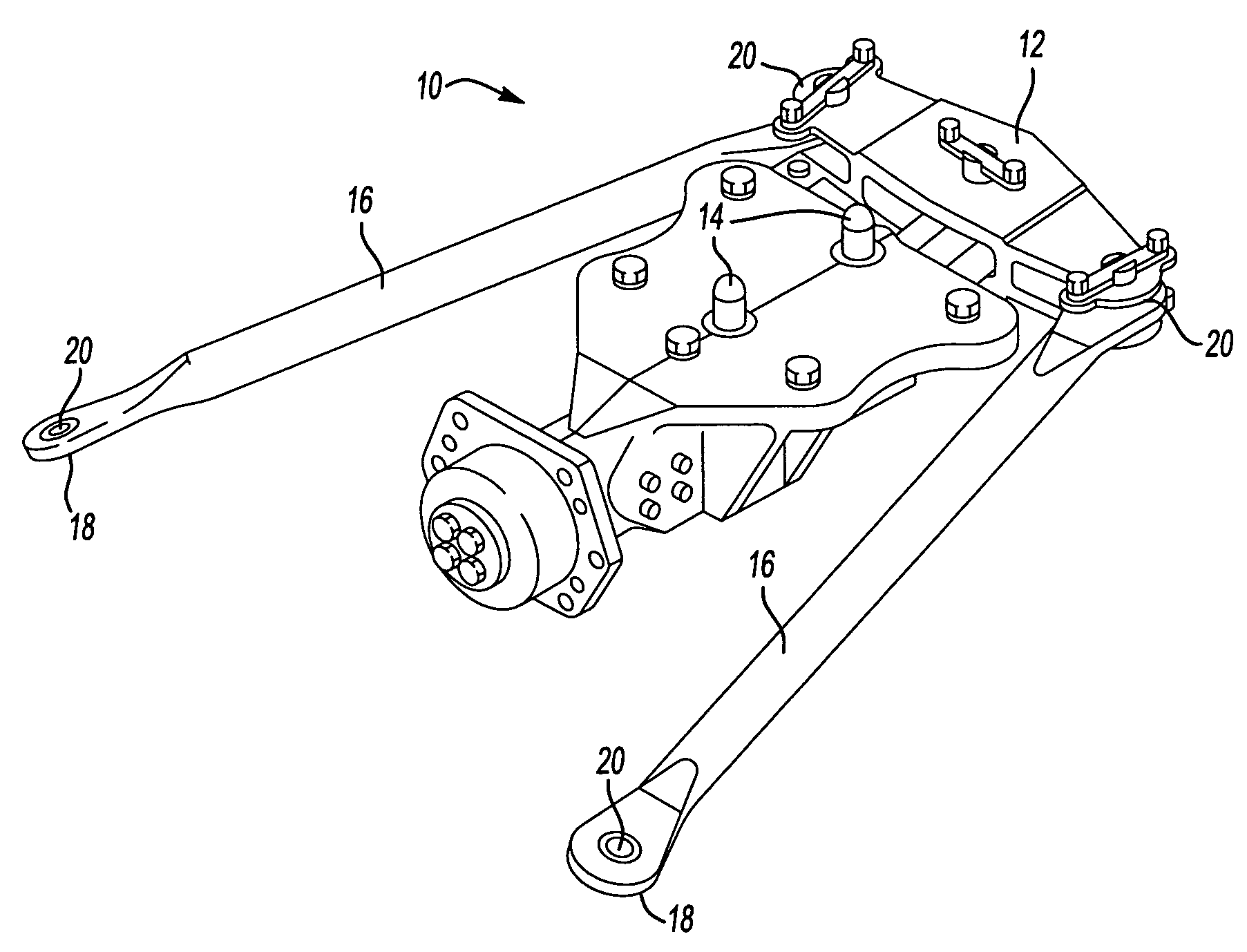

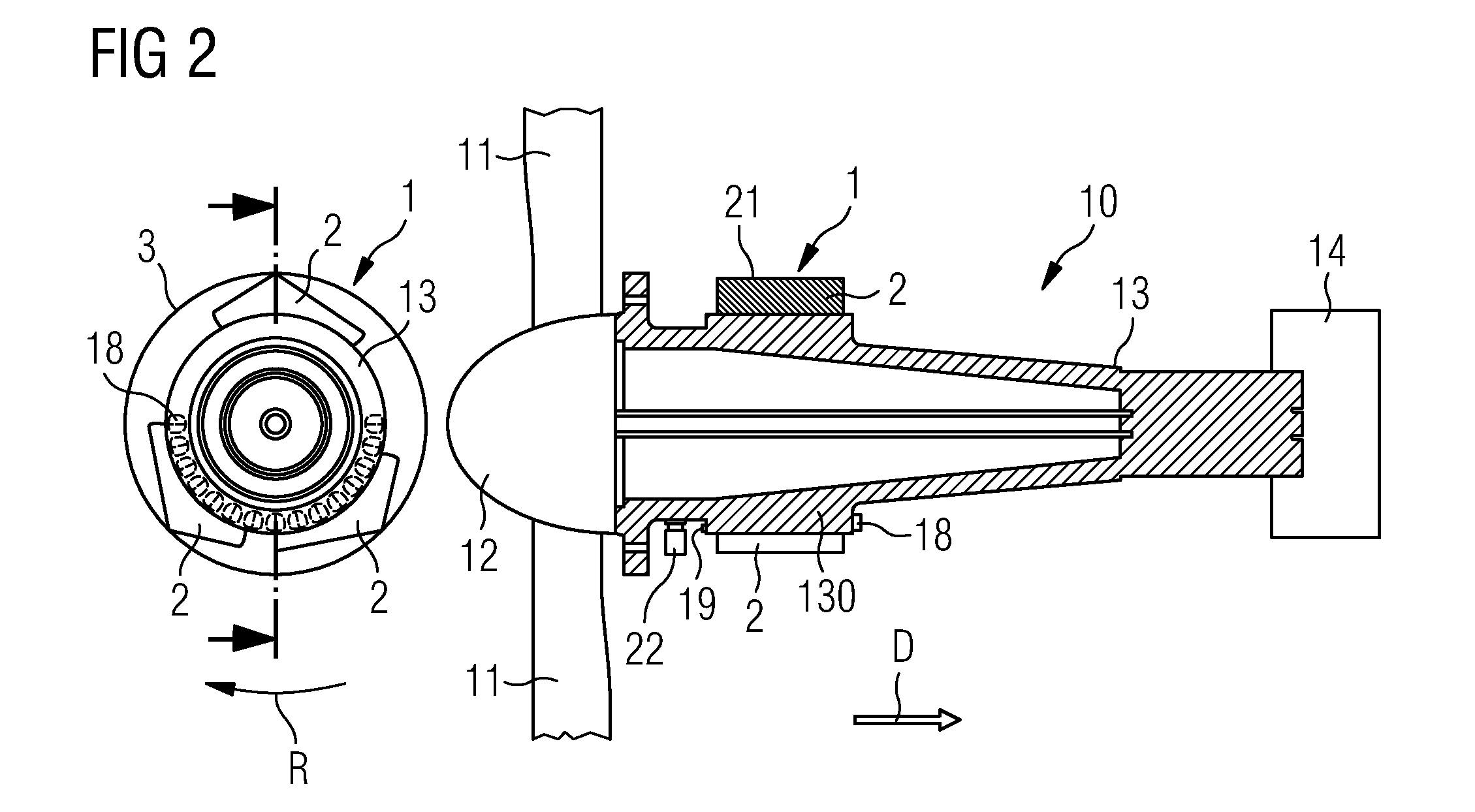

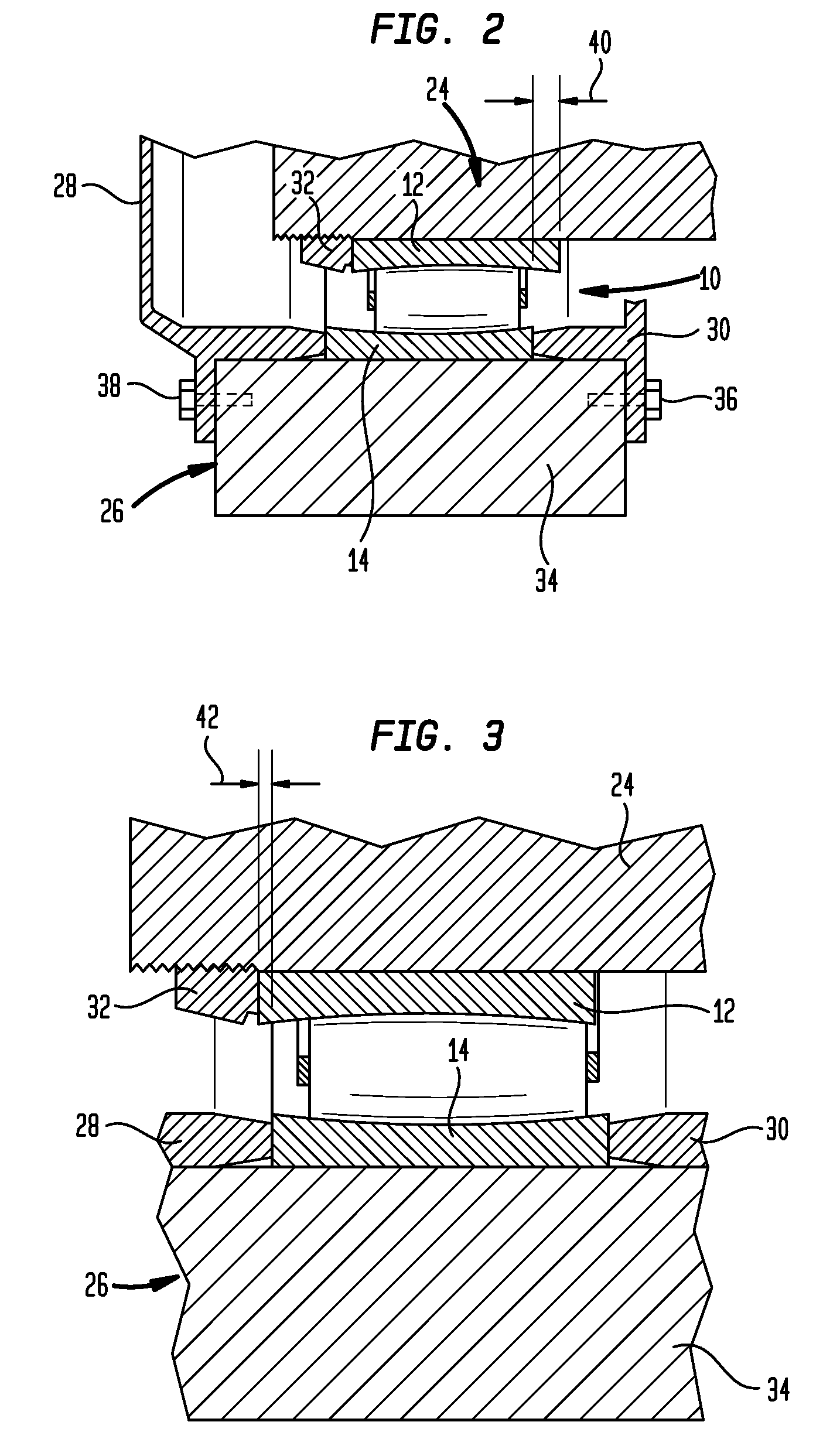

Removable bearing arrangement for a wind turbine generator

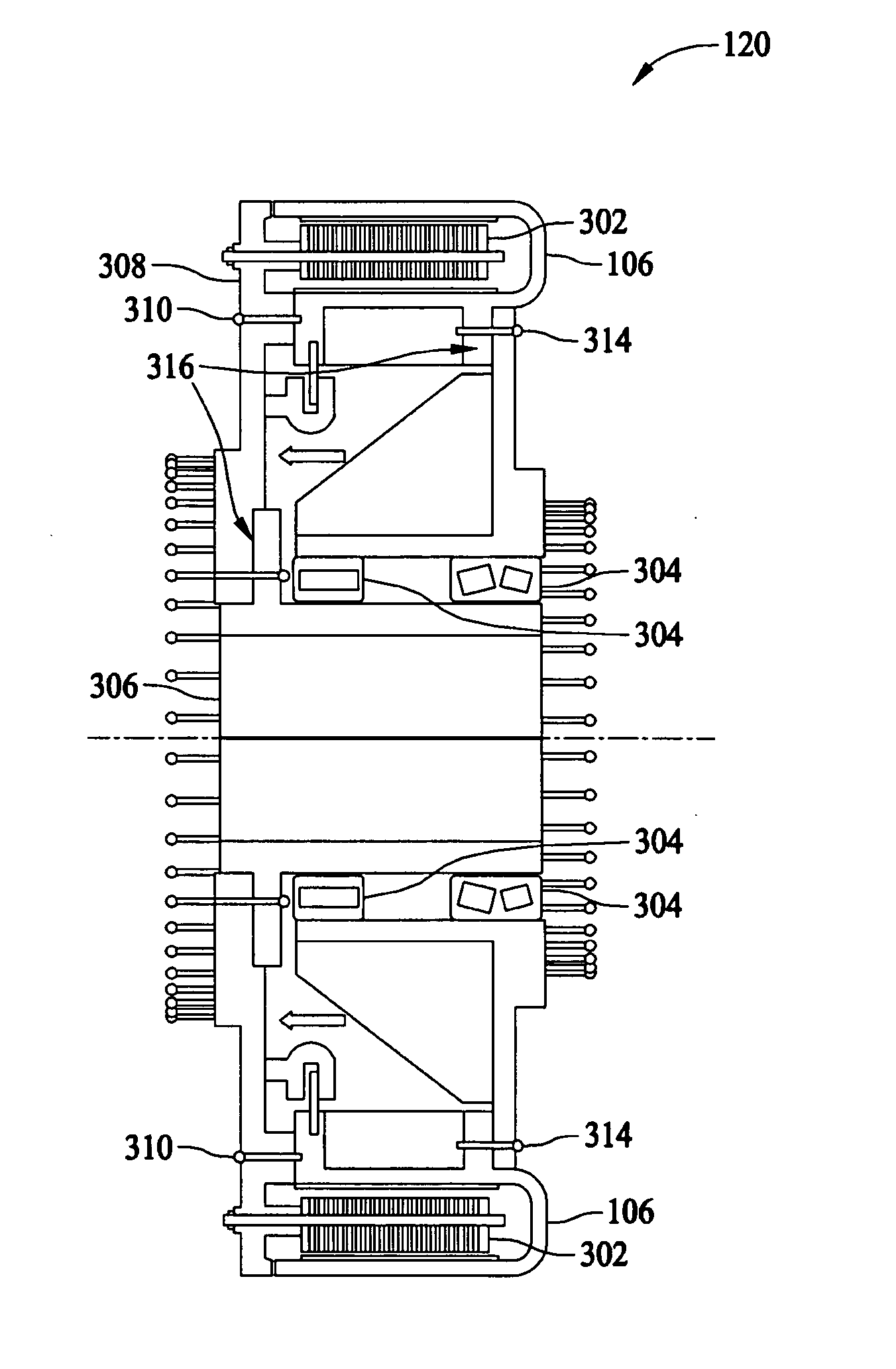

InactiveUS20070075548A1Easy to disassembleBearing repair/replacementEngine manufactureTurbineWind force

A wind generator having removable change-out bearings includes a rotor and a stator, locking bolts configured to lock the rotor and stator, a removable bearing sub-assembly having at least one shrunk-on bearing installed, and removable mounting bolts configured to engage the bearing sub-assembly and to allow the removable bearing sub-assembly to be removed when the removable mounting bolts are removed.

Owner:GENERAL ELECTRIC CO

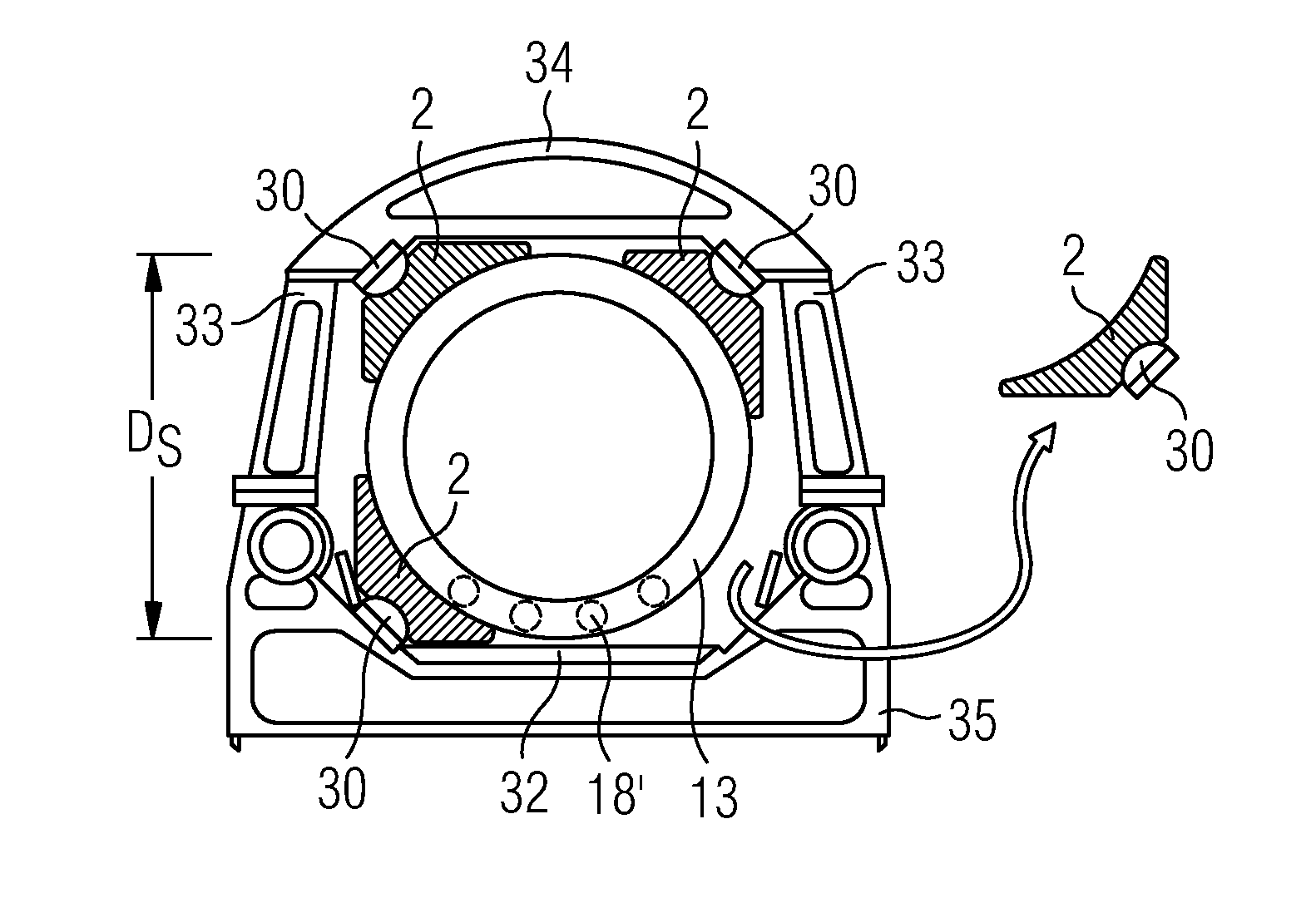

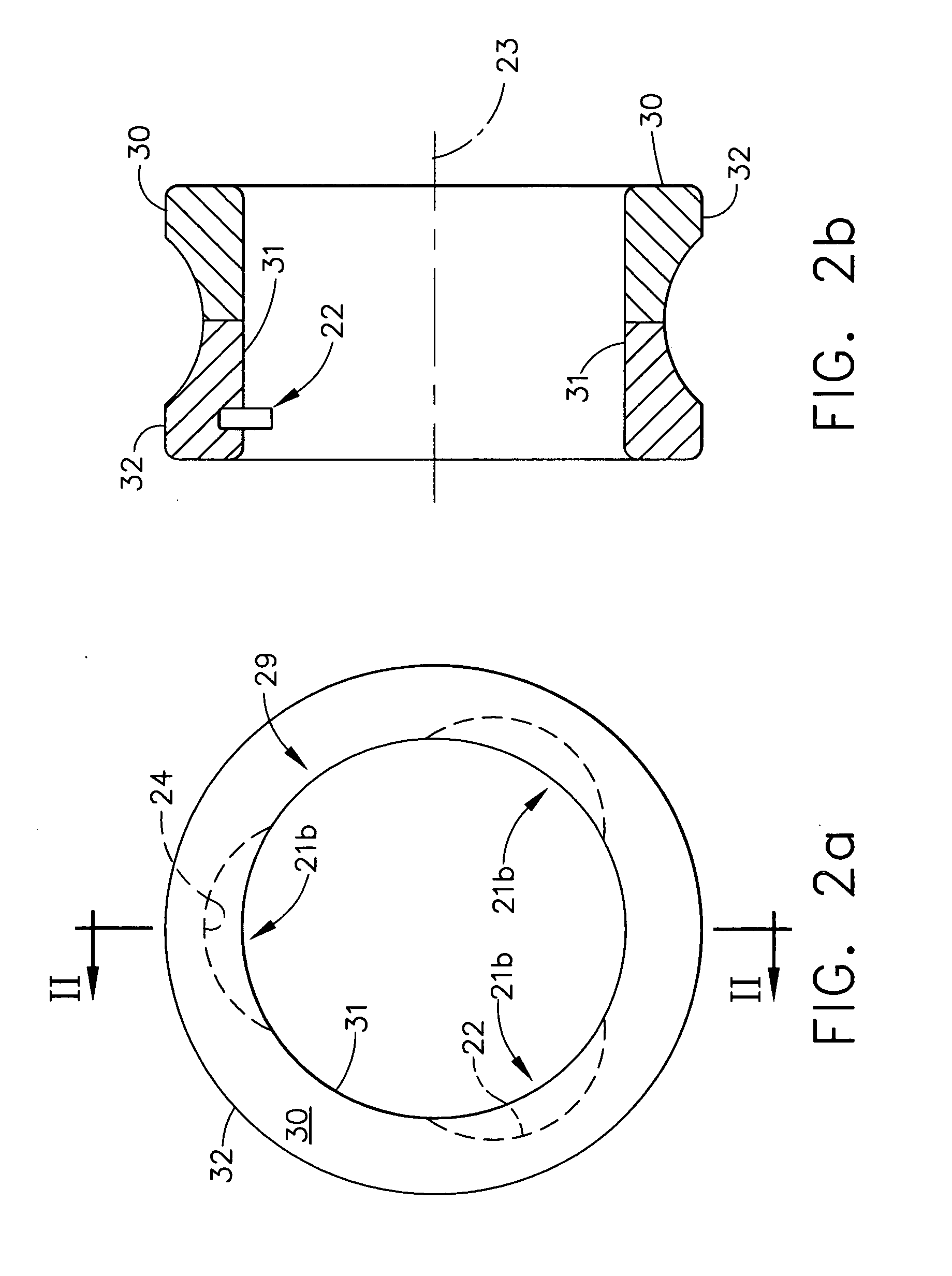

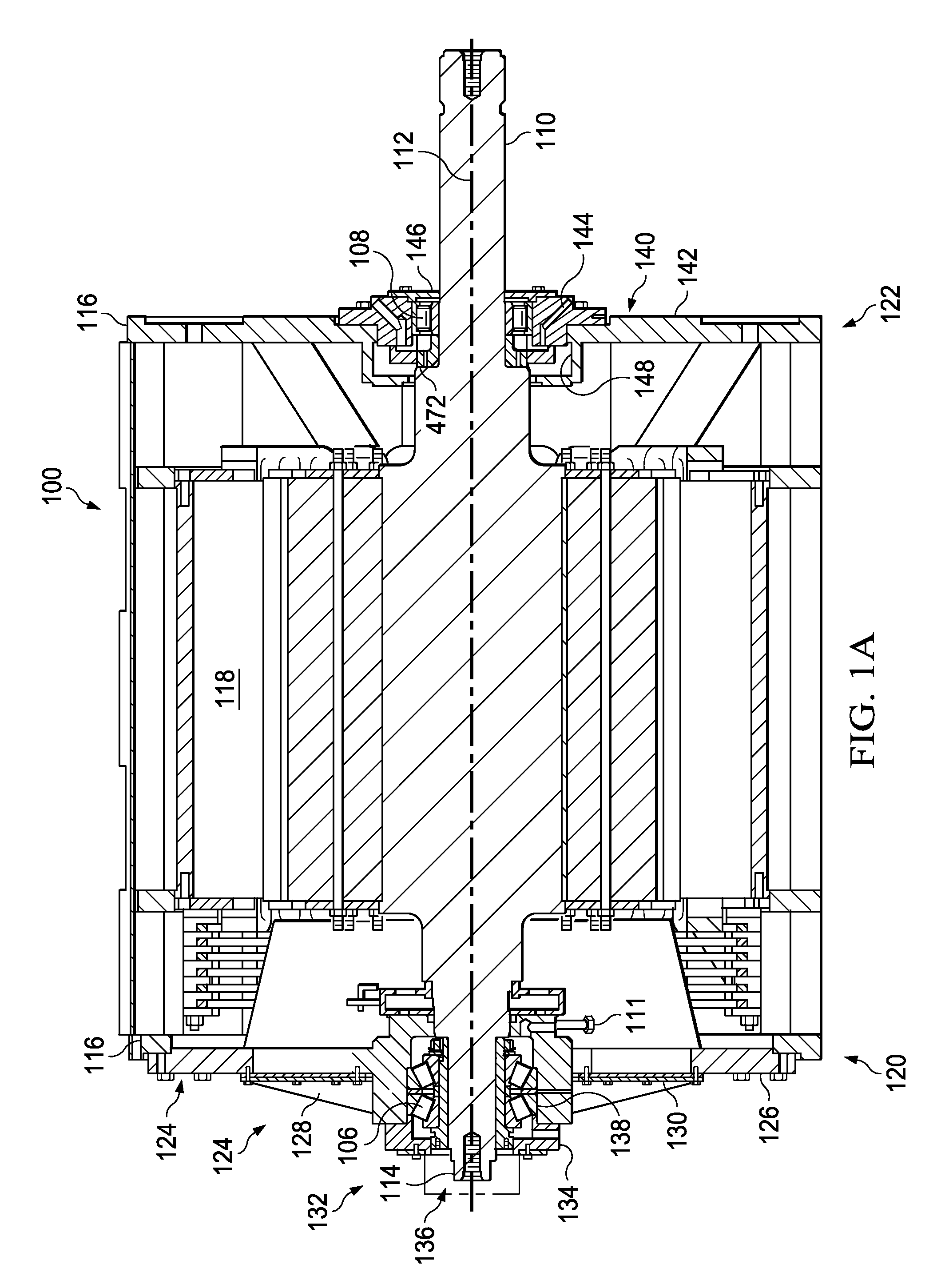

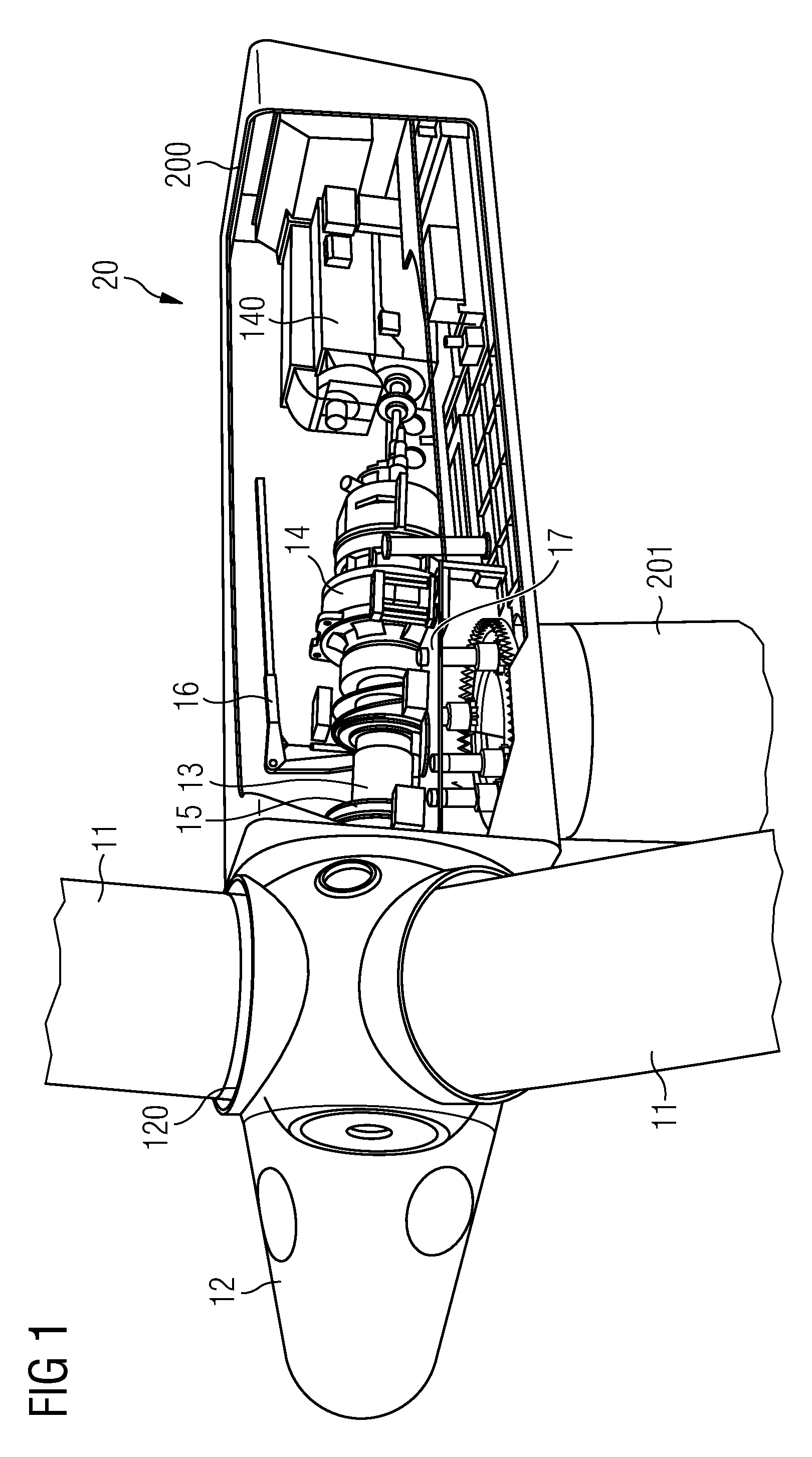

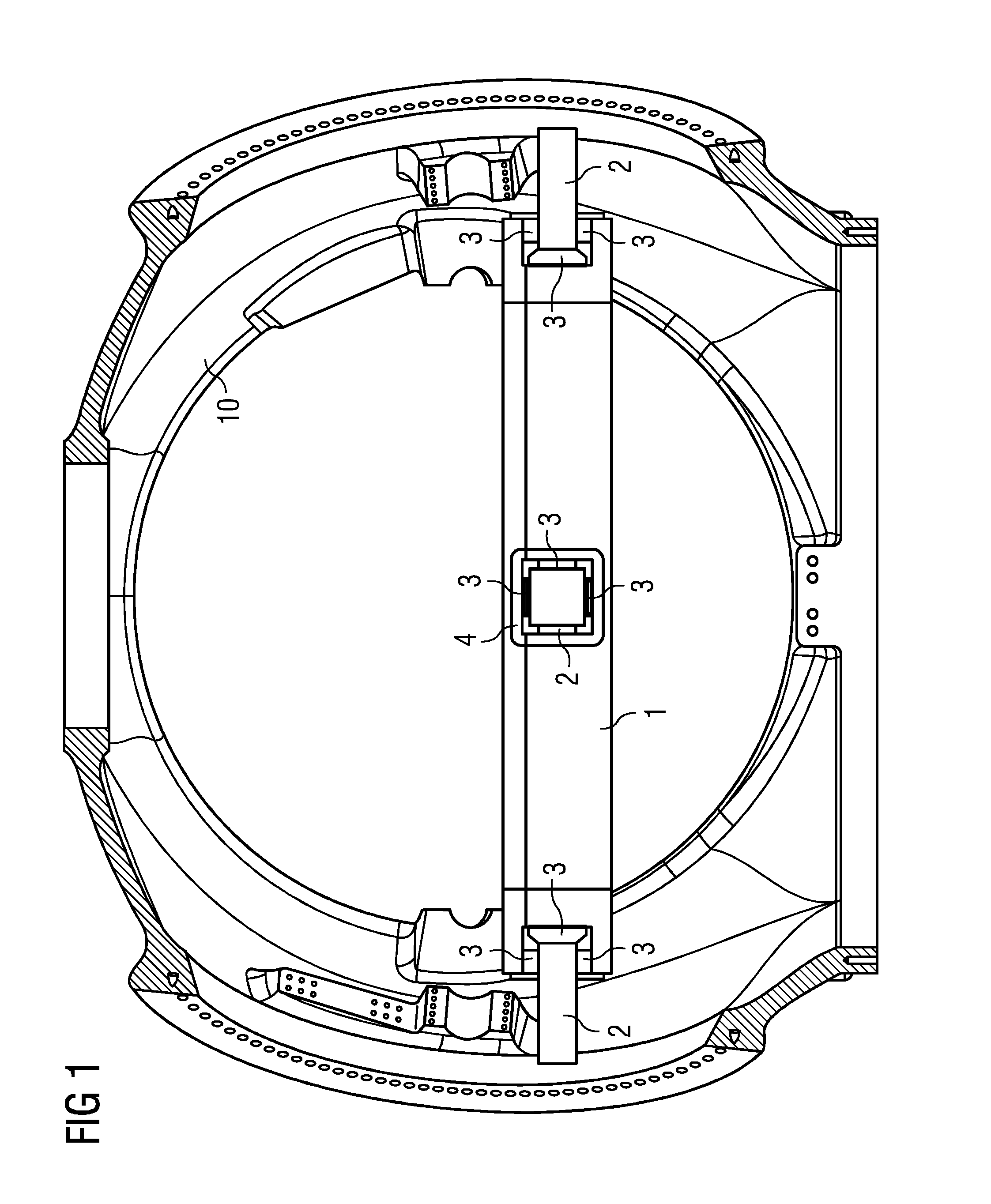

Wind turbine main bearing

ActiveUS20120099993A1Reduce loadEasy to removeBearing repair/replacementPropellersTurbineFluid bearing

