Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about "Meat pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

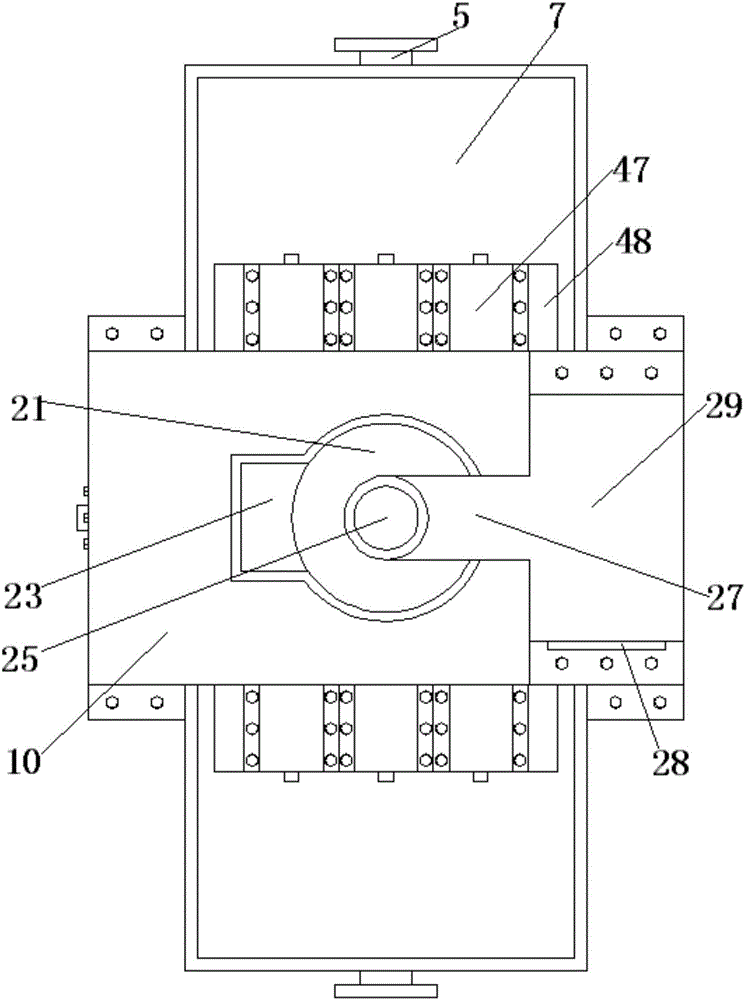

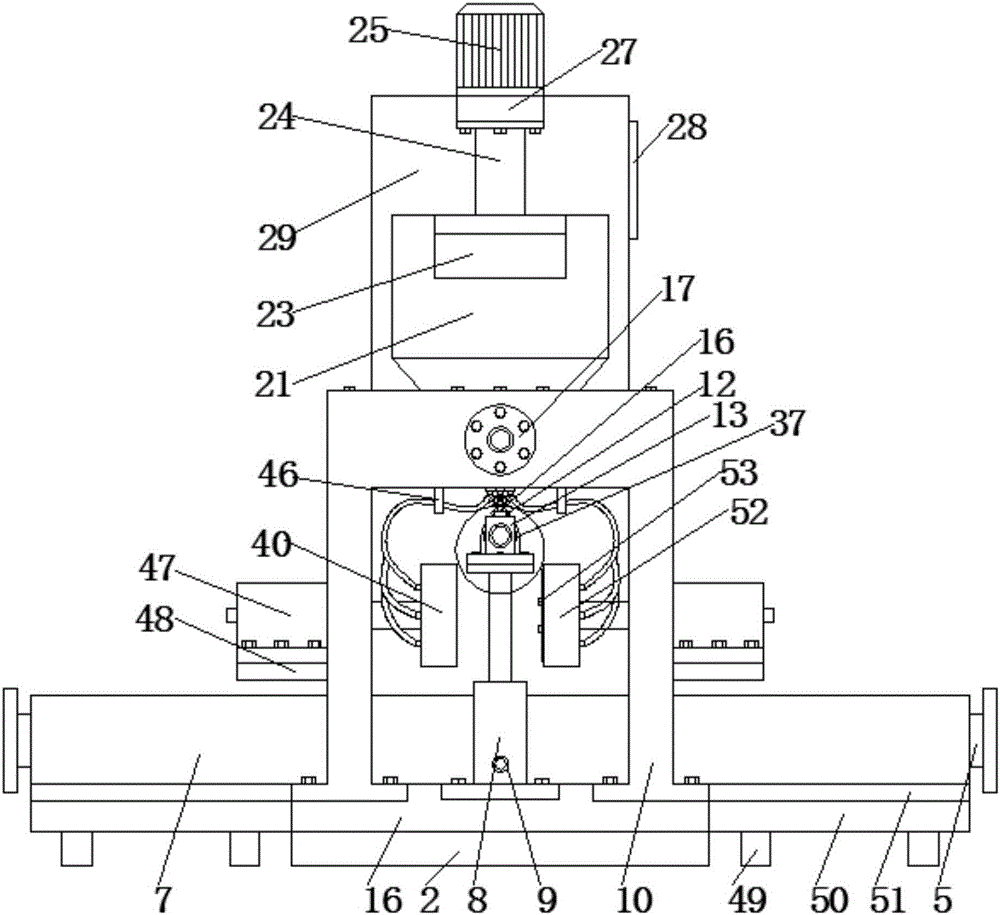

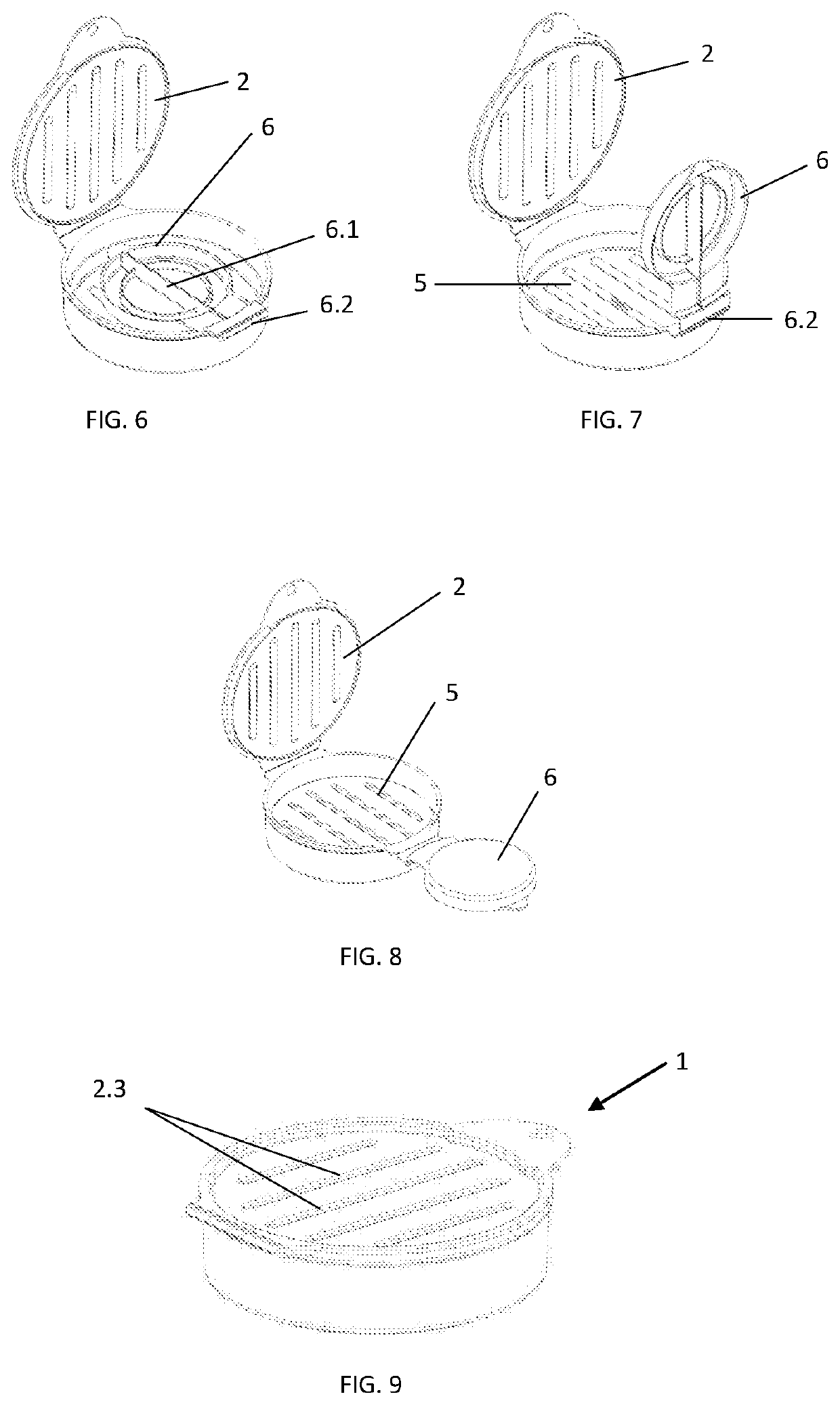

Food forming apparatus with a food feed member

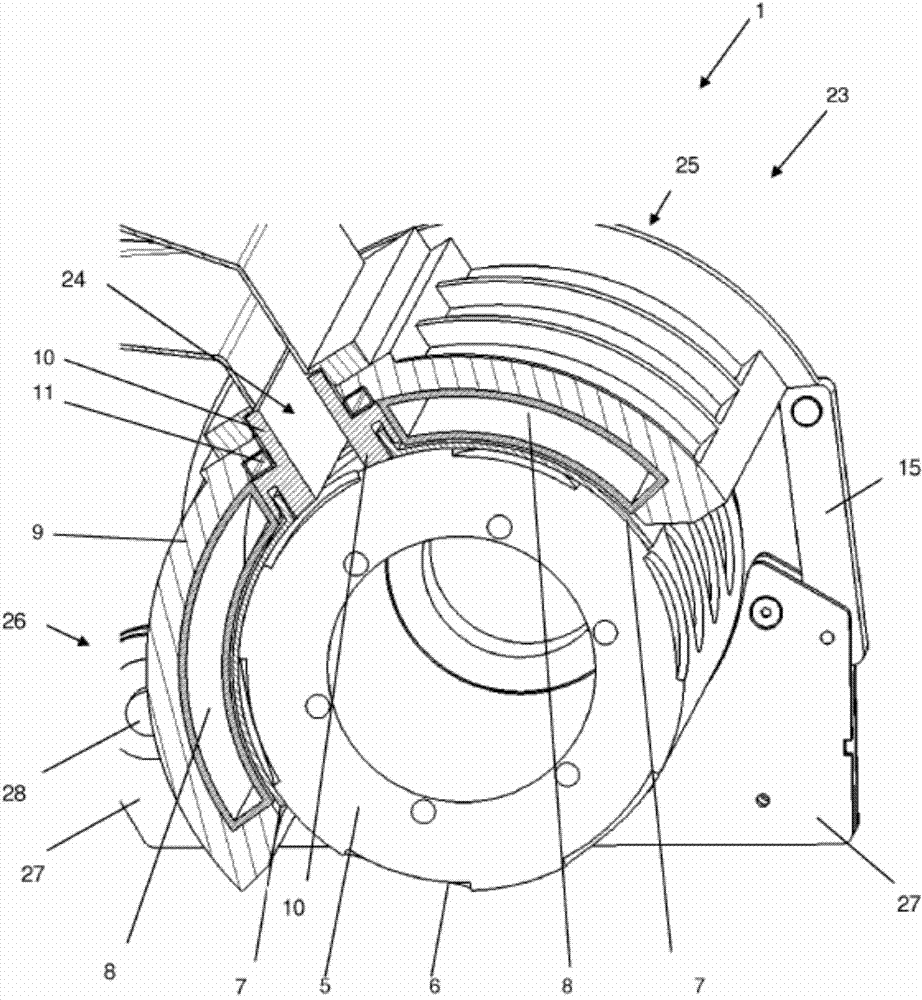

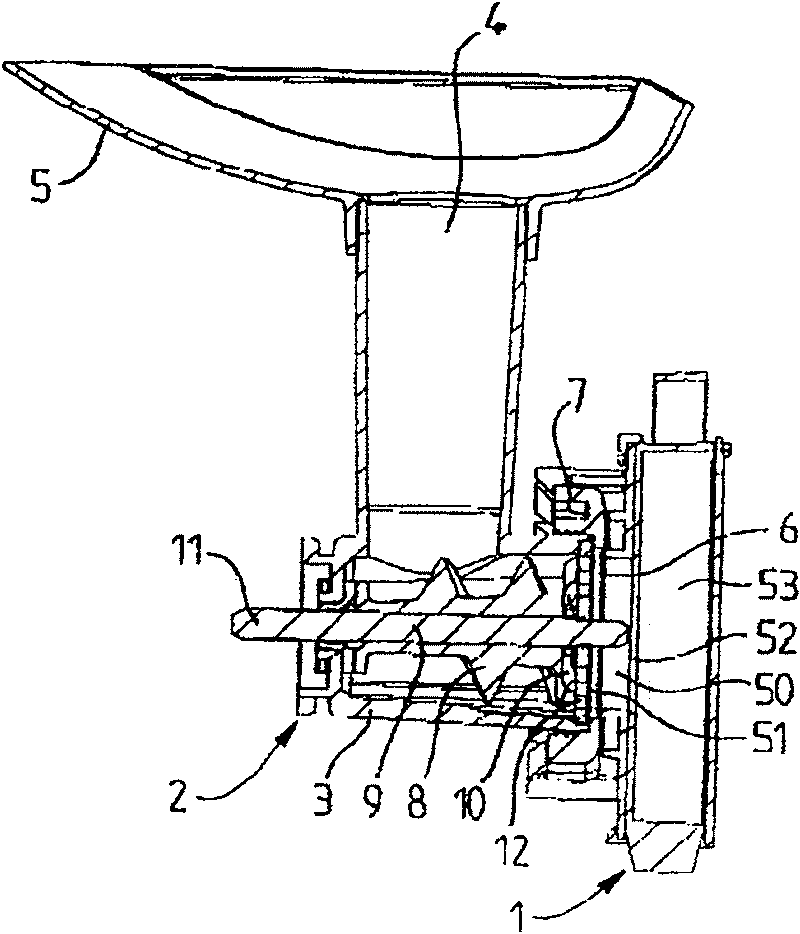

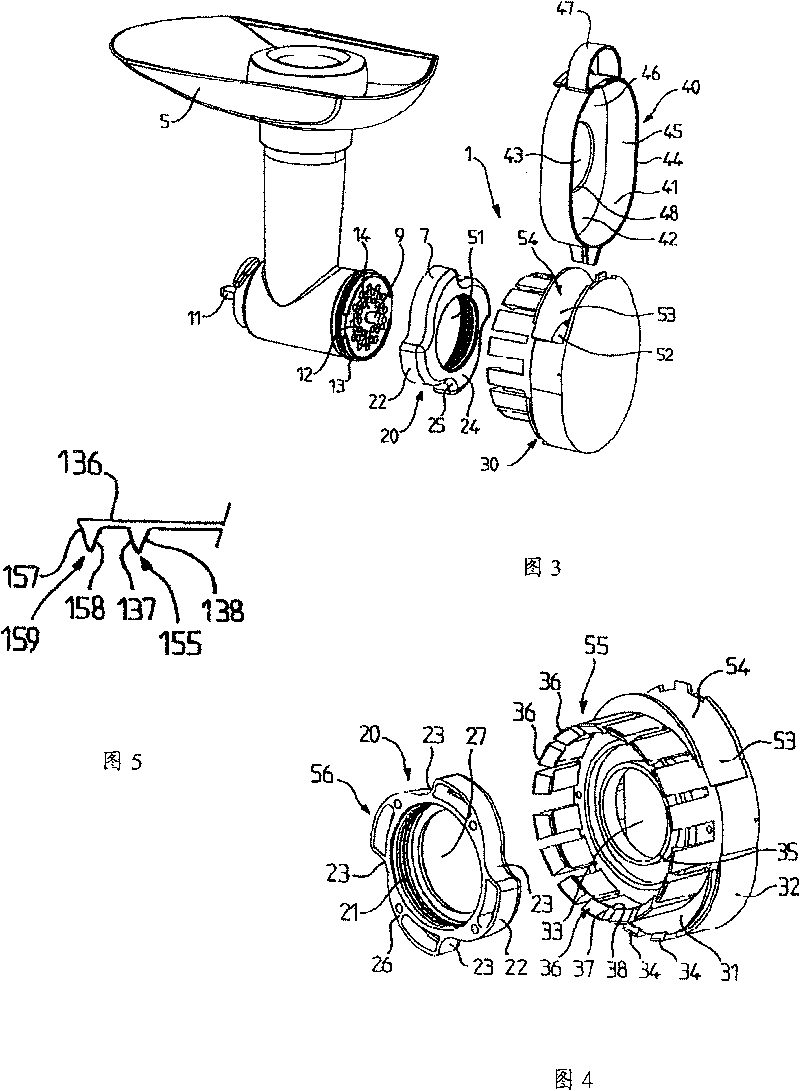

The present invention relates to a food-forming-apparatus with: a rotating drum (5) which comprises product cavities in which a food product is formed from a food mass and a food mass feed member (23), which comprises a housing with an infeed channel (24) and at least one upstream sealing area (25) and / or a downstream sealing area (26) and a flexible pressure plate (7) which is pressed against the outer surface of the drum and thereby provides a seal between the food mass member and the drum. The drum has at its outer surface a multitude of rows of cavities.

