Sliding bearing and method to perform service at sliding bearing

A sliding bearing and bearing technology, applied in sliding contact bearings, bearing maintenance/replacement, shaft maintenance/replacement, etc., to save maintenance time and reduce possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

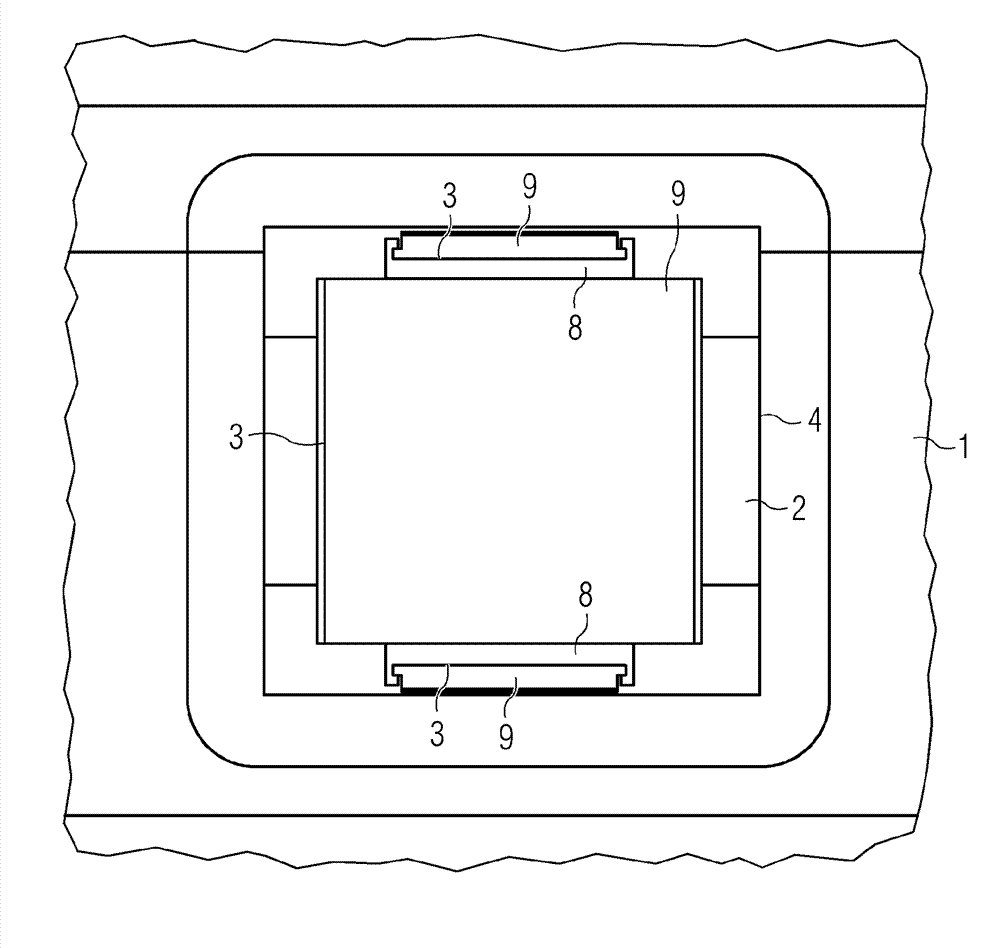

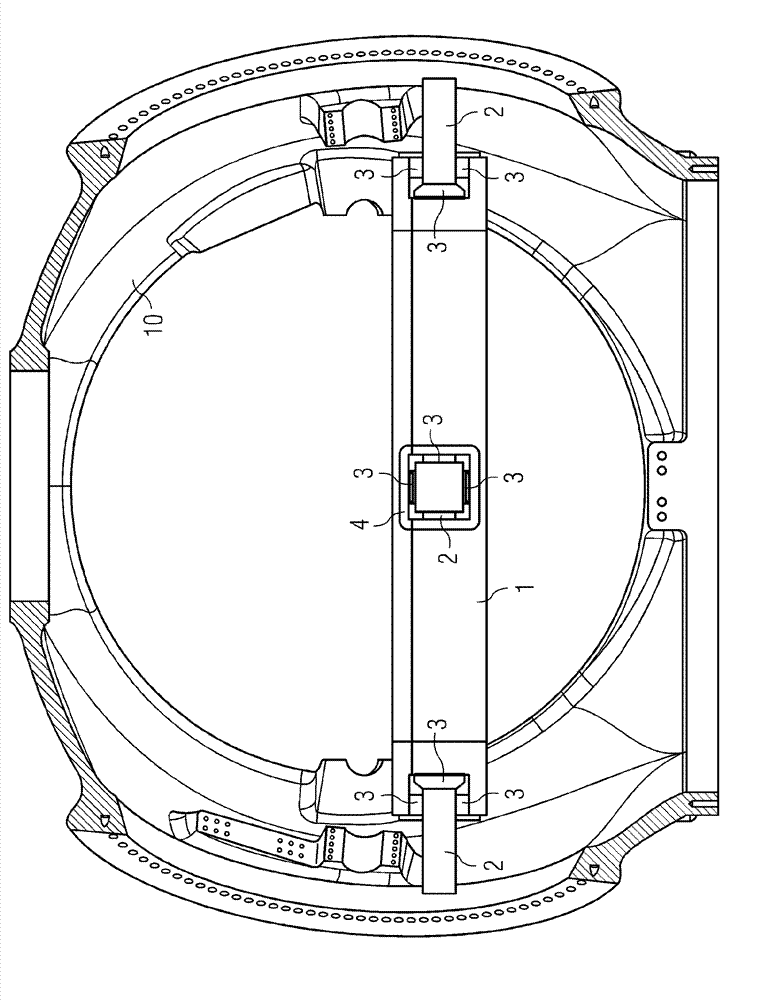

[0078] figure 1 A slide bearing with openings is shown.

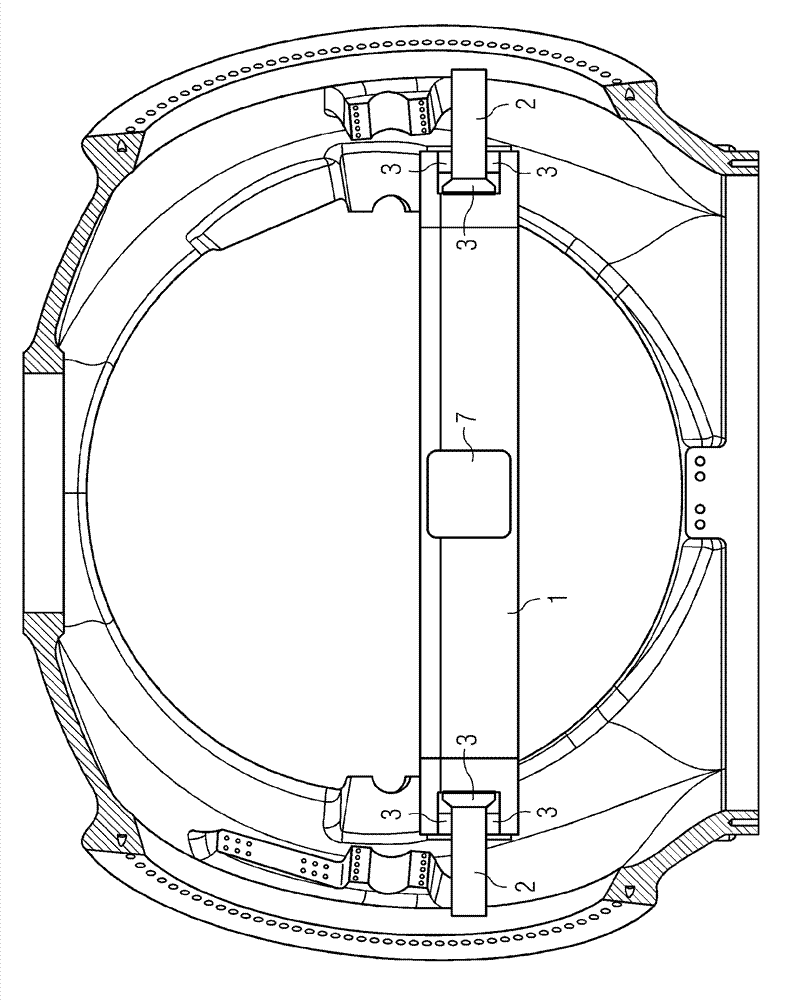

[0079] figure 1 A cut through a plain bearing of a hub 10 of a wind turbine is shown. The bearing includes a first bearing shell 1 and a second bearing shell 2 . The second bearing shell 2 is attached to the hub 10 of the wind turbine. The second bearing shell 2 rotates together with the hub 10 of the wind turbine and is thus a rotatable part of the bearing.

[0080] The first bearing shell 1 is attached to a stationary part of the wind turbine (not shown) and is thus the stationary part of the bearing.

[0081] A plurality of bearing pads 3 are provided between the first bearing shell 1 and the second bearing shell 2 .

[0082] The first bearing shell 1 comprises an opening 4 . The bearing pad 3 is visible through this opening 4 .

[0083] The location of the opening 4 is at a location with good accessibility eg during maintenance of the wind turbine. The position of the opening 4 can also be chosen so as to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com