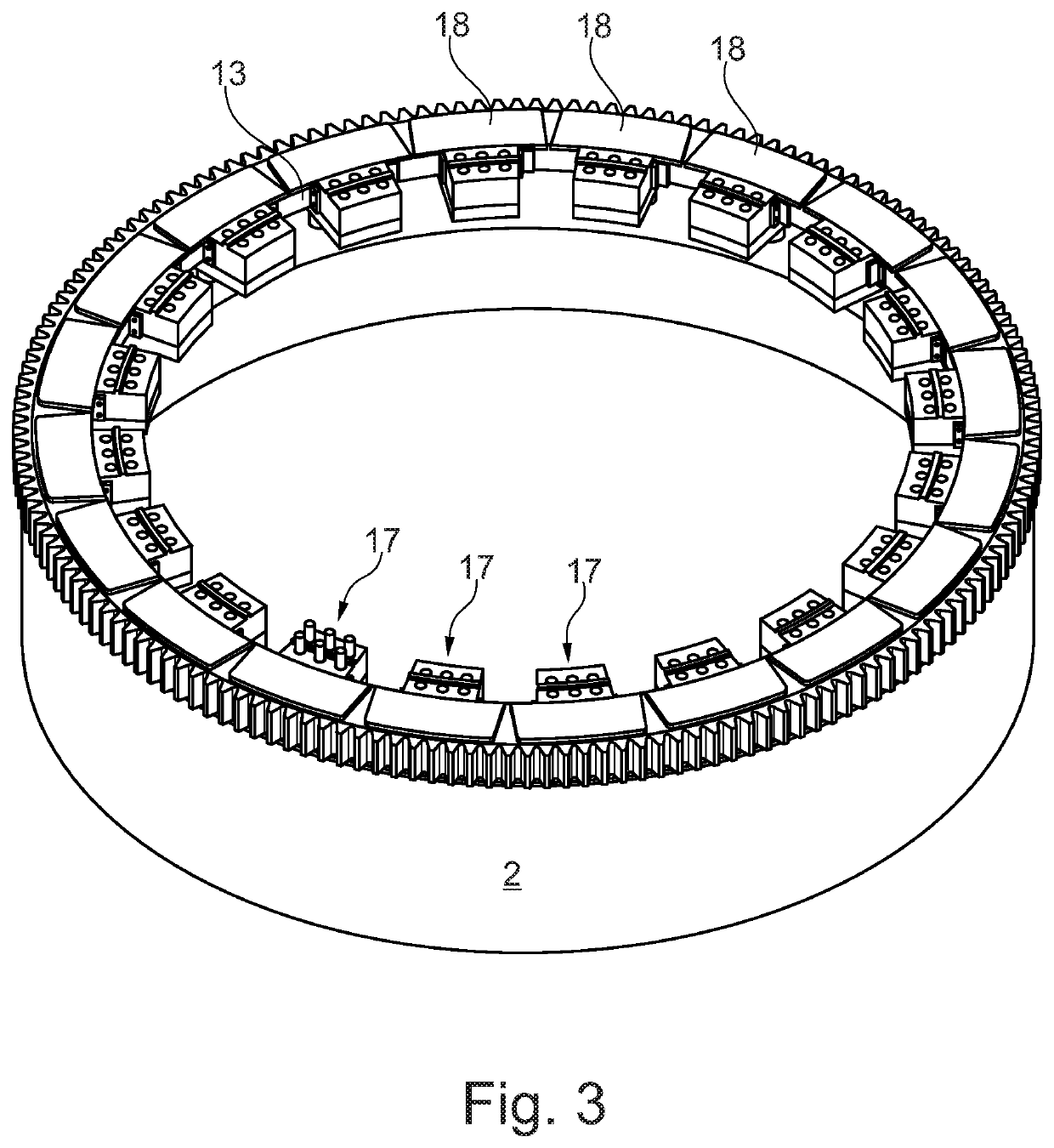

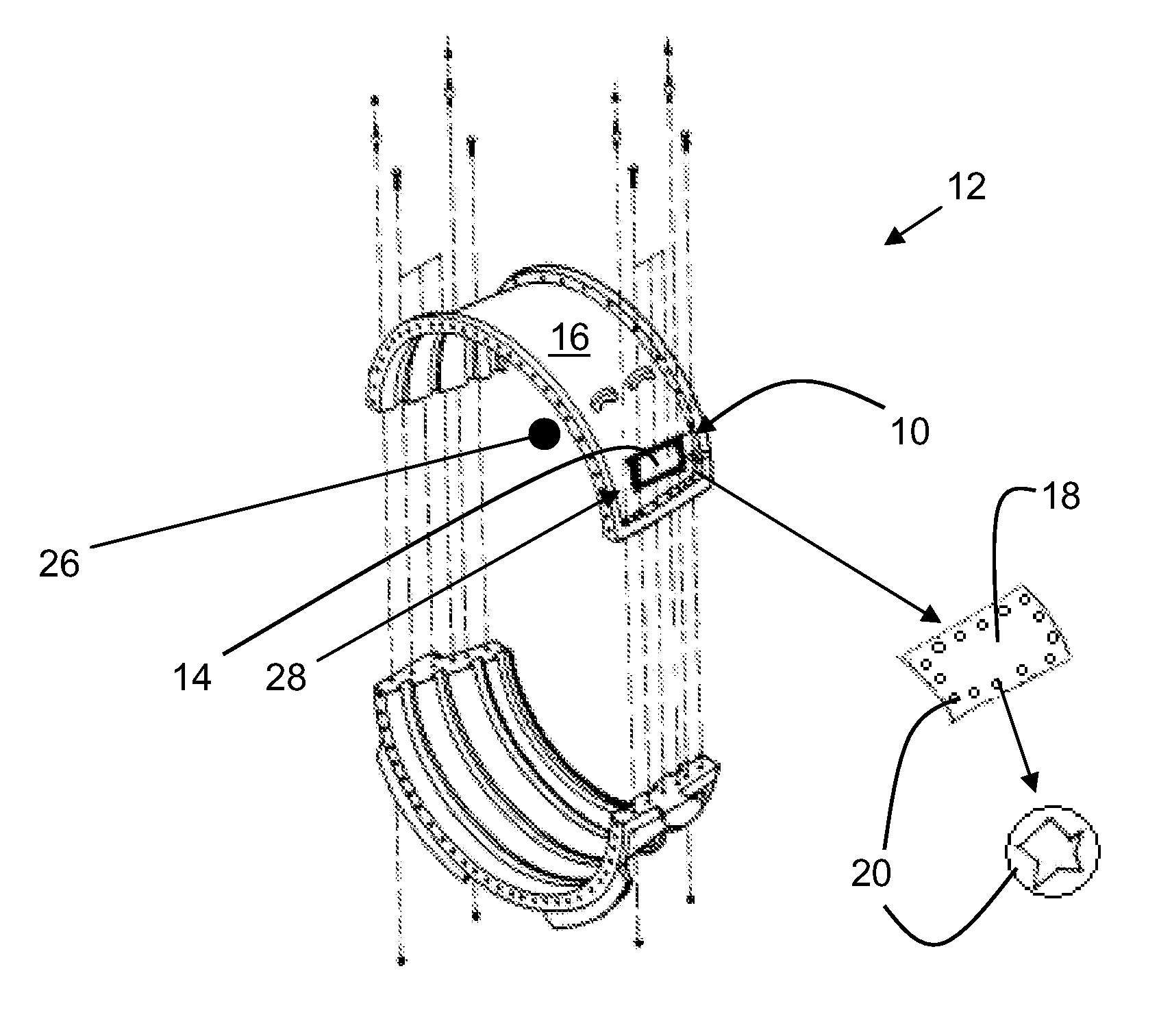

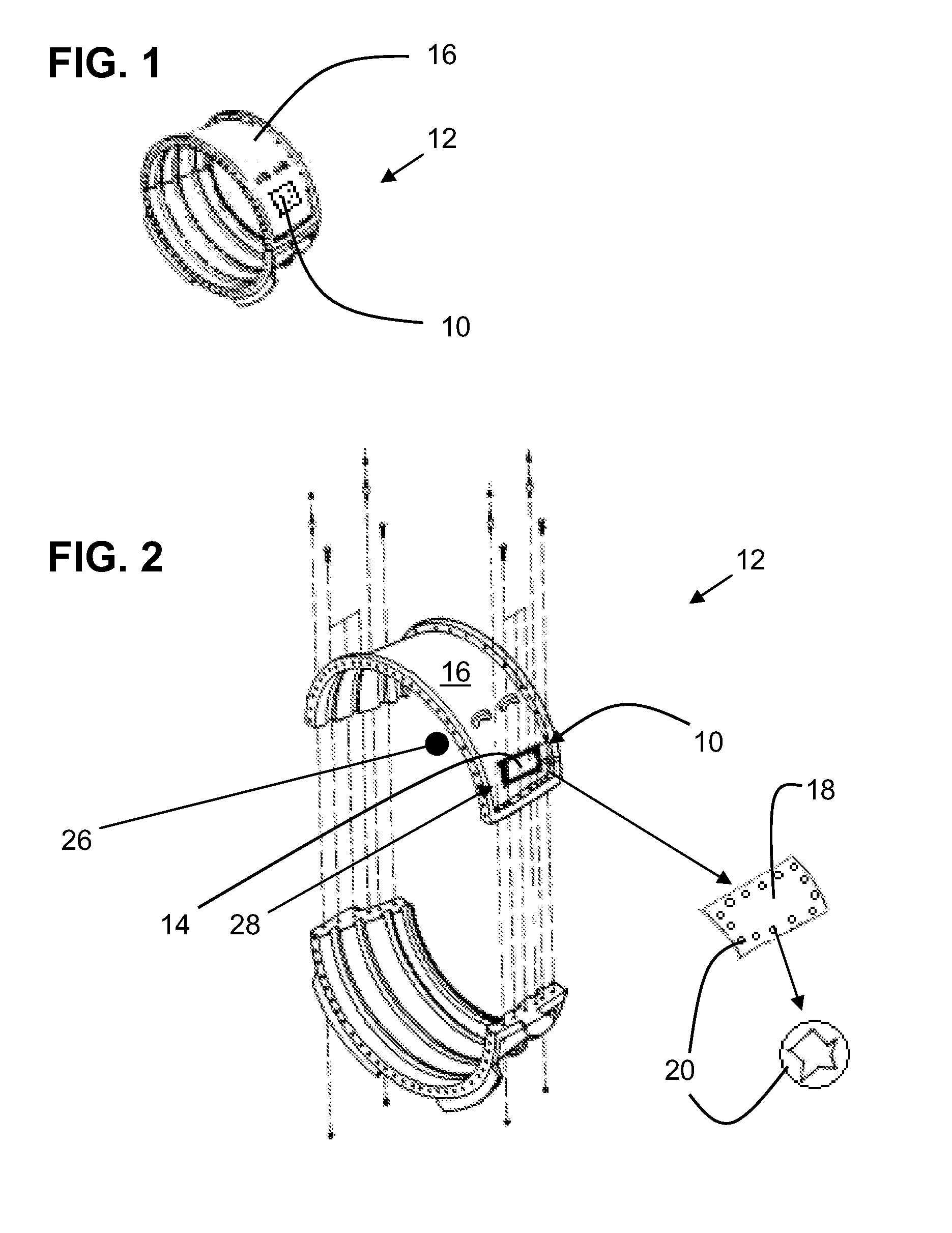

A wind turbine main bearing realized to bear a shaft of a wind turbine, which shaft is caused to rotate by a number of blades connected to the shaft is disclosed. The wind turbine main bearing includes a fluid bearing with a plurality of bearing pads arranged about the shaft. Also disclosed is a wind turbine with a number of blades connected to a shaft and realized to rotate the shaft, which wind turbine includes as main bearing a wind turbine main bearing. Further described is a method of performing maintenance on a wind turbine, including the steps of halting a rotation of the shaft, operating a lifting arrangement to raise the shaft, and removing a bearing pad of the wind turbine main bearing from the bearing housing of the wind turbine main bearing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

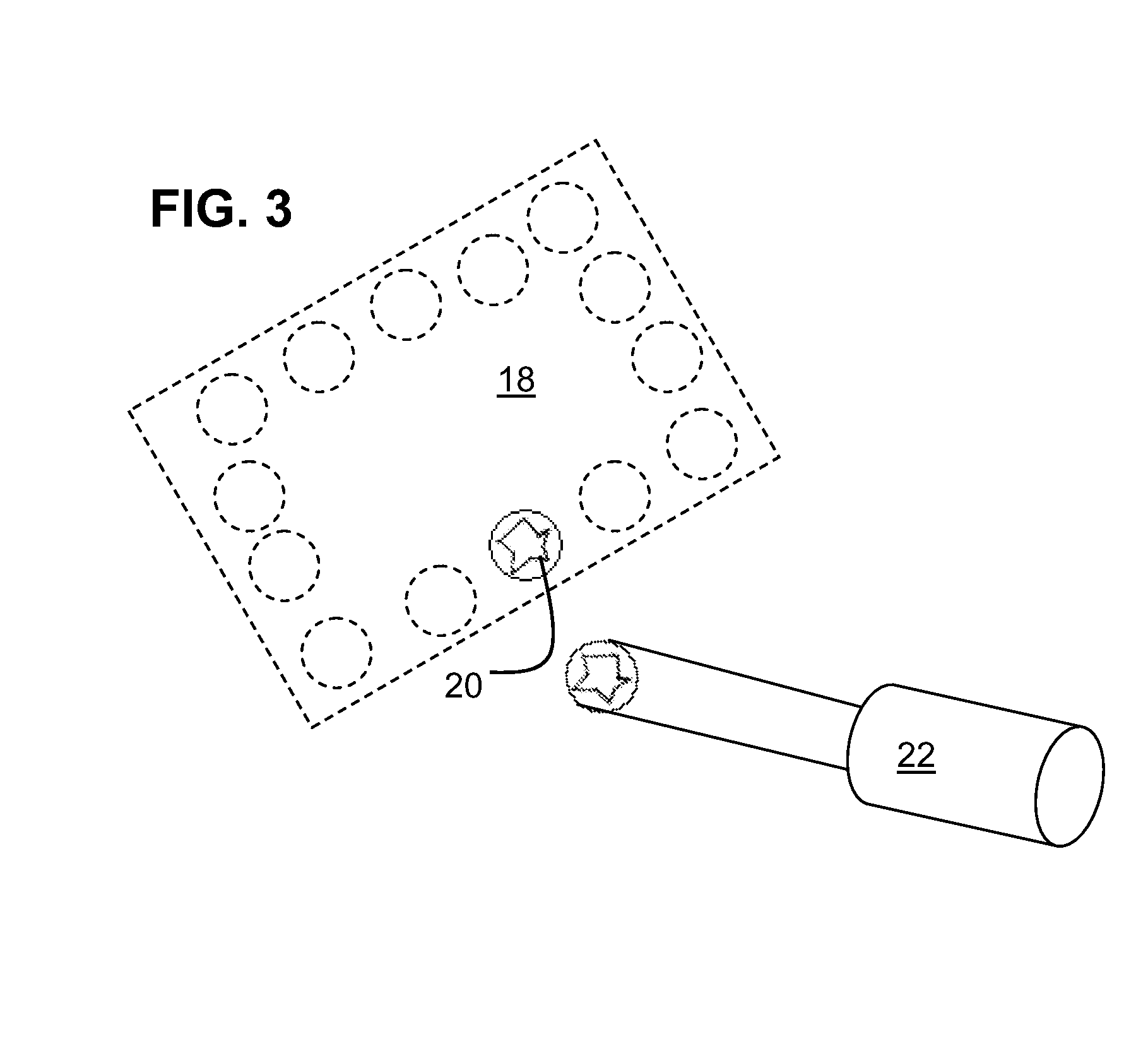

Method for changing removable bearing for a wind turbine generator

A wind generator having removable change-out bearings includes a rotor and a stator, locking bolts configured to lock the rotor and stator, a removable bearing sub-assembly having at least one shrunk-on bearing installed, and removable mounting bolts configured to engage the bearing sub-assembly and to allow the removable bearing sub-assembly to be removed when the removable mounting bolts are removed.

Owner:GENERAL ELECTRIC CO

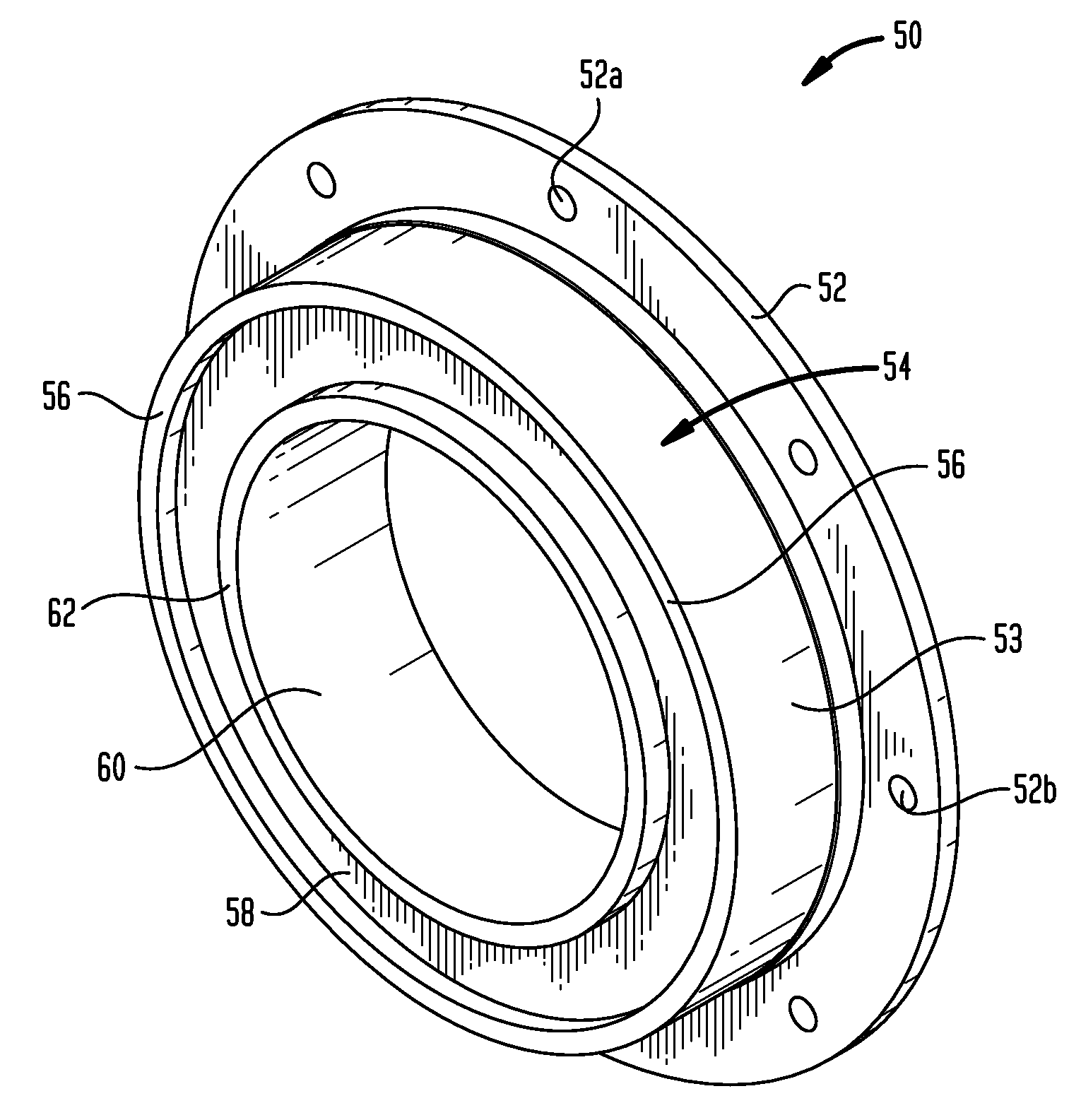

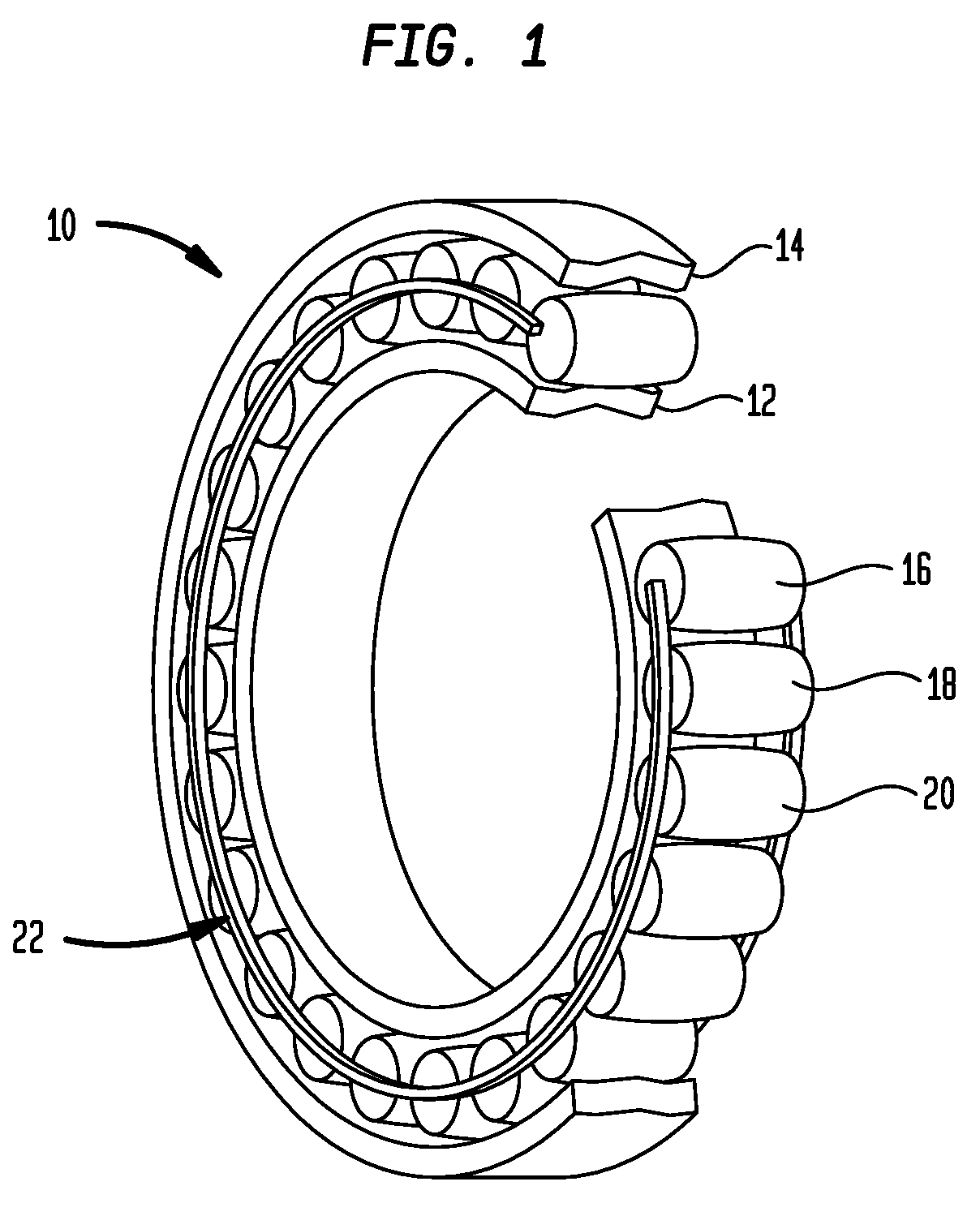

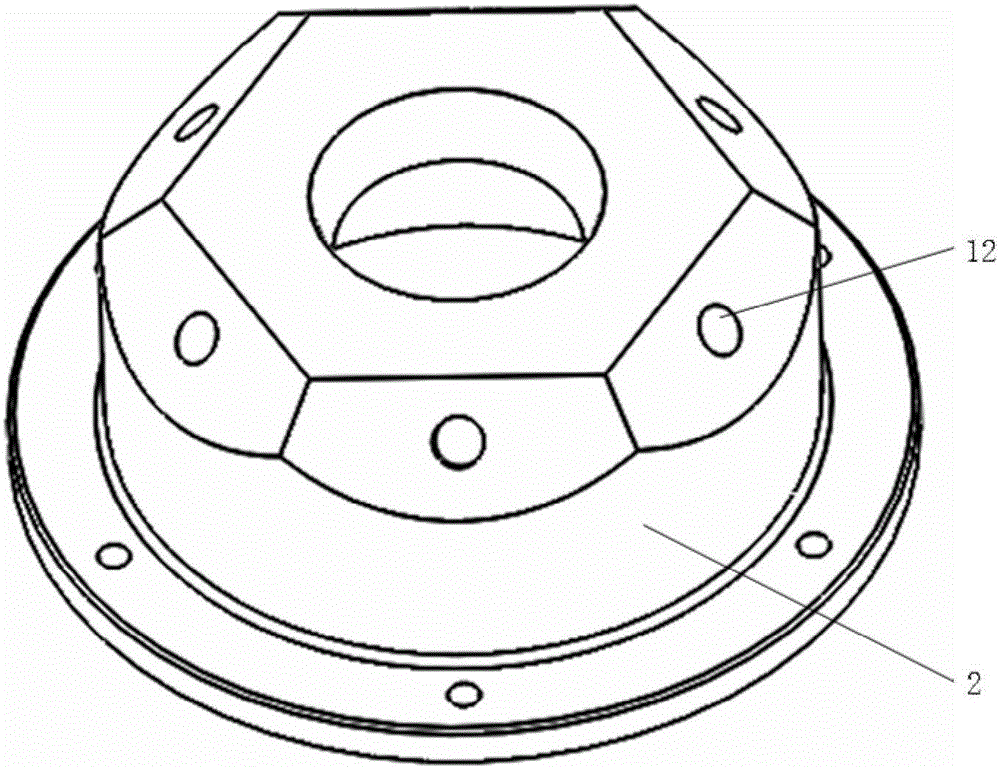

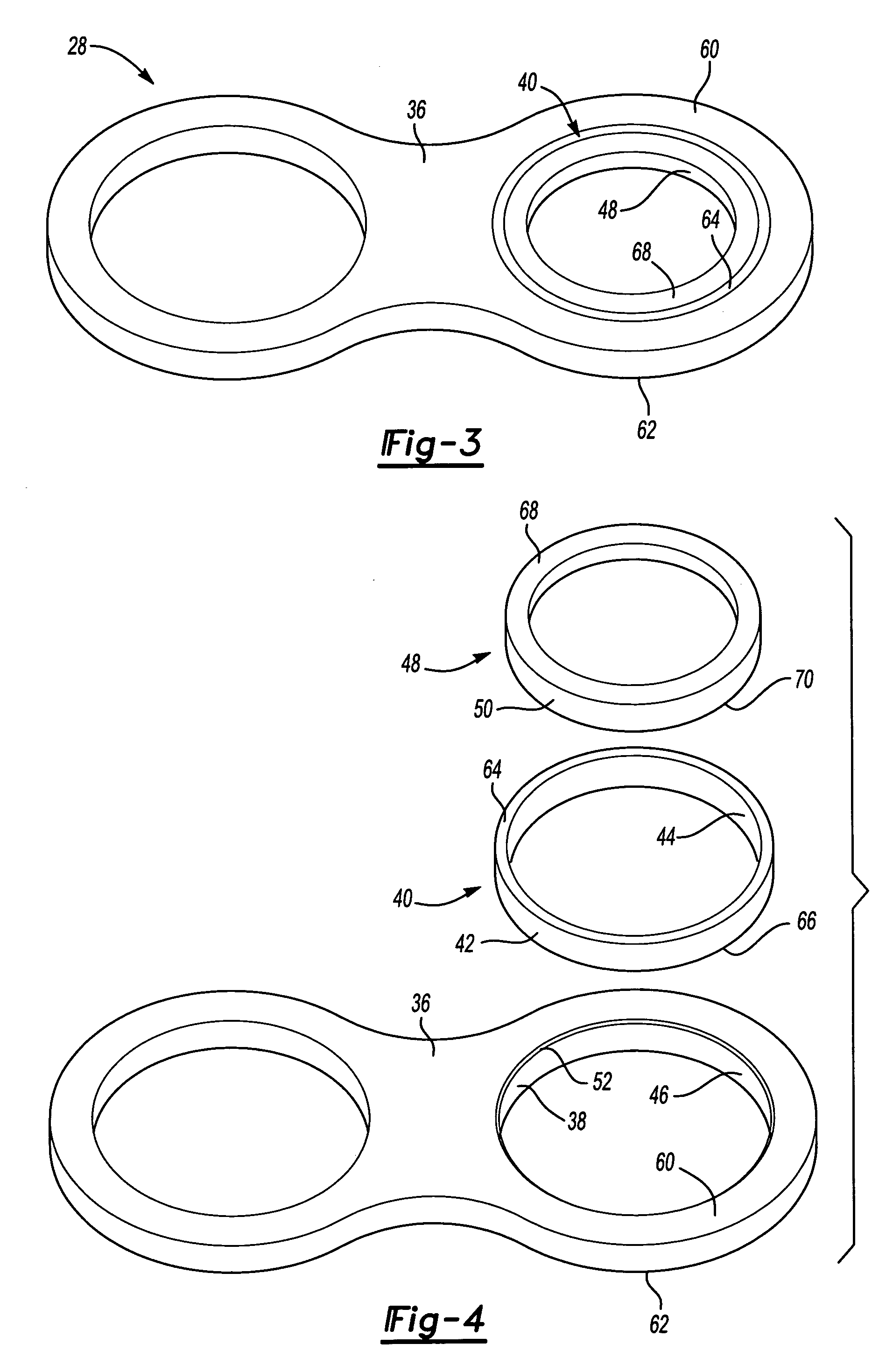

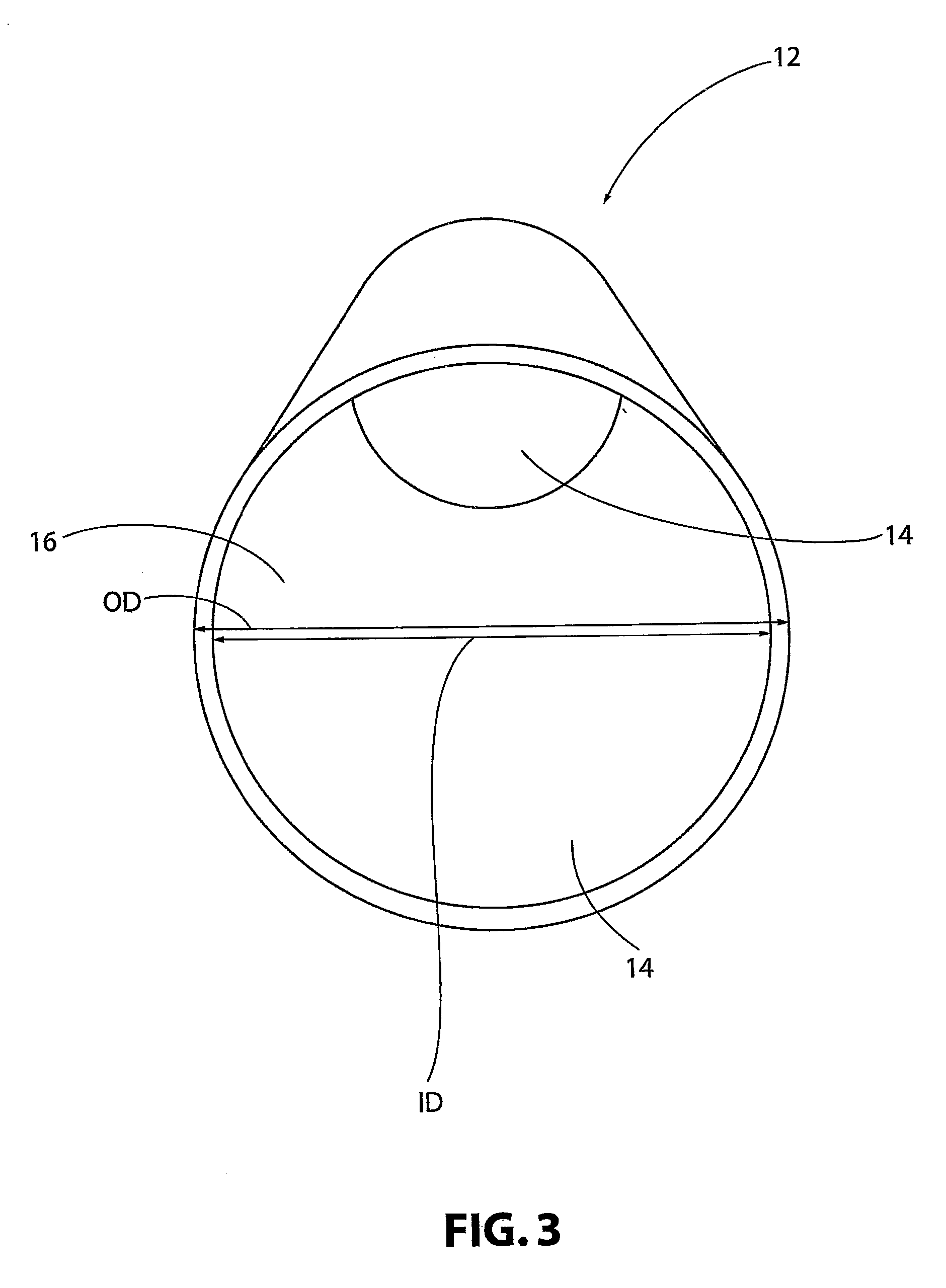

Replaceable roller bearing

ActiveUS20140050428A1Easy to separateControl displacementBearing repair/replacementRoller bearingsAxial displacementThrust bearing

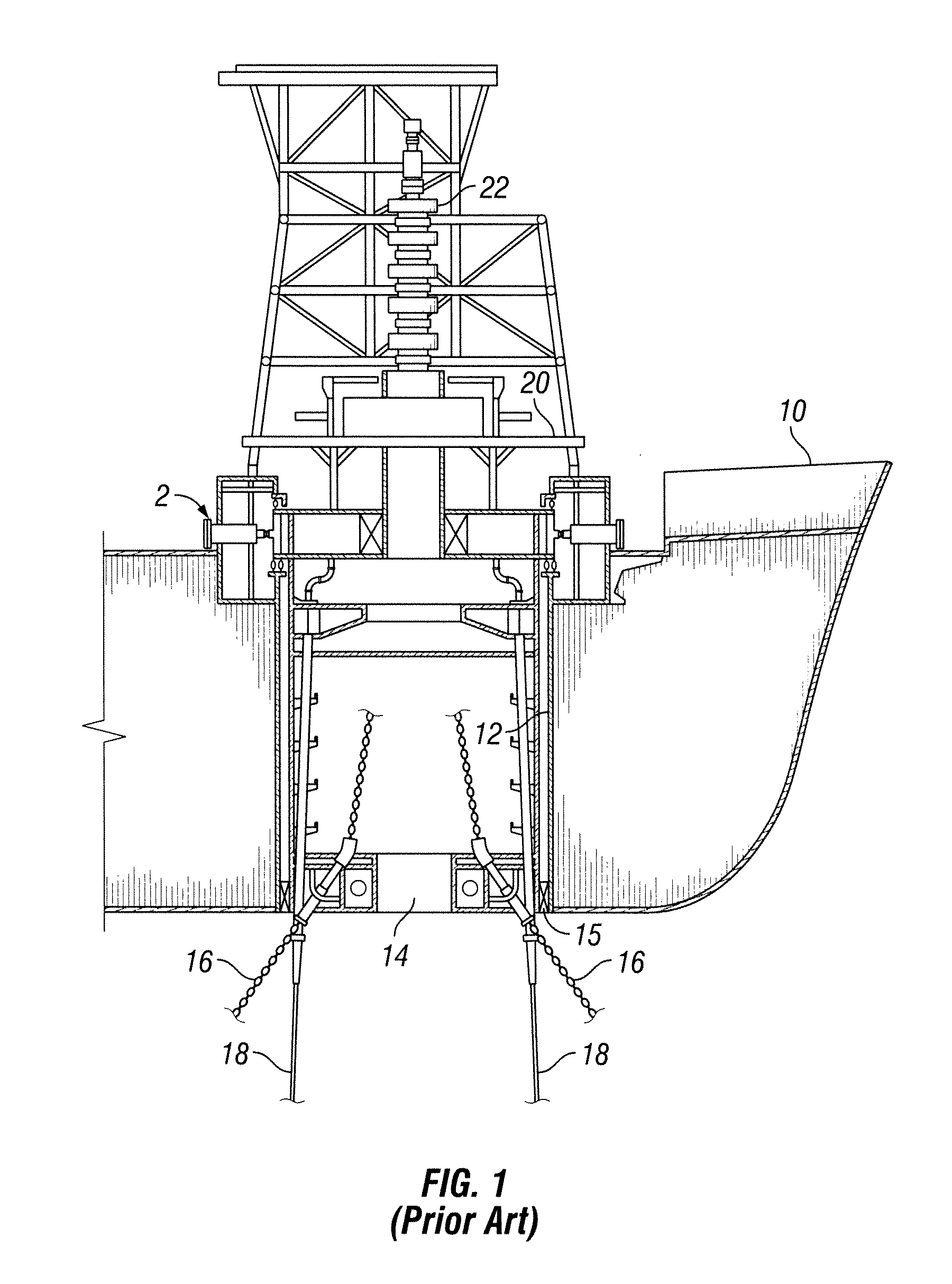

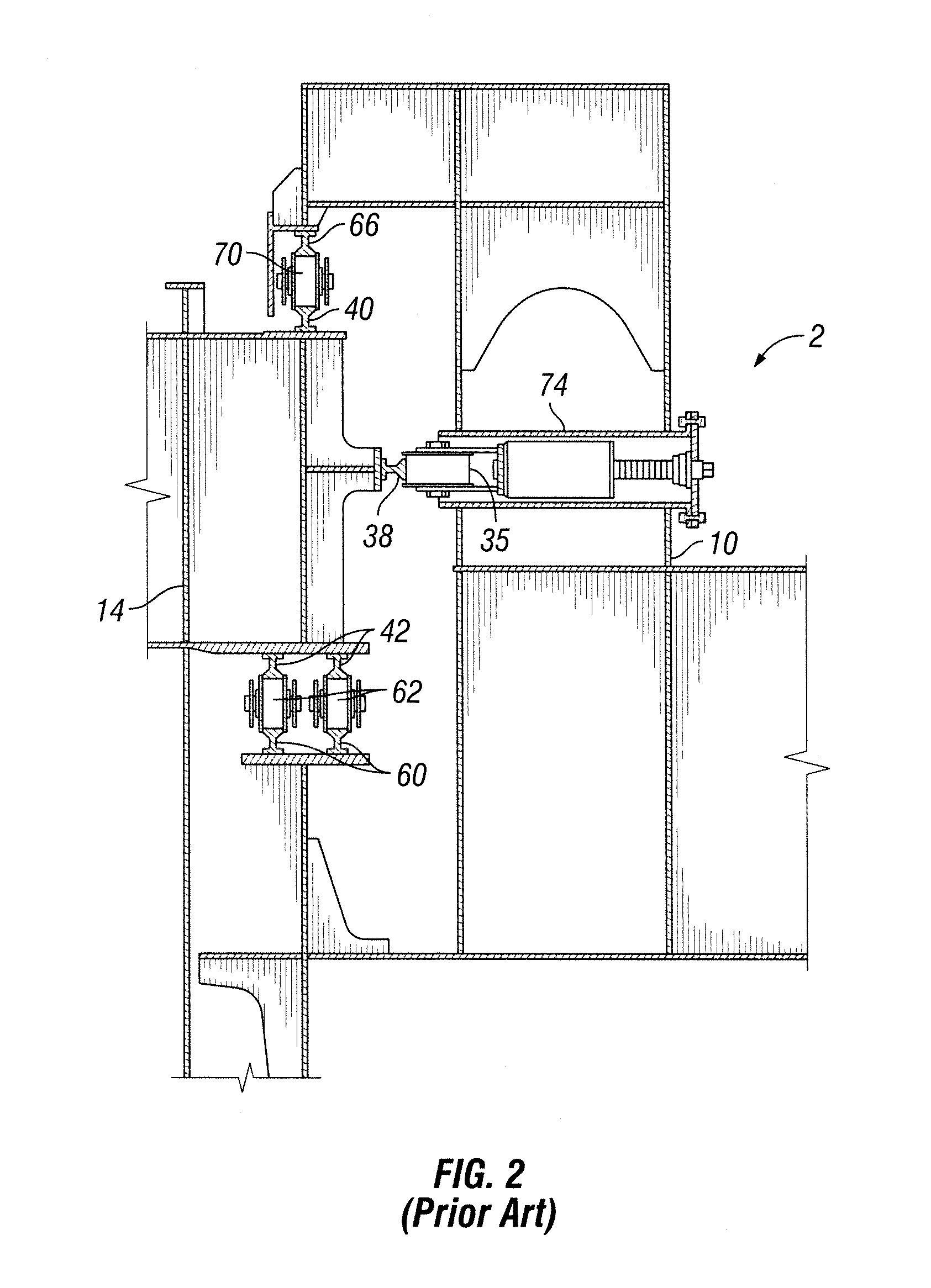

A turret / vessel bearing arrangement and method for replacing bearings in situ without removing other bearings. The bearings are capable of being separated. A removable axial spacer secures the vessel and the turret into engagement with the upper and lower thrust bearings. Removal of the spacer allows increased separation between vessel and turret flanges that sandwich the thrust bearings. The mid radial bearing assembly includes one or more radially arranged bearing pads that allow for limited axial displacement of the turret with respect to the vessel during thrust bearing replacement while still bearing radial loads and allowing rotation. The addition of a temporary thrust bearing allows the vessel to weathervane about the turret while thrust bearing are replaced in situ.