Owner:GEA FOOD SOLUTIONS BAKEL

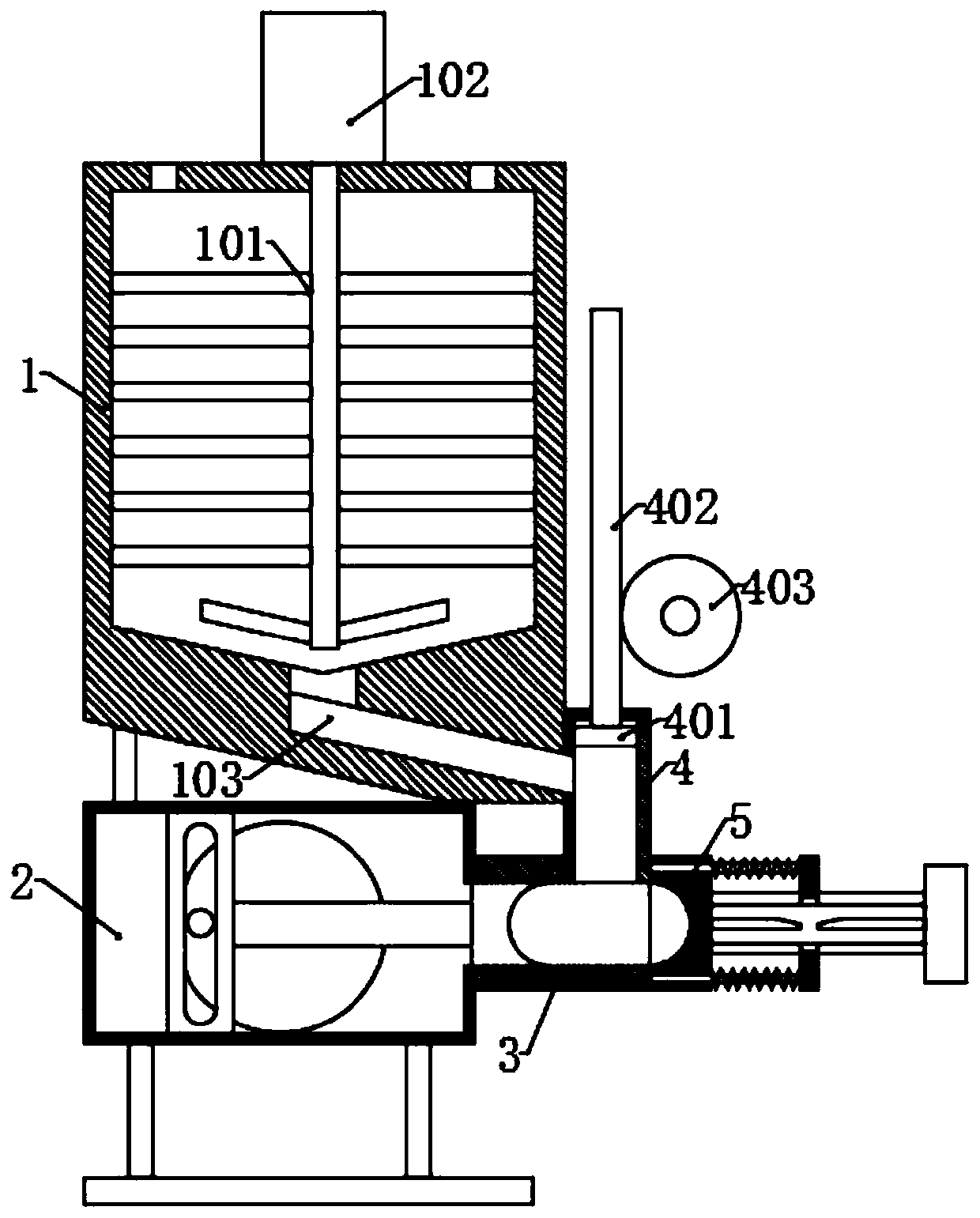

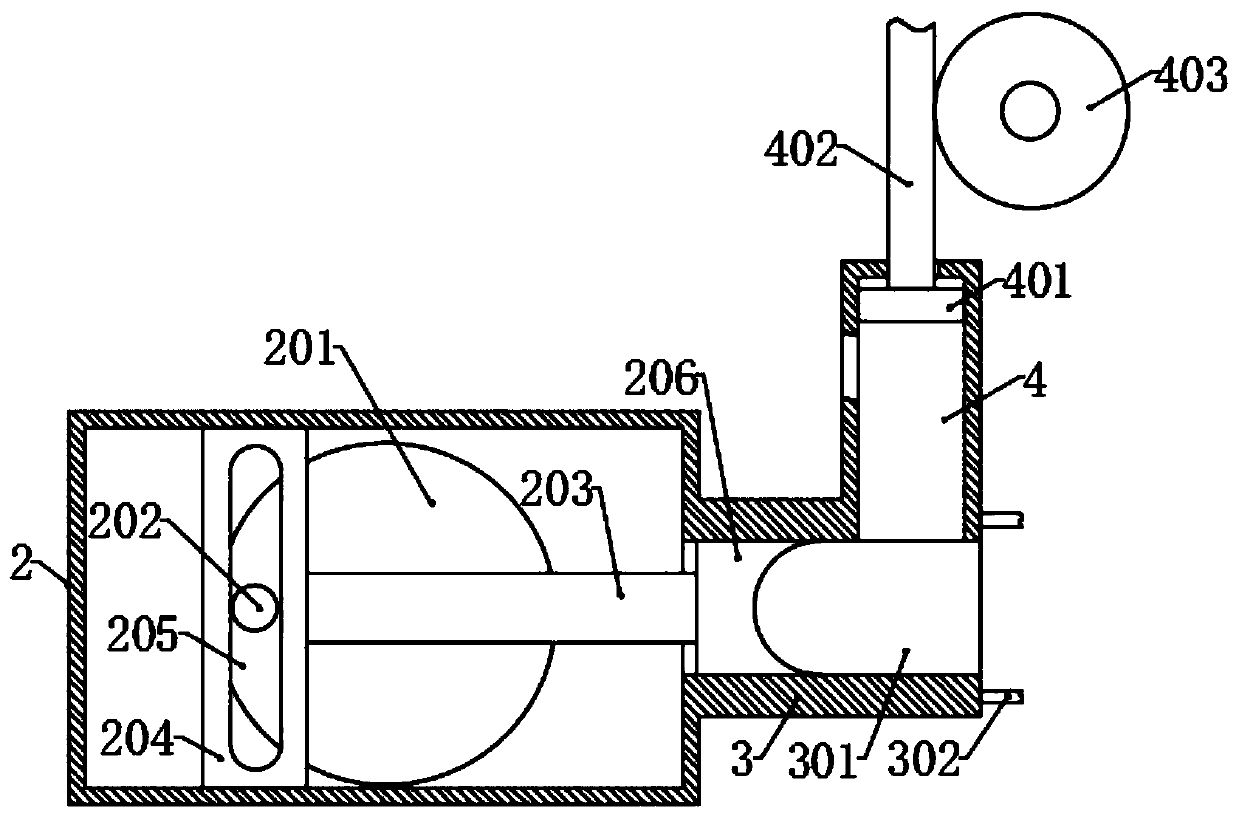

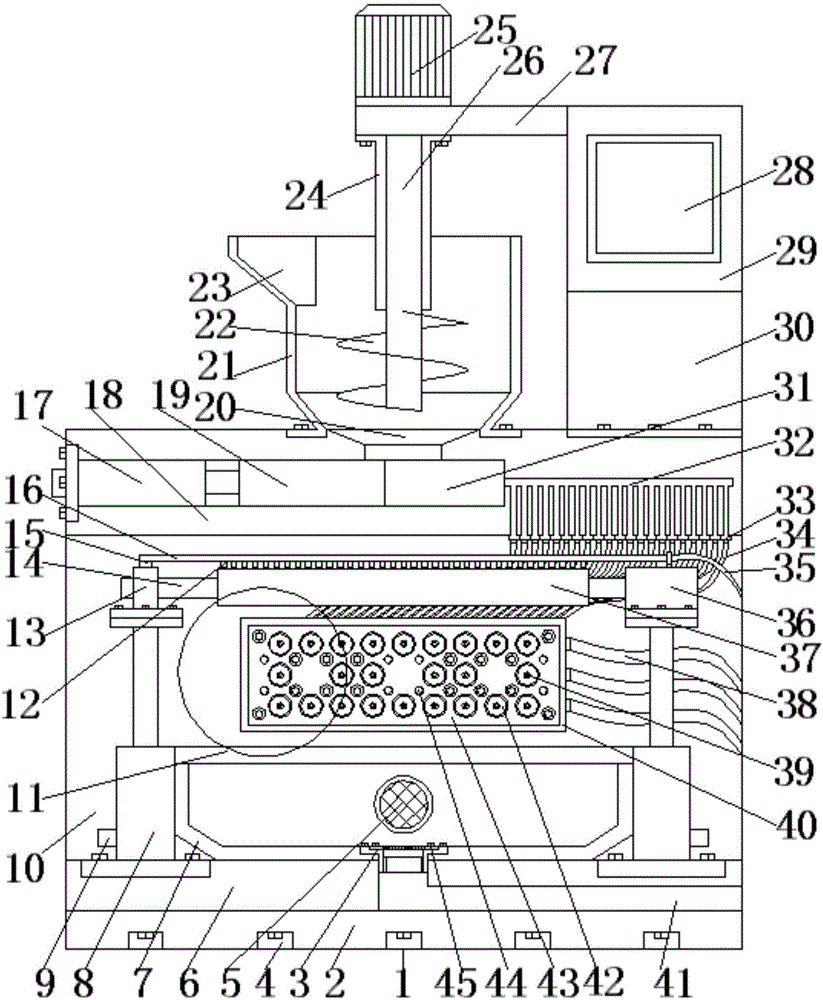

Processing device for meat ball food

The invention discloses a processing device for meat ball food in the technical field of food processing. The processing device comprises a mixing box, a driving box, an extrusion plate, a fixed plateand a molding die plate. According to the invention, various raw materials for meat ball processing are put into the mixing box; the raw materials are fully mixed through a stirring shaft to enter amaterial guiding cavity and moving cavities; the mixed raw materials are completely pushed into extrusion grooves through moving assemblies to avoid waste caused by residual raw materials in moving grooves; a driving assembly and an extrusion block of an extrusion assembly move forwards, and cooperate with the molding die plate to fully extrude the raw materials; meanwhile, through cooperation oftwo semispherical grooves, the raw materials are extruded into balls; through a positioning motor, the molding die plate can move outwards under the action of the extrusion block, and gradually returns under the action of a spring and makes contact with the extrusion plate; and through rotation of the positioning motor, a positioning block is clamped again, and the molding die plate is tightly pressed on the extrusion plate.

Owner:安徽麦壳科技有限公司

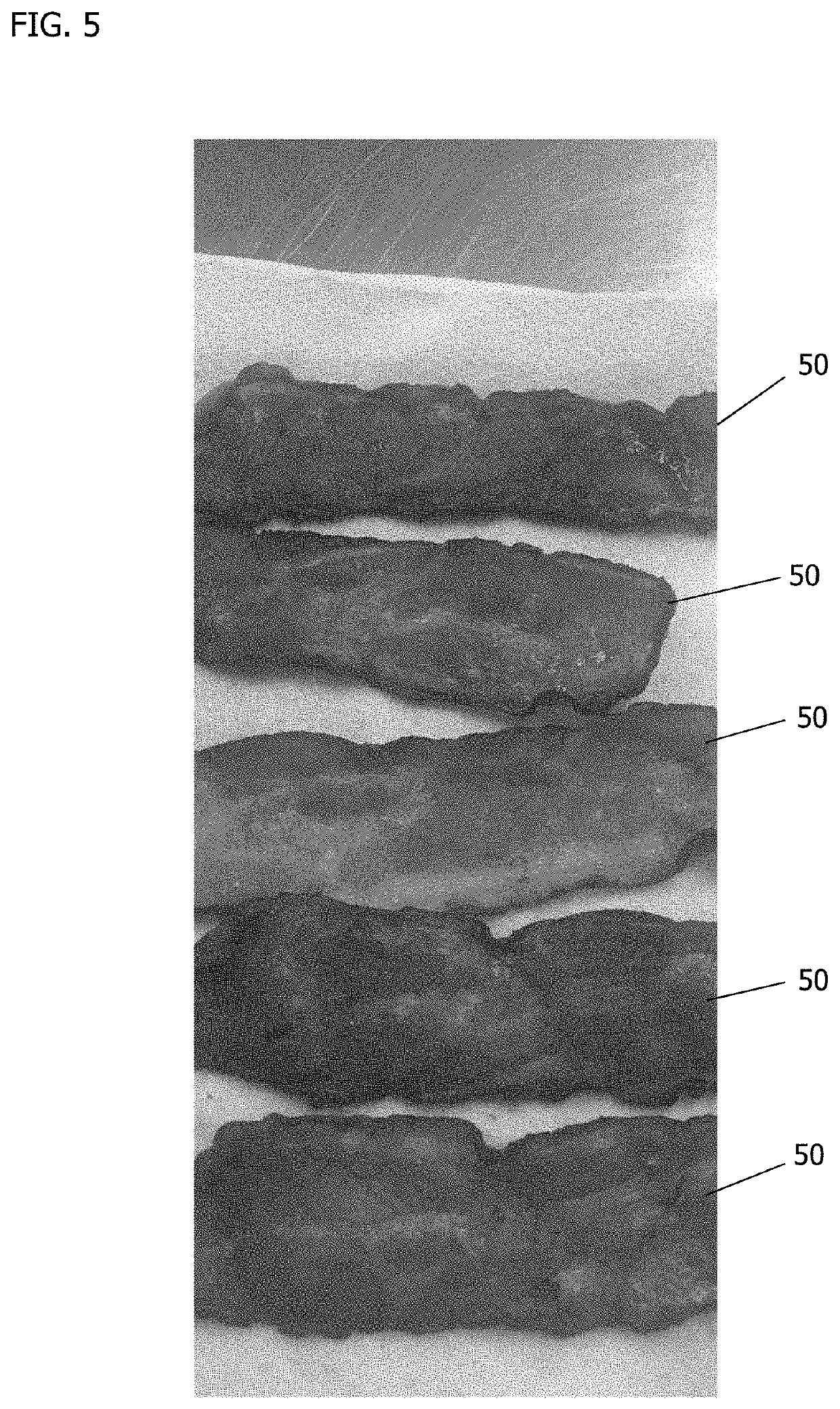

Reconstructed bacon product

A reconstructed bacon product includes meat sourced exclusively from pork bellies. The product includes a cohesive mass of compressed layers of pork belly fat trimmings and pork belly lean trimmings of whole muscle segments. A method of forming a reconstructed bacon product includes obtaining pork belly lean trimmings of whole muscle segments and pork belly fat trimmings, macerating the pork belly lean trimmings, layering the pork belly lean trimmings and pork belly fat trimmings, compressing the layers, heat processing the layers in a mold to form a cohesive mass, and demolding the cohesive mass.

Owner:SMITHFIELD FOODS

Mass-distributing device and moulding device comprising a mass distributing device of this type