Owner:SOFEC

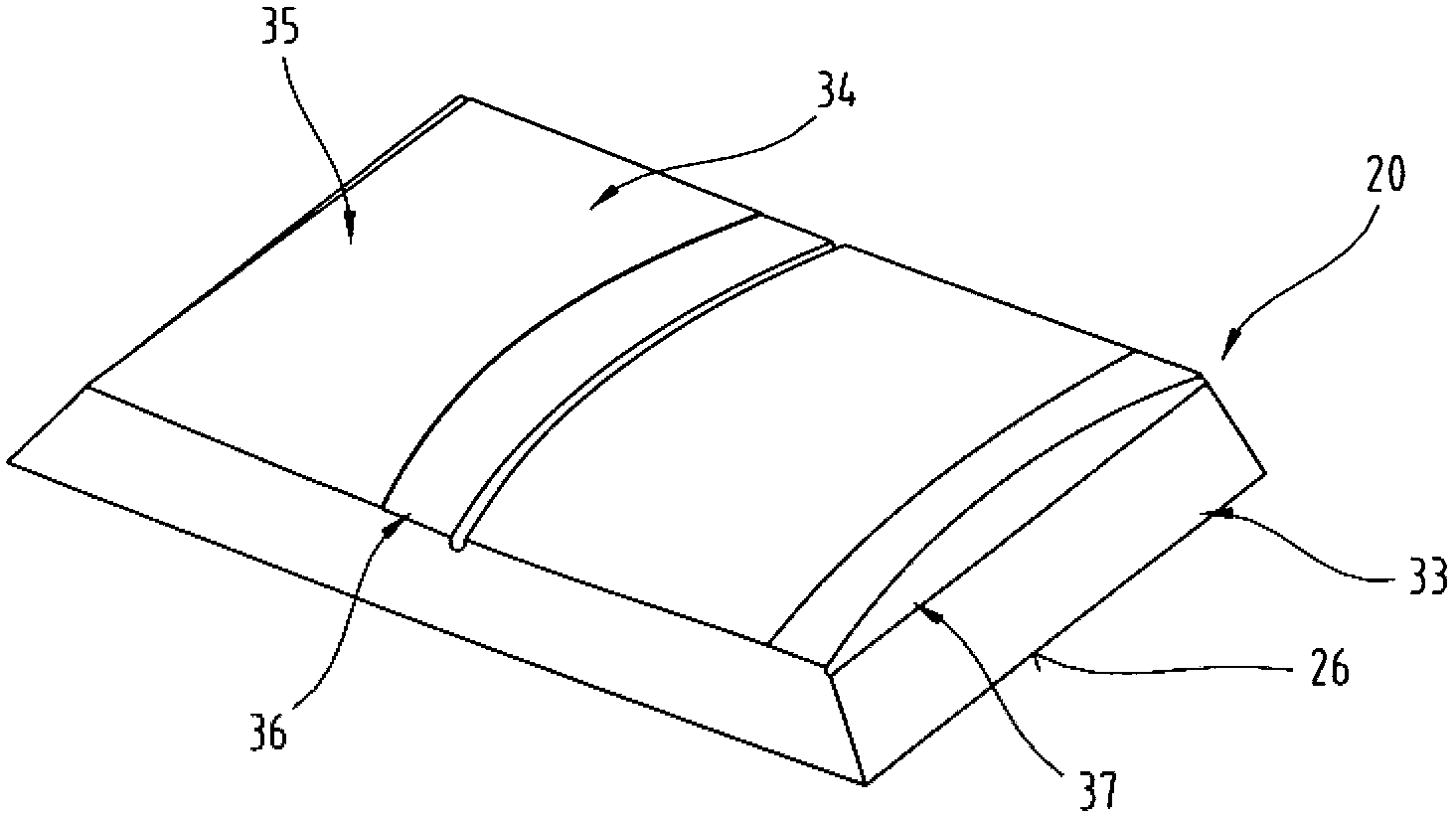

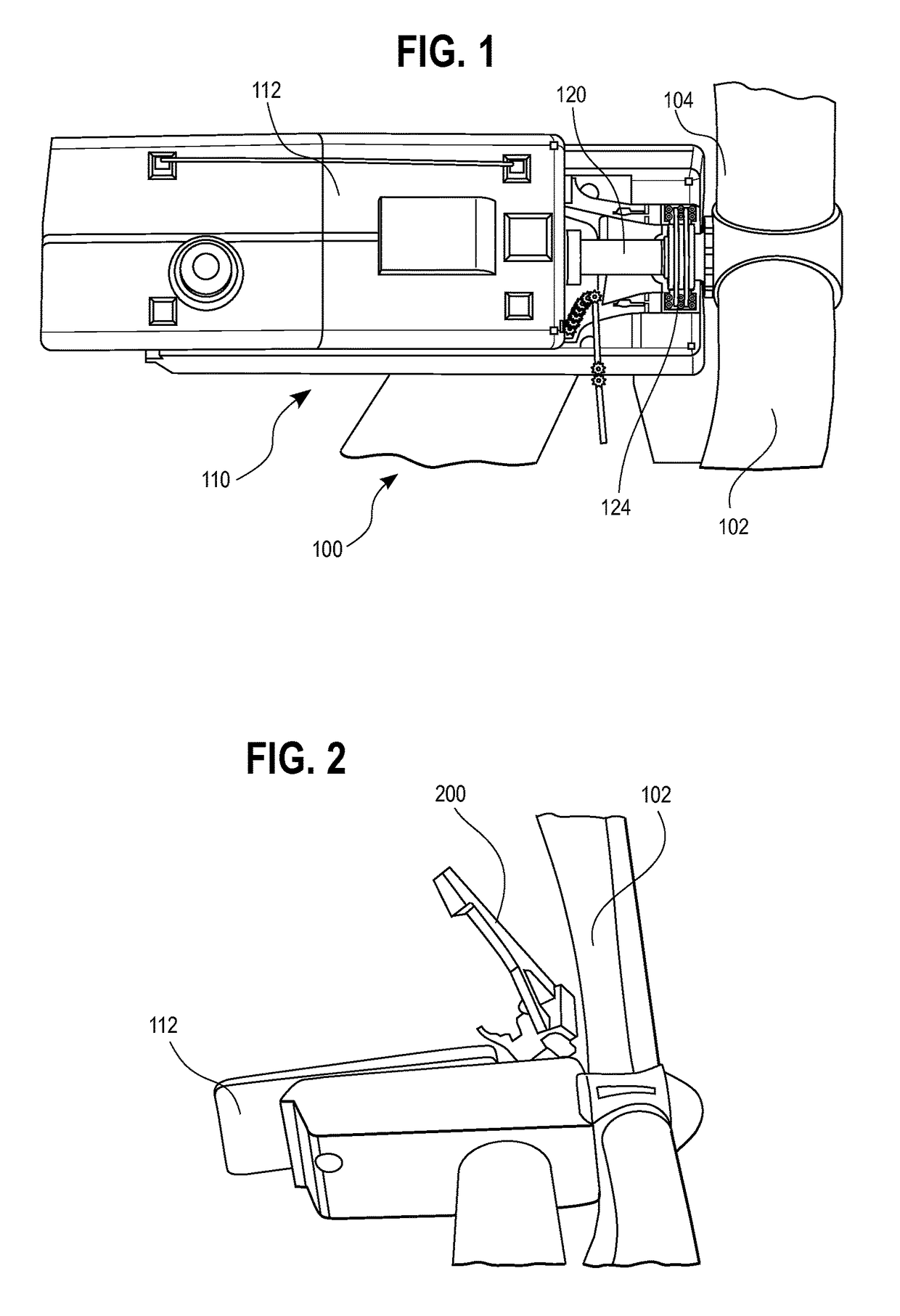

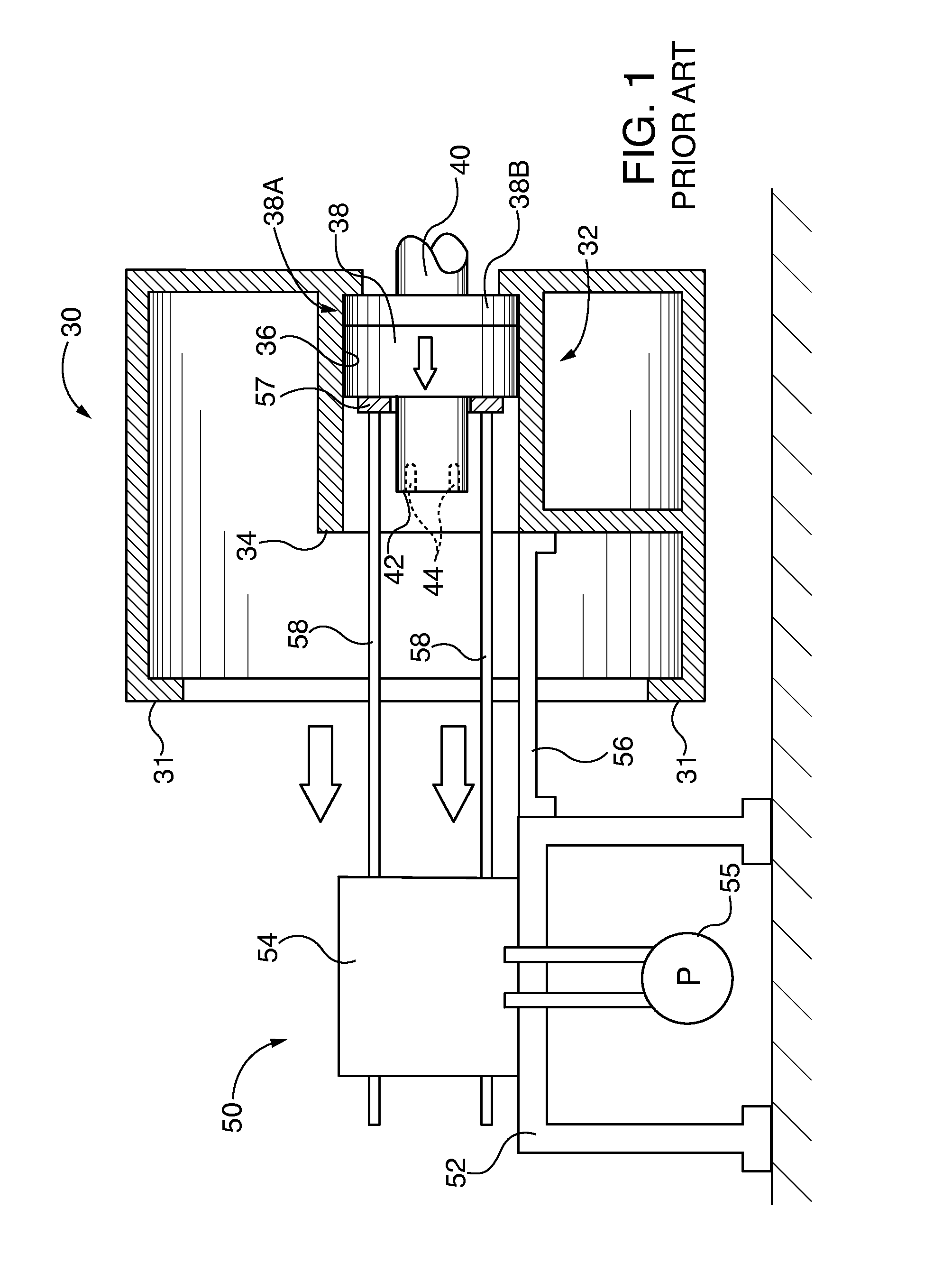

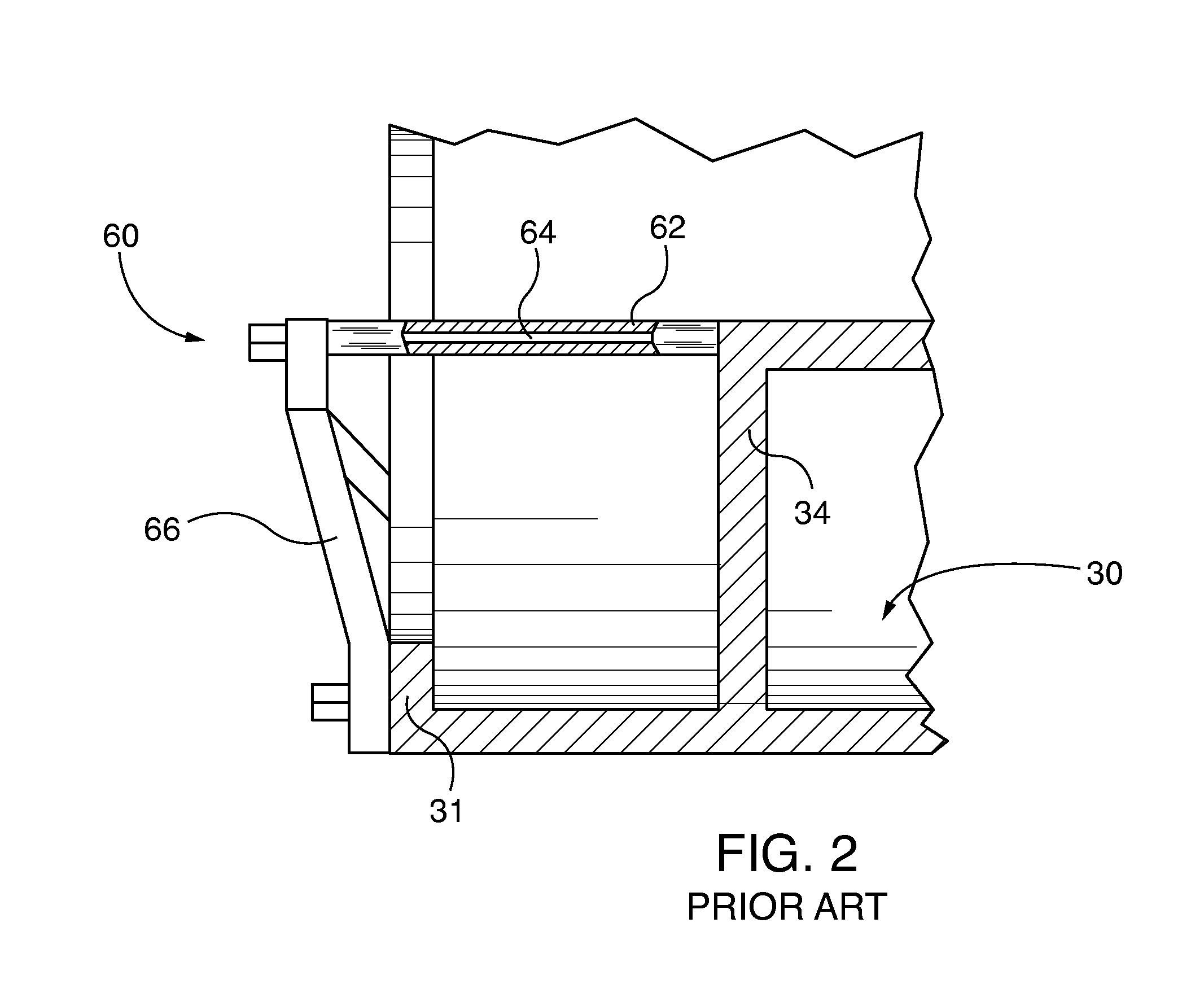

External casing functional access port

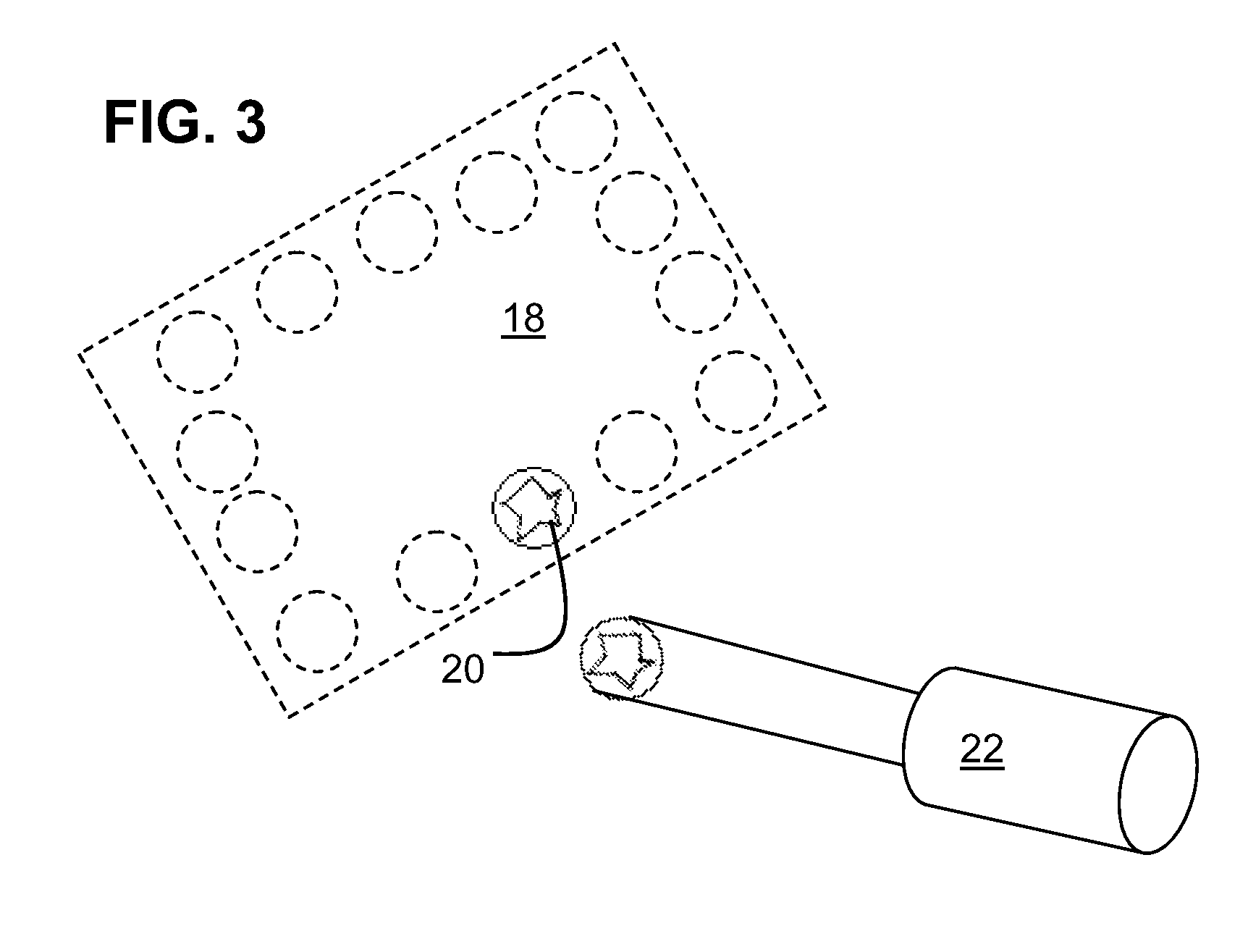

A functional access port in a machine casing, a machine having a functional access port, and a method of monitoring a machine via a functional access port are disclosed herein. In an embodiment, an access port is provided in the external casing of an industrial machine. The access port comprises a passageway through the external casing of the machine, providing access to an interior of the machine. The access port further includes a removable passageway cover for removably occluding the passageway. A location, a size, a shape, and an orientation of the passageway relative to the external casing are strategically selected in accordance with engineering and design requirements to provide access through the passageway to a desired location on the interior of the machine while the external casing is in place, with minimal to no disassembly of the casing.

Owner:GENERAL ELECTRIC CO

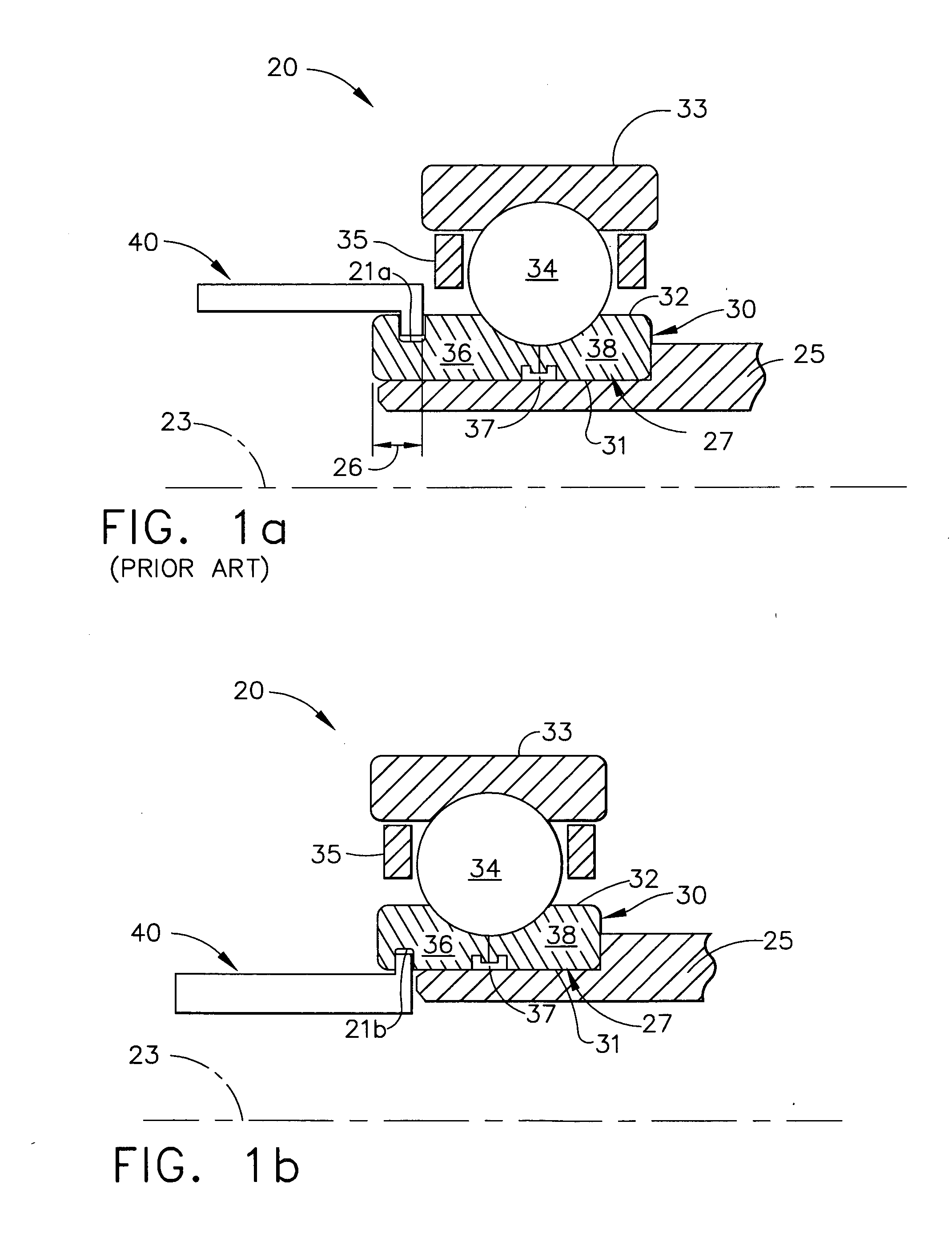

Compact removal feature and removal tool for rolling element bearings

InactiveUS20050132554A1Bearing repair/replacementShaft repair/replacementRolling-element bearingEngineering

A compact removal feature comprises a plurality of recesses, such as radius slots, on an inner diameter (ID) of a bearing inner ring. The removal tool can engage the removal feature and remove the entire bearing assembly without damage to the parts. The placement of the removal feature on the bearing inner ring ID allows for a reduction in inner ring length (and weight) while maintaining bearing assembly integrity.

Owner:HONEYWELL INT INC

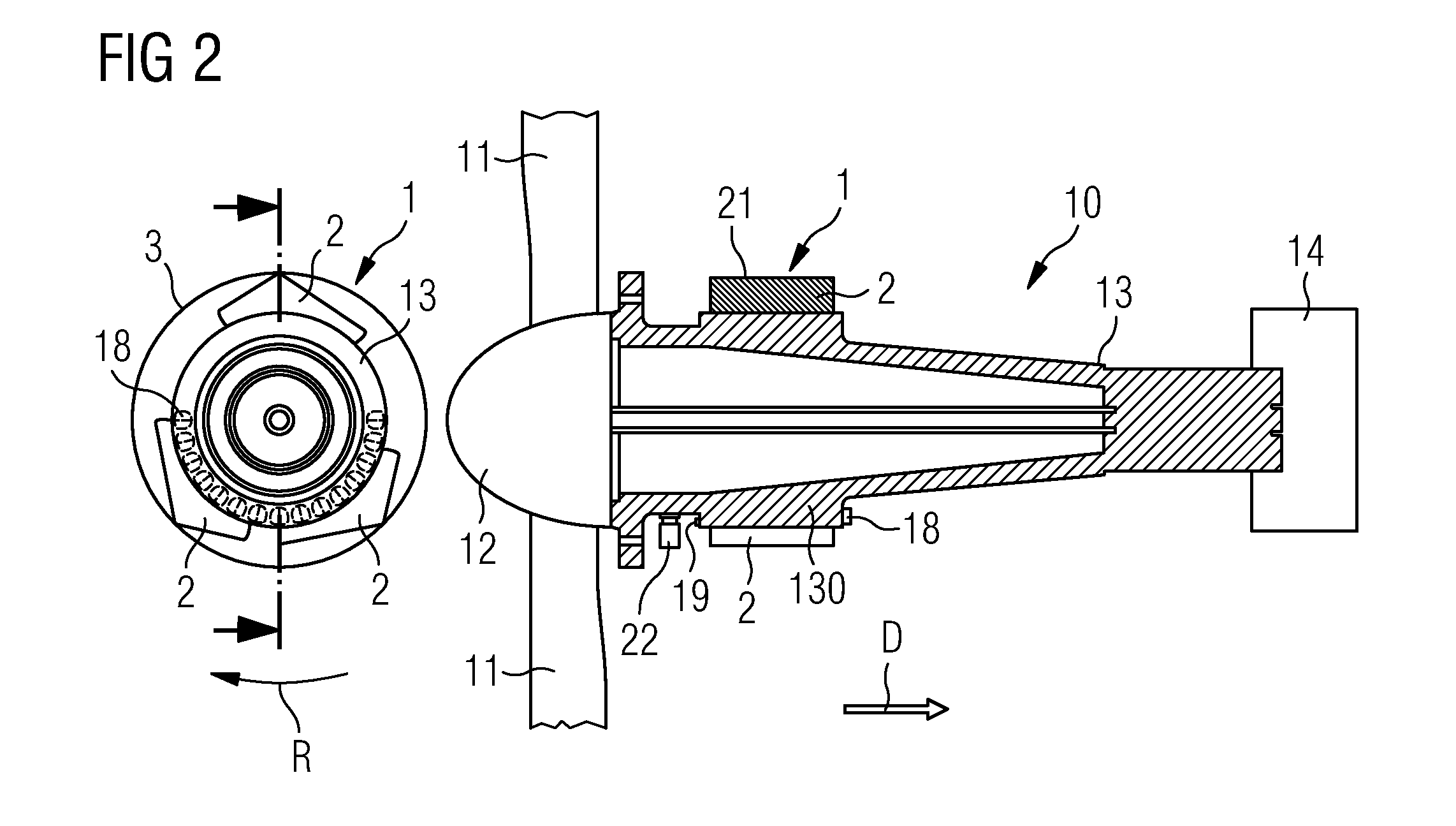

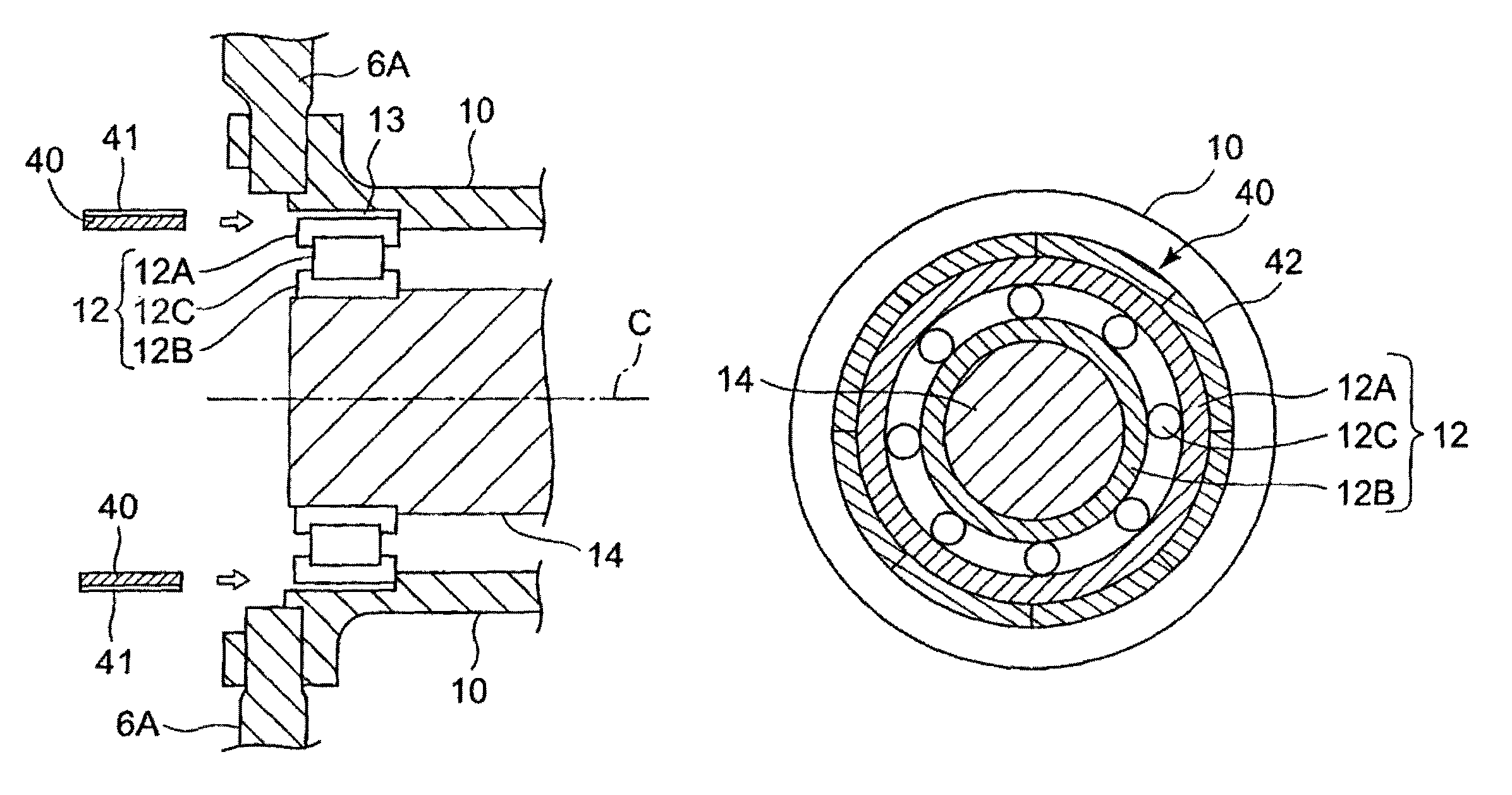

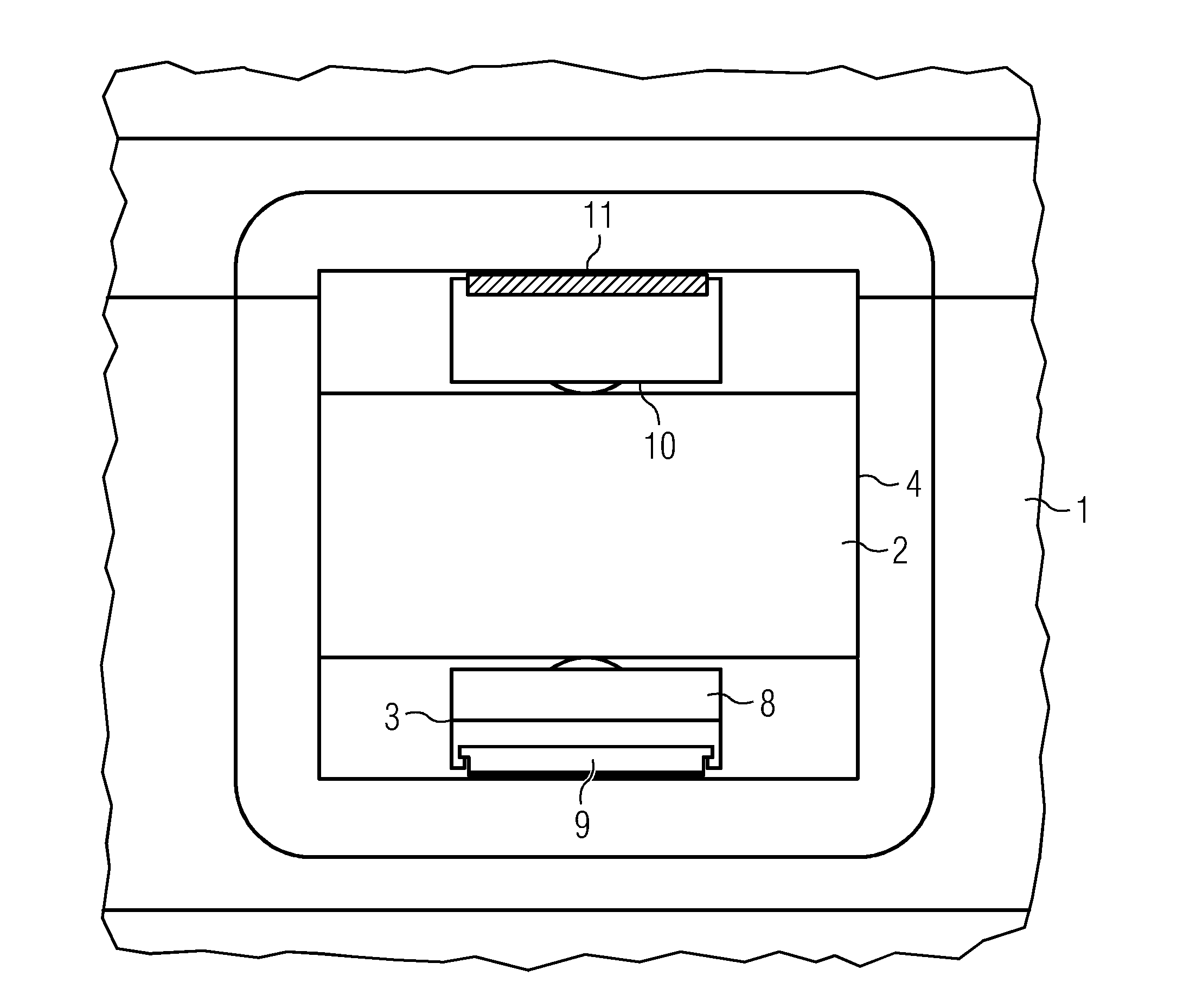

Method of repairing bearing of wind turbine generator

A method of repairing a bearing of a wind turbine generator is provided which is able to more permanently repair a gap which occurred between a constituent member of the wind turbine generator and a bearing ring of the bearing. For example, in the case of repairing the gap 13 between the main shaft outer cylinder 10 of the wind turbine generator 1 and the outer ring 12A of the main bearing 12, the plate 40 is inserted between the main shaft outer cylinder 10 and the outer ring 12A, and also the plate 40 is fixed to an inner circumferential surface of the main shaft outer cylinder 10 by the adhesive agent 41. On the other hand, slip is permitted between the plate 40 and the outer ring 12A of the main bearing 12.