Owner:MAREL TOWNSEND FURTHER PROCESSING

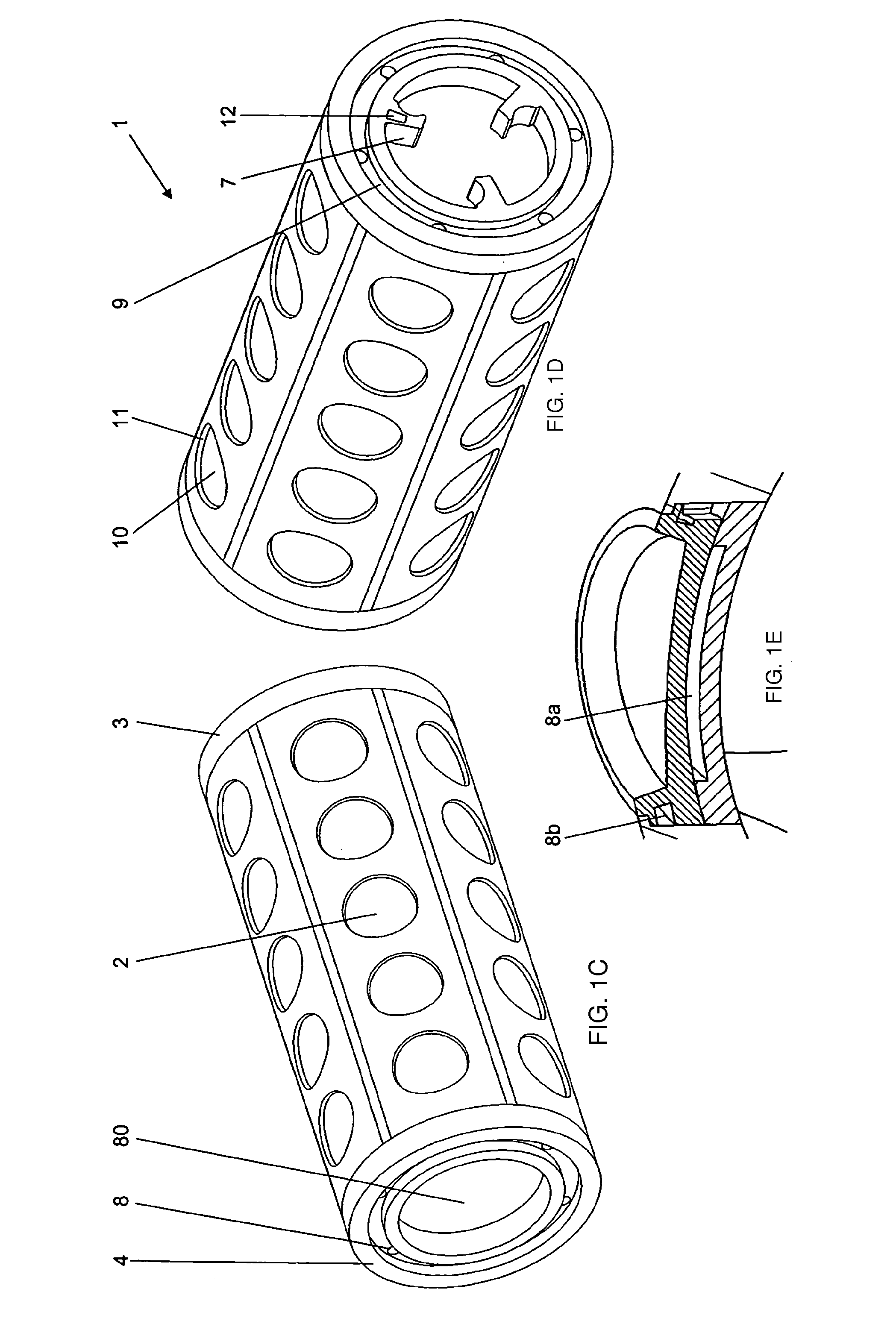

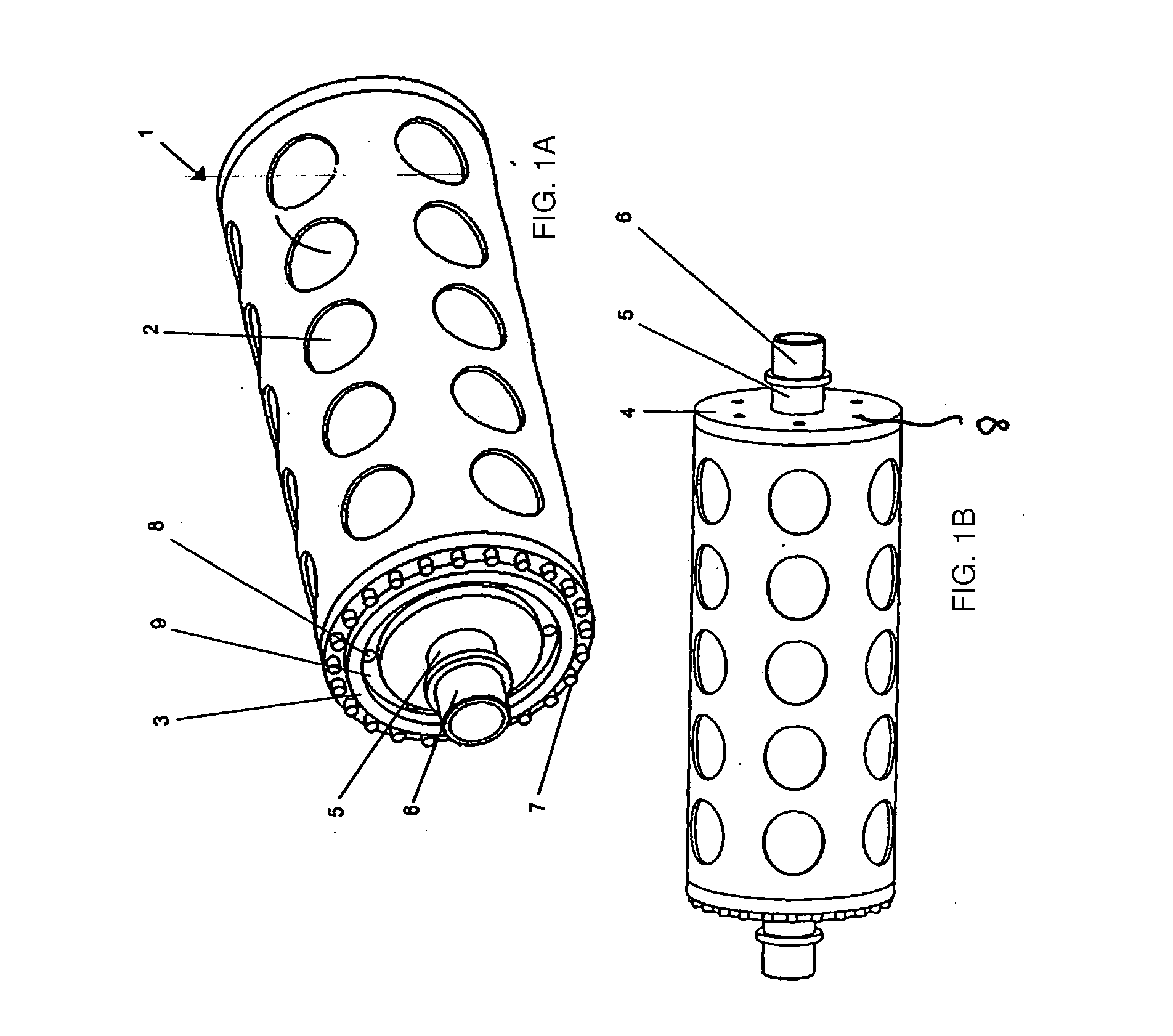

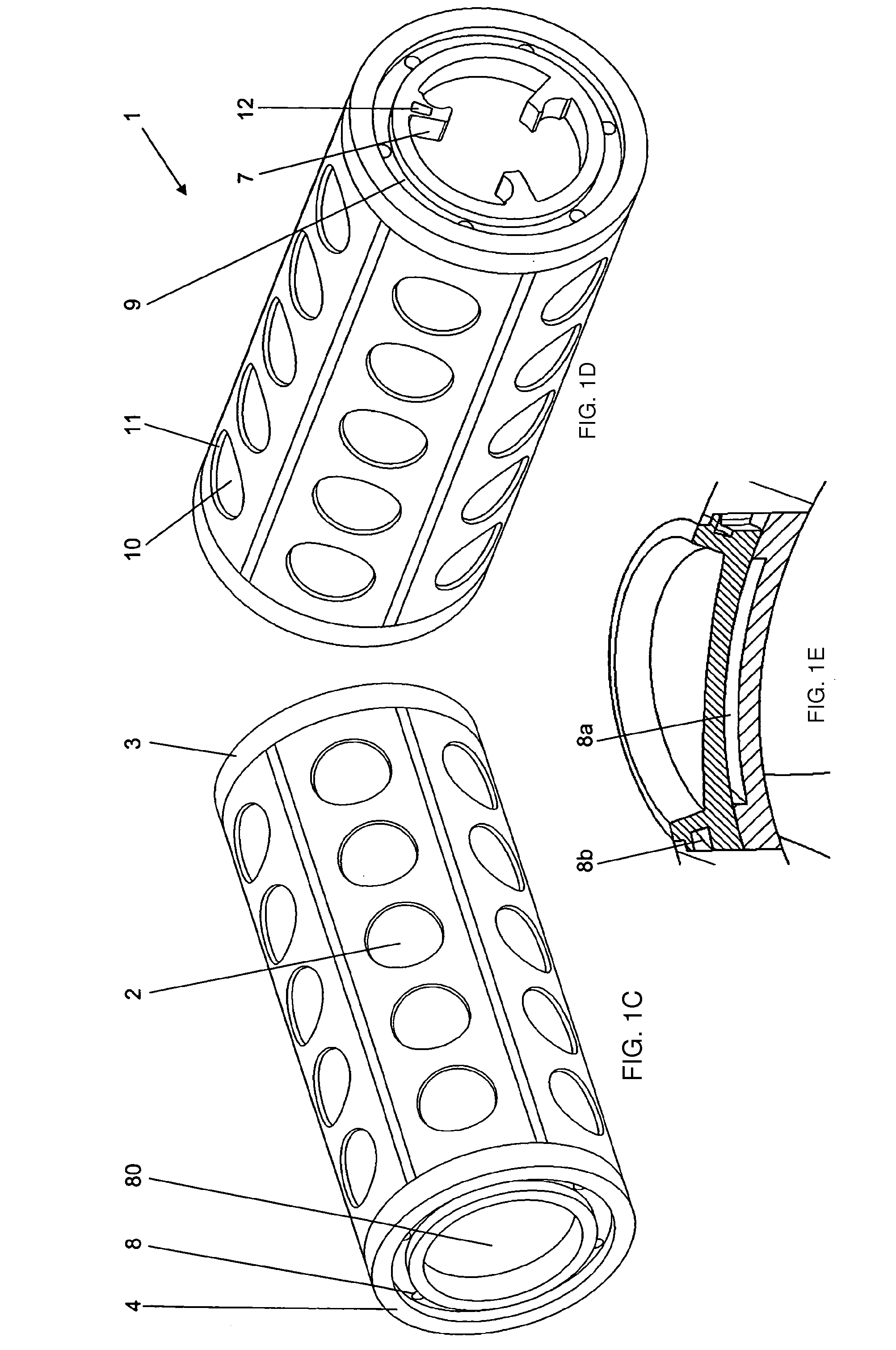

Method and system for preparing a jerky food product

InactiveUS7870820B2Efficient productionEliminate needMeat/fish preservationMeat pressingEngineeringRaw meat