Owner:MITSUBISHI HEAVY IND LTD

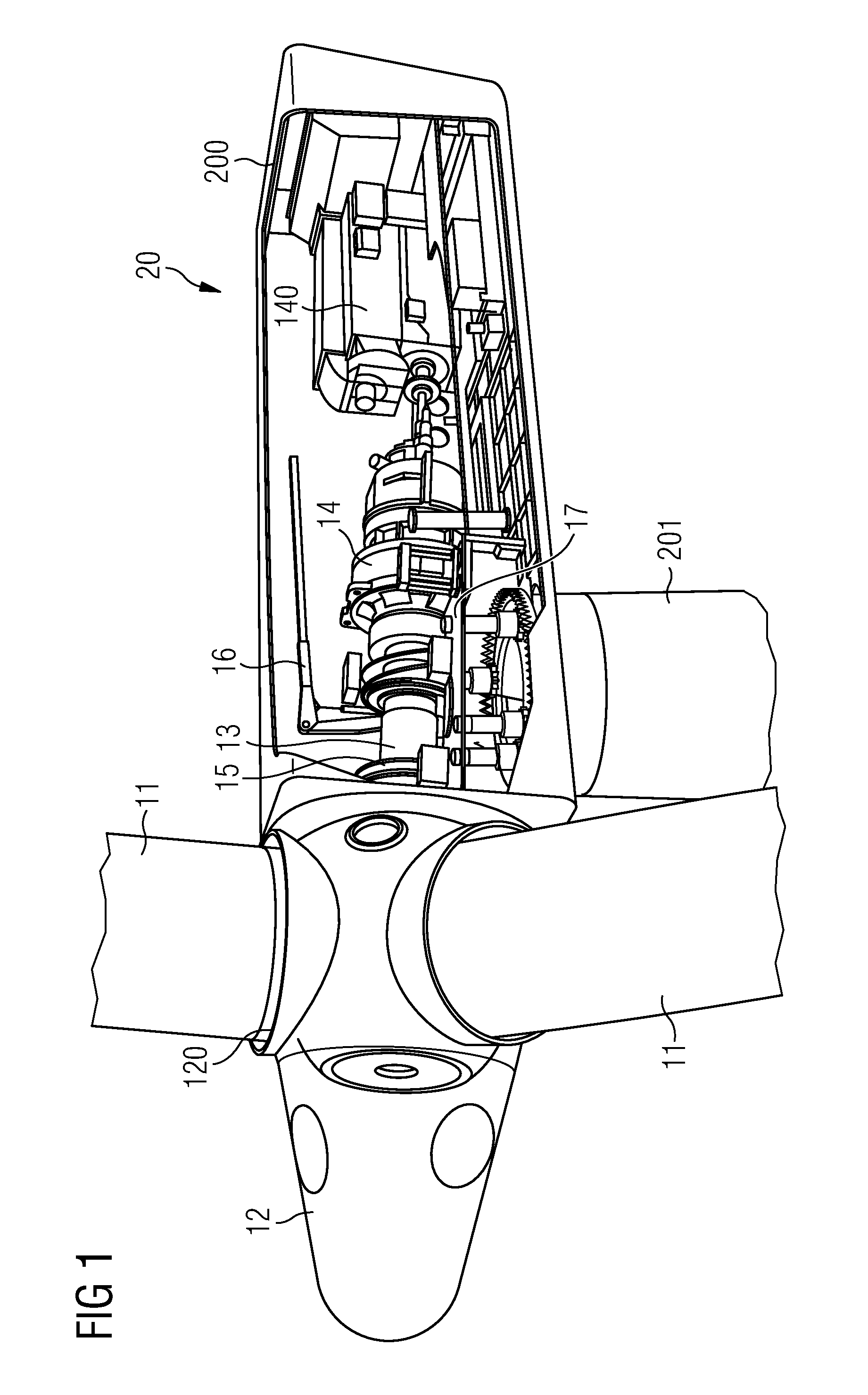

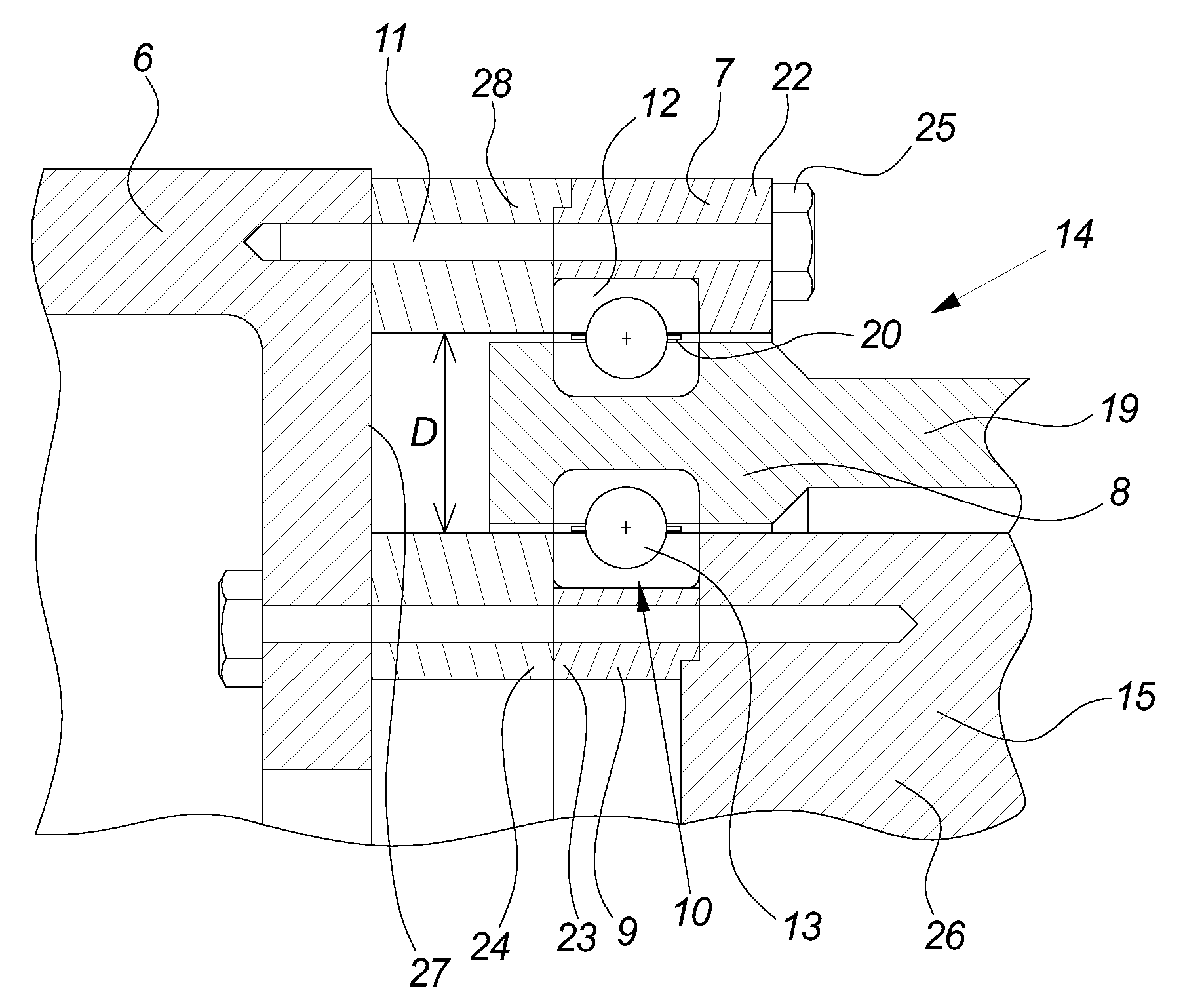

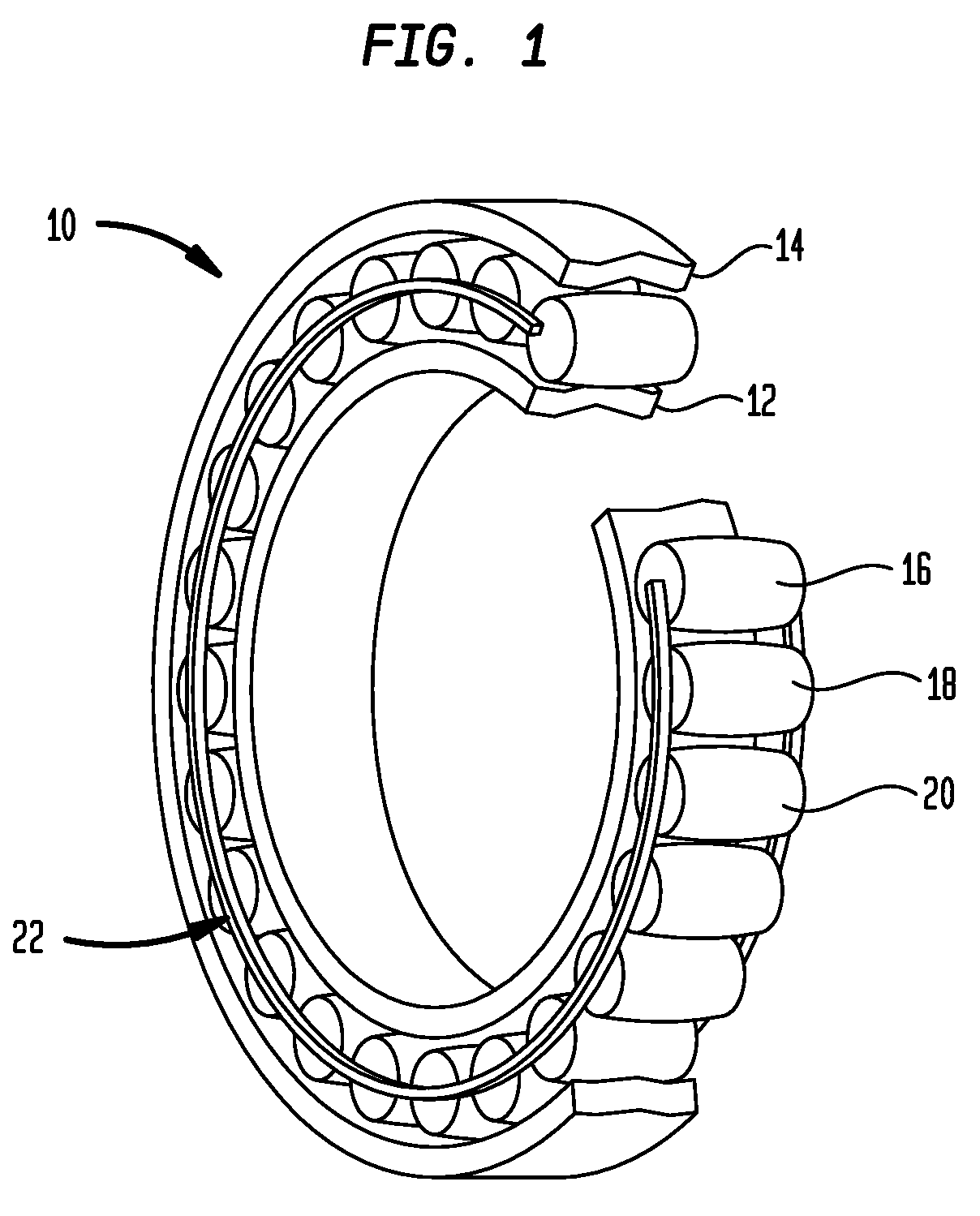

Wind Turbine, A Method For Servicing A Main Bearing Unit Of A Wind Turbine And Use Thereof

InactiveUS20090285693A1Extended Part LifeSimple methodBearing repair/replacementRotary bearingsNacelleWind force

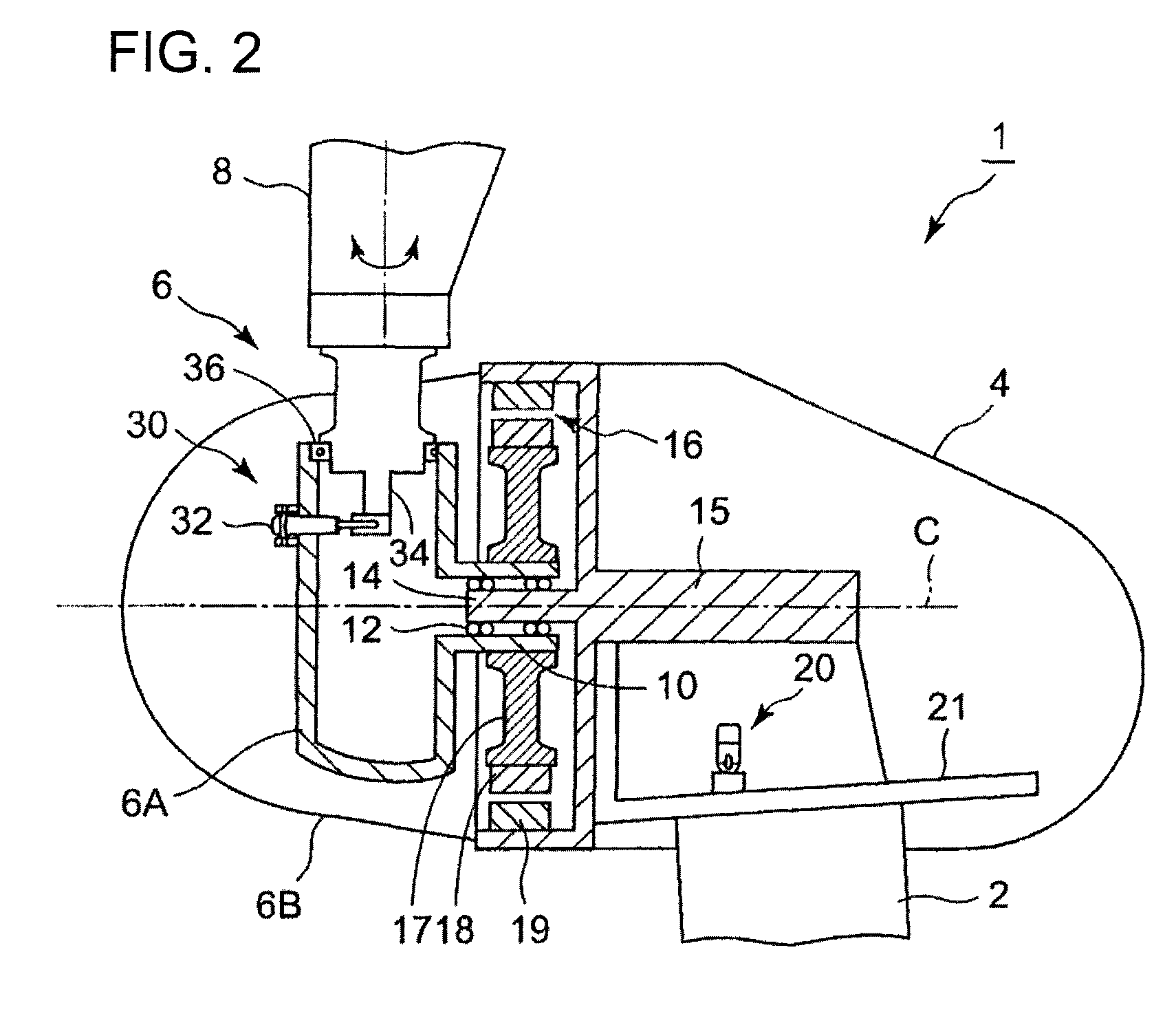

A wind turbine includes a nacelle and a rotor, the rotor being rotatably mounted on the nacelle by means of at least one main bearing unit. The wind turbine is characterized in that the main bearing unit includes at least one outer ring, at least one centre ring and at least one inner ring and wherein the centre ring is capable of rotation in relation to the outer ring and the inner ring or the outer ring and the inner ring are capable of rotation in relation to the centre ring. A method for servicing a main bearing unit of a wind turbine and a use hereof are also provided.

Owner:VESTAS WIND SYST AS

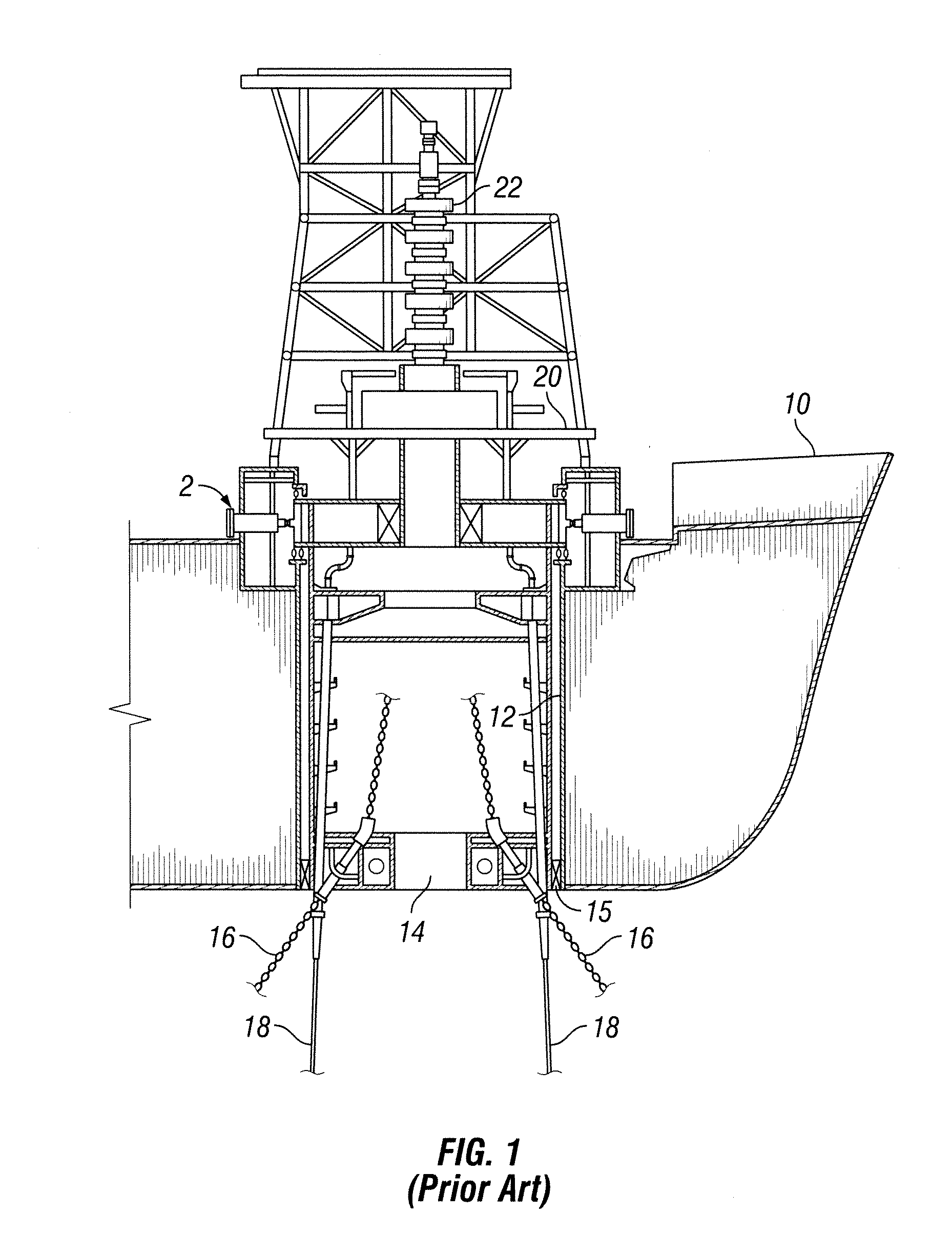

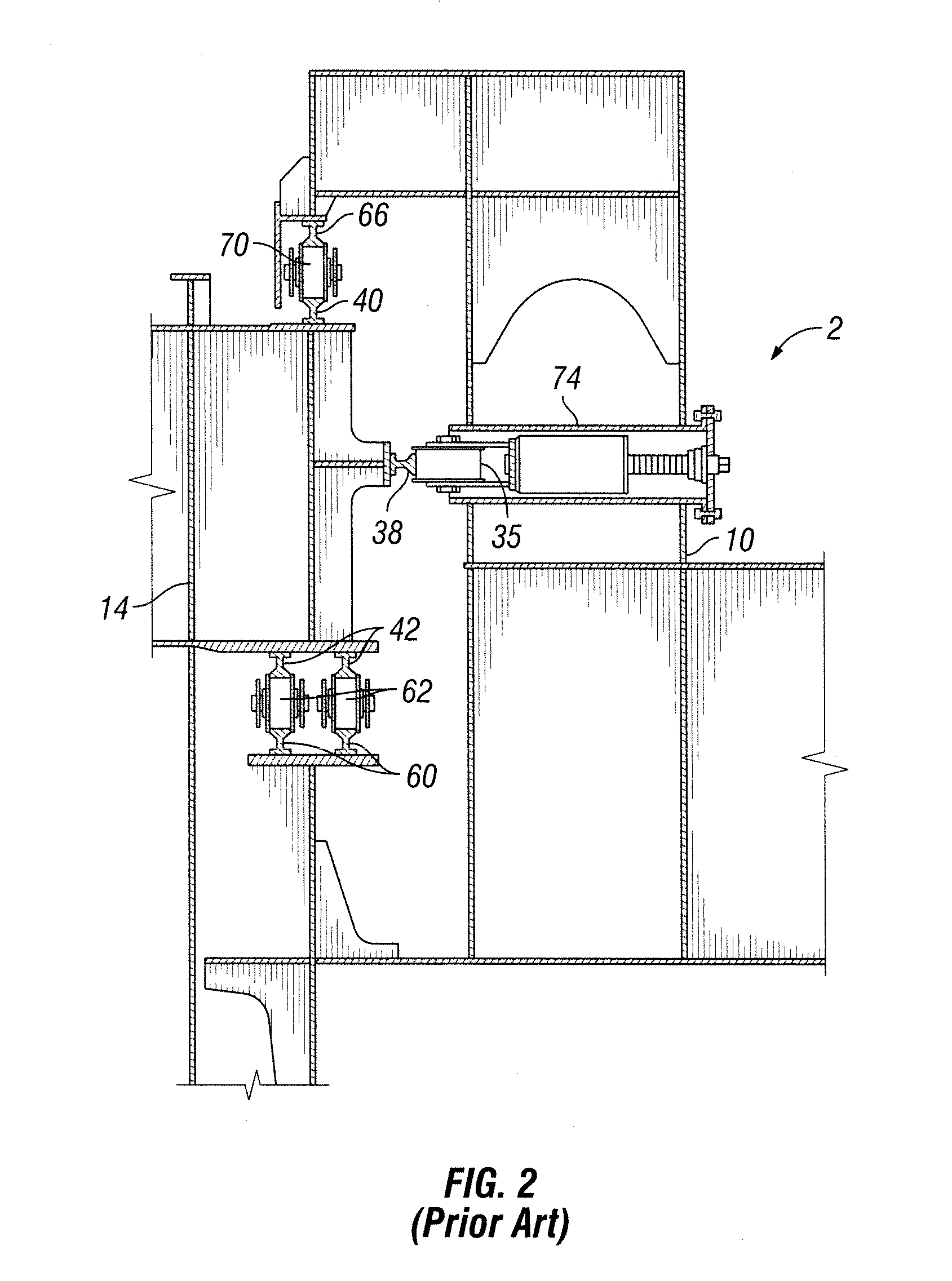

Replaceable roller bearing

ActiveUS8950349B2Improve reliabilityIncrease load capacityBearing repair/replacementRotary combination bearingsAxial displacementThrust bearing

A turret / vessel bearing arrangement and method for replacing bearings in situ without removing other bearings. The bearings are capable of being separated. A removable axial spacer secures the vessel and the turret into engagement with the upper and lower thrust bearings. Removal of the spacer allows increased separation between vessel and turret flanges that sandwich the thrust bearings. The mid radial bearing assembly includes one or more radially arranged bearing pads that allow for limited axial displacement of the turret with respect to the vessel during thrust bearing replacement while still bearing radial loads and allowing rotation. The addition of a temporary thrust bearing allows the vessel to weathervane about the turret while thrust bearing are replaced in situ.

Owner:SOFEC

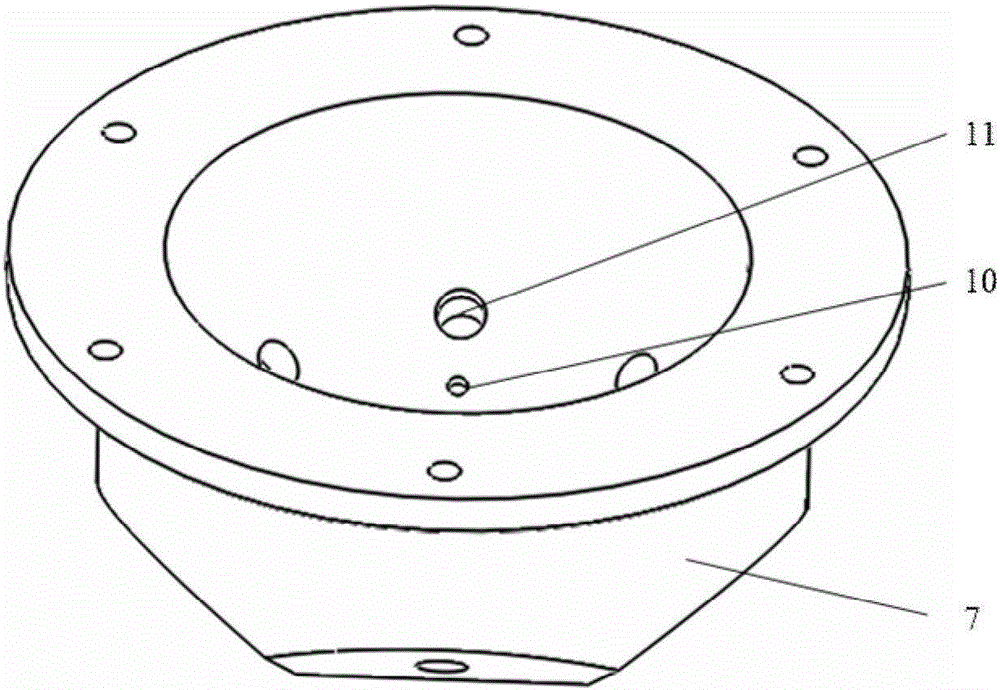

Sliding bearing and method to perform service at sliding bearing

ActiveCN103670948AEasy to controlExtended service lifeBearing repair/replacementRolling contact bearingsMechanical engineeringPlain bearing

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

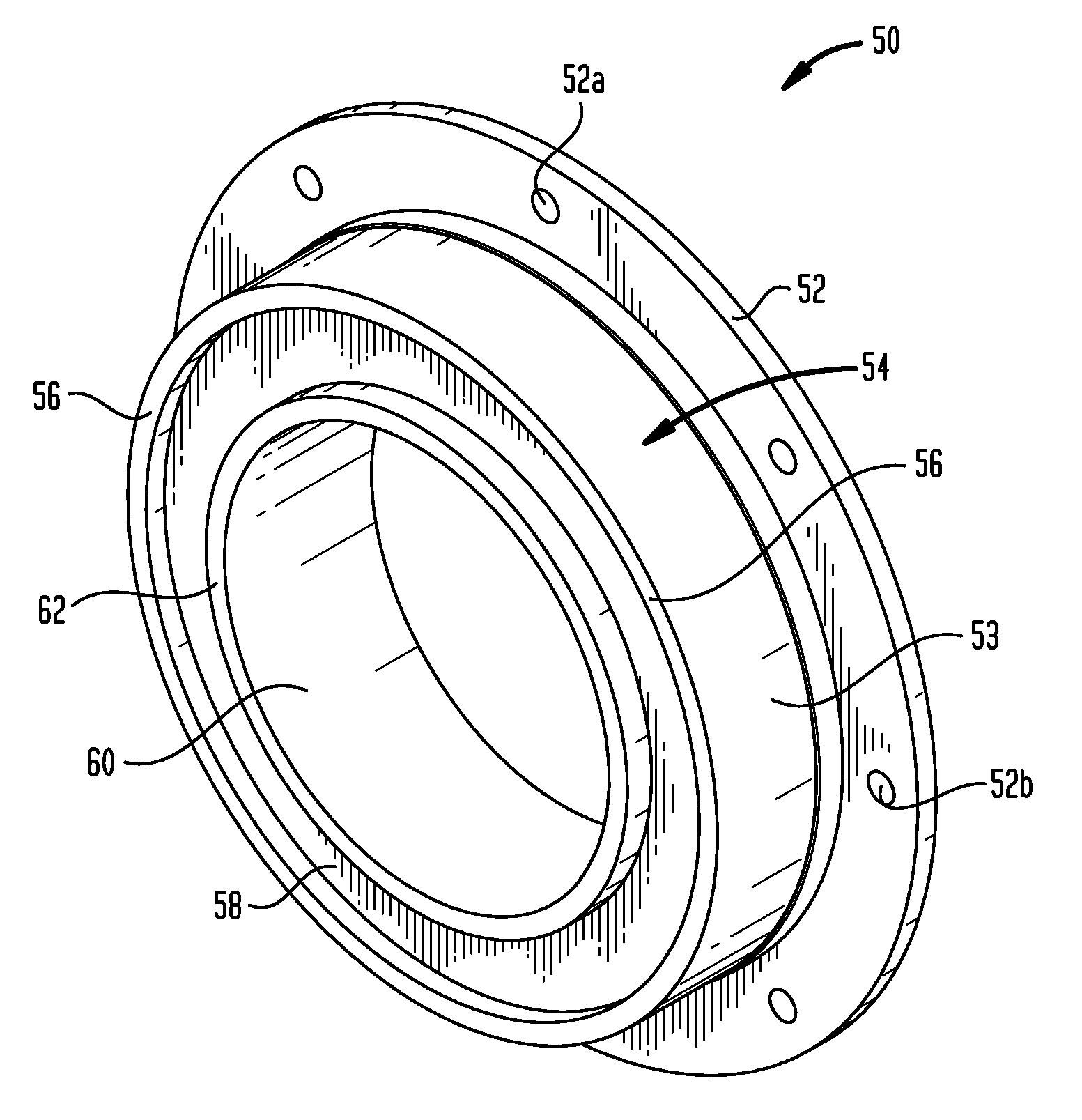

Bearing Alignment Tool and Method Of Use

InactiveUS20090265947A1Better load distributionLow frictional runningBearing repair/replacementRoller bearingsClassical mechanicsStructural engineering

A bearing alignment tool and method of use is provided for aligning inner and outer races of a roller bearing of the class wherein the inner and outer races of the roller bearing are axially displaceable with respect to each other in order to accommodate thermal growth of a rotating shaft. A bearing replacement procedure includes: (a) affixing the roller bearing to the shaft at its inner race; (b) disposing the shaft in a housing; (c) aligning the inner and outer races of the roller bearing with respect to each other and the housing in a predetermined spatial relationship by affixing an alignment tool to the housing, wherein the alignment tool has (i) an outer aligning surface which engages the outer race of the roller bearing; and (ii) an inner aligning surface which engages the inner race of the roller bearing; (d) removing the alignment tool from the housing; and (e) securing the housing to a fixed position on a support while maintaining the predetermined spatial relationship established in step (c). The method and alignment tool are particularly useful for quickly replacing bearings on an afterdryer of a papermachine where precision alignment and downtime are significant considerations.

Owner:GPCP IP HLDG LLC

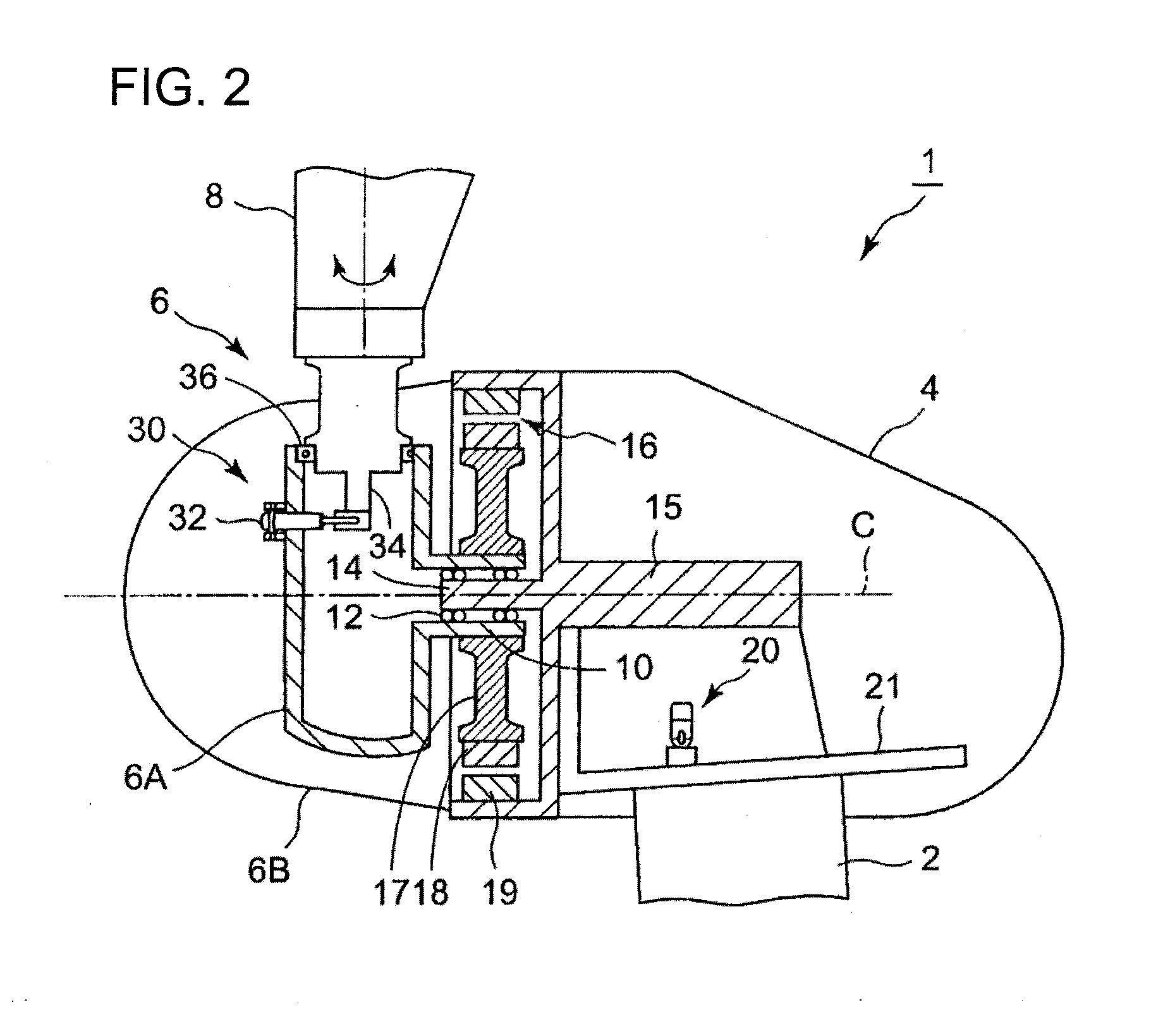

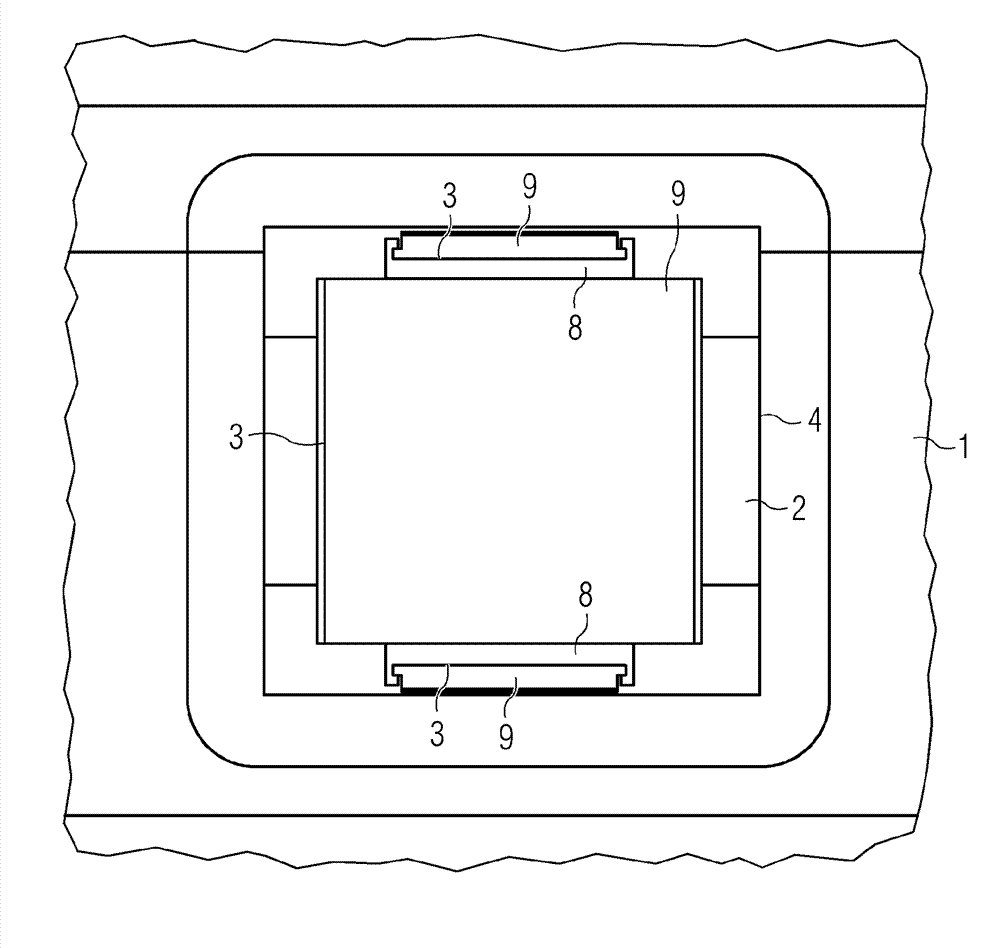

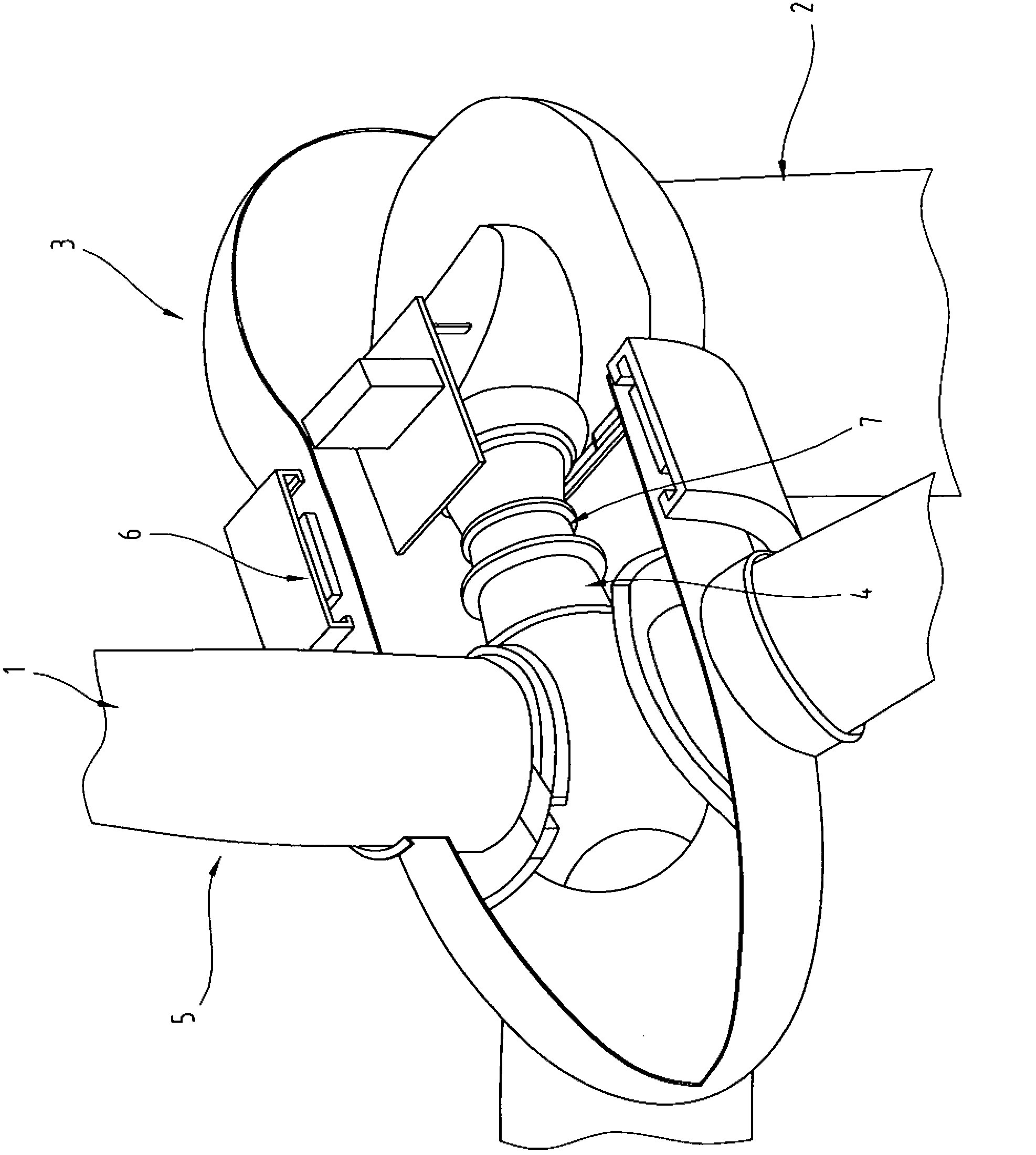

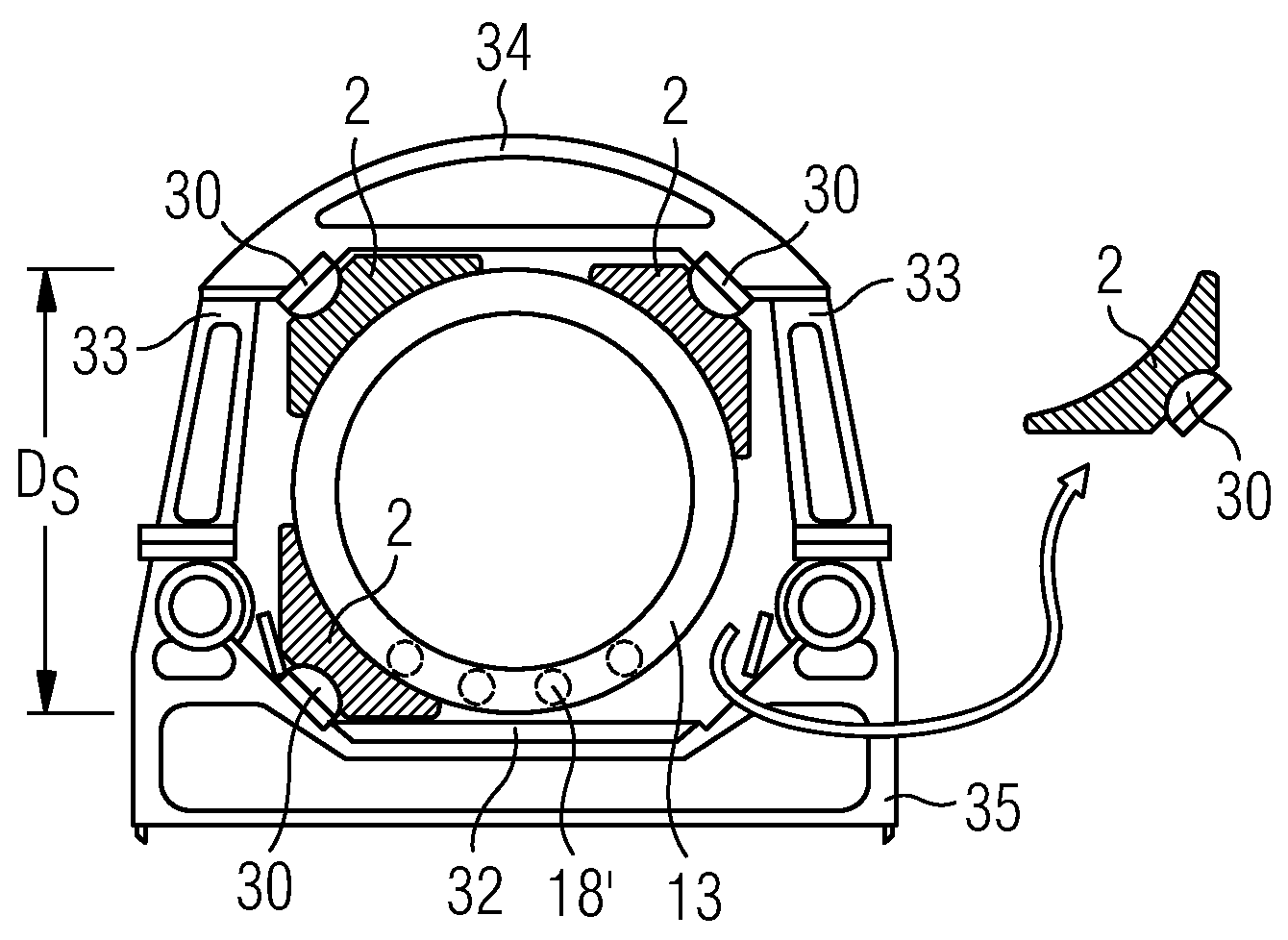

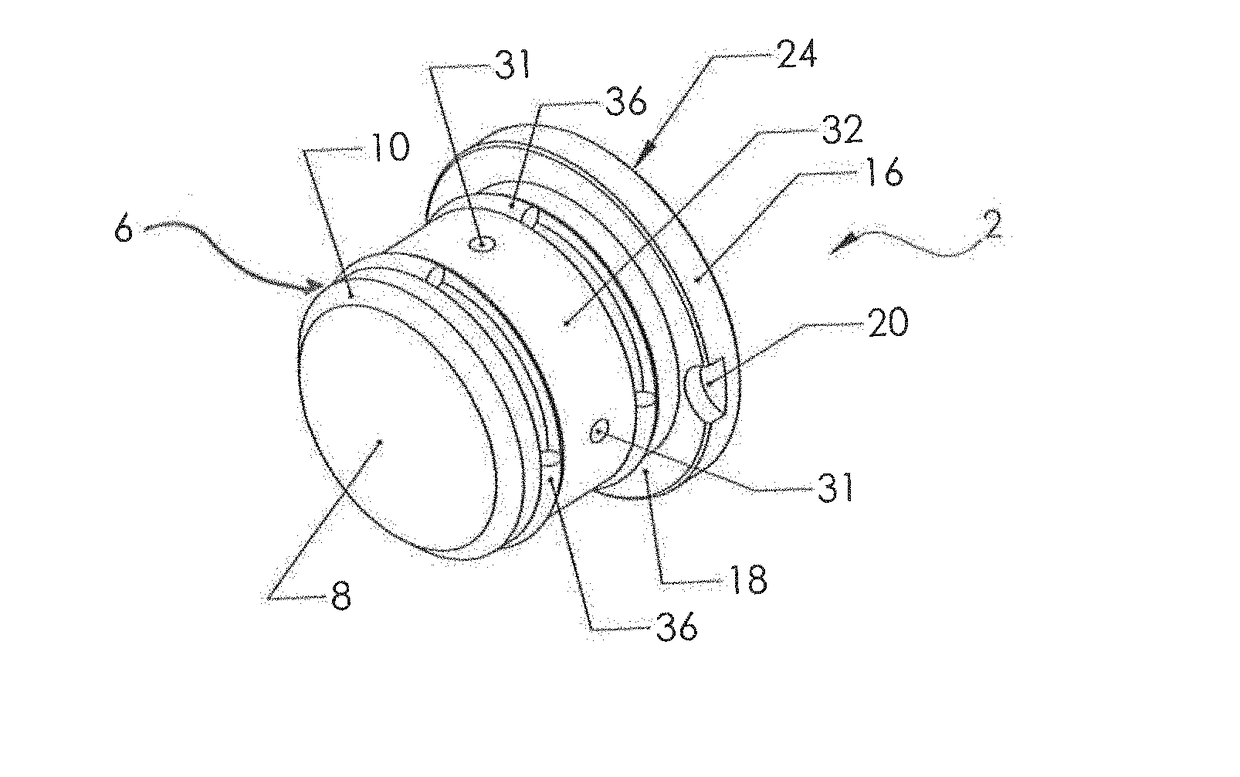

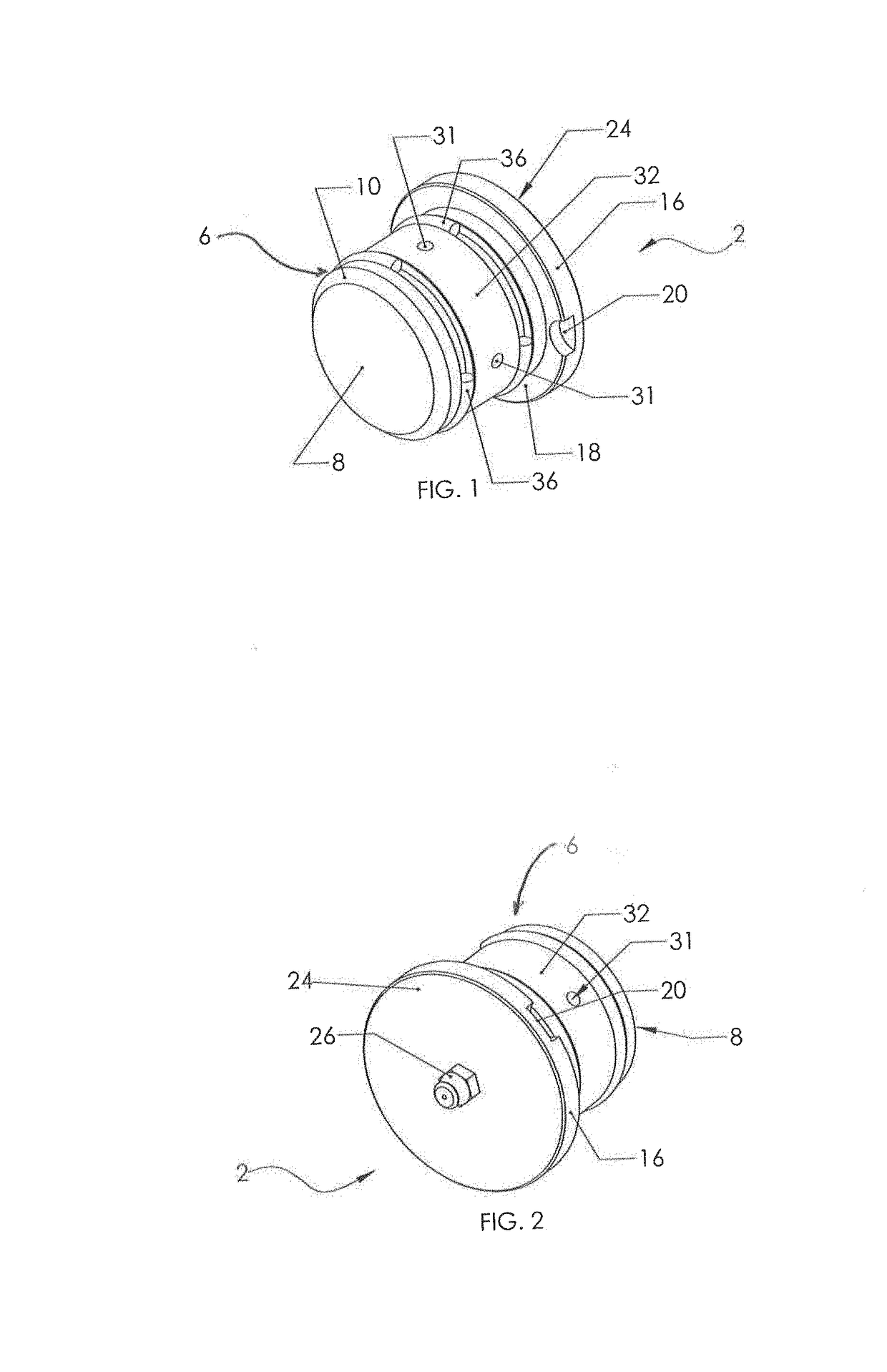

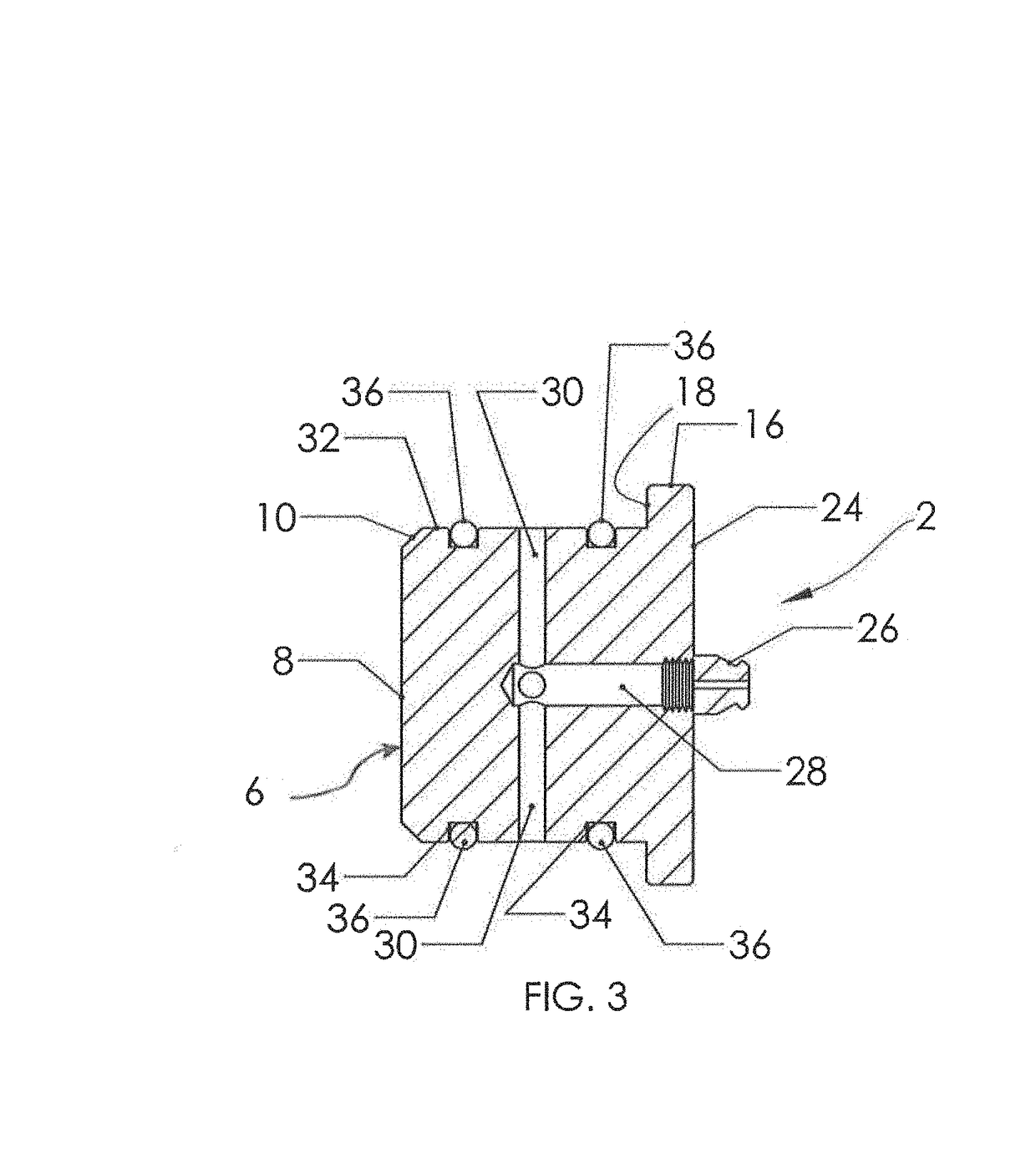

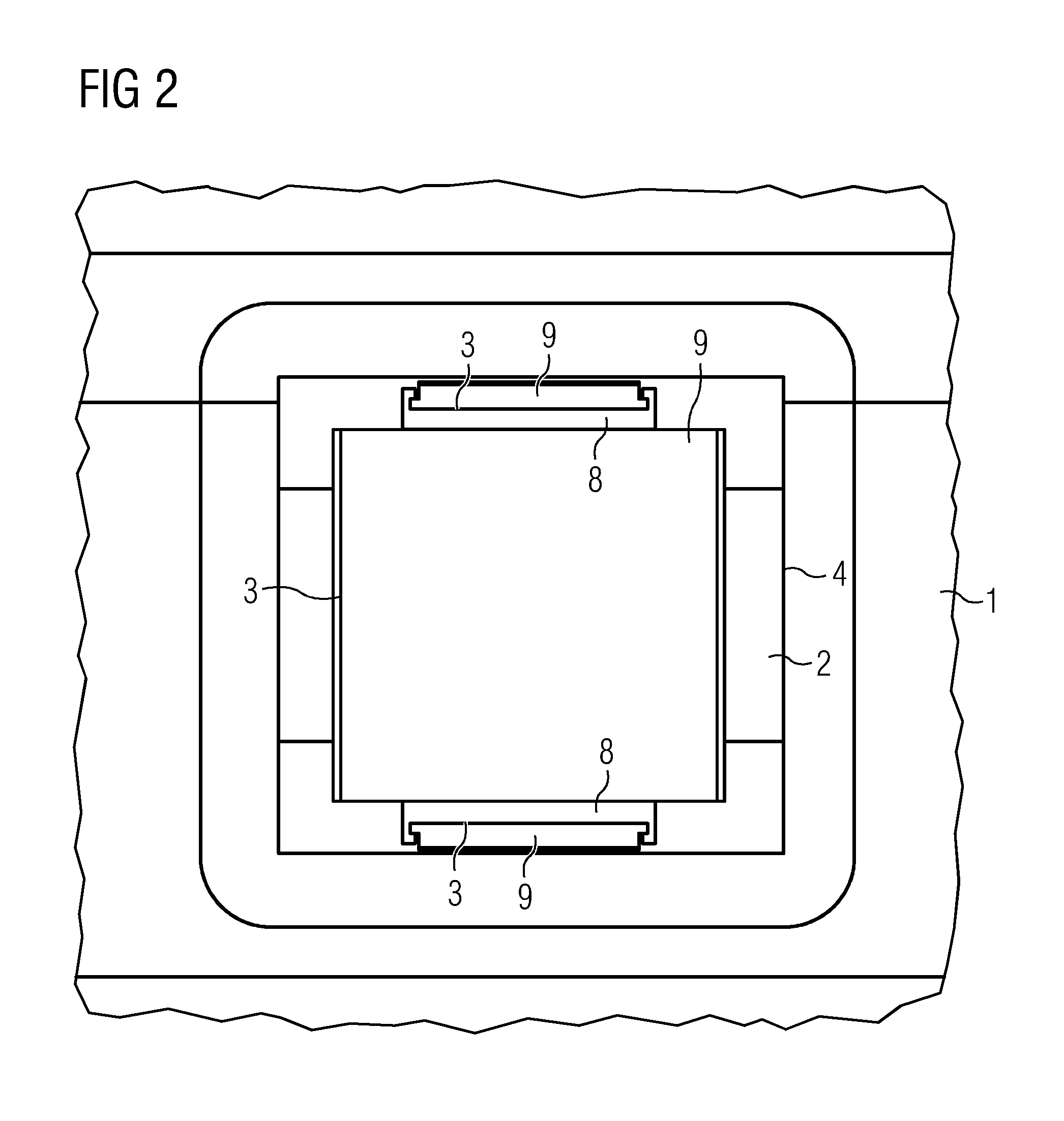

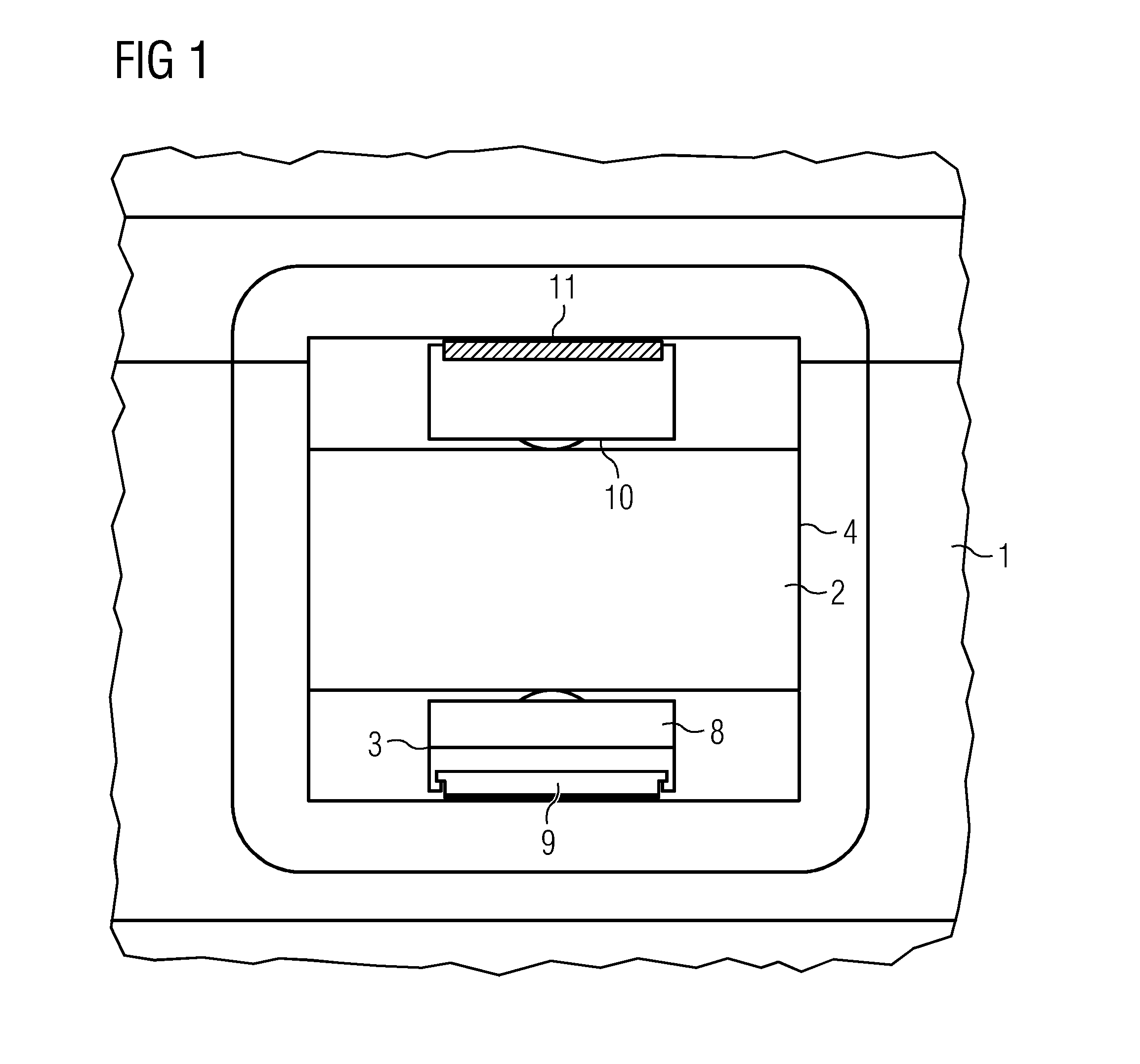

Bearing element

ActiveCN102834611AGood radialGood axial supportBearing repair/replacementBearing assemblyEngineeringAxial distance