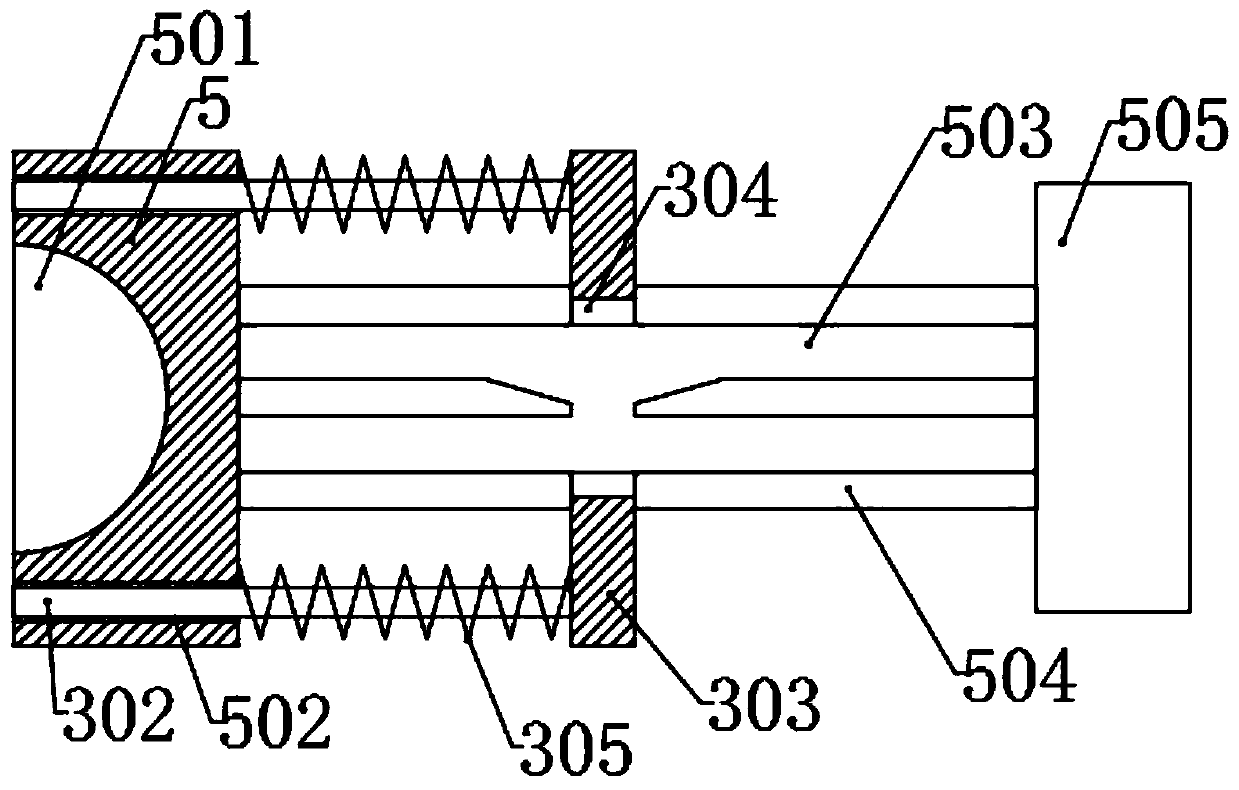

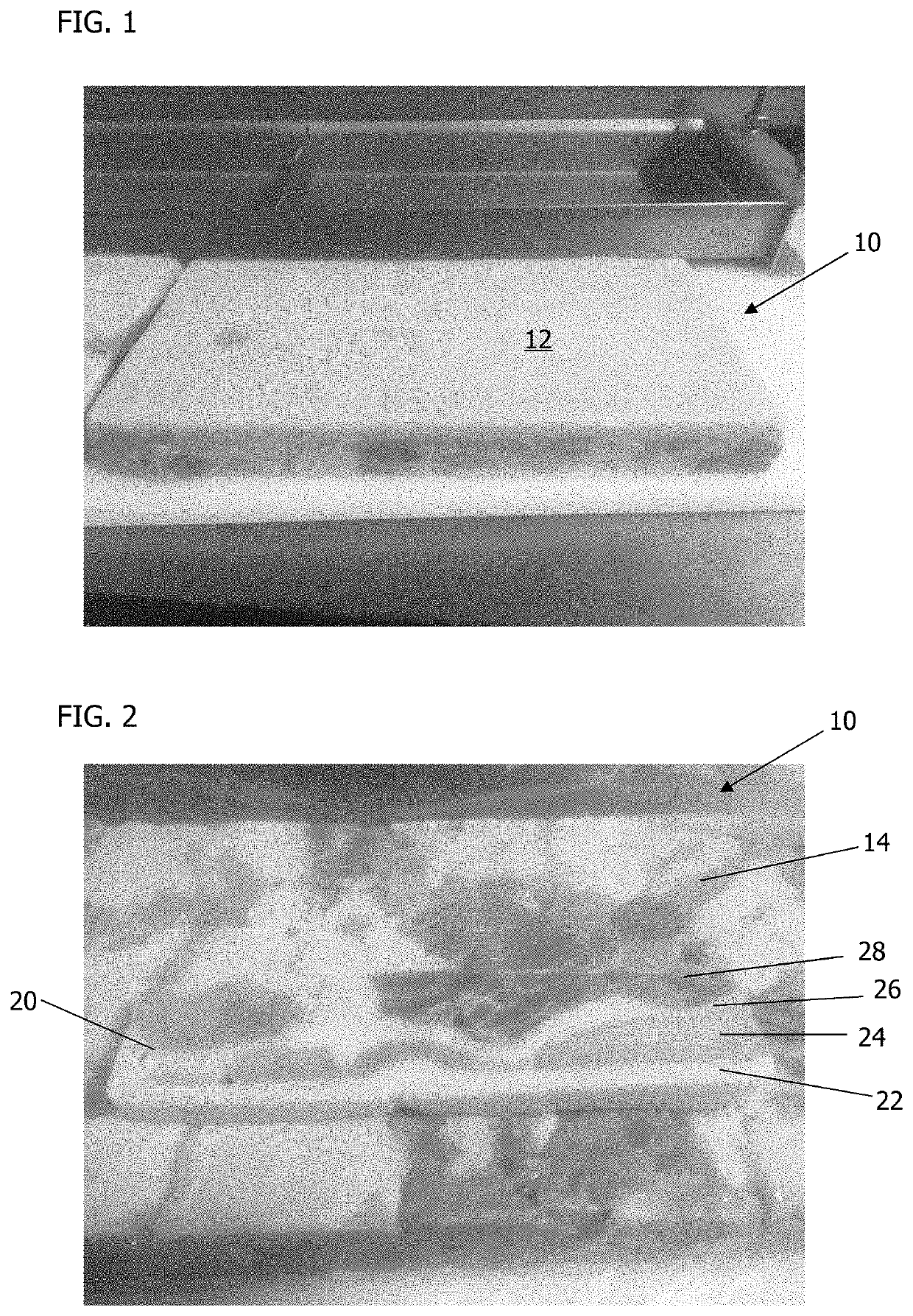

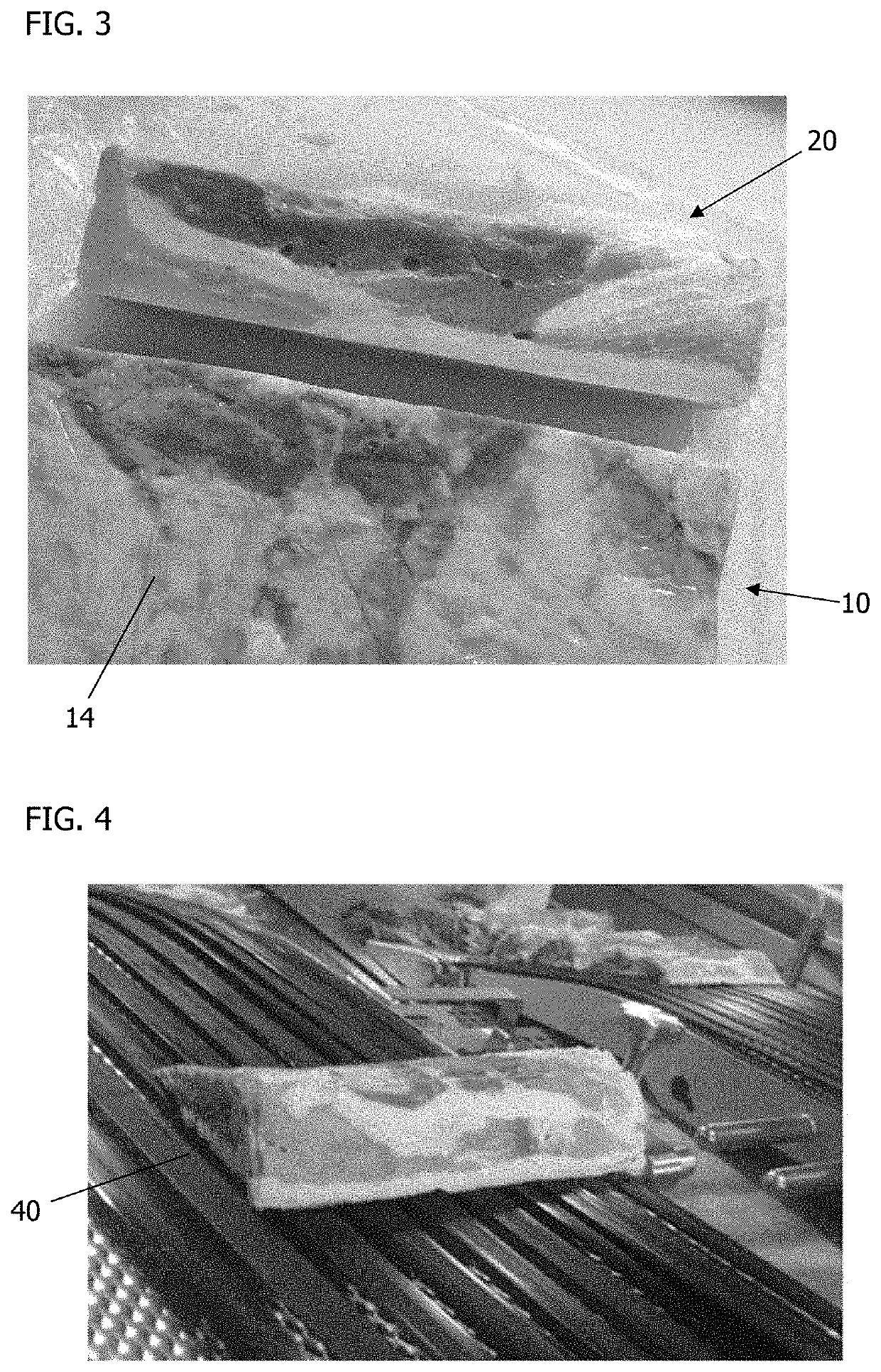

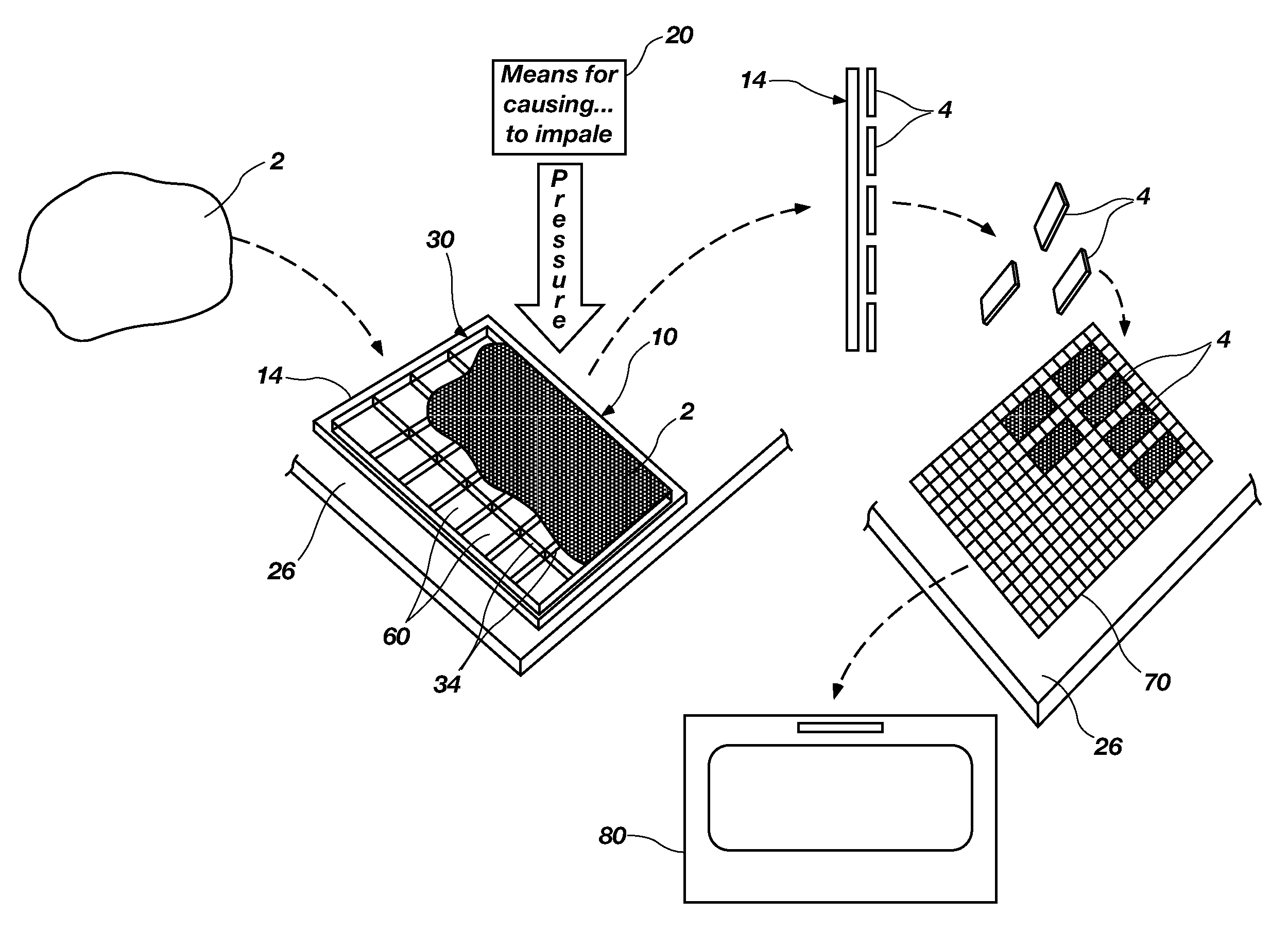

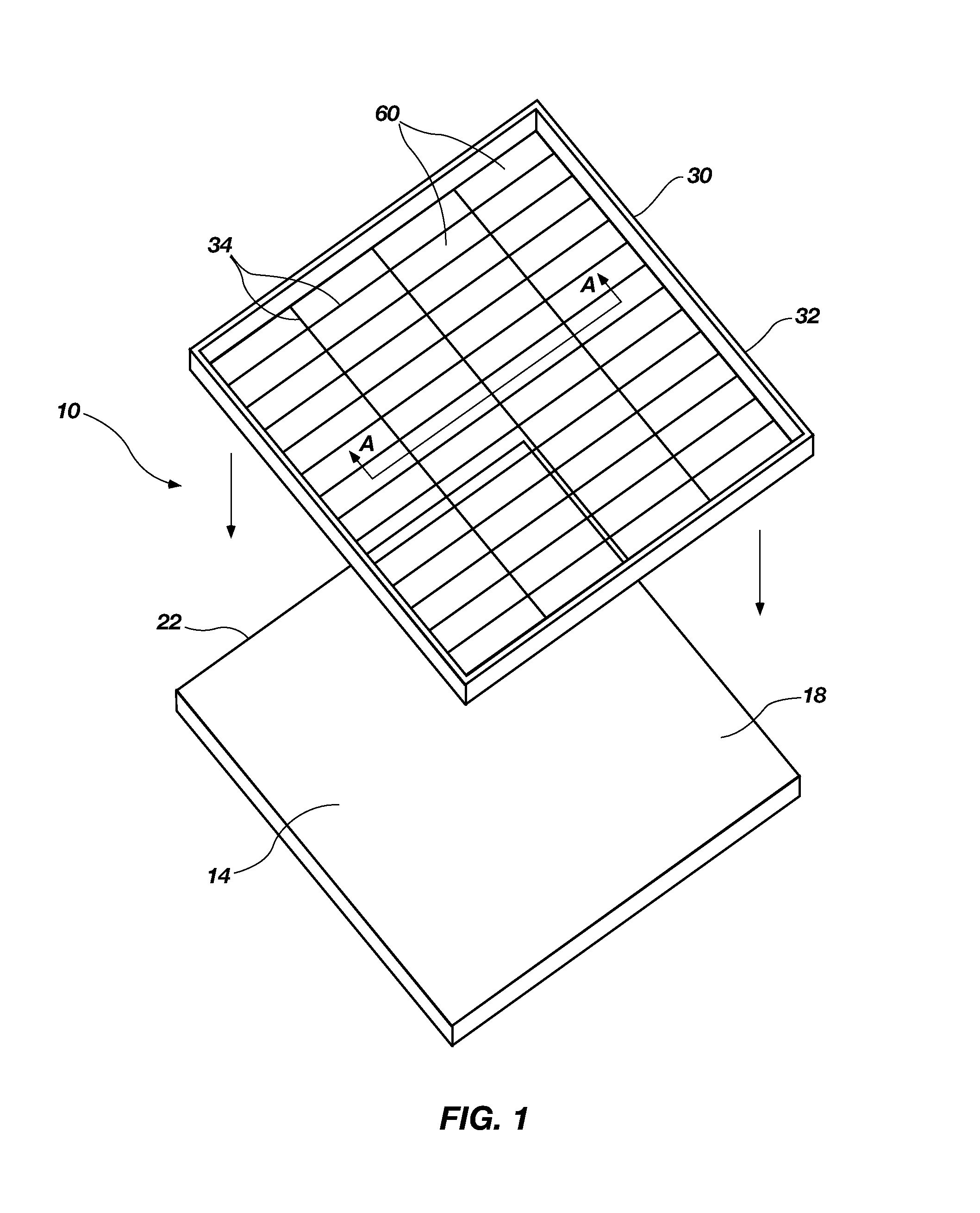

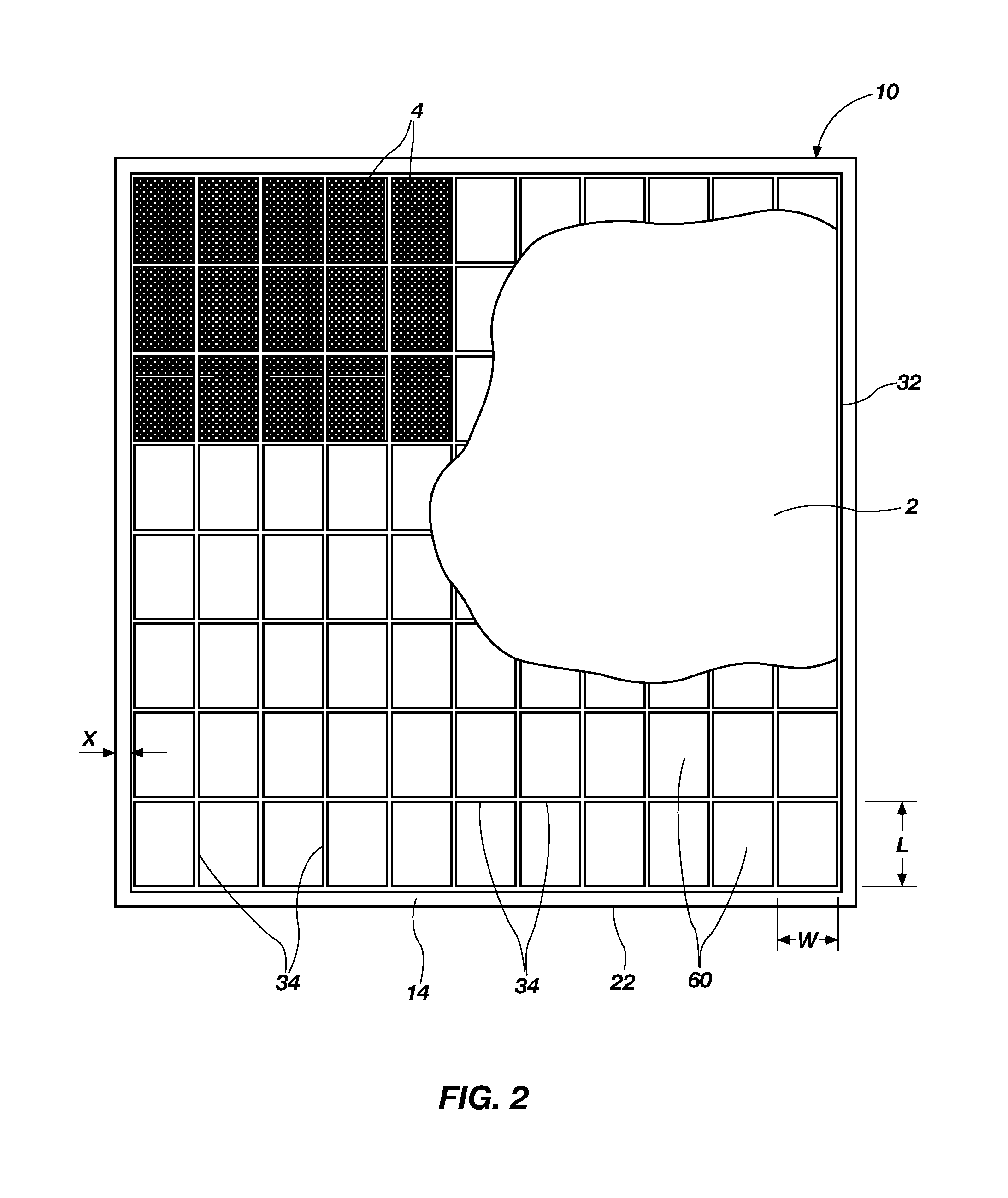

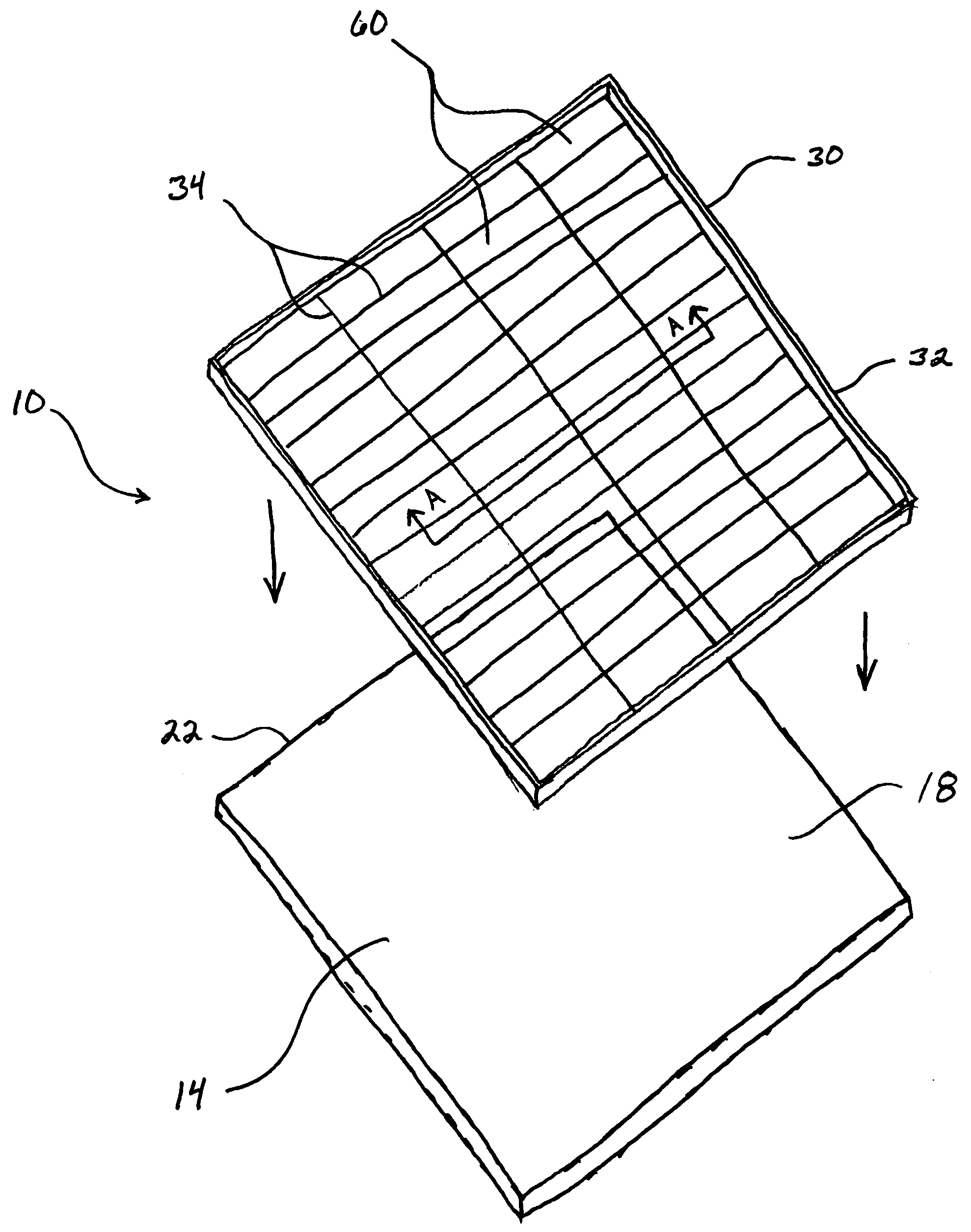

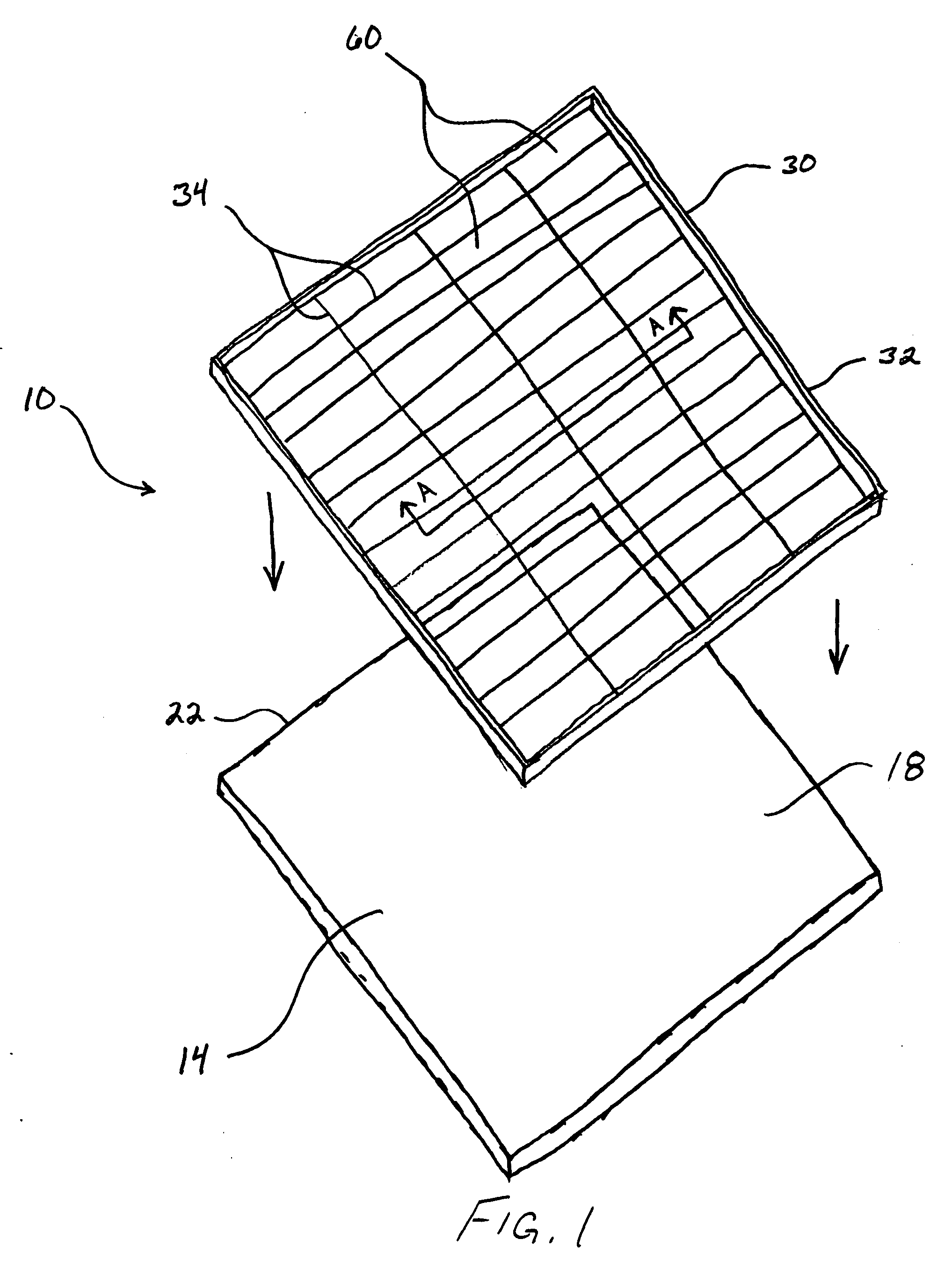

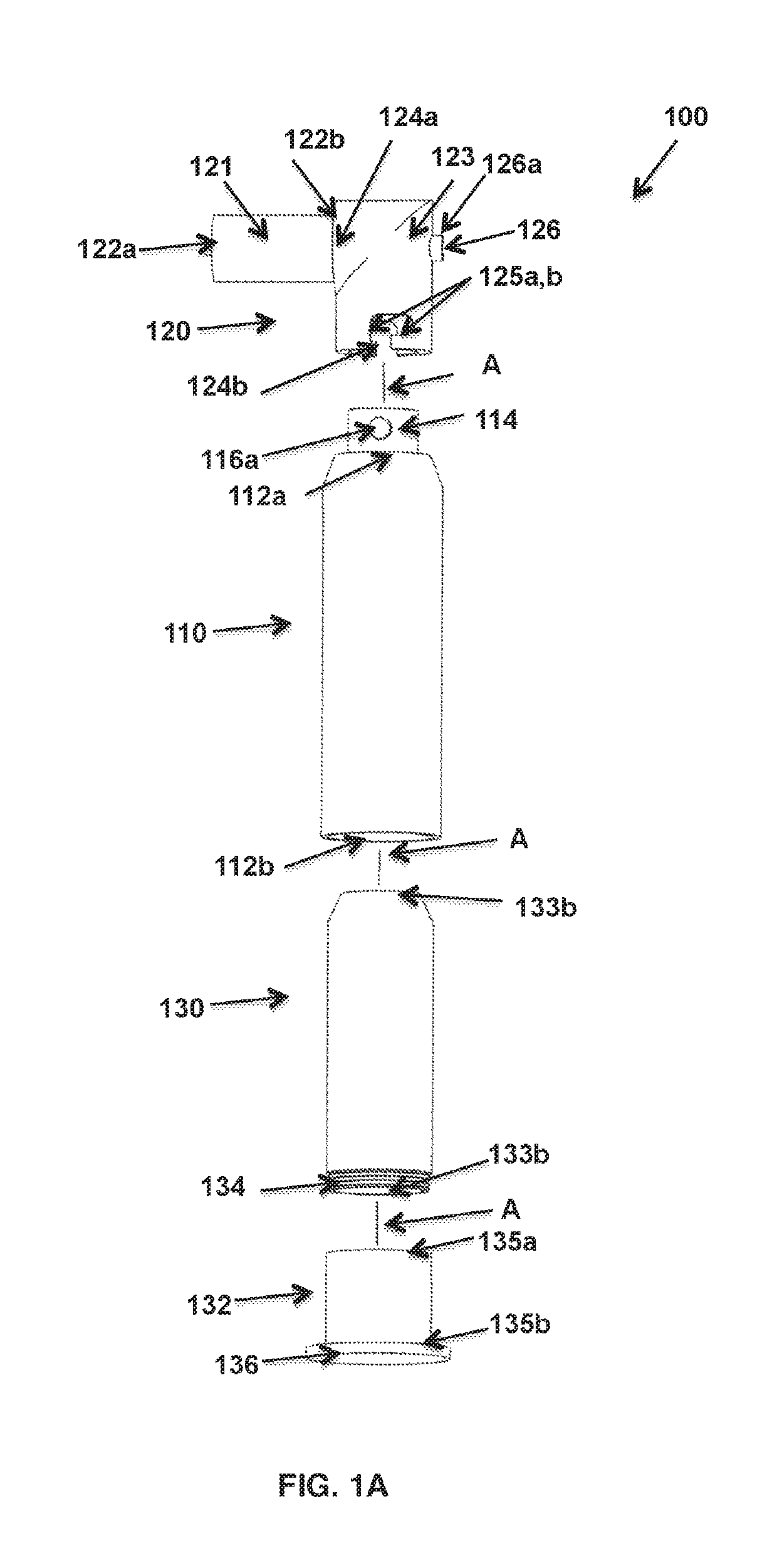

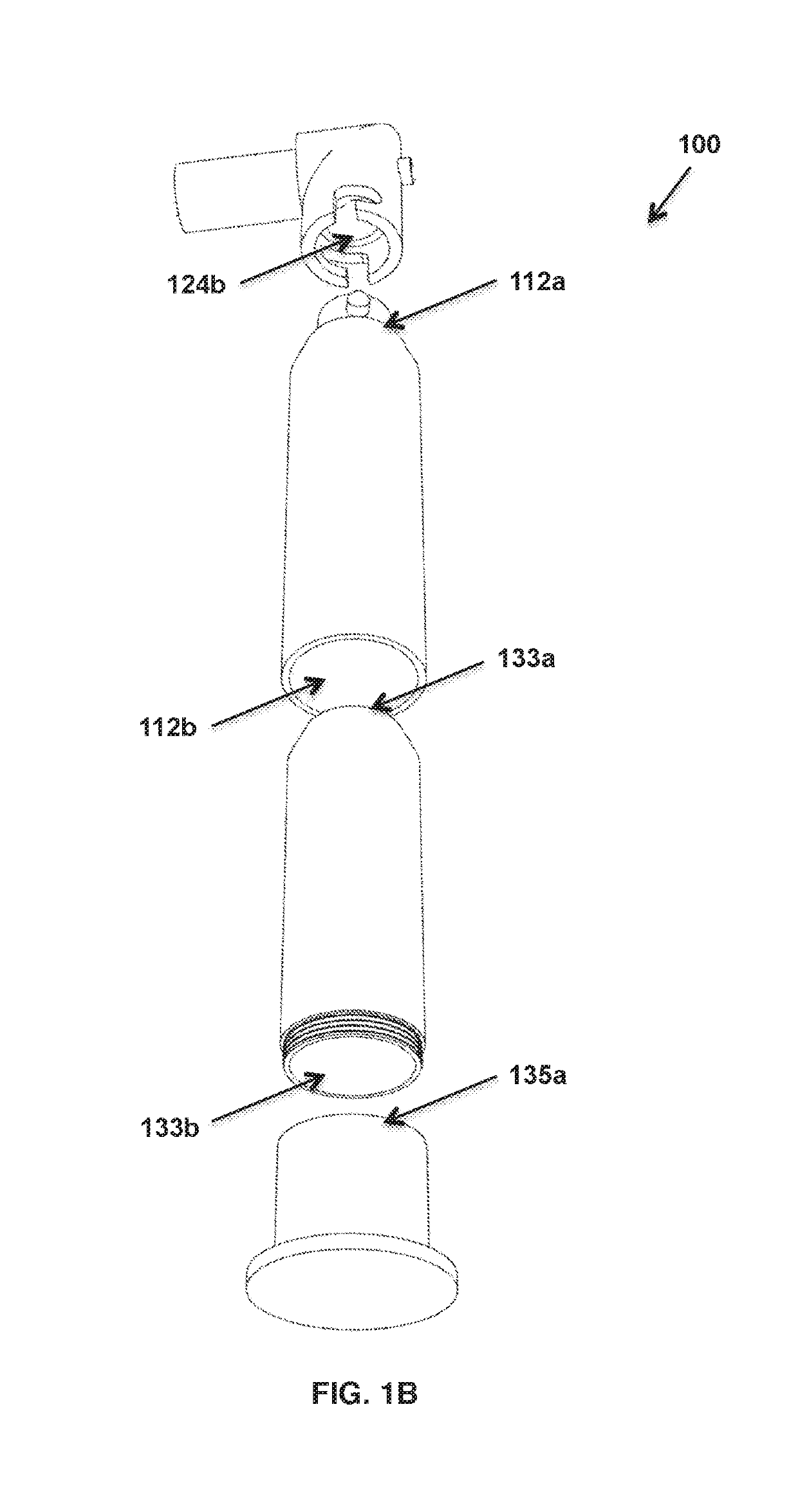

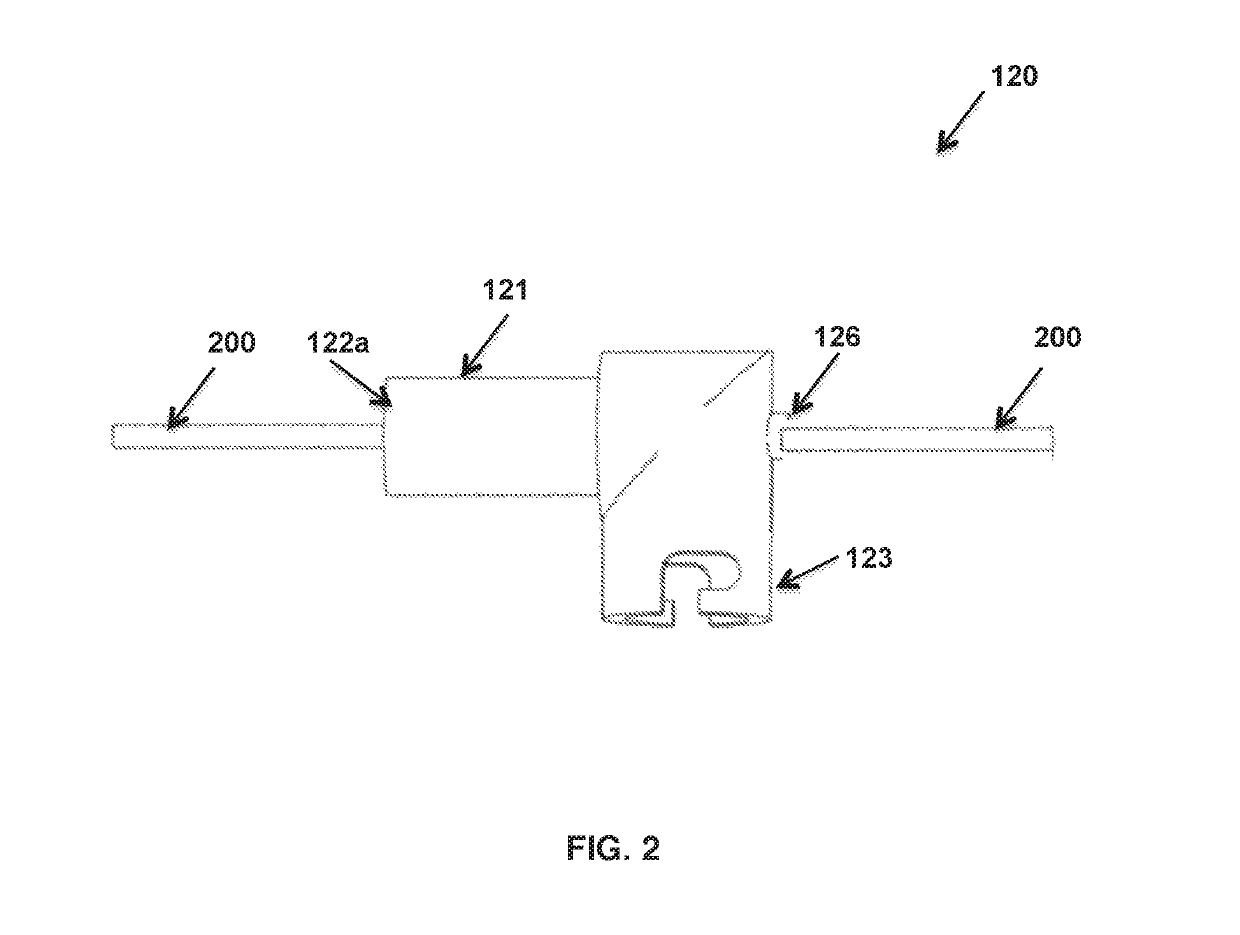

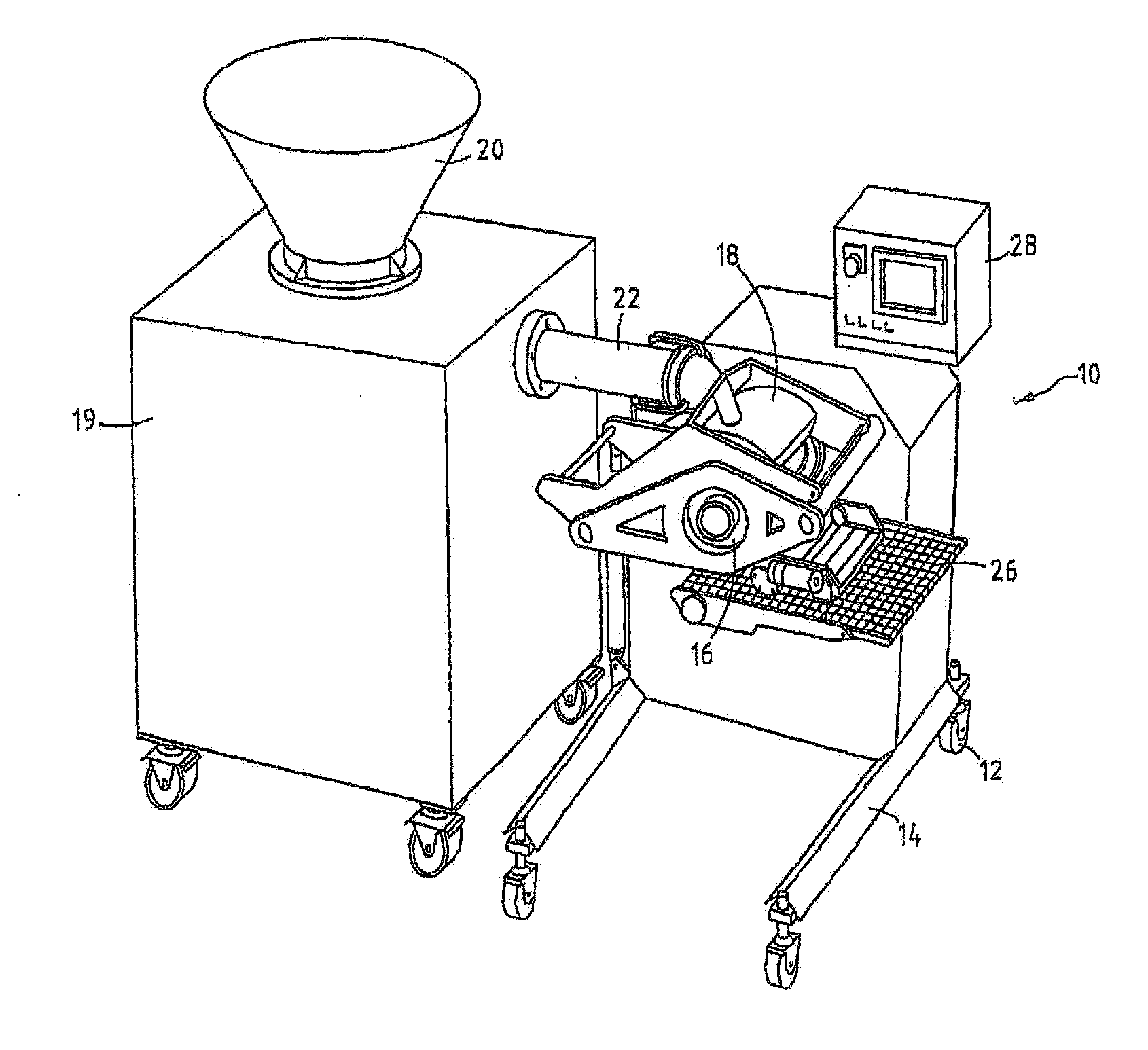

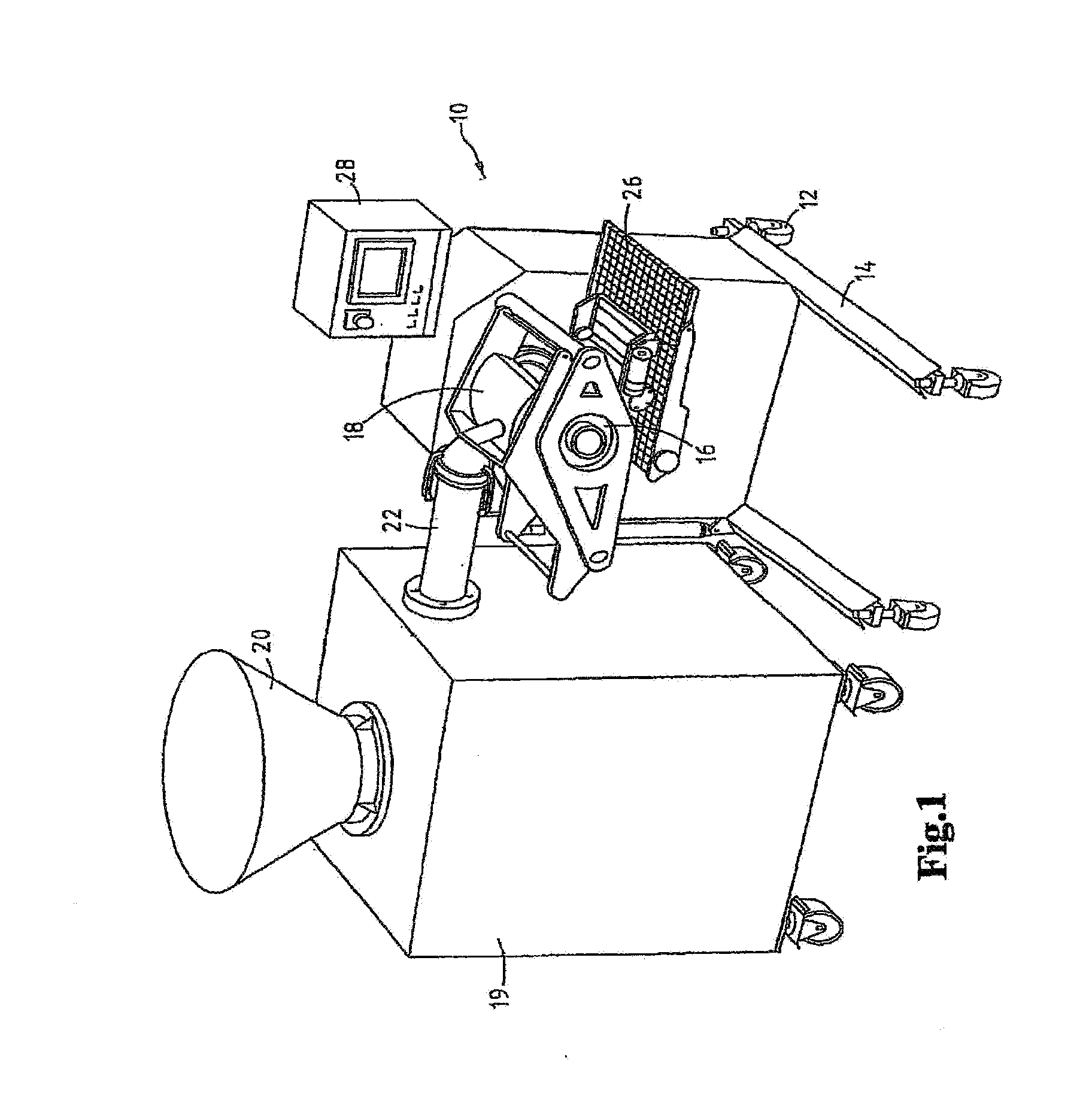

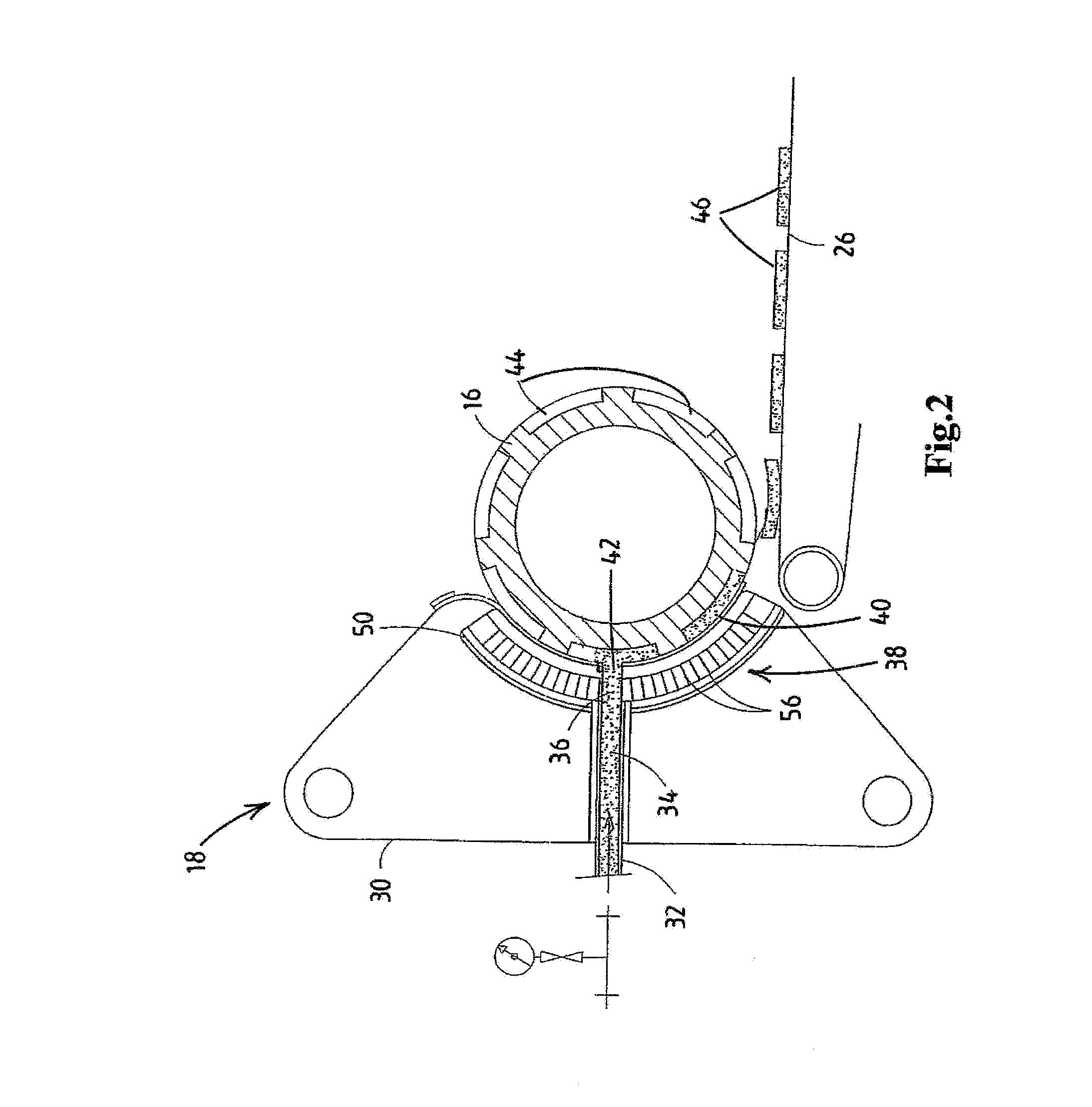

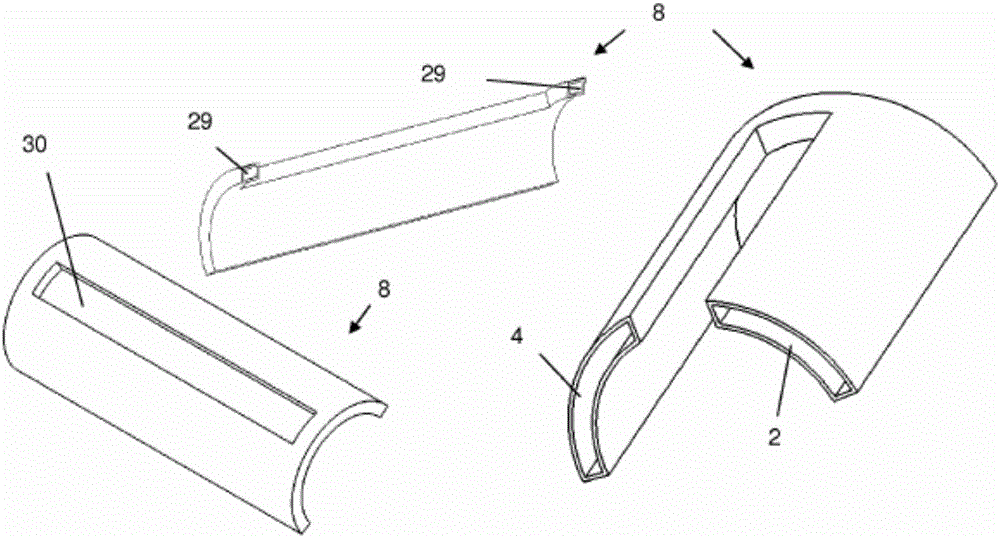

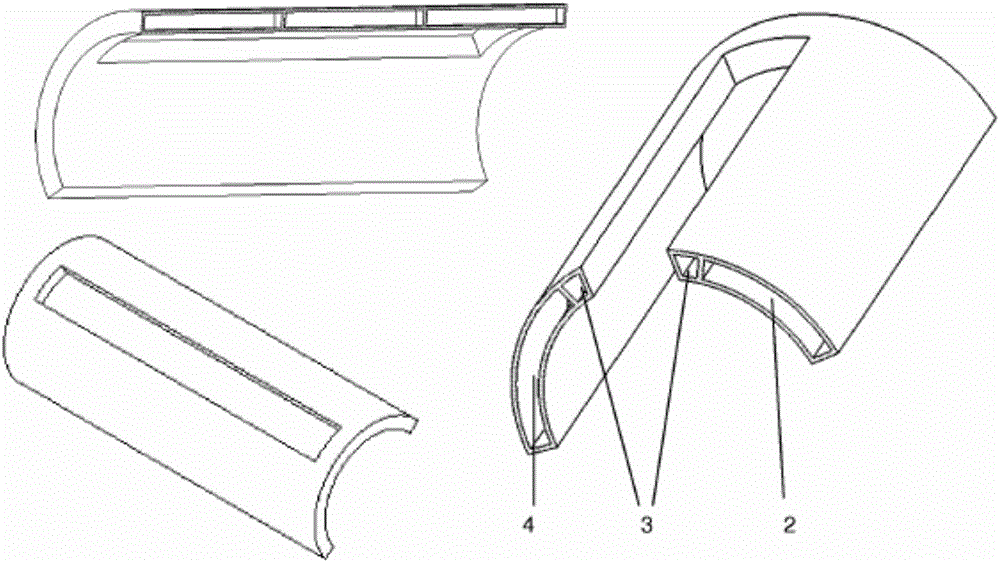

A method and apparatus for preparing a jerky food product. The method comprises: (a) preparing a raw meat to obtain a moldable meat dough; (b) contacting at