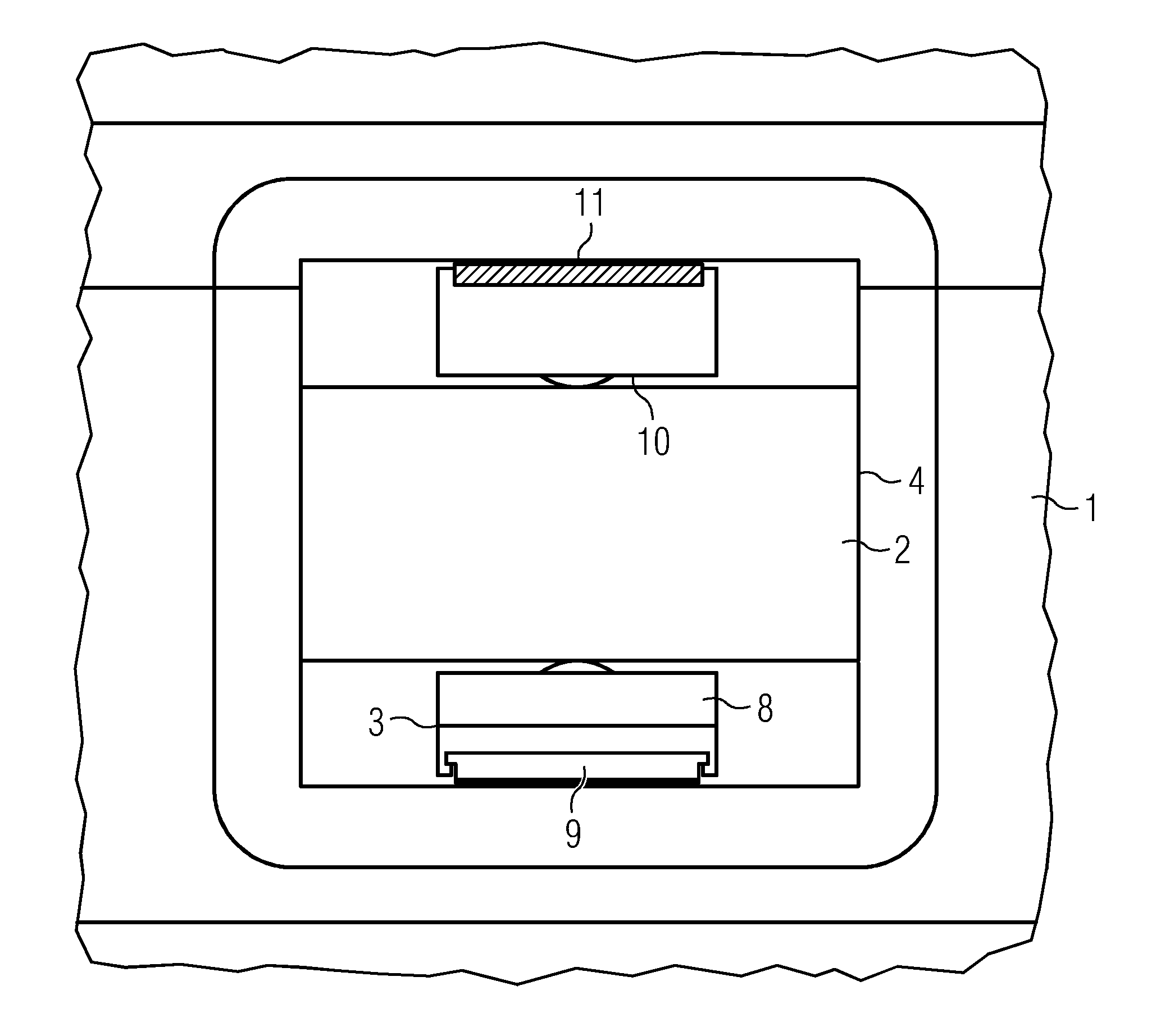

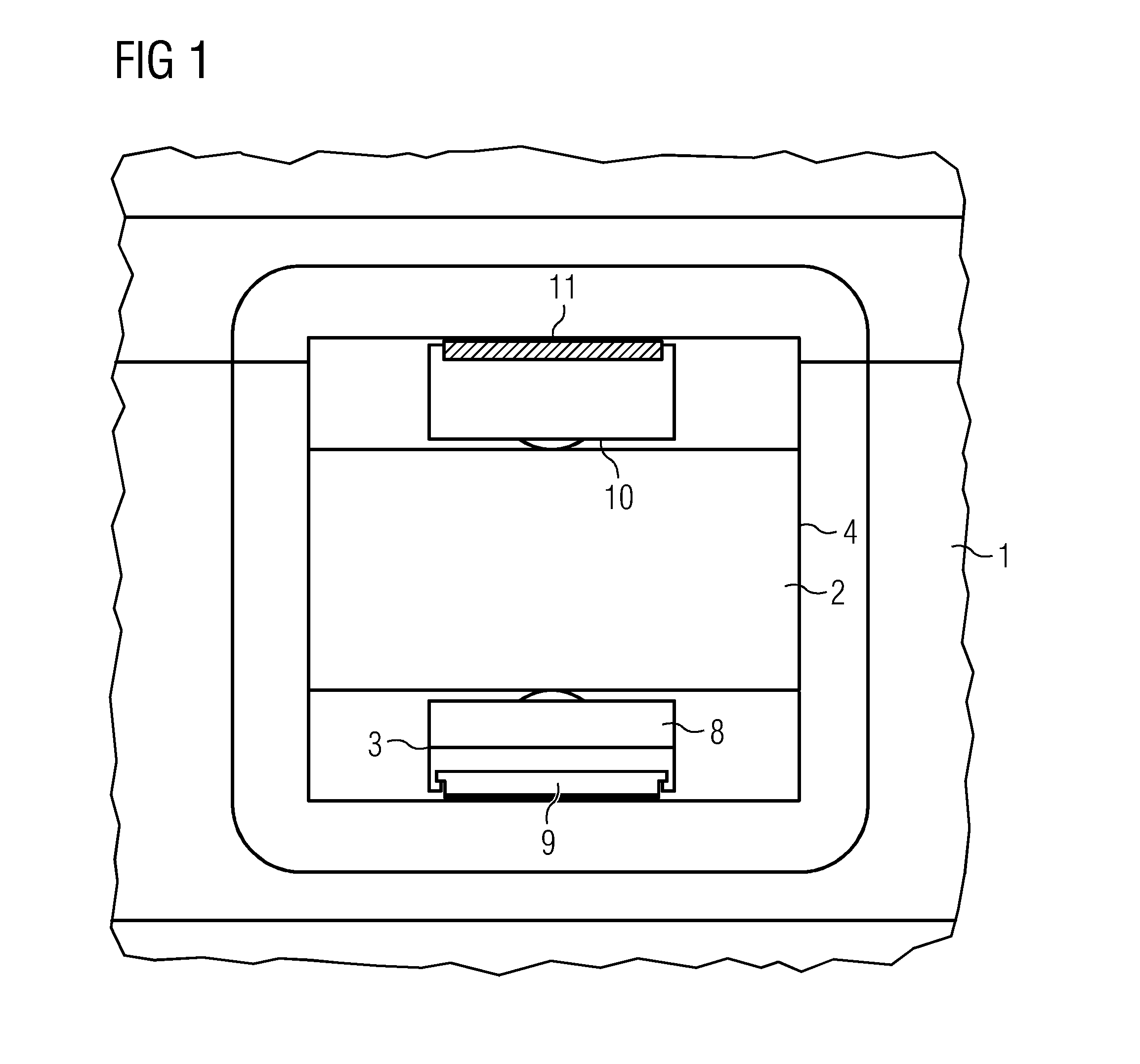

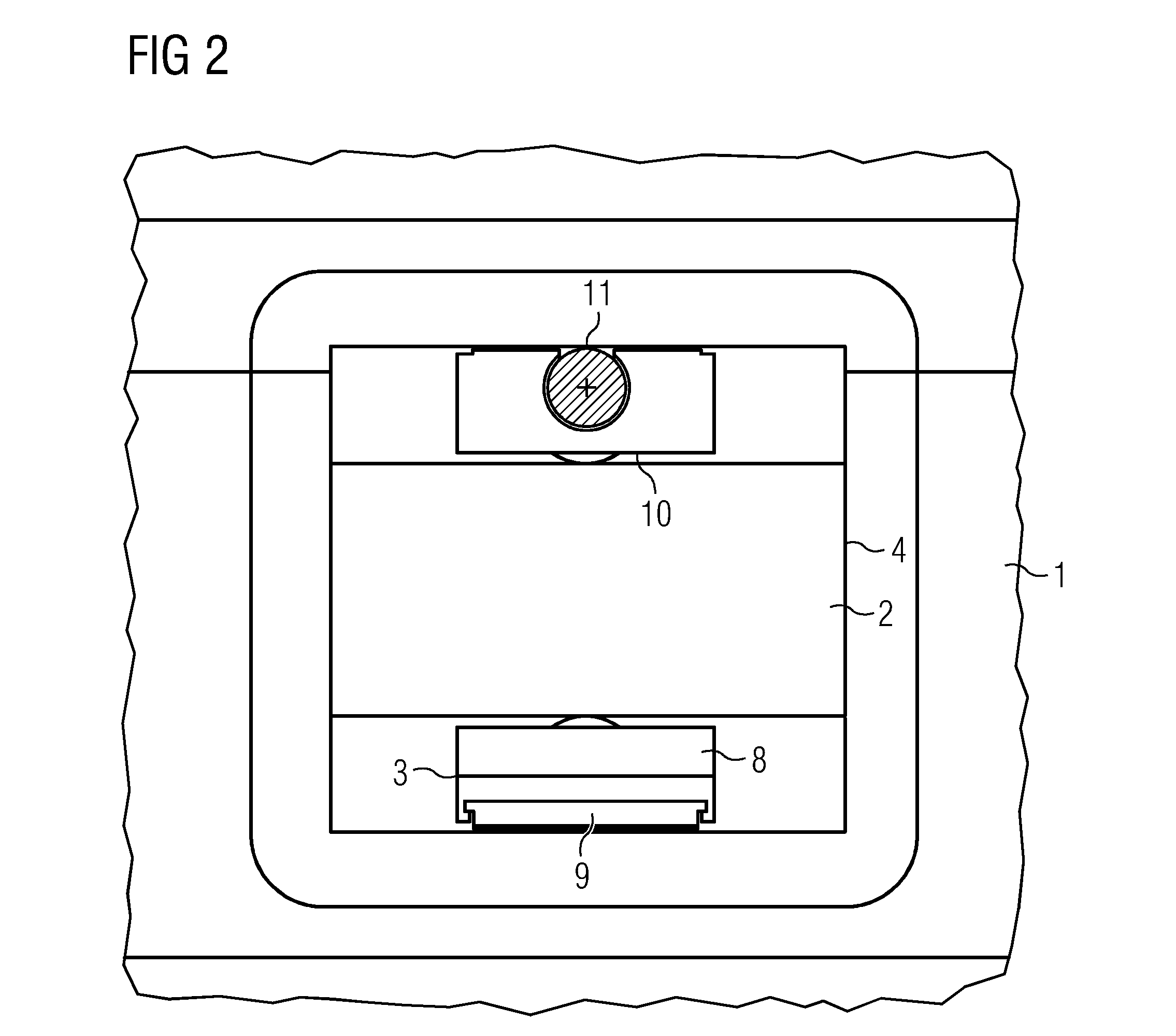

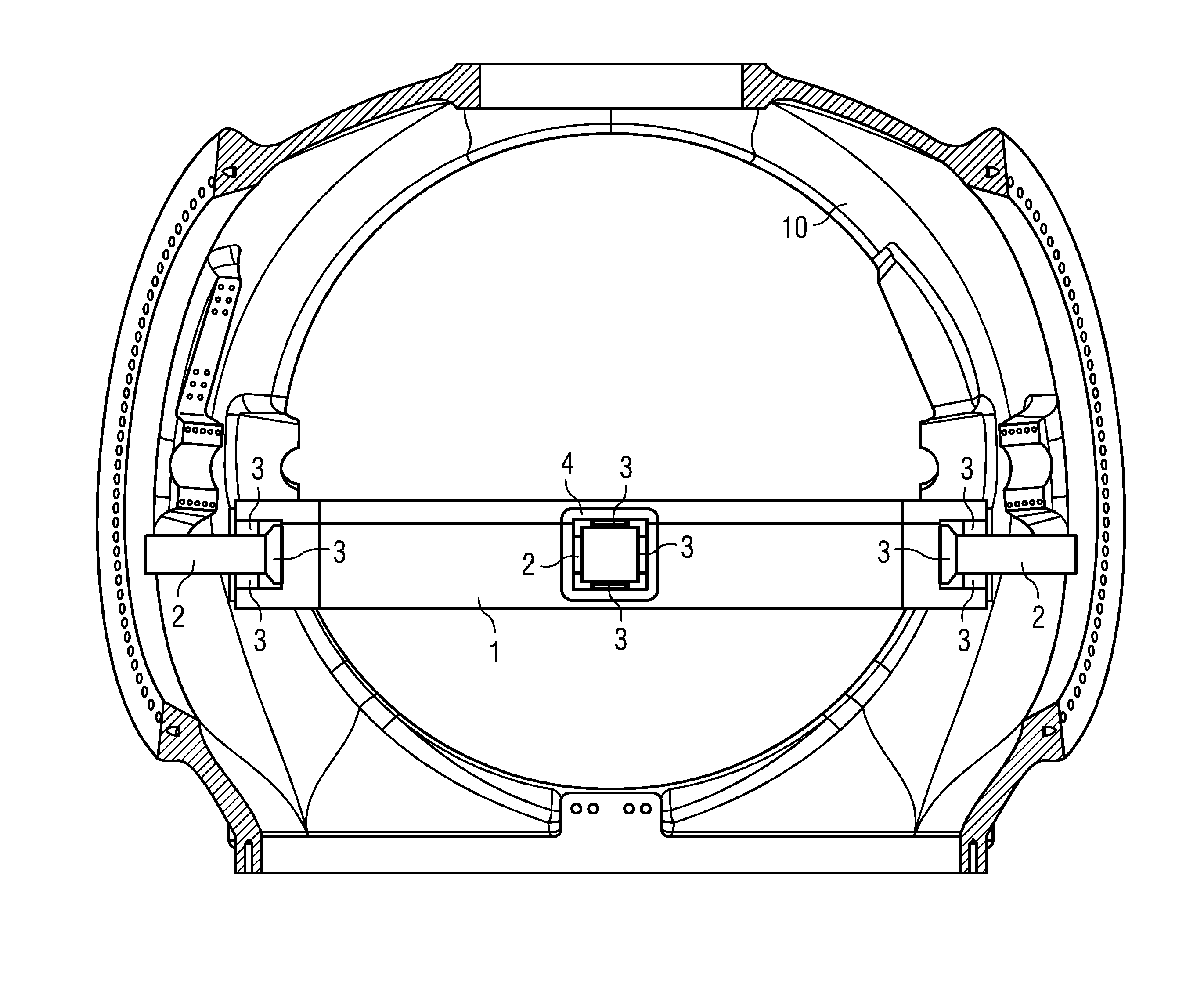

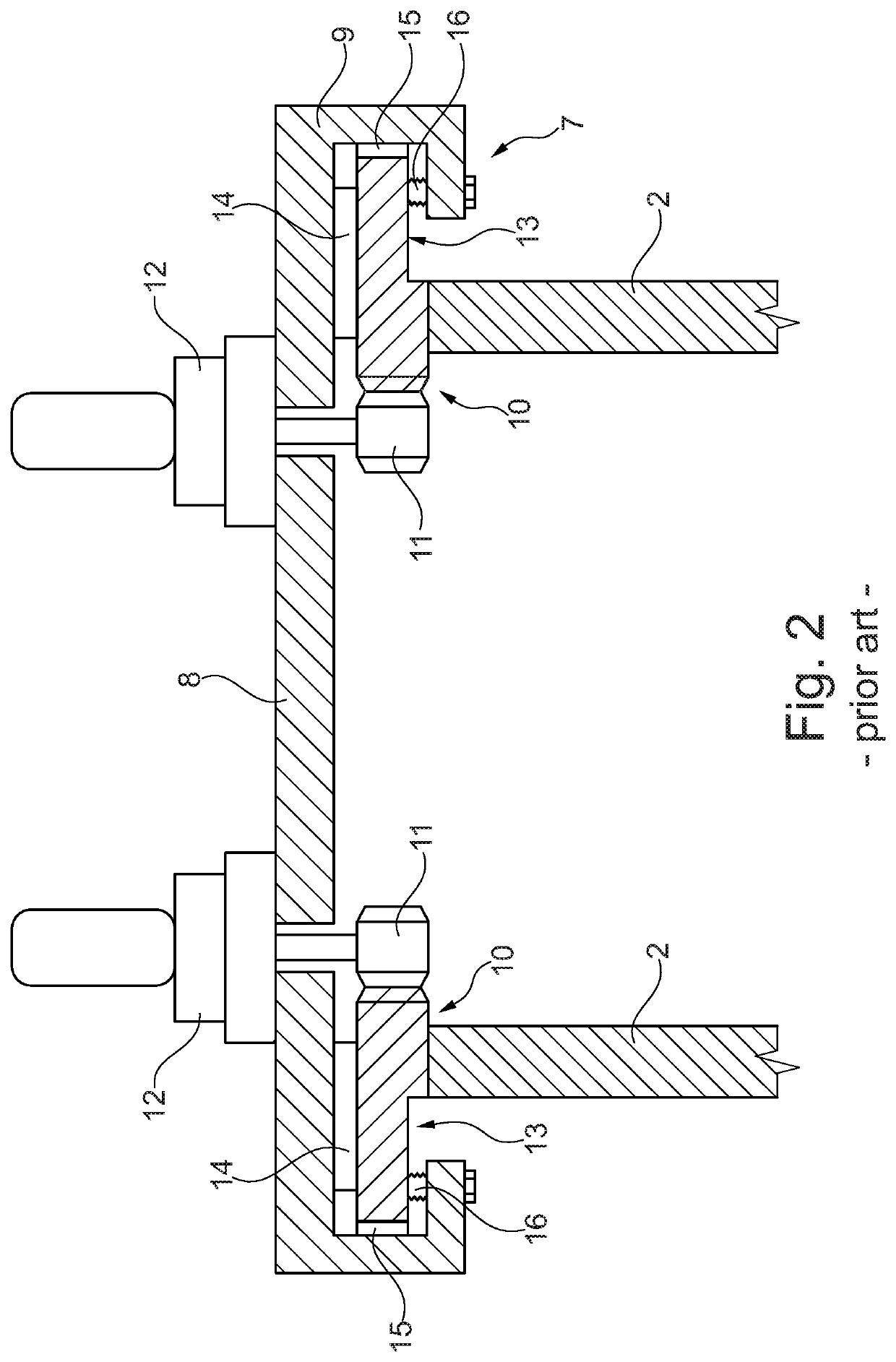

The invention relates to a bearing element (7) for supporting the rotor hub (4) of a wind turbine (1), comprising at least one inner ring element (10, 40) and at least one outer ring element (11, 41), wherein a plain bearing support is developed between the inner ring element (10, 40) and the outer ring element (11, 41), and wherein the plain bearing support is formed by at least two plain bearings (8, 9, 38, 39) arranged at an axial distance (44) from each other.

Owner:MIBA SINTER AUSTRIA

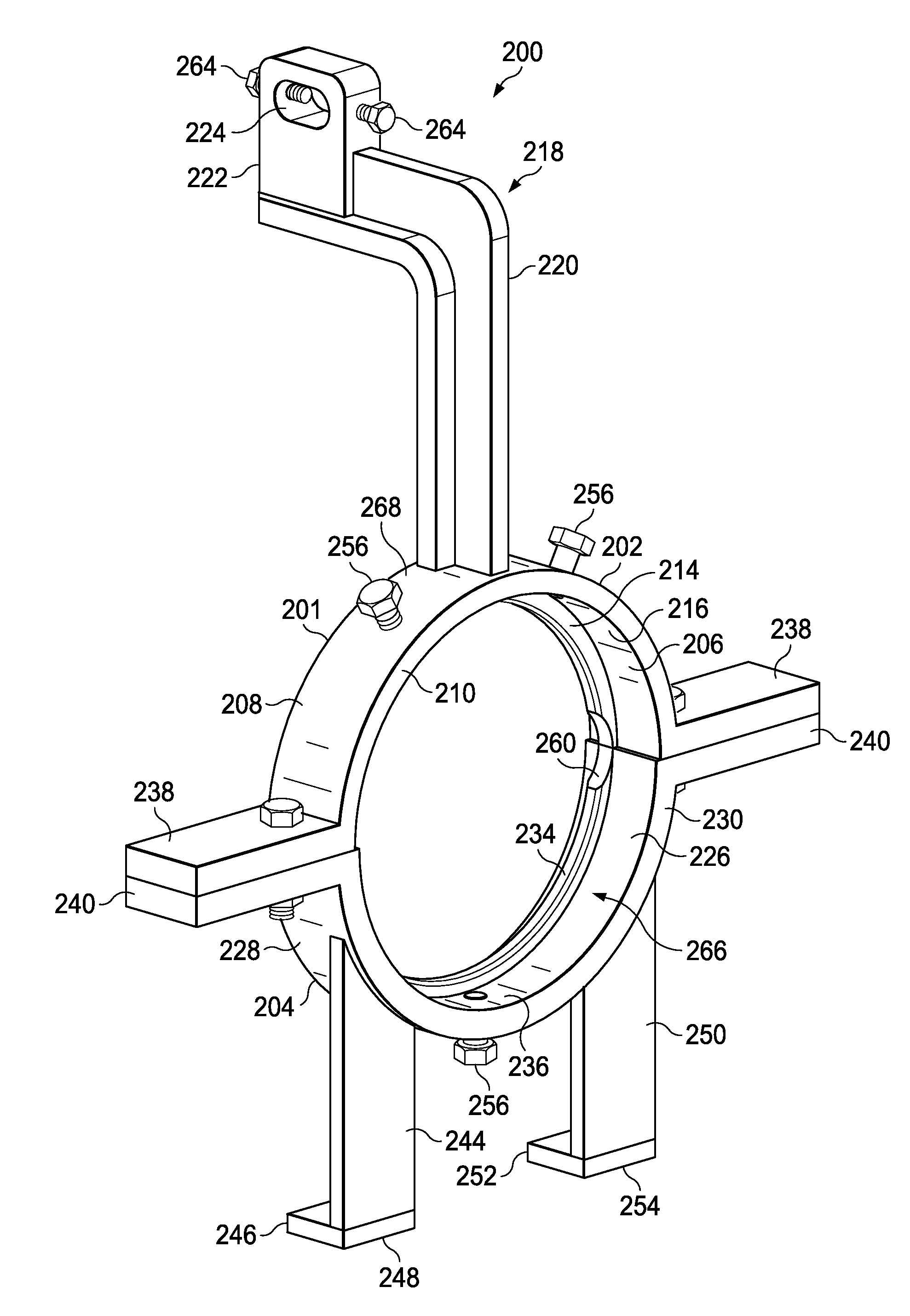

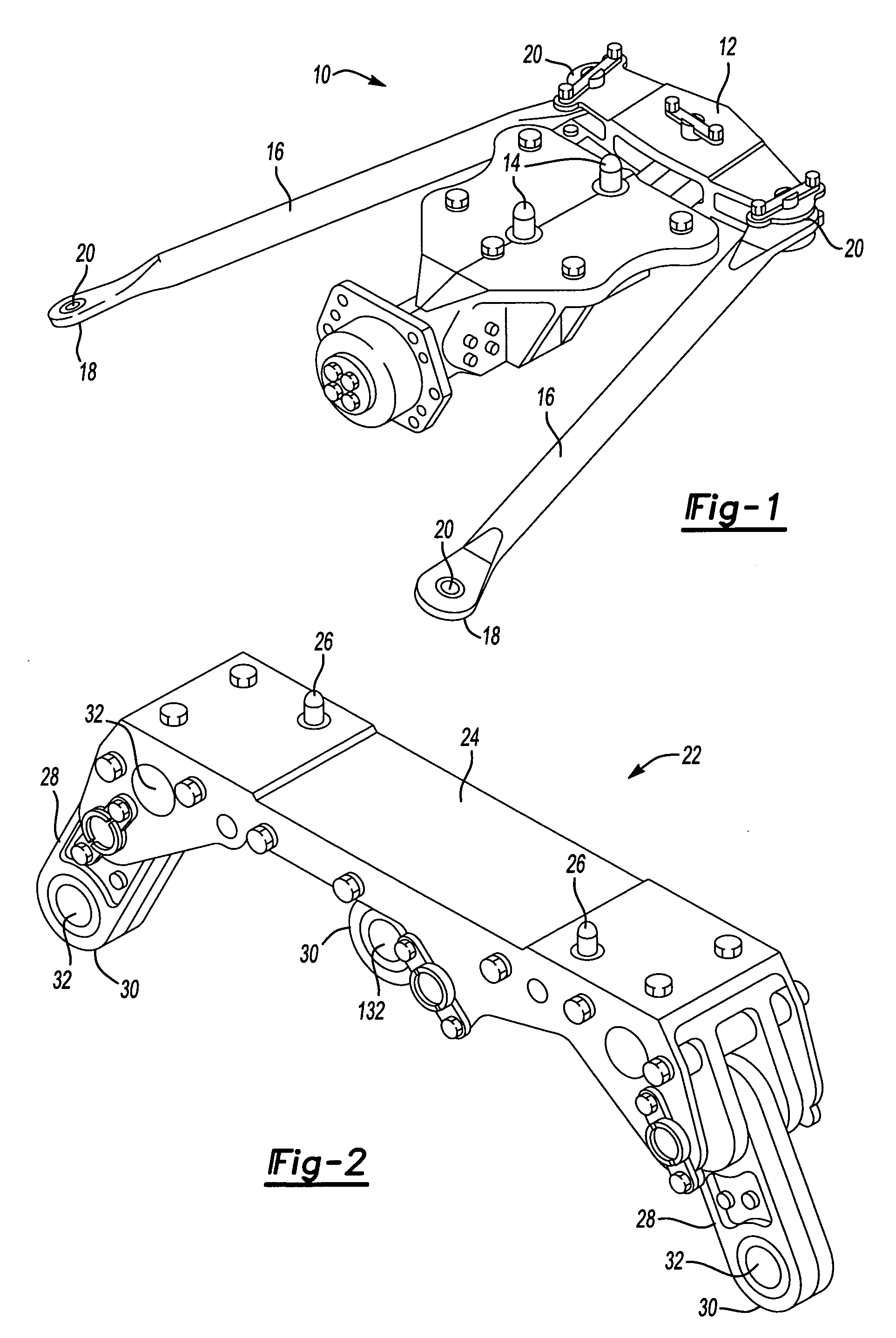

Systems, apparatuses and methods for lifting, positioning and removing a bearing assembly from a shaft

InactiveUS20150226265A1Easy to disassembleBearing repair/replacementRoller bearingsMechanical engineeringLower body

Apparatuses include an upper body and a lower body coupleable to the upper body for forming a channel to support a bearing assembly therein. A retention member extends into the channel from at least one of the upper body or the lower body. The retention member is configured to engage the bearing assembly to secure the bearing assembly within the channel. The apparatus further includes a lifting member formed in the upper body for receiving a hoisting member for lifting the bearing assembly.

Owner:WEIR SLURRY GRP INC

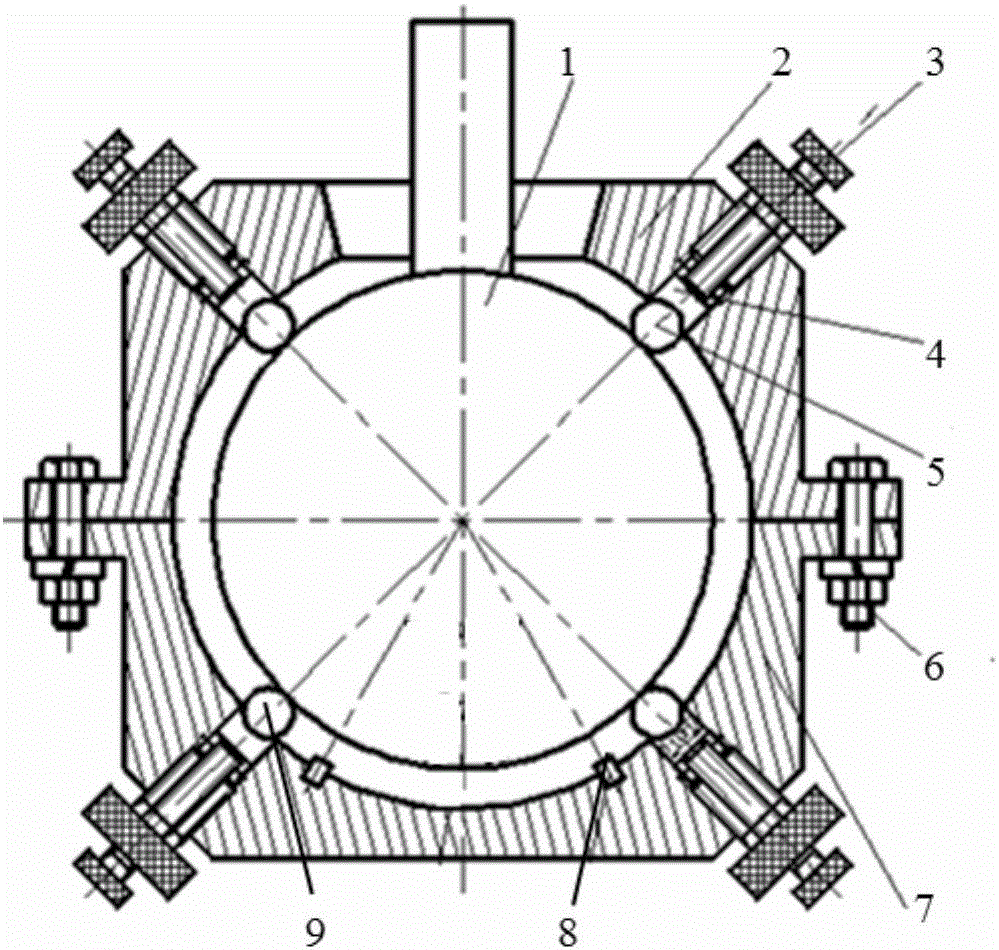

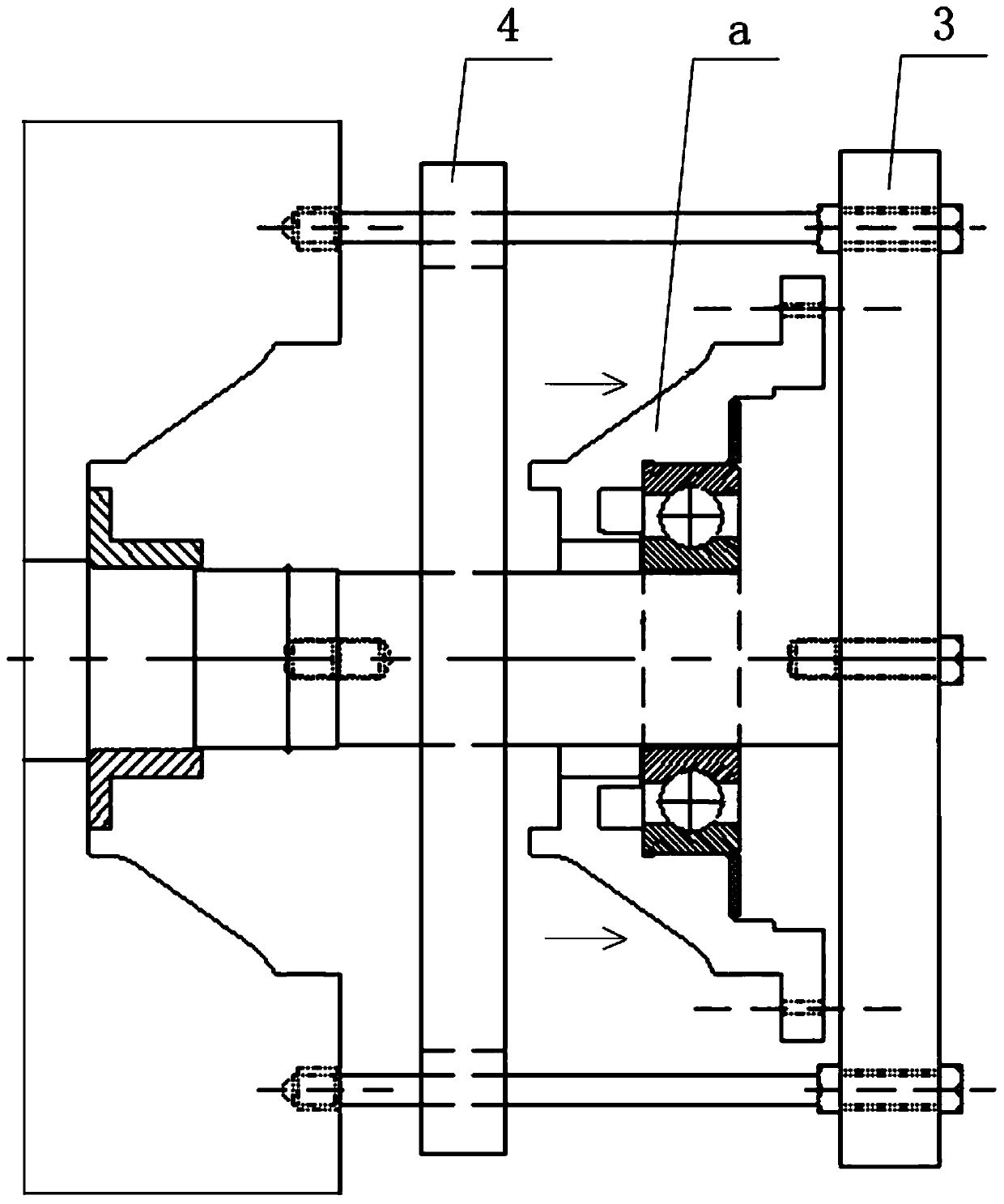

Center-adjustable ball spherical hinge joint and center adjusting method of center-adjustable ball spherical hinge joint

ActiveCN106015311ASimple structureMature processing technologyBearing repair/replacementShaft repair/replacementSteel ballEngineering

The invention discloses a center-adjustable ball spherical hinge joint and a center adjusting method of the center-adjustable ball spherical hinge joint. Due to machining and assembling errors, a spherical hinge joint is in an eccentric state usually. Supporting ball guide holes are formed in a supporting ball socket of the ball spherical hinge joint. A displacement sensor is installed in a sensor installation hole of the supporting ball socket. Restraining ball guide holes are formed in a restraining ball socket. Double-thread center adjusting mechanisms are installed in the supporting ball guide holes and the restraining ball guide holes to adjust ball steel balls. The center adjusting method includes the steps that the center-adjustable ball spherical hinge joint is installed; when the double-thread center adjusting mechanisms are installed, main threaded columns and auxiliary threaded columns rotate in the opposite directions, and the restraining ball steel balls and the supporting ball steel balls are quickly located; and when centering adjustment is conducted by the double-thread center adjusting mechanisms, the main threaded columns and the auxiliary threaded columns rotate in the same direction. The double-thread structures rotate in the opposite directions when the eccentric error is relatively large, and the eccentric error is quickly reduced; and the double-thread structures rotate in the same direction when the eccentric error is relatively small, and the centering condition of the balls and the ball sockets are finely adjusted.

Owner:HANGZHOU DIANZI UNIV

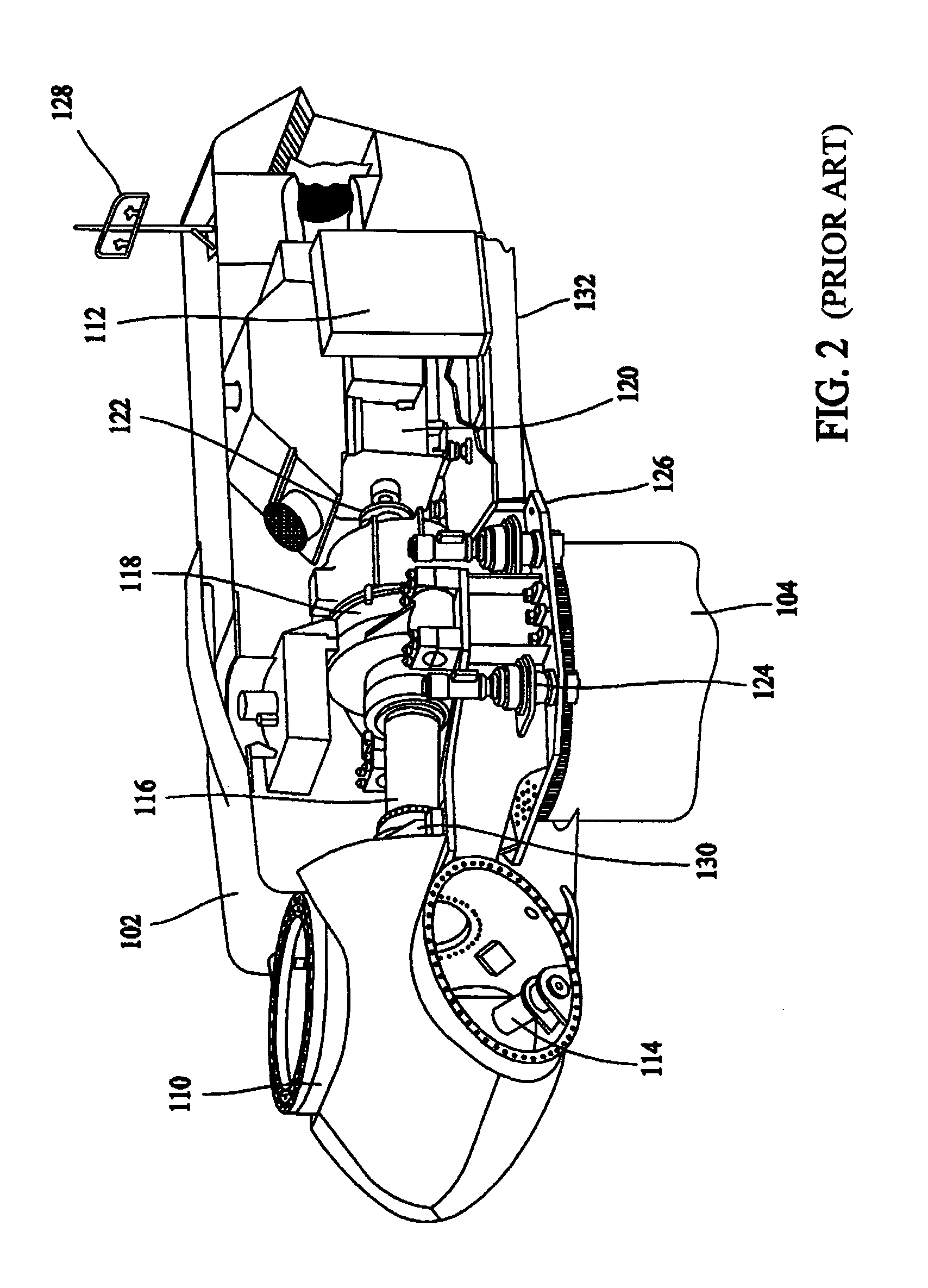

Engine mount bearing sleeve repair

ActiveUS20080104836A1Retaining and preventing relative movementBearing repair/replacementPower plant arrangements/mountingEngineeringEngine mount

Bearing bores for engine mount components must be periodically repaired. A component is disassembled and a bearing is removed from the bearing bore. An inner surface of the bearing bore is machined to remove any damage. A sizing sleeve is selected to have a press fit with the machined inner surface of the bearing bore and with the outer surface of a new bearing. The bearing is press fit into the sizing sleeve and the sizing sleeve is press fit into the bearing bore. The outer surfaces of the sizing sleeve and the bearing are swaged to assist in retaining and preventing relative movement between the bearing, sizing sleeve and engine mount component.

Owner:RTX CORP

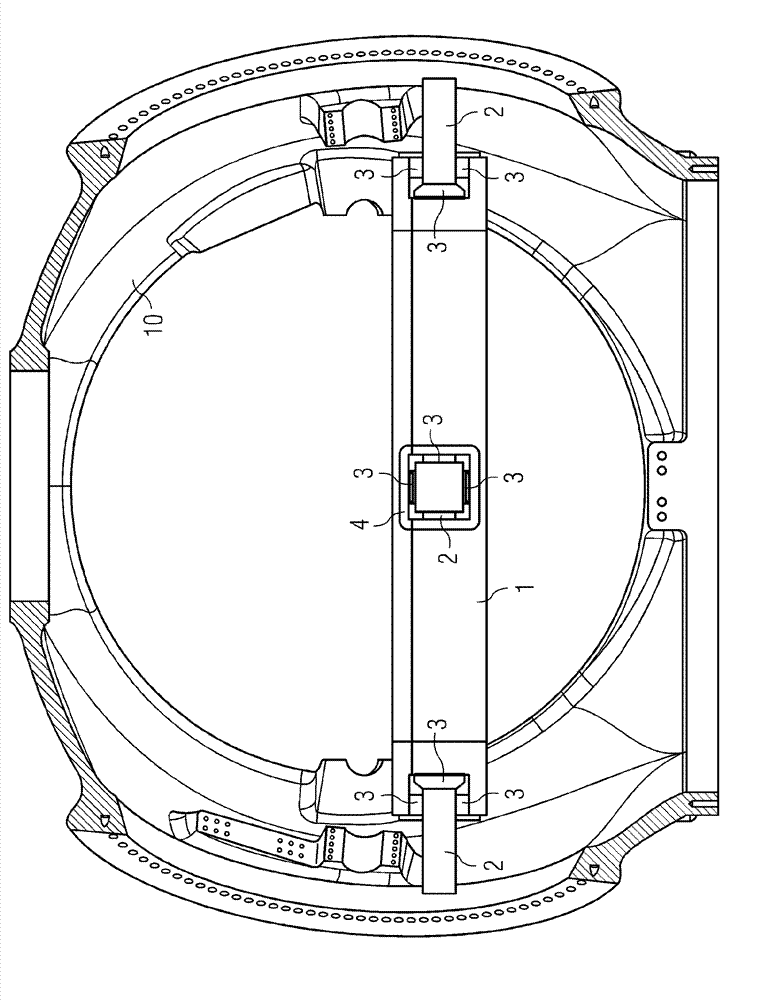

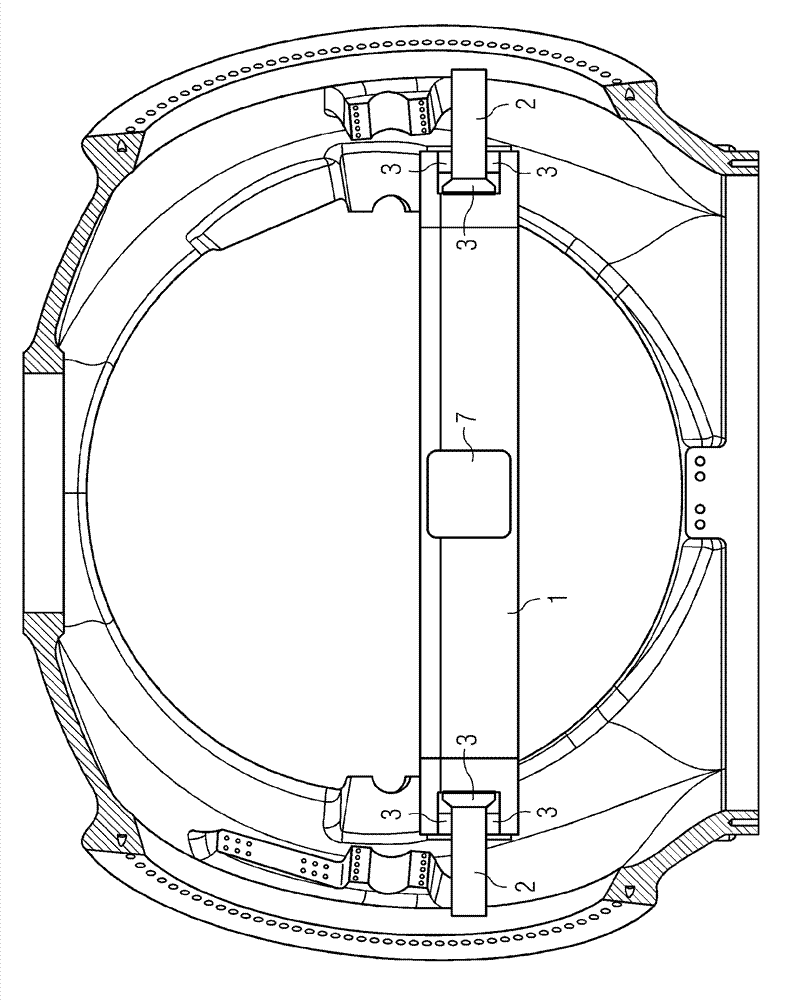

Wind turbine main bearing

ActiveUS9297363B2Easy maintenanceEasy to insertBearing repair/replacementPropellersTurbineFluid bearing

A wind turbine main bearing realized to bear a shaft of a wind turbine, which shaft is caused to rotate by a number of blades connected to the shaft is disclosed. The wind turbine main bearing includes a fluid bearing with a plurality of bearing pads arranged about the shaft. Also disclosed is a wind turbine with a number of blades connected to a shaft and realized to rotate the shaft, which wind turbine includes as main bearing a wind turbine main bearing. Further described is a method of performing maintenance on a wind turbine, including the steps of halting a rotation of the shaft, operating a lifting arrangement to raise the shaft, and removing a bearing pad of the wind turbine main bearing from the bearing housing of the wind turbine main bearing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Grease tool for repacking dual angular contact bearing with grease, and method of using same

ActiveUS20170370412A1Easy to disassembleEasy to cleanBearing repair/replacementRolling contact bearingsGrease fittingFlange

A grease tool and method for greasing a dual angular contact bearing where the grease tool is fabricated from a single unitary piece of material. The grease tool comprises a cylindrical hub, a flange supported adjacent only one end of the cylindrical hub, and a grease fitting attached to the grease tool to facilitate a supply of grease thereto. During use, a pair of spaced apart O-rings, accommodated by an exterior surface of the cylindrical hub, form a pair of grease seals with an inwardly facing surface of an inner race of the dual angular contact bearing. A supply passage conveys the supplied grease from the grease fitting to a grease outlet(s) located in an exterior cylindrical surface of the grease tool, between the pair of O-rings, for conveyance of the supplied grease radially to the inner race of the dual angular contact bearing and facilitate repacking thereof.

Owner:PETIT DENIS

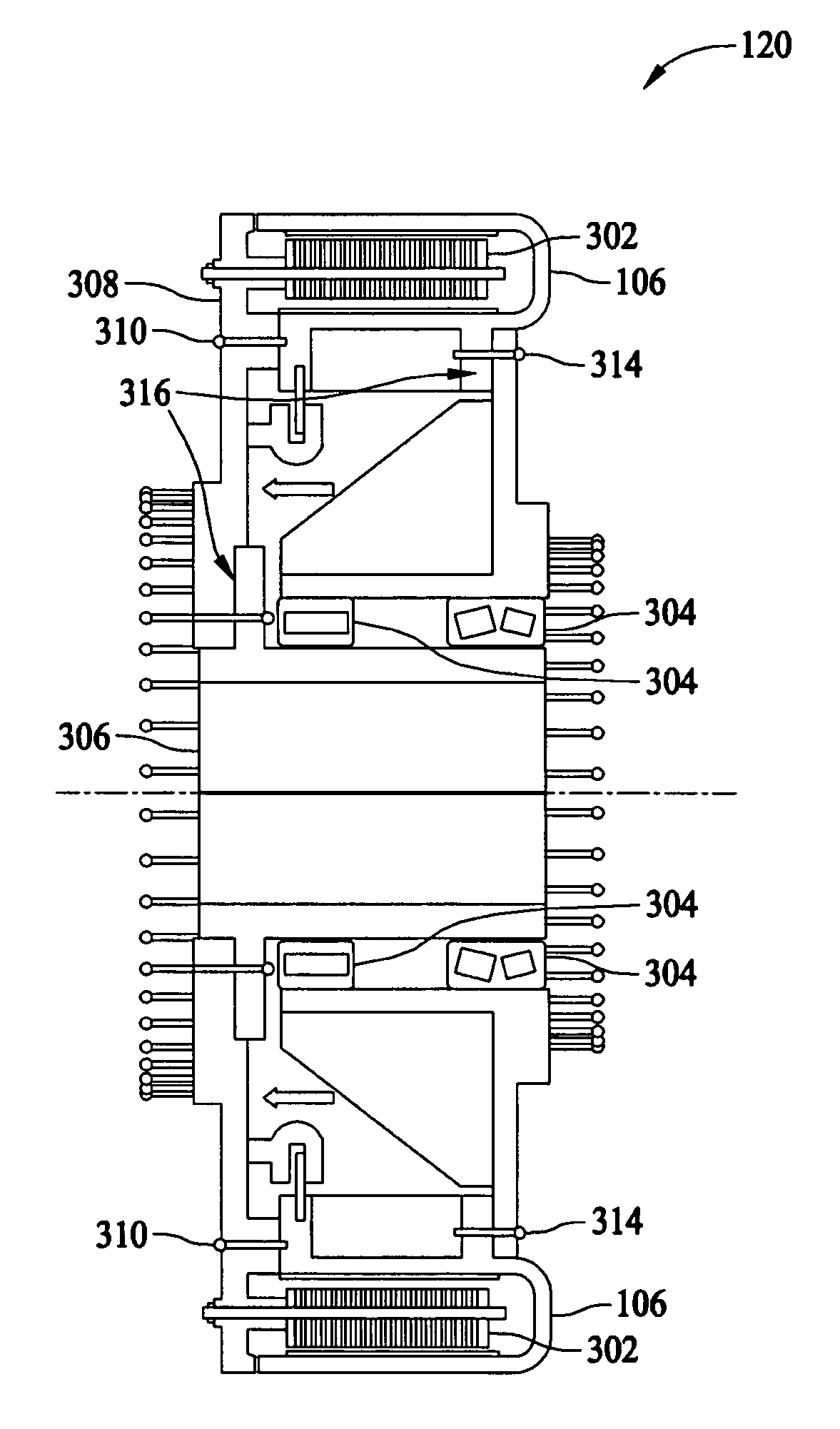

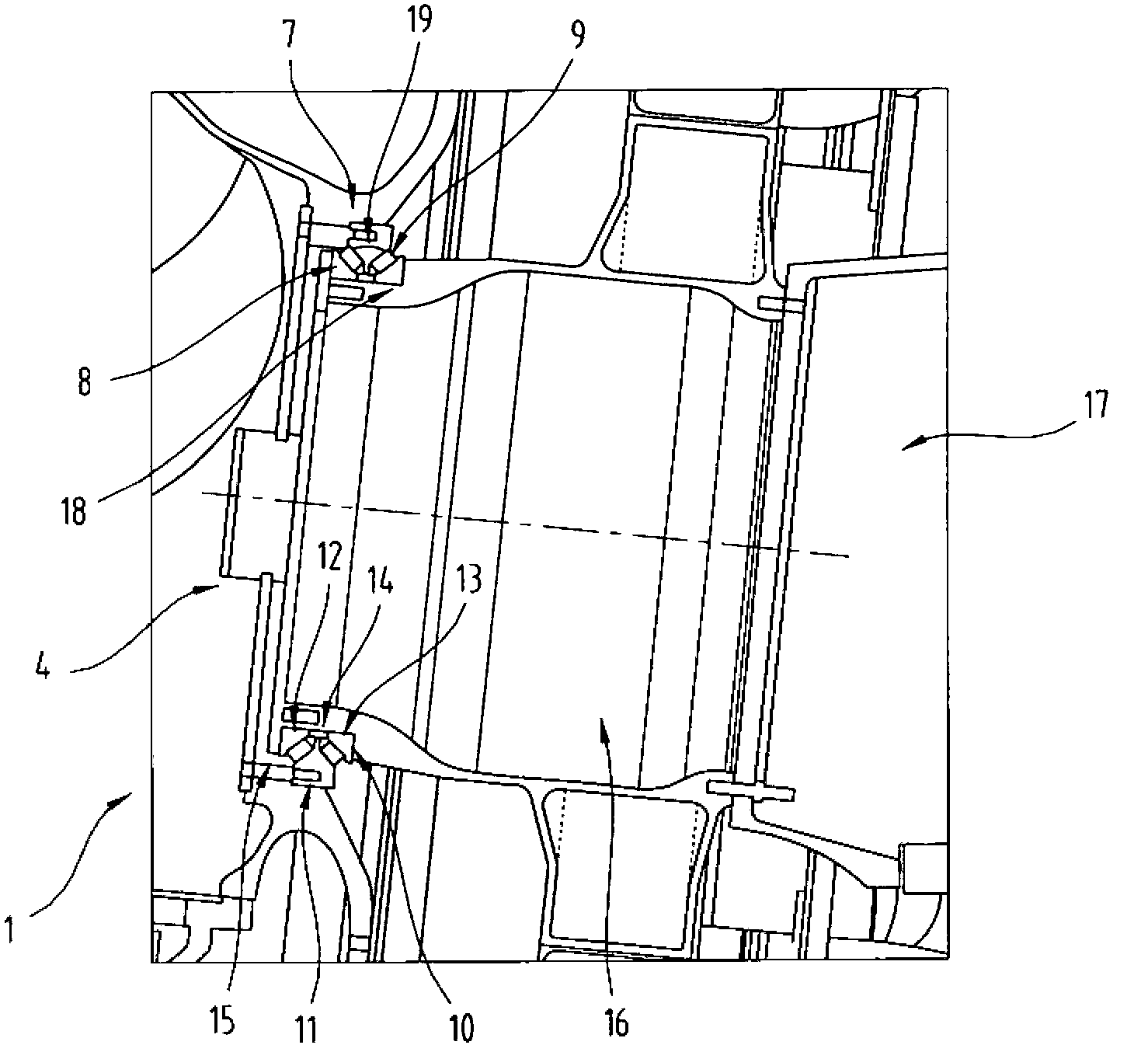

Sliding bearing and method to perform service at a sliding bearing

ActiveUS8936397B2Weak lubricationEasy to wearBearing repair/replacementBearing cleaningTurbinePlain bearing

A sliding bearing of a wind turbine and a method to perform a service at a sliding bearing are proposed. The sliding bearing has a first bearing shell and a second bearing shell and a plurality of bearing pads arranged between the first bearing shell and the second bearing shell. The bearing pads are connected to the second bearing shell and the first bearing shell has a sliding surface that is prepared and arranged so that the bearing pads can slide along the sliding surface when the bearing shells are moved in respect to each other. A machining element is arranged between the first bearing shell and the second bearing shell to treat the sliding surface of the first bearing shell.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Slide bearing and method to perform service at the sliding bearing

ActiveUS20140086516A1Risk minimizationReduce risk of damageBearing repair/replacementRolling contact bearingsEngineeringMechanical engineering

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

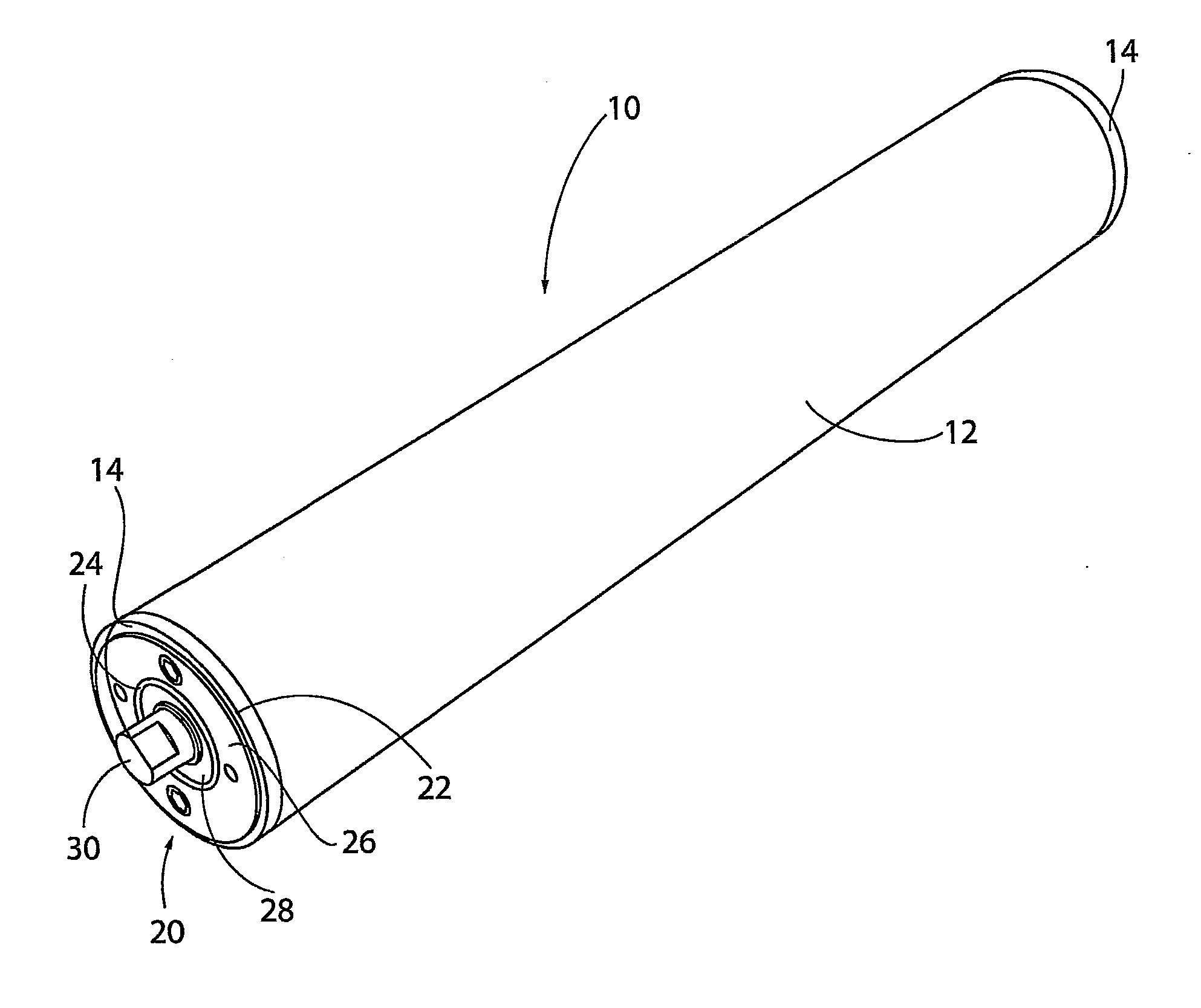

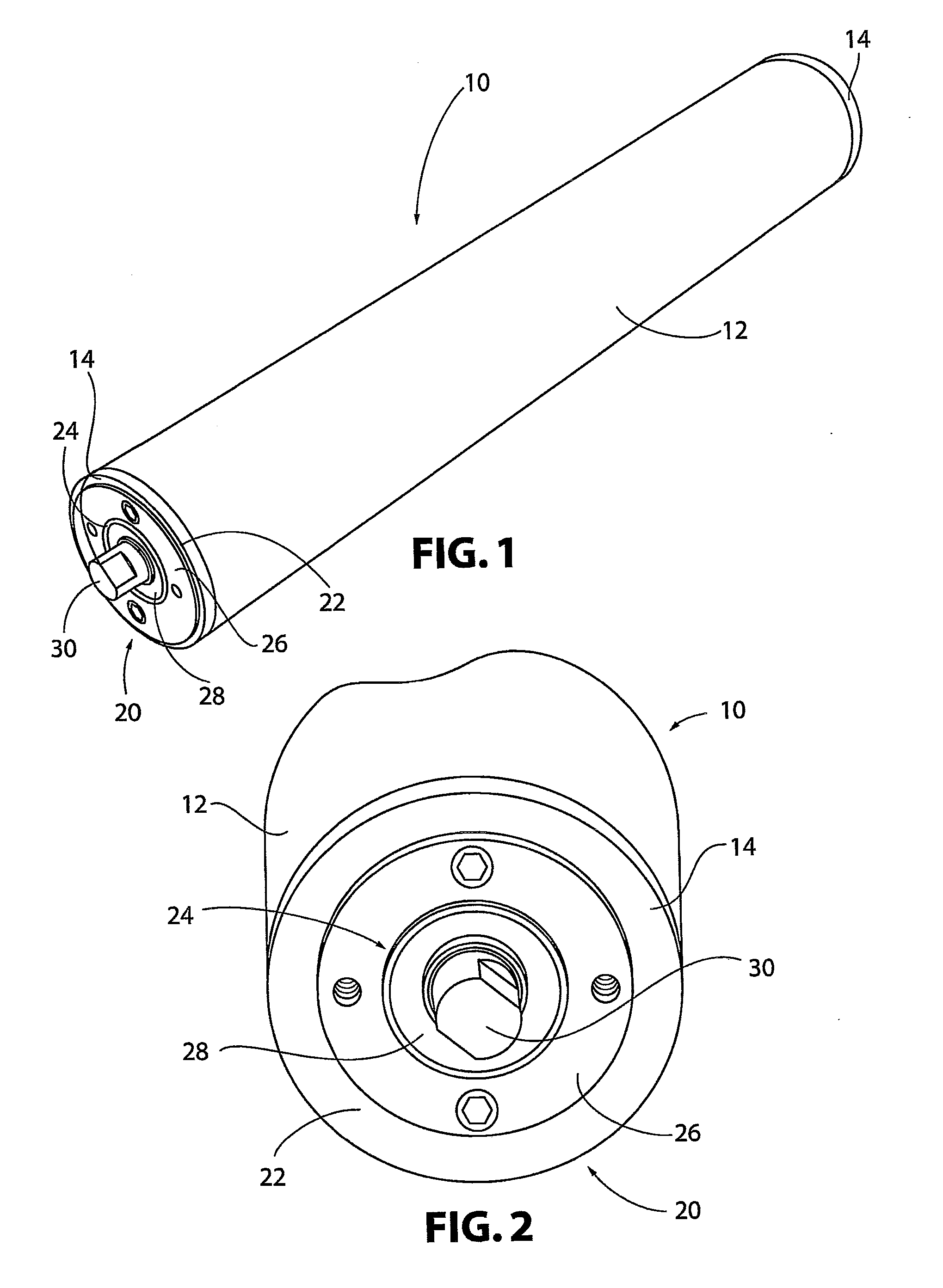

Rebuildable Roller and Roller Bearing Assembly for a Belt Line Conveyor System and a Method of Use Thereof

InactiveUS20130140131A1Bearing repair/replacementRolling contact bearingsBelt conveyorRoller bearing

A rebuildable conveyor roller includes a hollow, cylindrical roller tube having a first end opposite a second end. The roller tube has a rebuildable conveyor roller bearing assembly provided at the first end and the second end. The rebuildable conveyor roller bearing assembly is affixed to the roller tube such that at least a part of the rebuildable conveyor roller bearing assembly is removable from the roller tube. A hub of the rebuildable conveyor roller bearing assembly has a generally circular shape that is dimensioned to fit inside the internal diameter of the roller tube. The hub has a centrally located hole through which a stub shaft may be inserted. A bearing holder is inserted in an internal cavity provided within the hub for securing the rebuildable conveyor roller bearing assembly to the roller tube.

Owner:KAMINSKI JR MICHAEL RICHARD

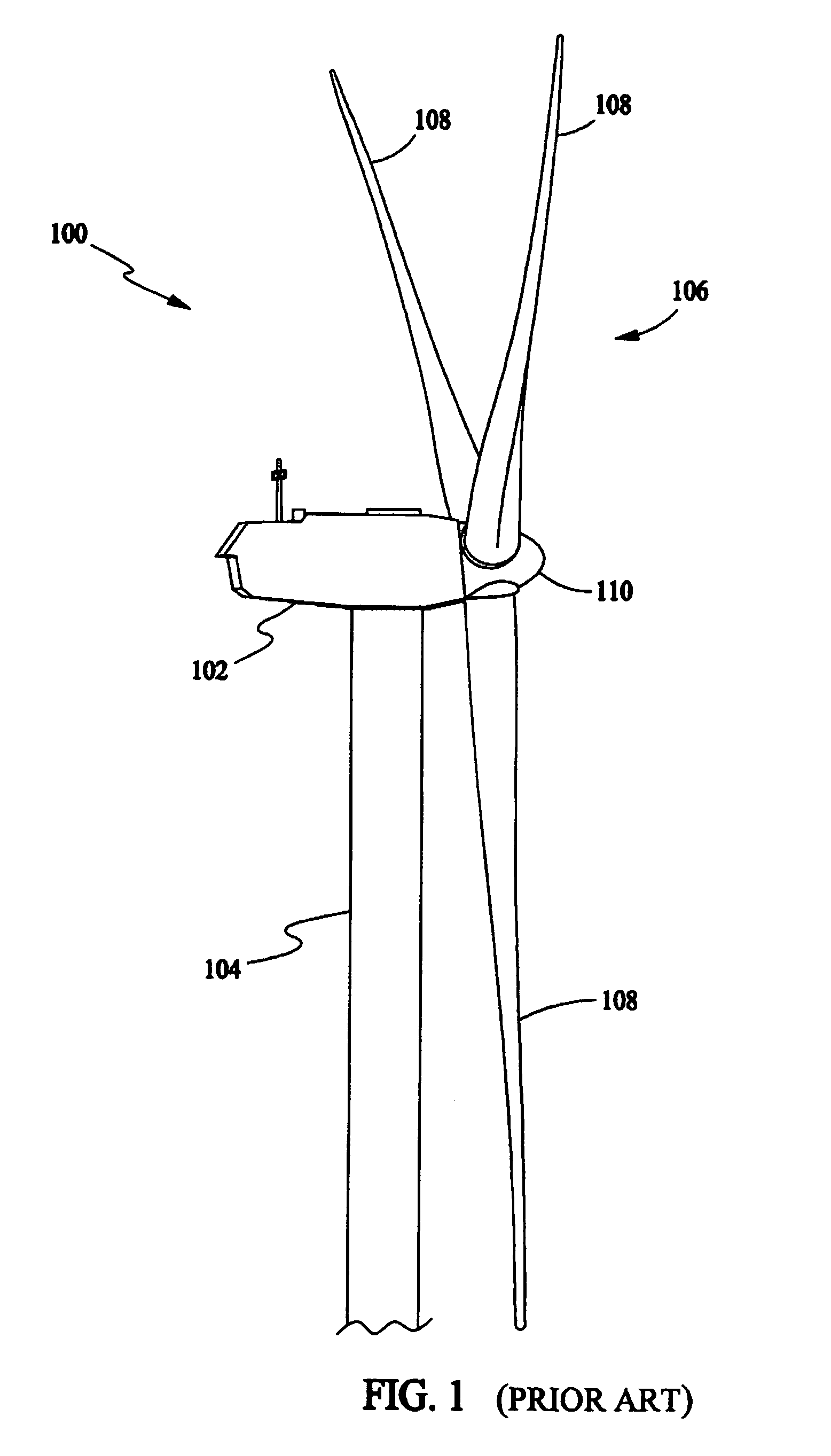

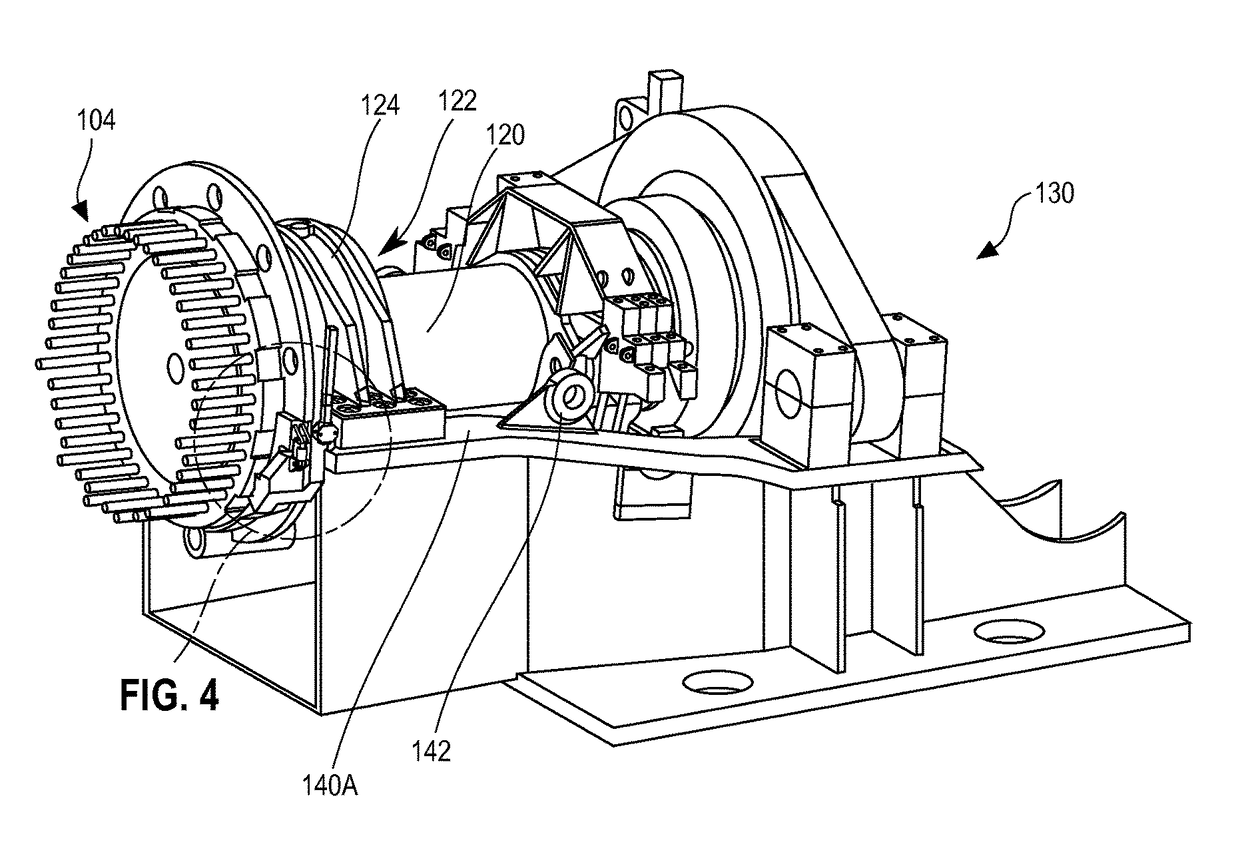

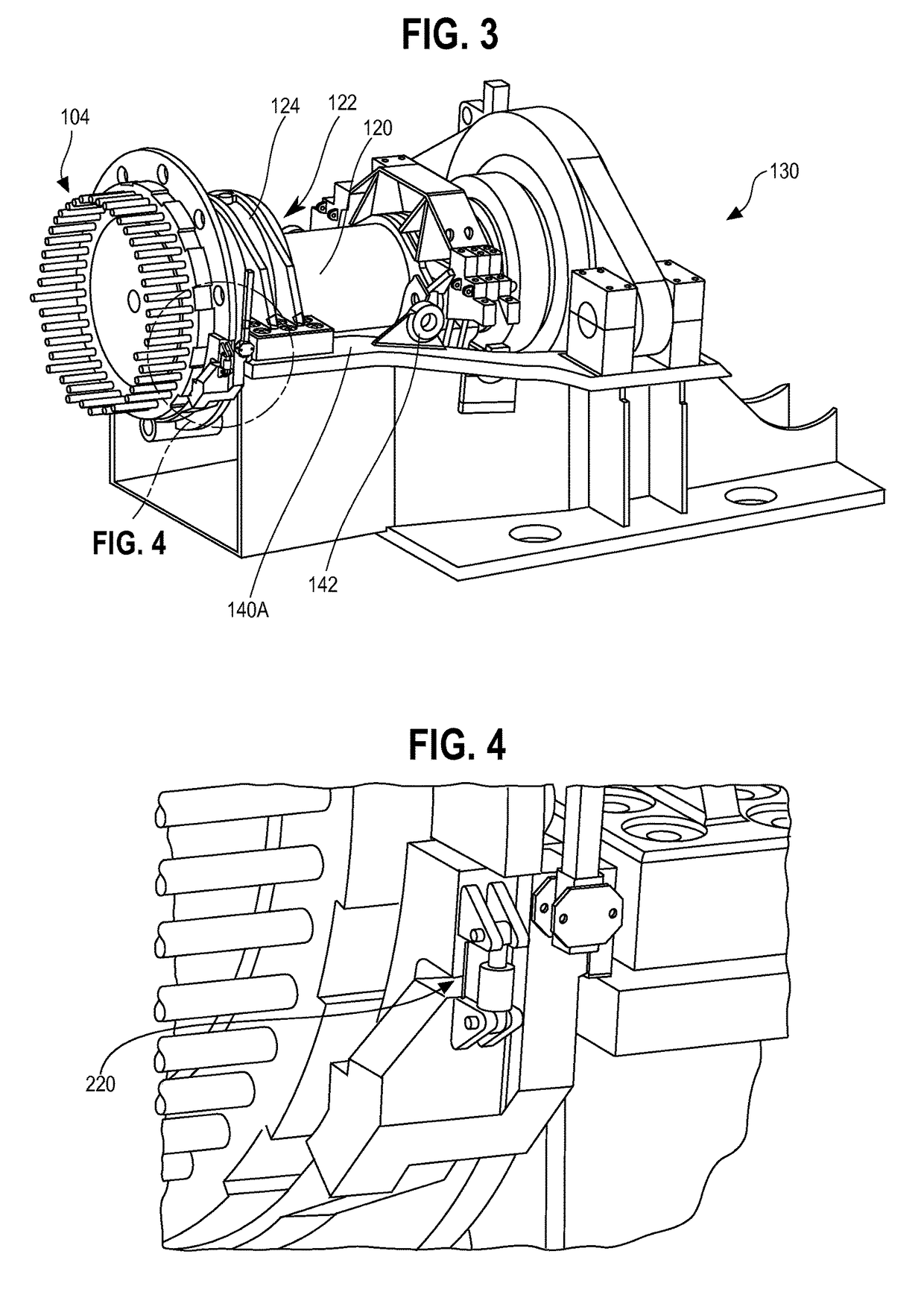

Uptower wind turbine component replacement

A method for performing uptower maintenance of a wind turbine in order to replace the main bearing on the turbine shaft is disclosed. Embodiments of this method to perform maintenance may include installing a rotor lock to resist rotation of the main shaft during maintenance, providing a lifting device in order to elevate the main shaft, removing the main bearing from its main bearing housing, and installing a replacement split main bearing. A crane may also be installed uptower to assist in the maintenance.

Owner:INVENTUS HLDG

Method of repairing bearing of wind turbine generator

A method of repairing a bearing of a wind turbine generator is provided which is able to more permanently repair a gap which occurred between a constituent member of the wind turbine generator and a bearing ring of the bearing. For example, in the case of repairing the gap 13 between the main shaft outer cylinder 10 of the wind turbine generator 1 and the outer ring 12A of the main bearing 12, the plate 40 is inserted between the main shaft outer cylinder 10 and the outer ring 12A, and also the plate 40 is fixed to an inner circumferential surface of the main shaft outer cylinder 10 by the adhesive agent 41. On the other hand, slip is permitted between the plate 40 and the outer ring 12A of the main bearing 12.

Owner:MITSUBISHI HEAVY IND LTD

Wind turbine comprising a yaw bearing system

ActiveUS10781797B2Improved extreme and fatigue strengthImprove adhesionBearing repair/replacementEngine manufactureNacelleClassical mechanics

Owner:ENVISION ENERGY DENMARK

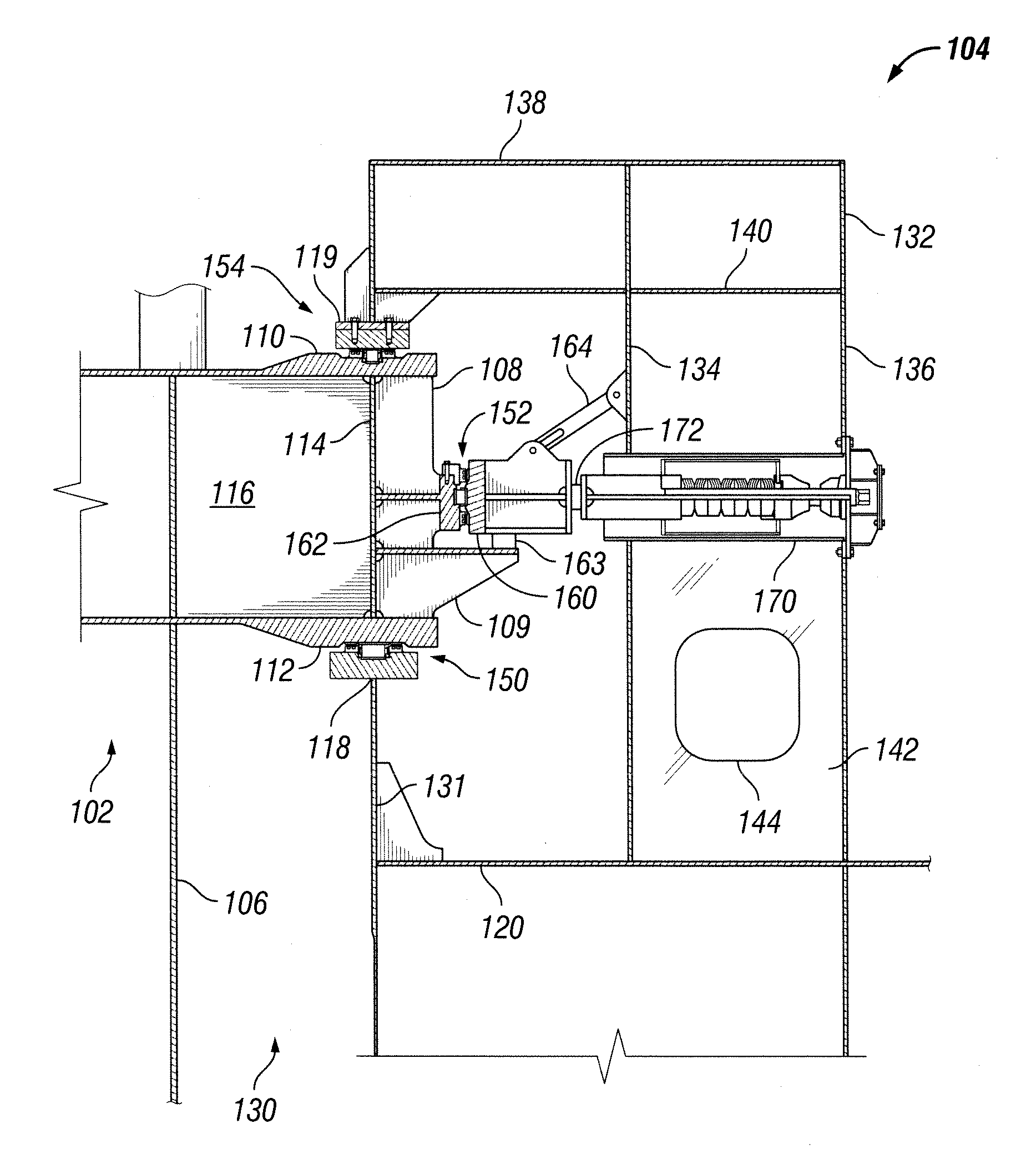

External casing functional access port

ActiveUS8820148B2Bearing repair/replacementGas-turbine engine testingIndustrial machineEmbedded system

A functional access port in a machine casing, a machine having a functional access port, and a method of monitoring a machine via a functional access port are disclosed herein. In an embodiment, an access port is provided in the external casing of an industrial machine. The access port comprises a passageway through the external casing of the machine, providing access to an interior of the machine. The access port further includes a removable passageway cover for removably occluding the passageway. A location, a size, a shape, and an orientation of the passageway relative to the external casing are strategically selected in accordance with engineering and design requirements to provide access through the passageway to a desired location on the interior of the machine while the external casing is in place, with minimal to no disassembly of the casing.