least a portion of the meat dough with a jerky mold apparatus having a pre-determined geometric configuration, wherein a plurality of sectors are spatially separated and defined by supported partitions arranged in a pre-determined pattern; (c) causing at least one of the partitions of the jerky mold to impale the meat dough to dispose portions of the meat dough into at least one of the sectors, thus separating the meat dough into a plurality of meat segments having a size and shape corresponding to that of the sectors; (d) removing the meat segments from the jerky mold; and (e) treating the meat segments to produce a plurality of jerky pieces.

Owner:WIND RIVER JERKY CORP

Method and system for preparing a jerky food product

InactiveUS20070110882A1Efficient productionEliminate needMeat/fish preservationMeat pressingEngineeringRaw meat

A method and apparatus for preparing a jerky food product. The method comprises: (a) preparing a raw meat to obtain a moldable meat dough; (b) contacting at least a portion of the meat dough with a jerky mold apparatus having a pre-determined geometric configuration, wherein a plurality of sectors are spatially separated and defined by supported partitions arranged in a pre-determined pattern; (c) causing at least one of the partitions of the jerky mold to impale the meat dough to dispose portions of the meat dough into at least one of the sectors, thus separating the meat dough into a plurality of meat segments having a size and shape corresponding to that of the sectors; (d) removing the meat segments from the jerky mold; and (e) treating the meat segments to produce a plurality of jerky pieces.

Owner:WIND RIVER JERKY CORP

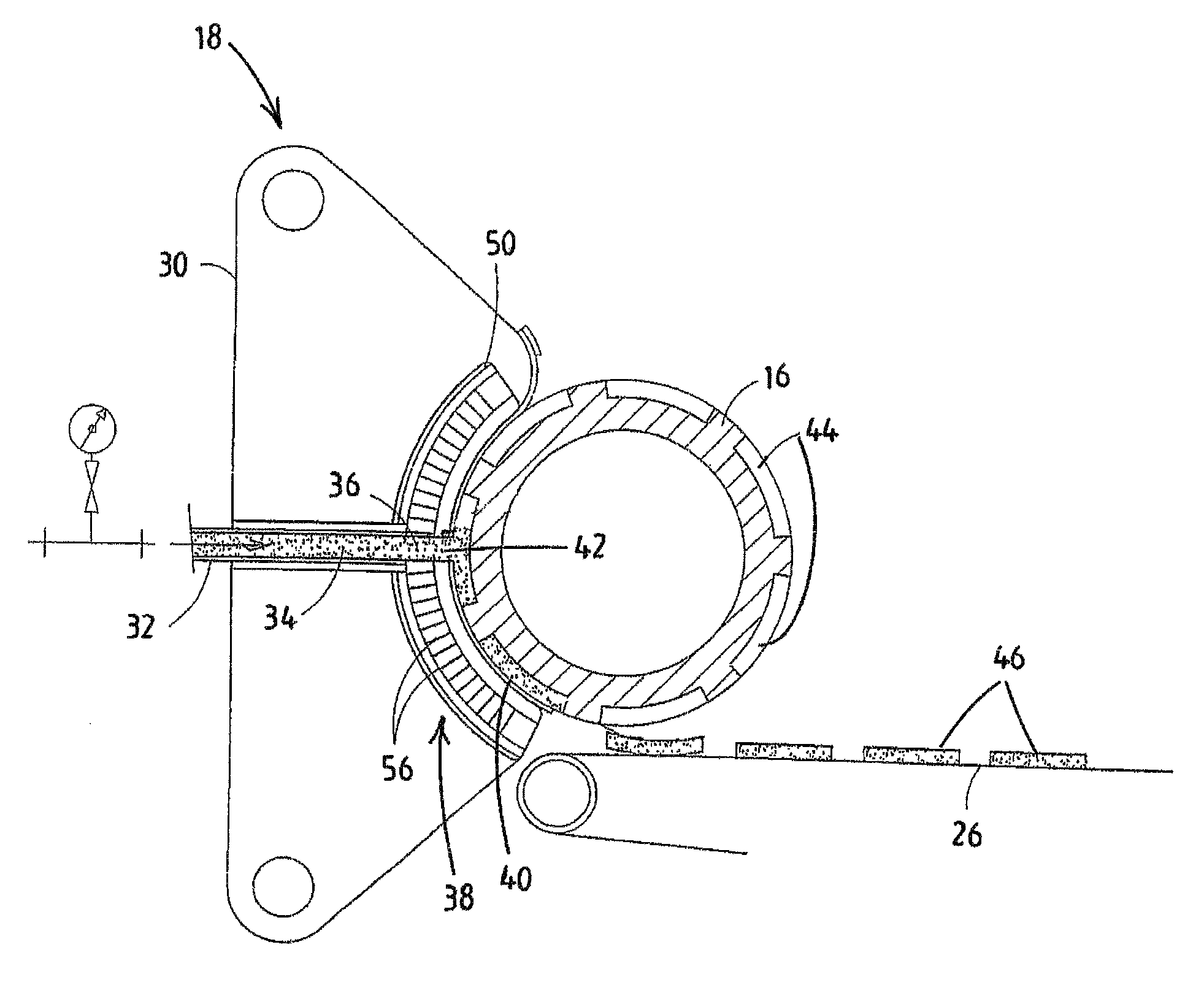

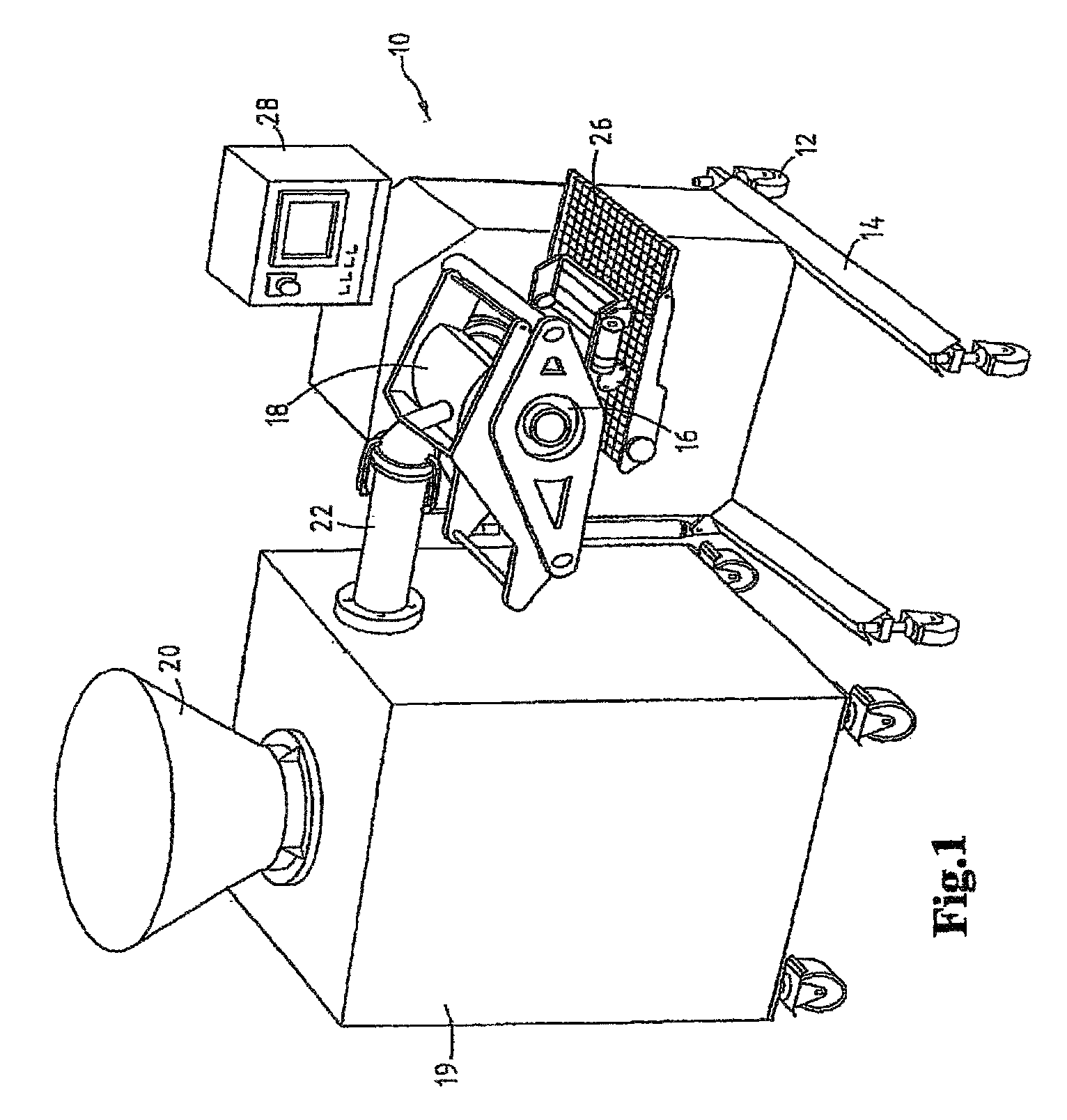

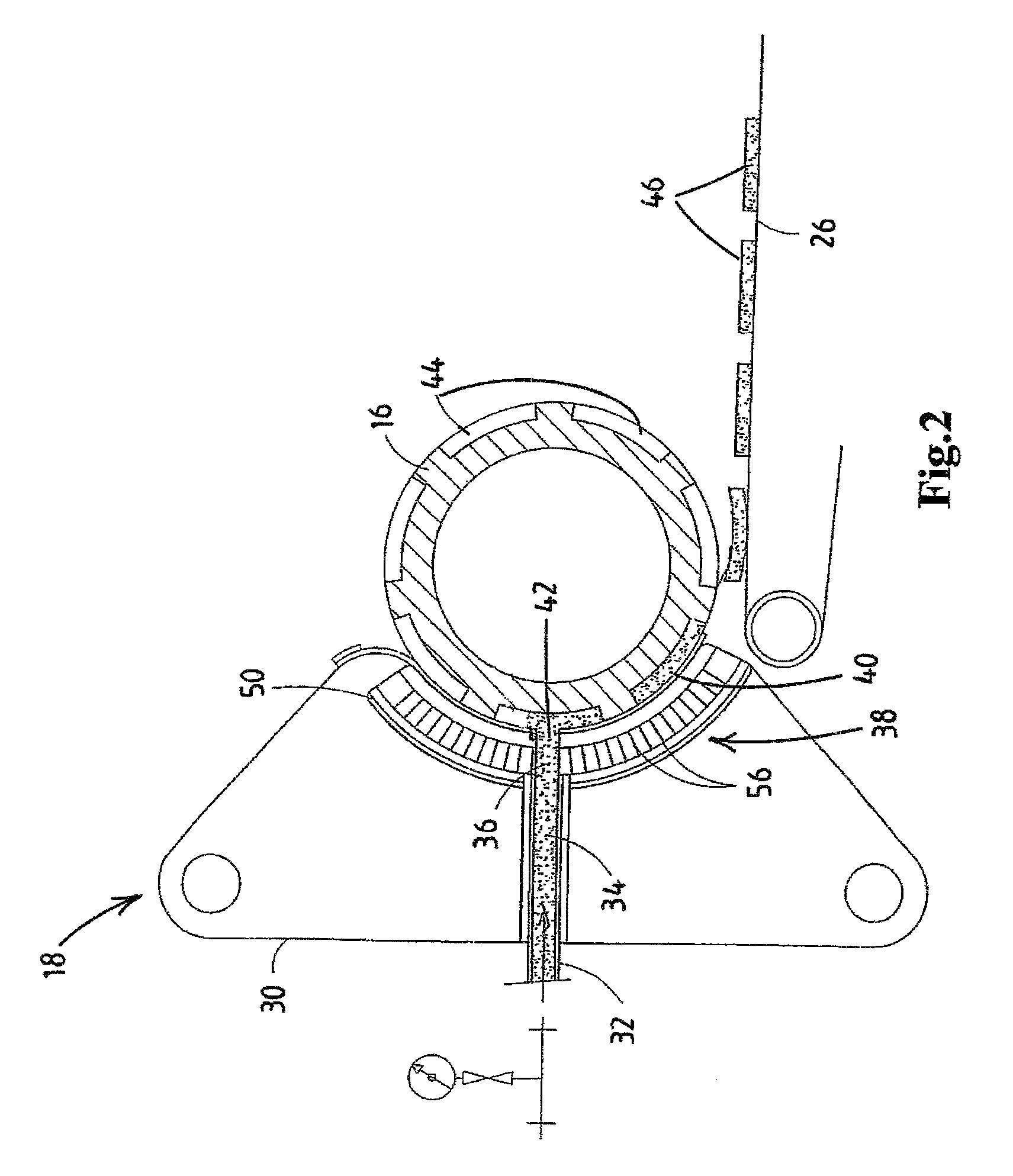

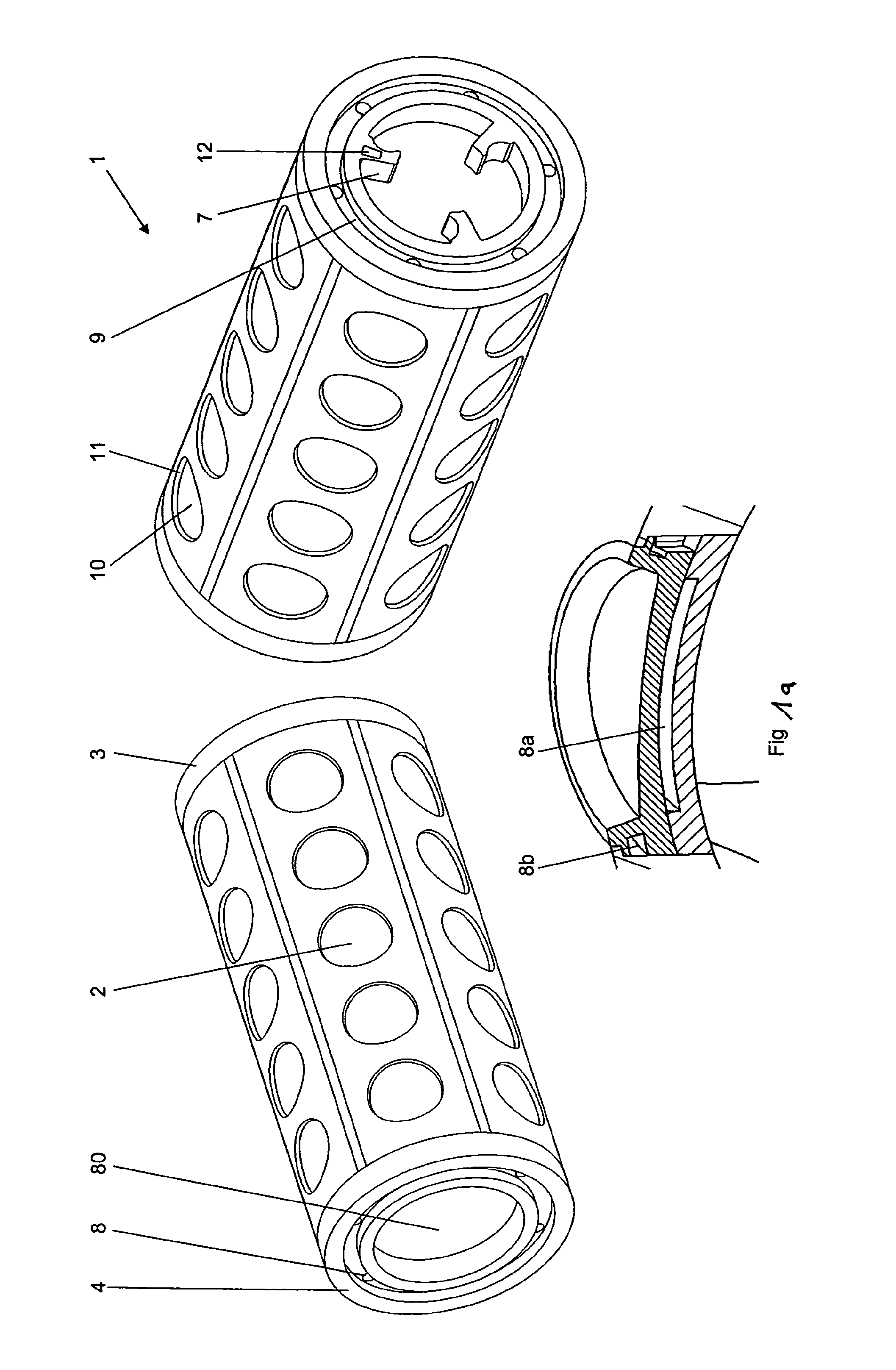

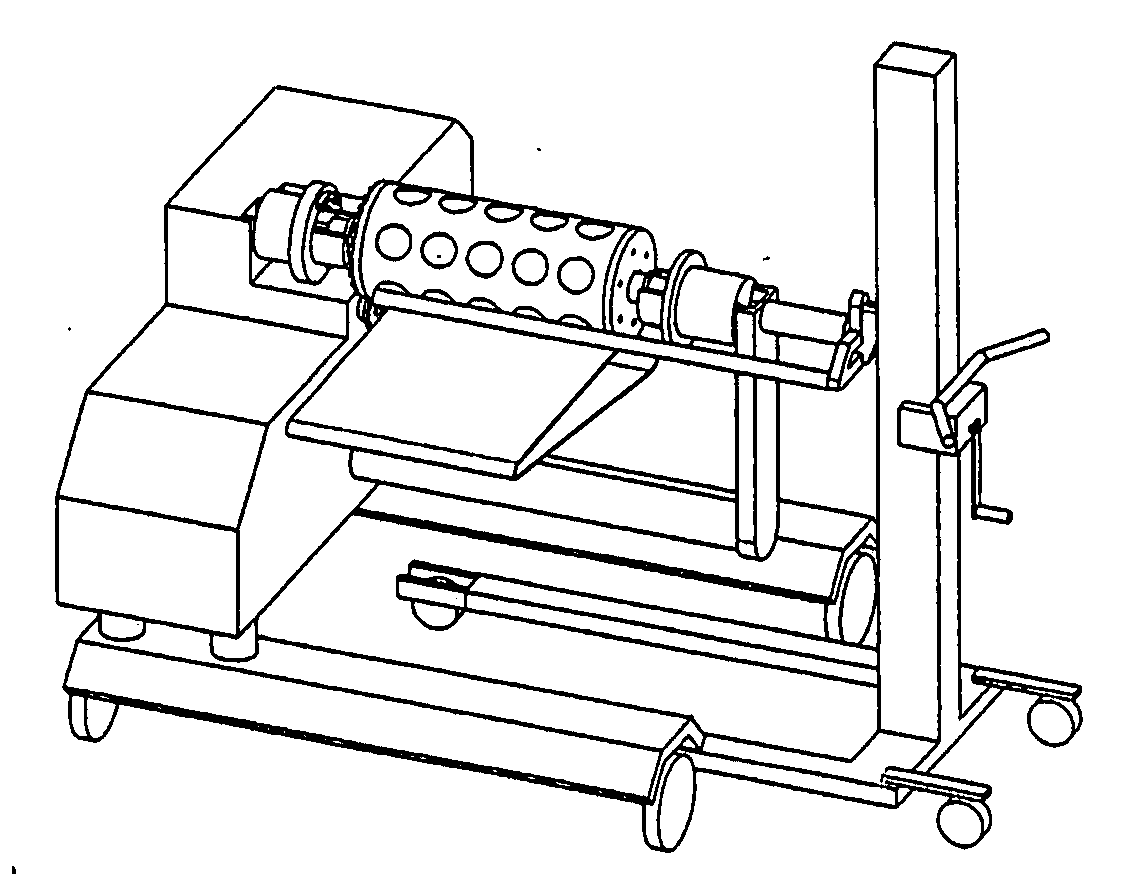

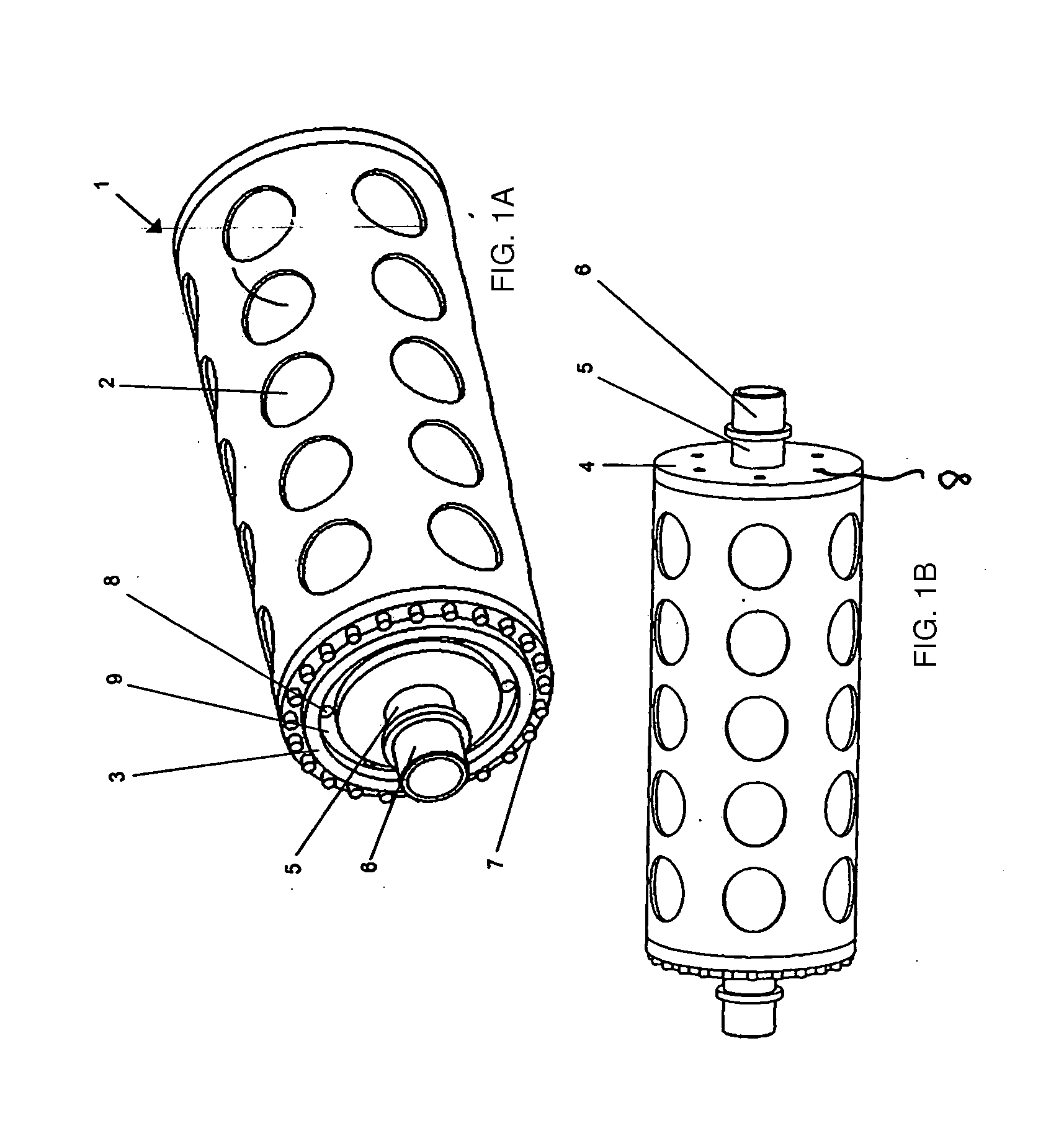

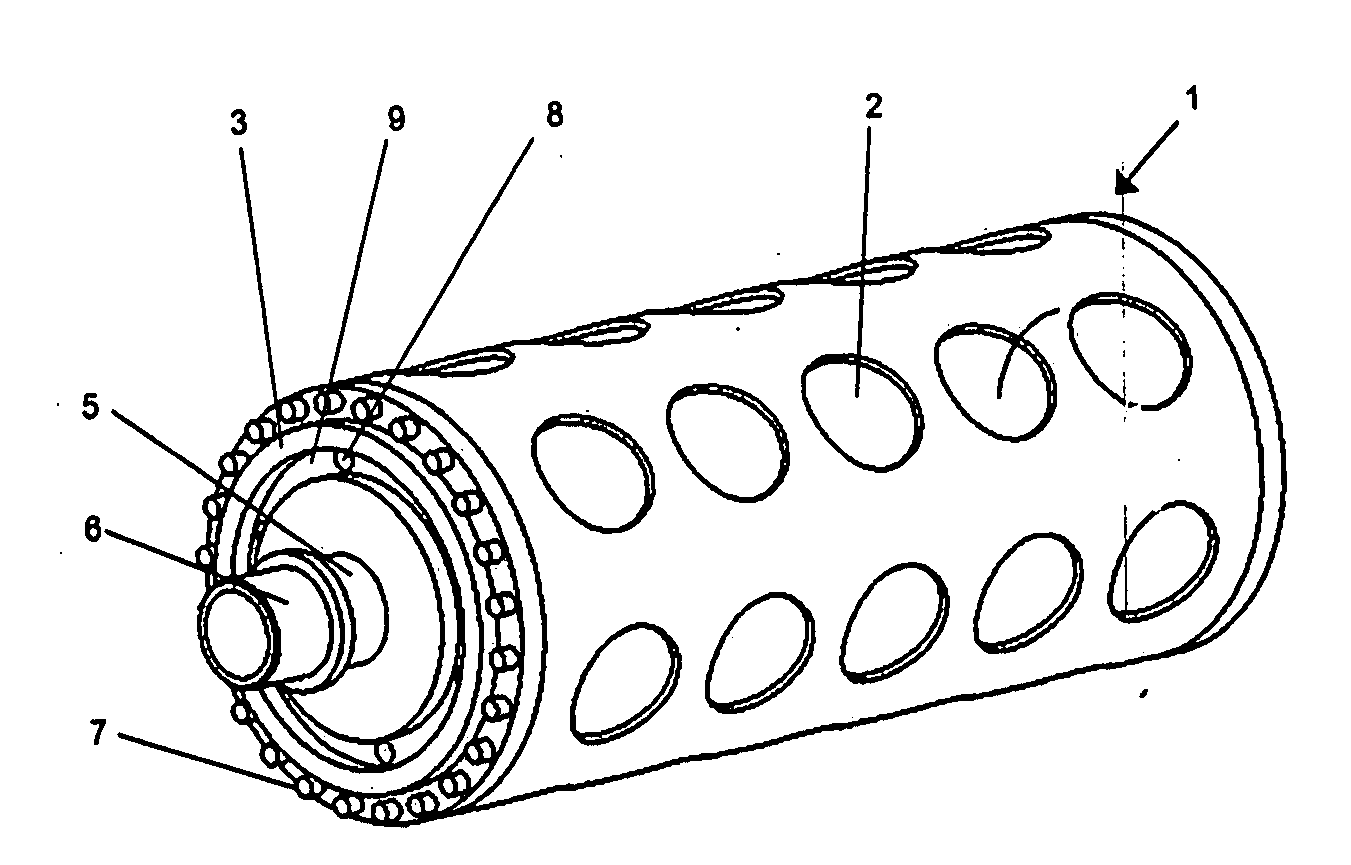

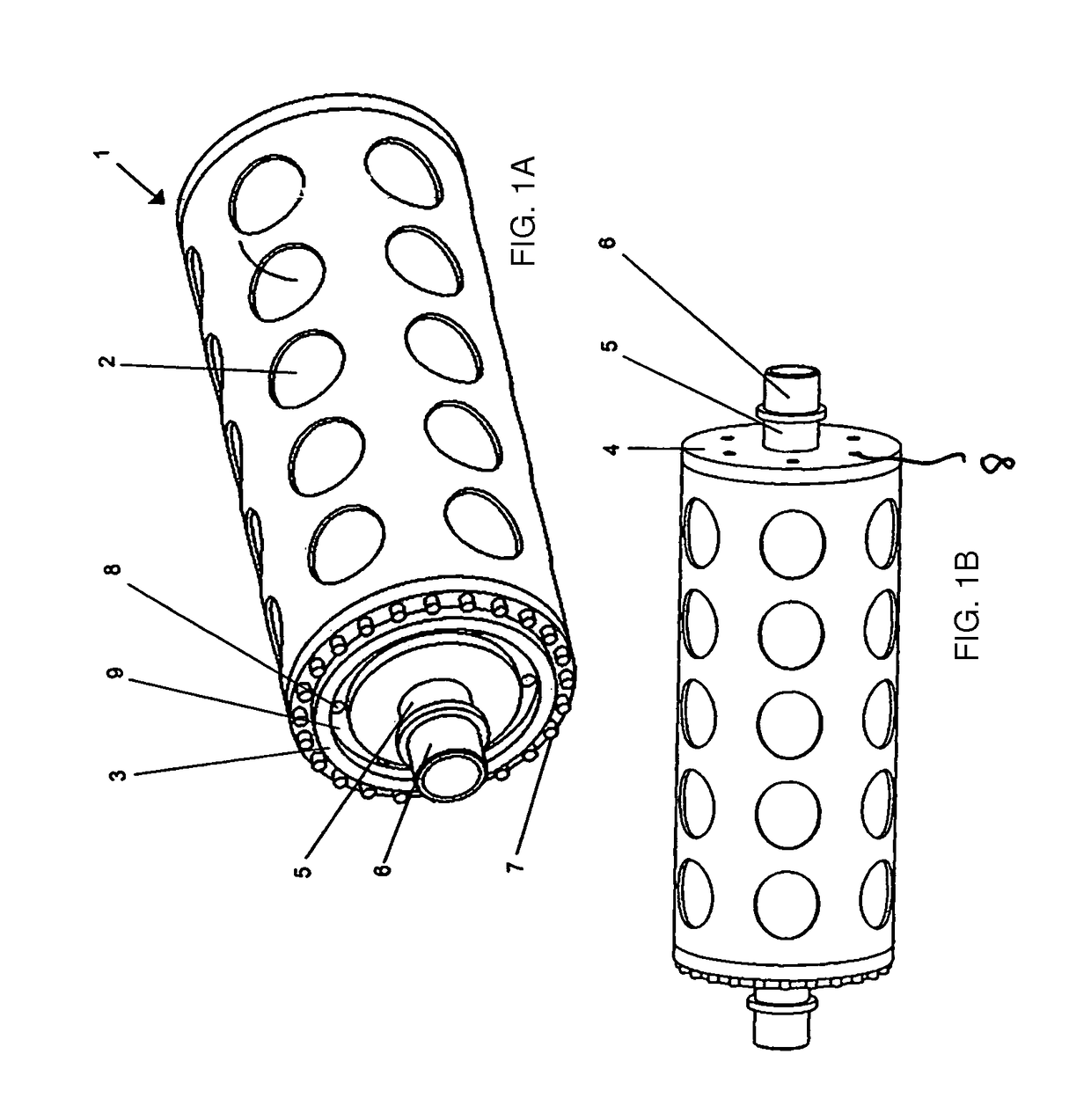