Owner:GE INFRASTRUCTURE TECH INT LLC

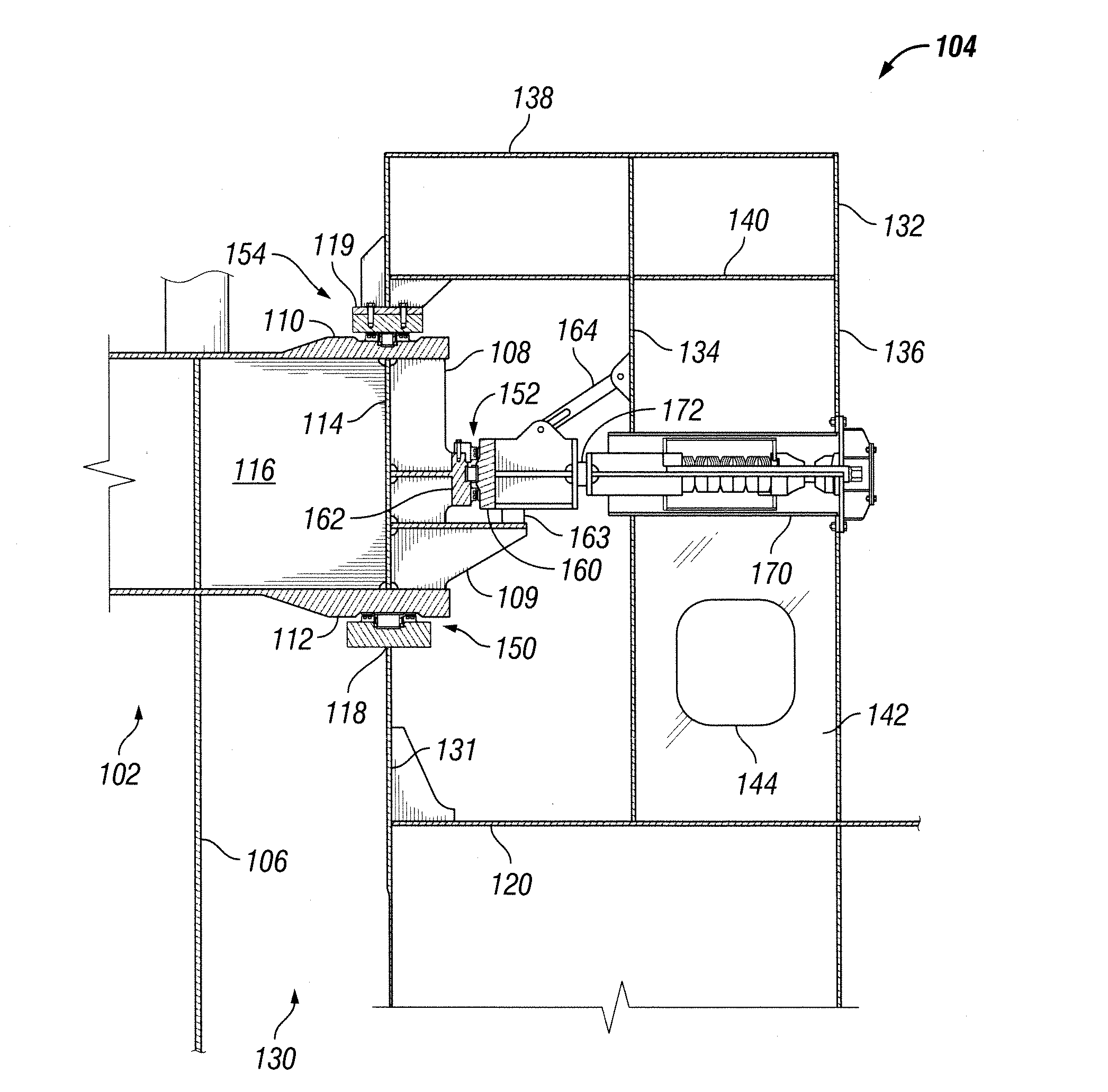

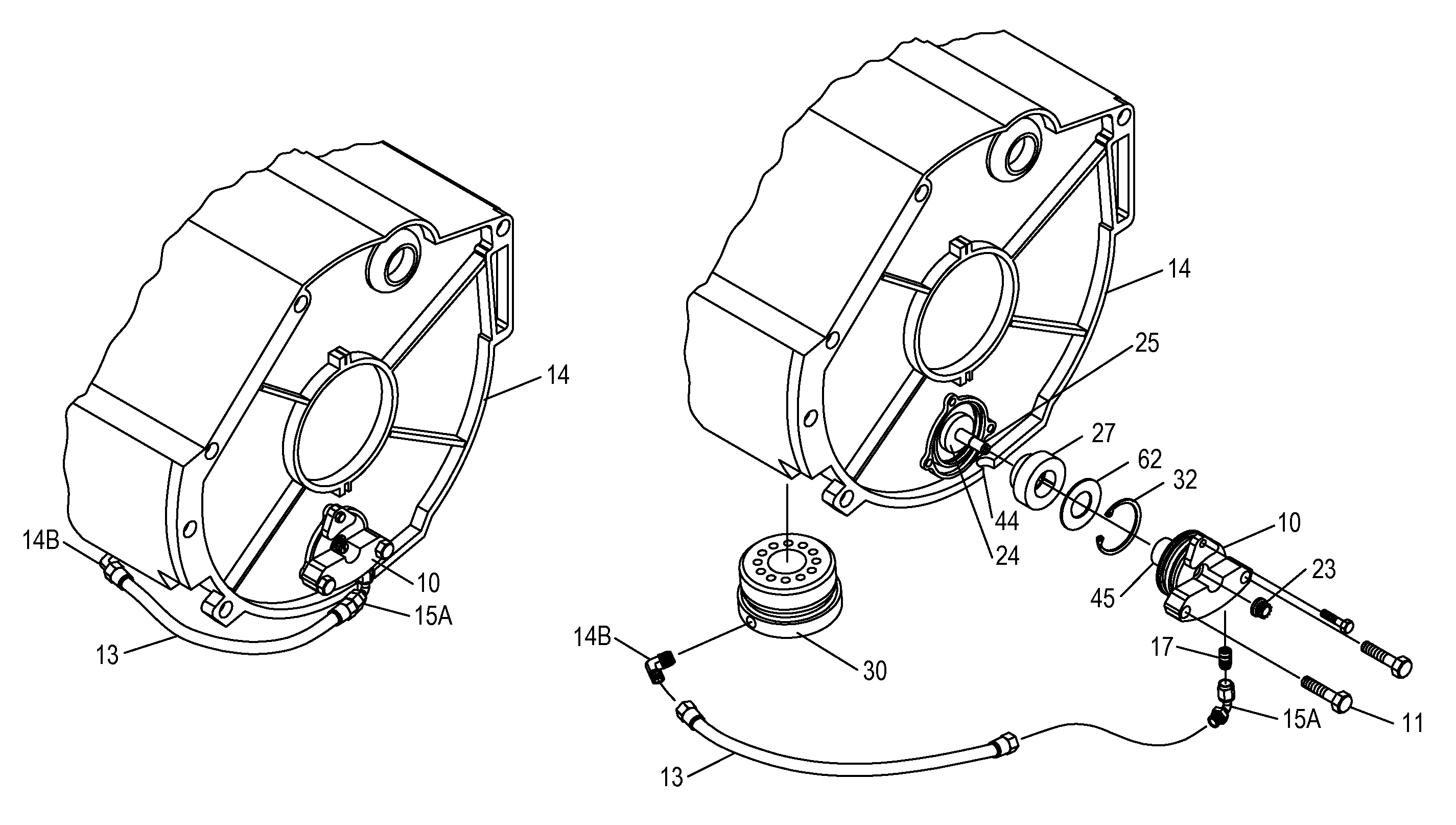

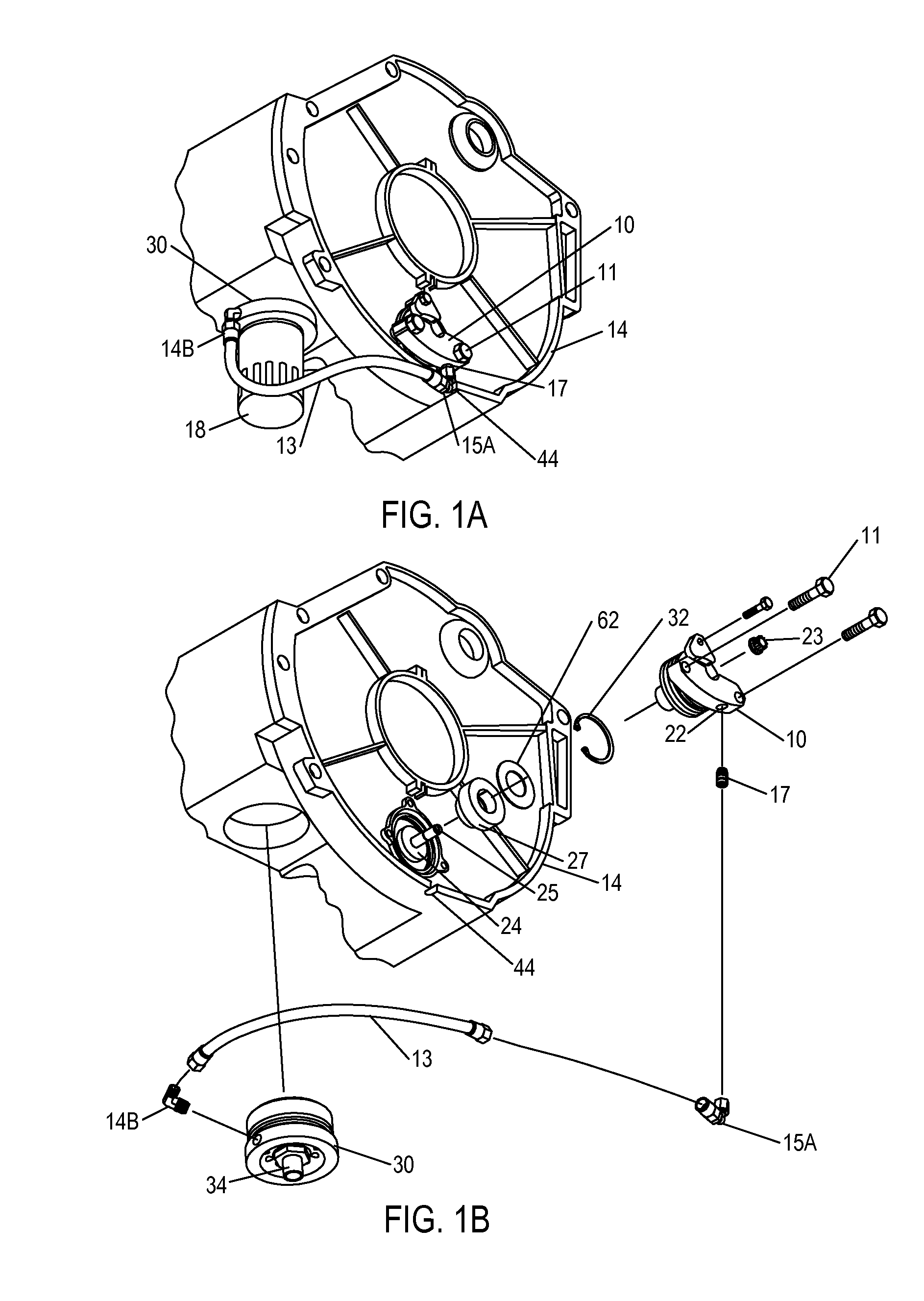

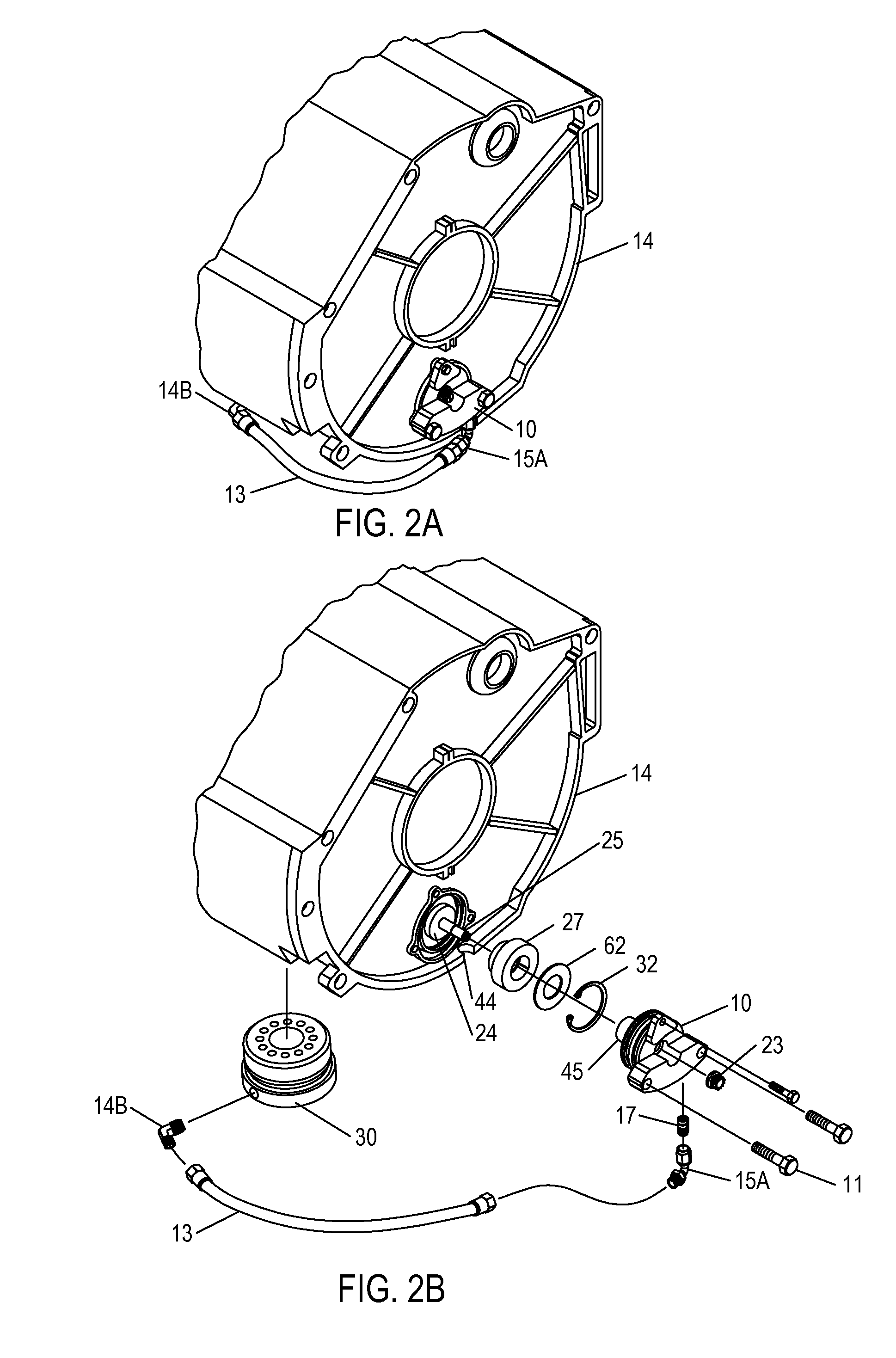

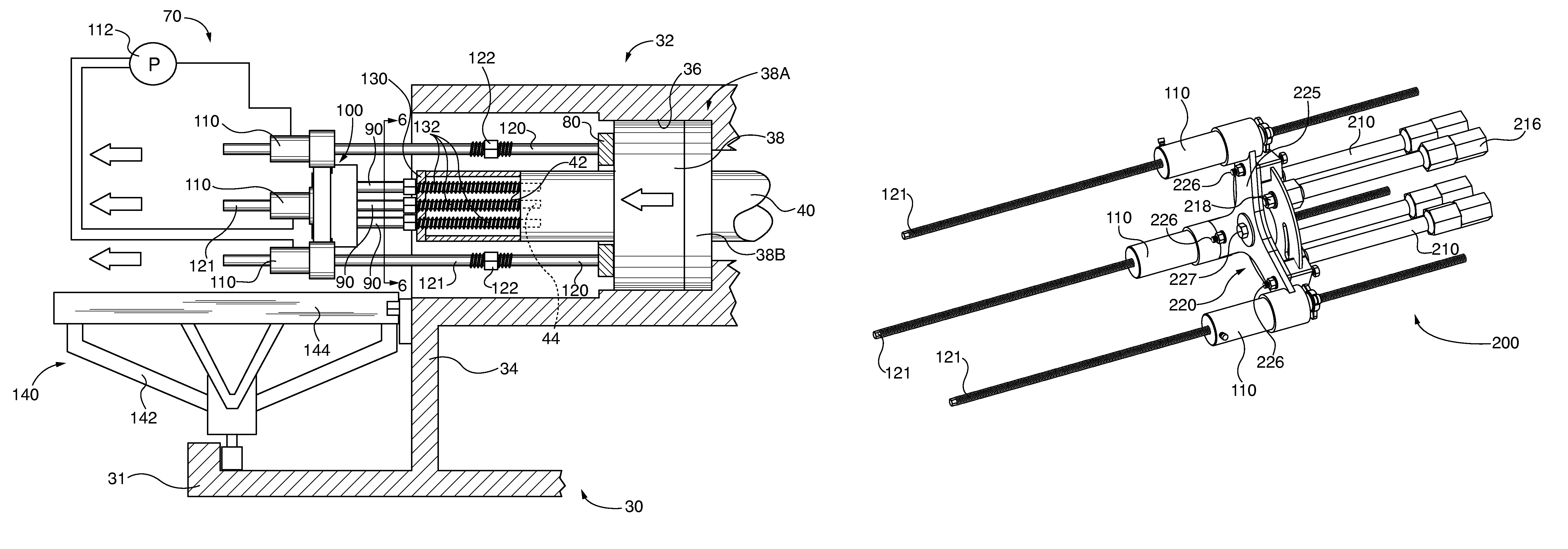

Layshaft end bearing retrofit with external positive oil pressure delivery

ActiveUS8992089B2Effective upgrade and repair pathReliable supportBearing repair/replacementRolling contact bearingsLubricationLubricant

A bearing for retro-fit or repair of an engine provides high reliability through a sleeved bearing design having externally-supplied lubrication. The bearing assembly may be supplied as a kit including a lubrication delivery tube and an oil filter adapter having a port for supplying the external lubrication to a mounting flange of the bearing. In order to install the bearing a captive sleeve is inserted in a hollow end of the shaft being supported. A cap having a threaded stud is inserted with the sleeve into the hollow end of the shaft and secured by the required snap ring. Then a nut is used to secure the cap and the sleeve to a stud affixed to the mounting flange that secures the bearing assembly to the engine.

Owner:IMS SOLUTION

Sliding bearing and method to perform service at a sliding bearing

ActiveUS20140086515A1Bearing also increasesWeak lubricationBearing repair/replacementBearing cleaningEngineeringTurbine

A sliding bearing of a wind turbine and a method to perform a service at a sliding bearing are proposed. The sliding bearing has a first bearing shell and a second bearing shell and a plurality of bearing pads arranged between the first bearing shell and the second bearing shell. The bearing pads are connected to the second bearing shell and the first bearing shell has a sliding surface that is prepared and arranged so that the bearing pads can slide along the sliding surface when the bearing shells are moved in respect to each other. A machining element is arranged between the first bearing shell and the second bearing shell to treat the sliding surface of the first bearing shell.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Bearing alignment tool and method of use

InactiveUS7716846B2Improve distributionLow frictional runningsBearing repair/replacementRoller bearingsClassical mechanicsStructural engineering

A bearing alignment tool and method of use is provided for aligning inner and outer races of a roller bearing of the class wherein the inner and outer races of the roller bearing are axially displaceable with respect to each other in order to accommodate thermal growth of a rotating shaft. A bearing replacement procedure includes: (a) affixing the roller bearing to the shaft at its inner race; (b) disposing the shaft in a housing; (c) aligning the inner and outer races of the roller bearing with respect to each other and the housing in a predetermined spatial relationship by affixing an alignment tool to the housing, wherein the alignment tool has (i) an outer aligning surface which engages the outer race of the roller bearing; and (ii) an inner aligning surface which engages the inner race of the roller bearing; (d) removing the alignment tool from the housing; and (e) securing the housing to a fixed position on a support while maintaining the predetermined spatial relationship established in step (c). The method and alignment tool are particularly useful for quickly replacing bearings on an afterdryer of a papermachine where precision alignment and downtime are significant considerations.

Owner:GPCP IP HLDG LLC

Gas turbine shaft bearing system service tool and bearing system service method

ActiveUS9188007B2Easy to operateEasy maintenanceBearing repair/replacementBlade accessoriesTurbineFixed position

Owner:SIEMENS ENERGY INC

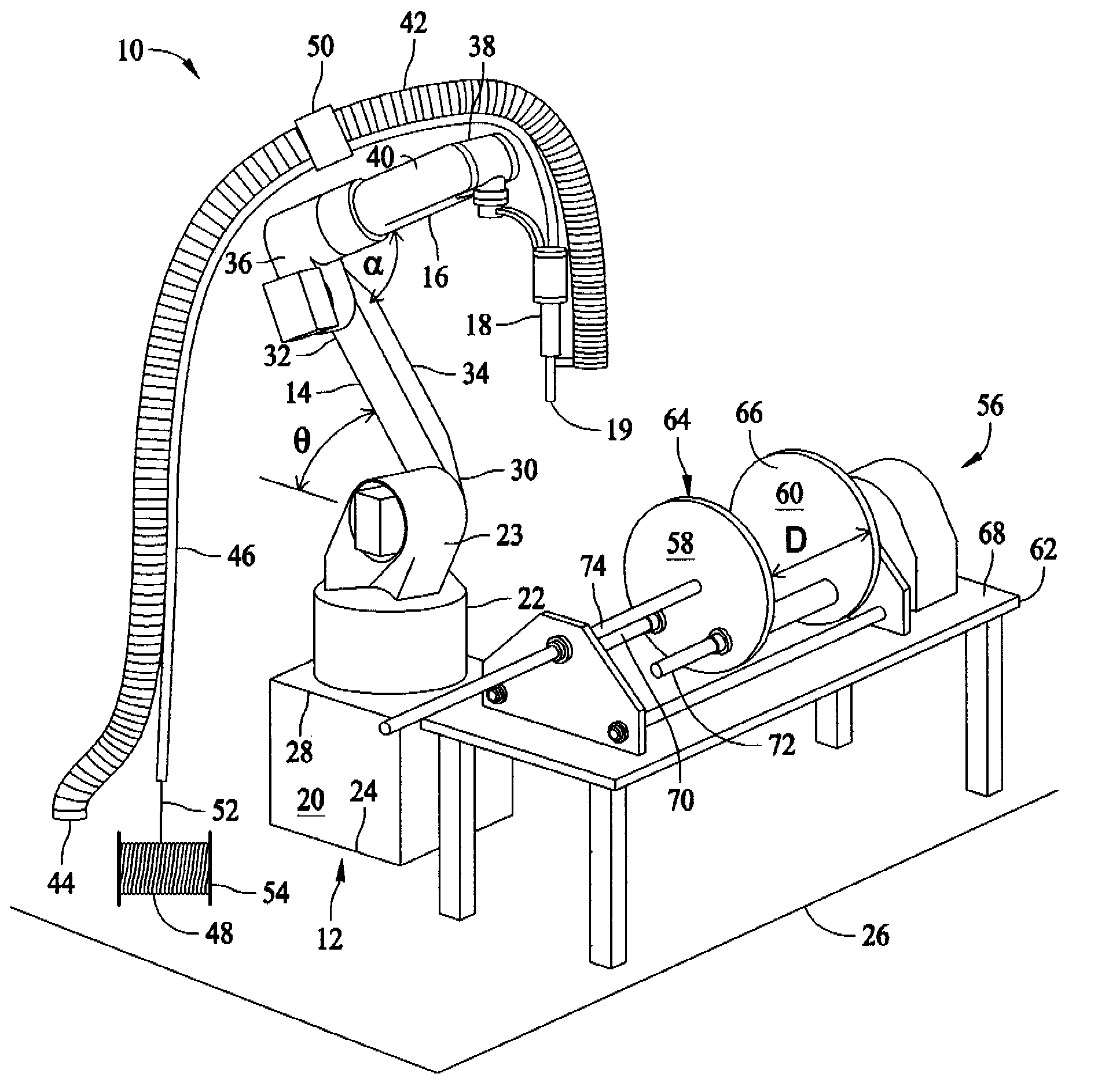

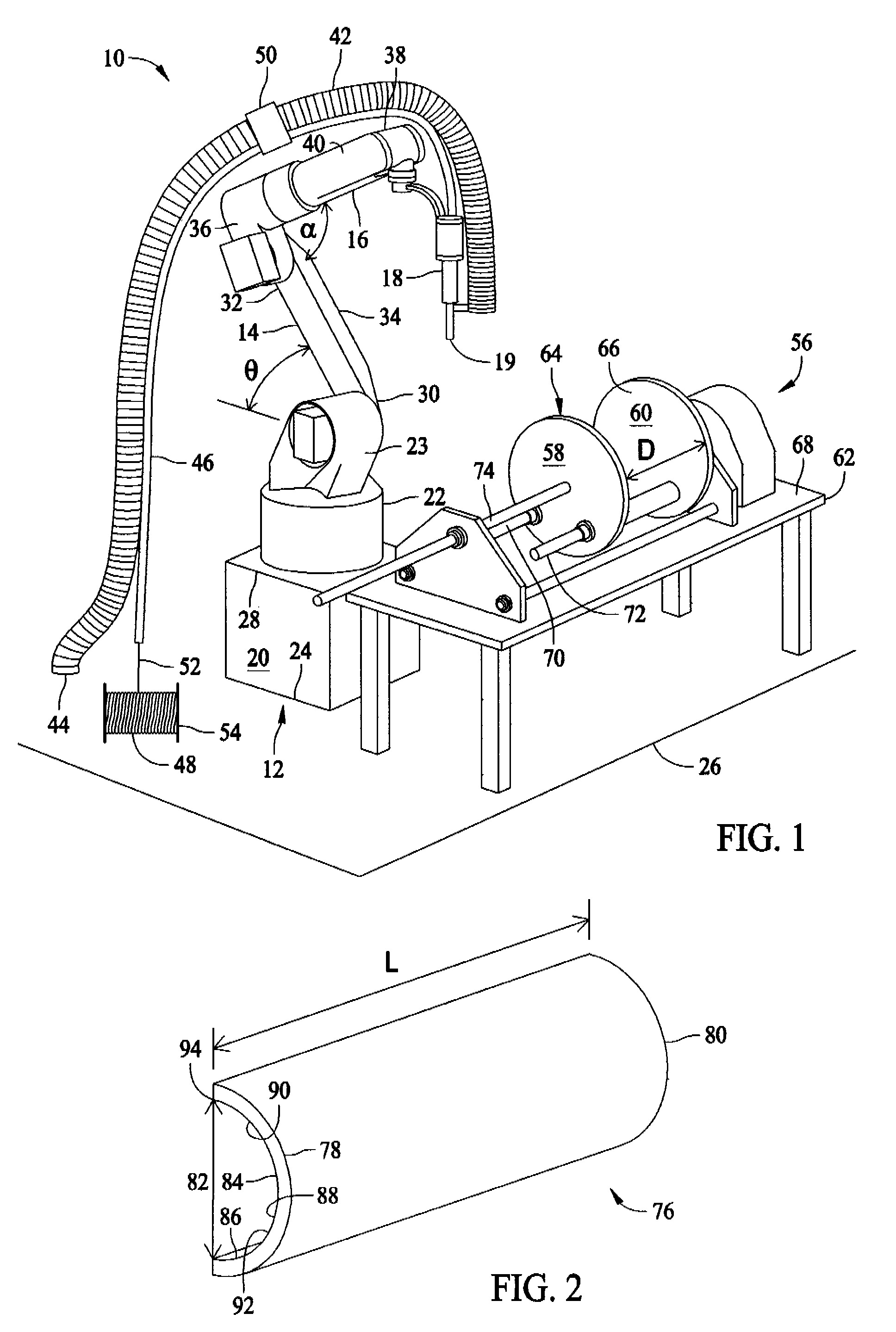

Method and system of welding a bearing

InactiveUS20080257868A1Bearing repair/replacementShaft repair/replacementEngineeringMechanical engineering

A method of welding a bearing is provided. The method includes providing an apparatus including at least one welding torch and a processor, positioning a holding fixture proximate the apparatus, securing a bearing in position in the holding fixture, applying a bead of weld to facilitate repairing a damaged surface of the bearing and incrementally rotating the bearing with the apparatus.

Owner:GENERAL ELECTRIC CO

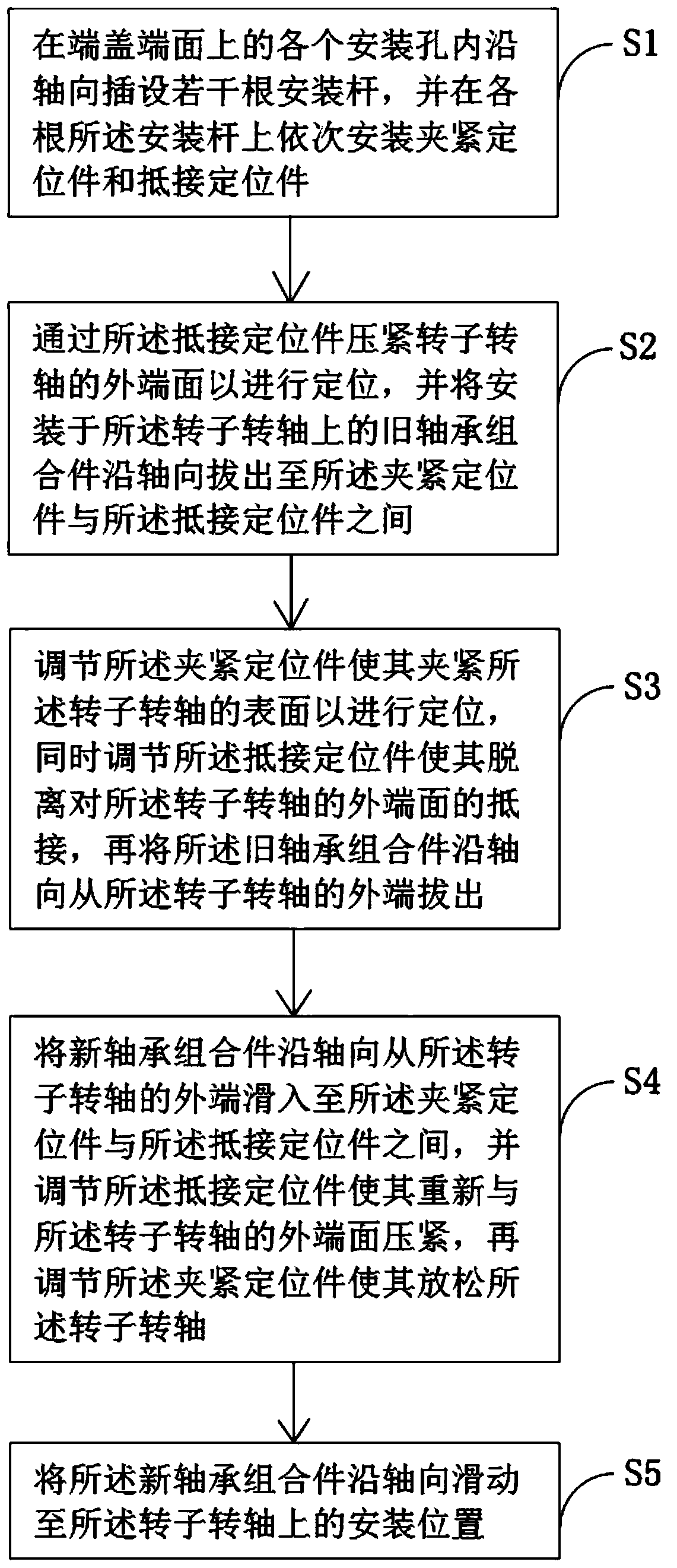

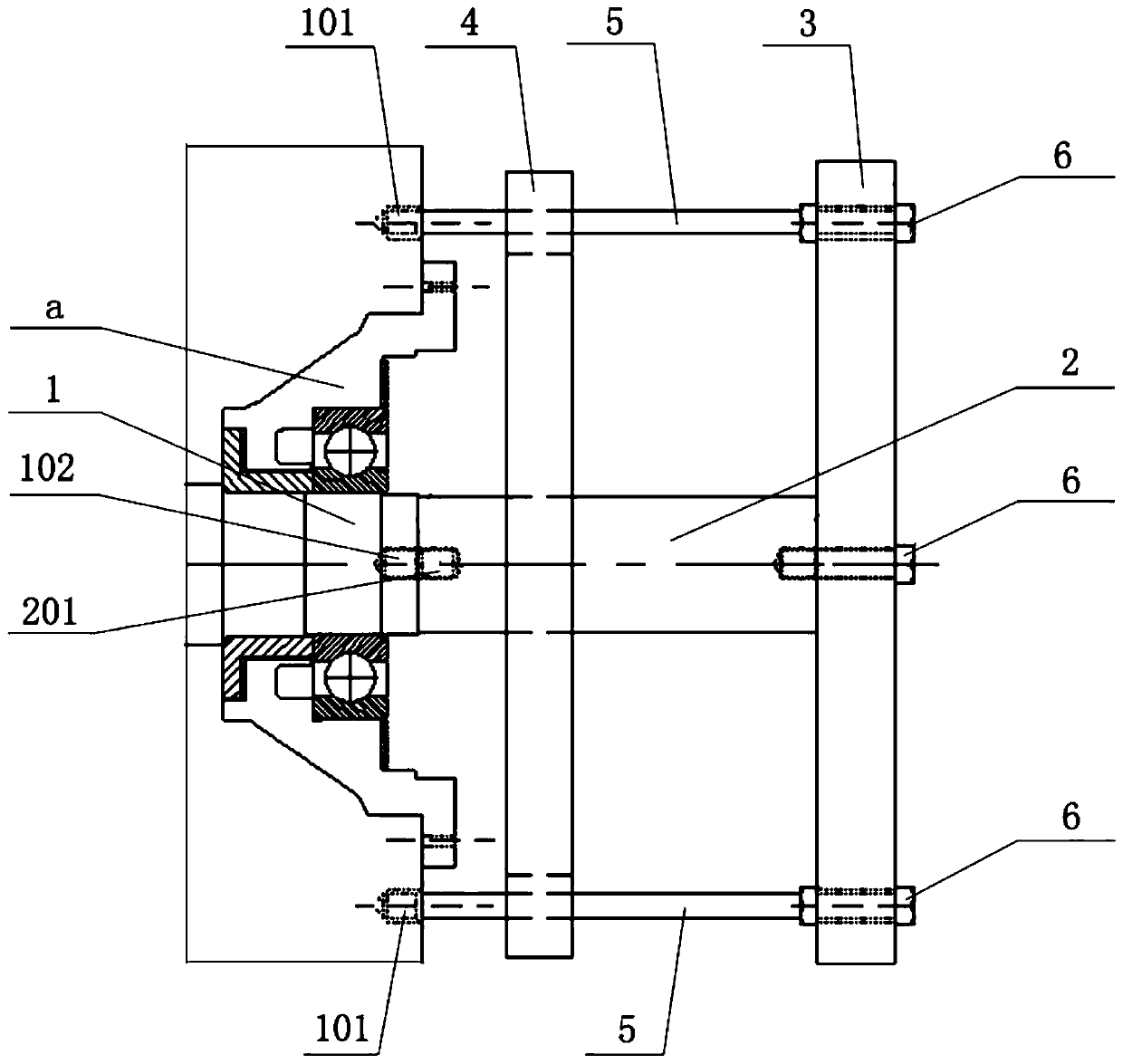

Method for disassembling and assembling motor bearing without disassembly

ActiveCN110829745AEnough room to slideAvoid displacementBearing repair/replacementShaft repair/replacementClassical mechanicsElectric machinery

The invention discloses a method for disassembling and assembling a motor bearing without disassembly, which comprises the steps of inserting a mounting rod on the end surface of an end cover, and sequentially mounting a clamping positioning member and an abutting positioning member; pressing the outer end surface of a rotor rotating shaft through the abutting positioning member for positioning, and pulling out an old bearing assembly in the axial direction; adjusting the clamping positioning member to clamp the rotor rotating shaft for positioning, adjusting the abutting positioning member toenable the abutting positioning member to release the pressing for the rotor rotating shaft, and pulling out the old bearing assembly from the outer end of the rotor rotating shaft in the axial direction; sliding a new bearing assembly into the space between the clamping positioning member and the abutting positioning member from the outer end of the rotor rotating shaft in the axial direction, adjusting the abutting positioning member to enable the abutting positioning member to press the outer end surface of the rotor rotating shaft again, and then adjusting the clamping positioning memberto loosen the rotor rotating shaft; and sliding the new bearing assembly to a mounting position on the rotor rotating shaft in the axial direction. According to the invention, the disassembly-free disassembly and replacement of the motor bearing can be achieved, the disassembly and replacement efficiency is improved, and rotor displacement in the disassembly and replacement process is avoided.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com