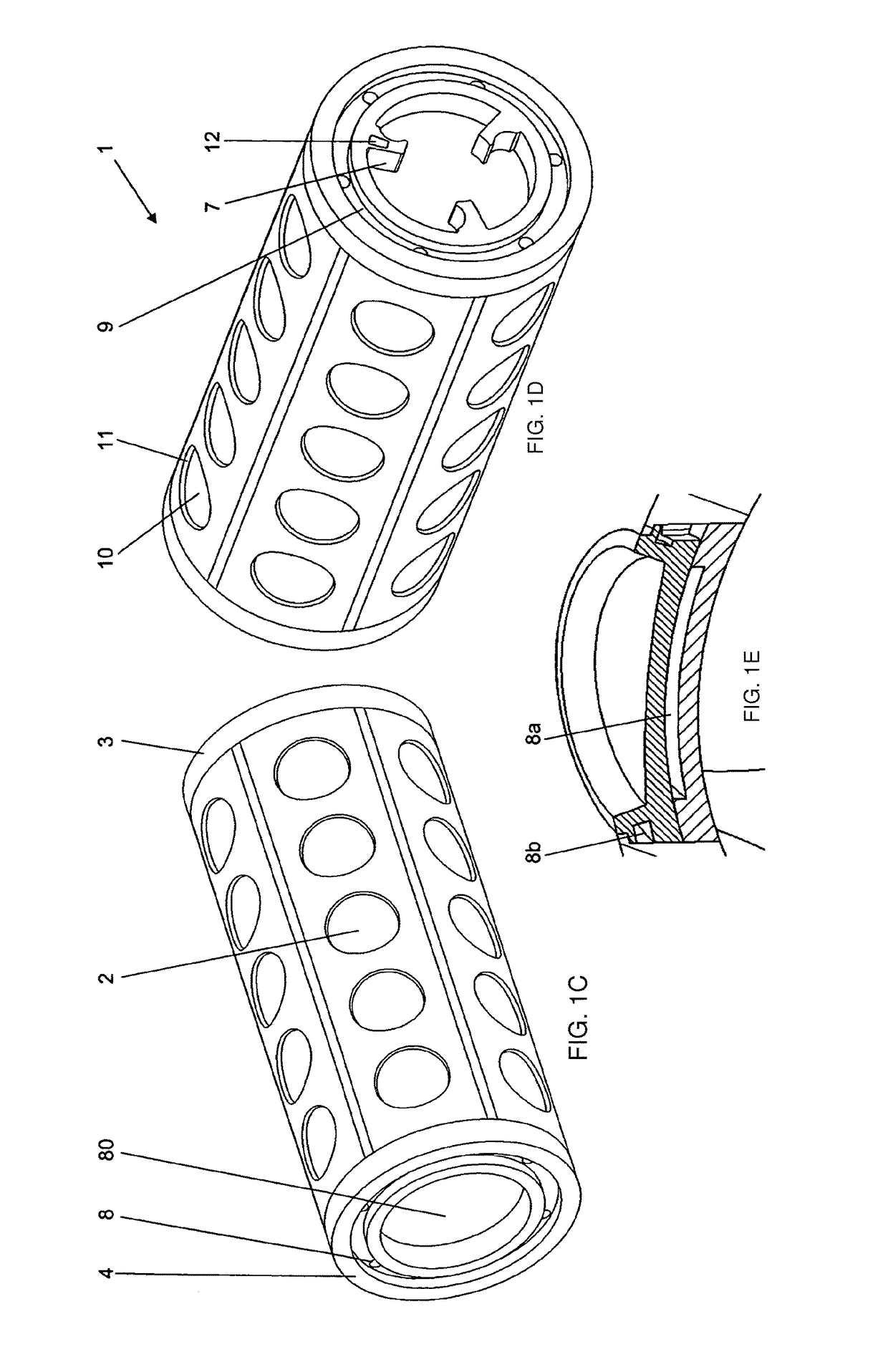

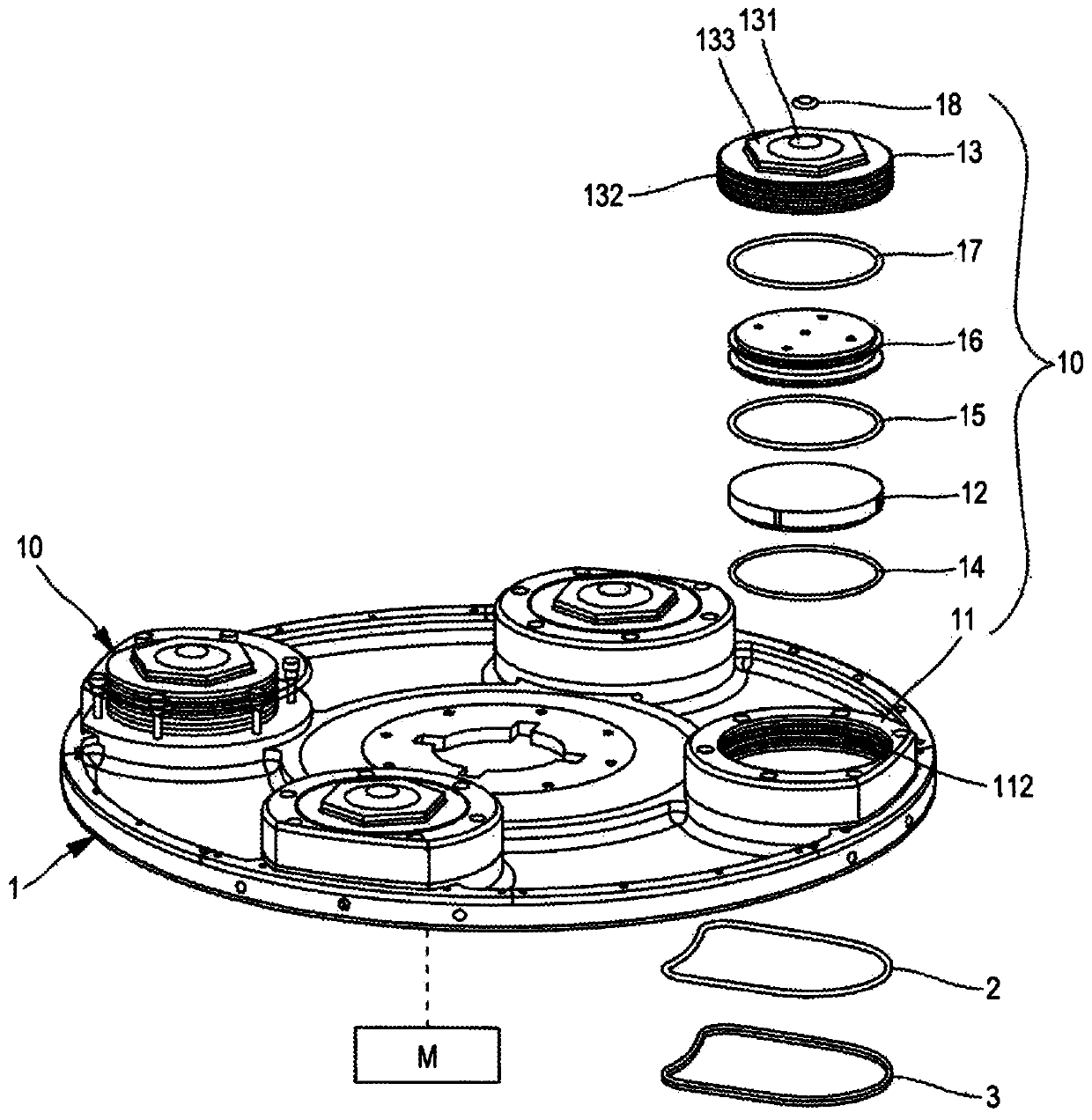

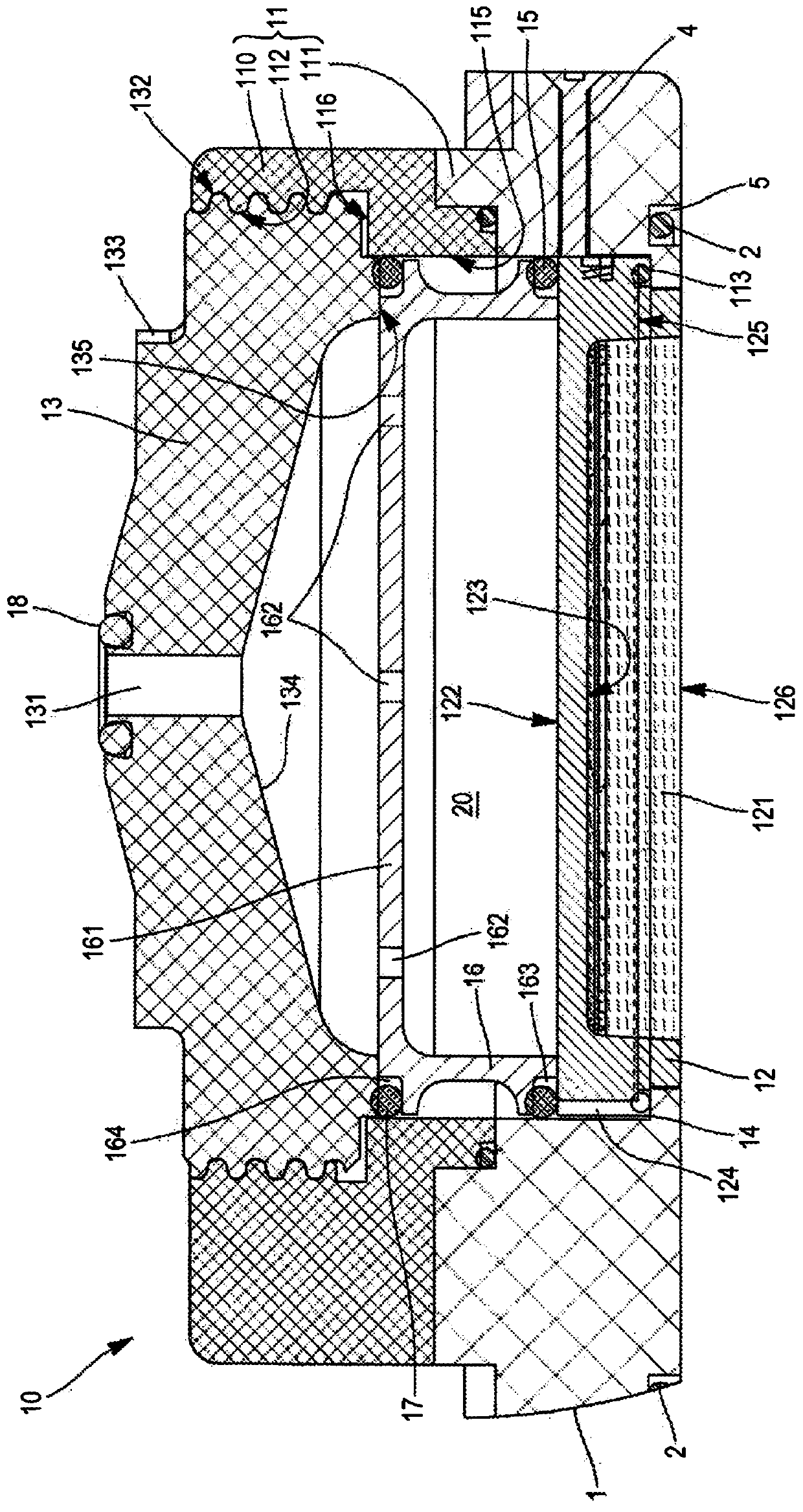

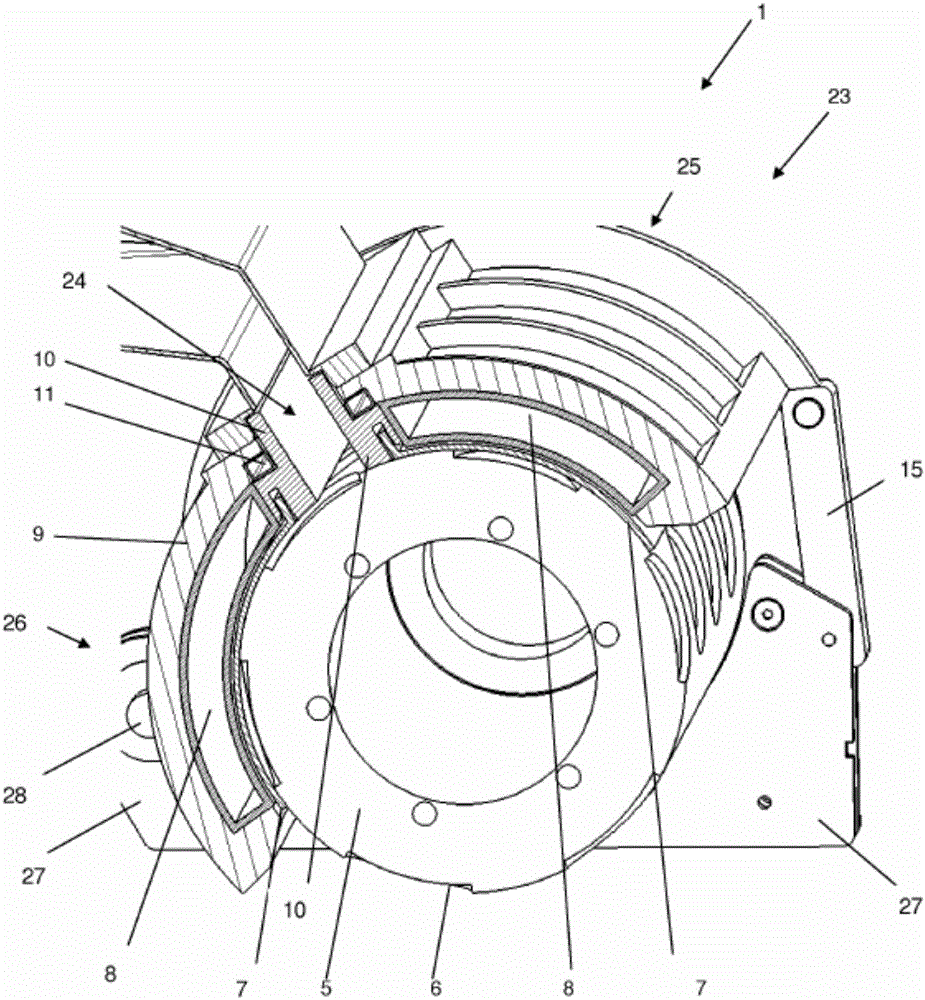

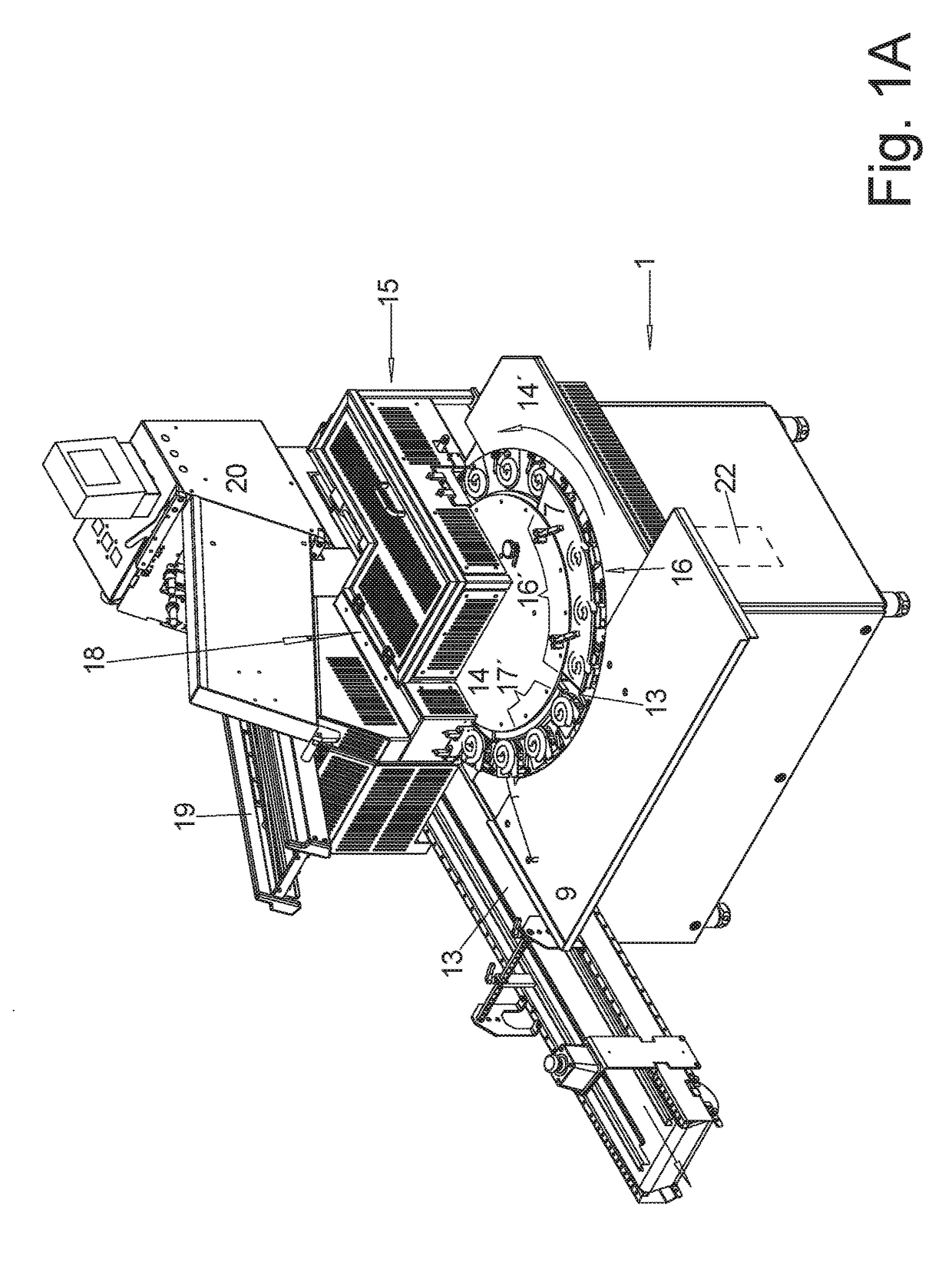

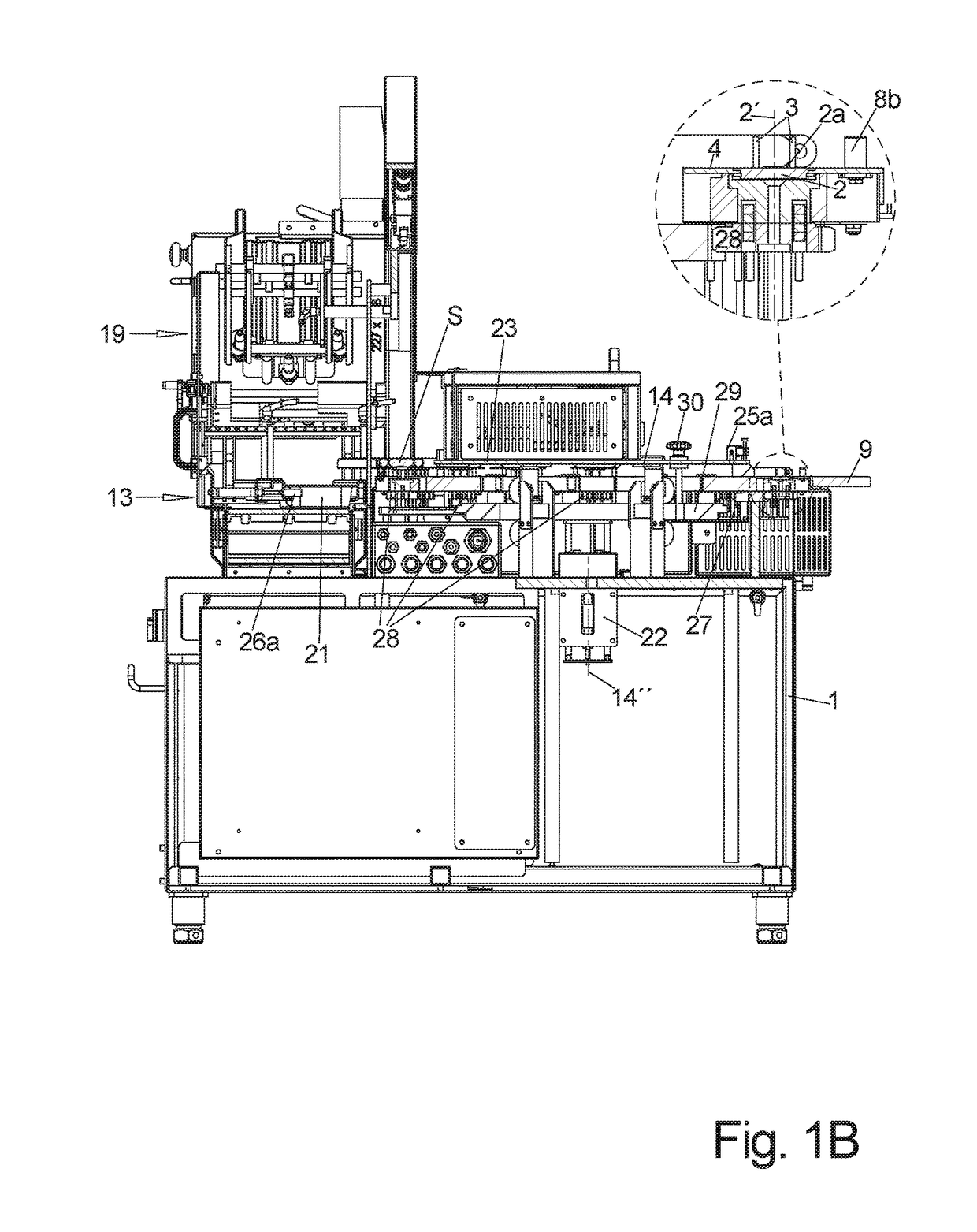

Mould drum and cleaning apparatus for a mould drum

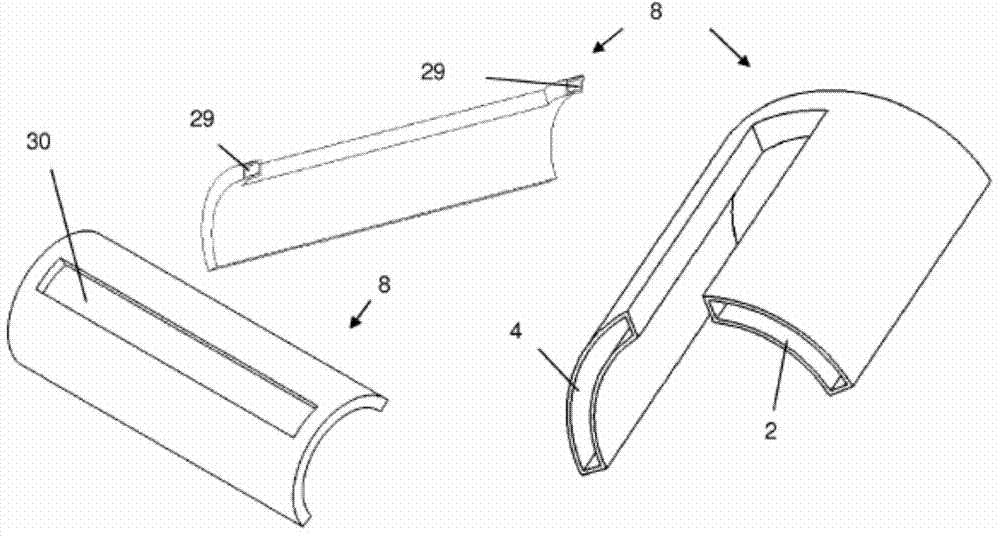

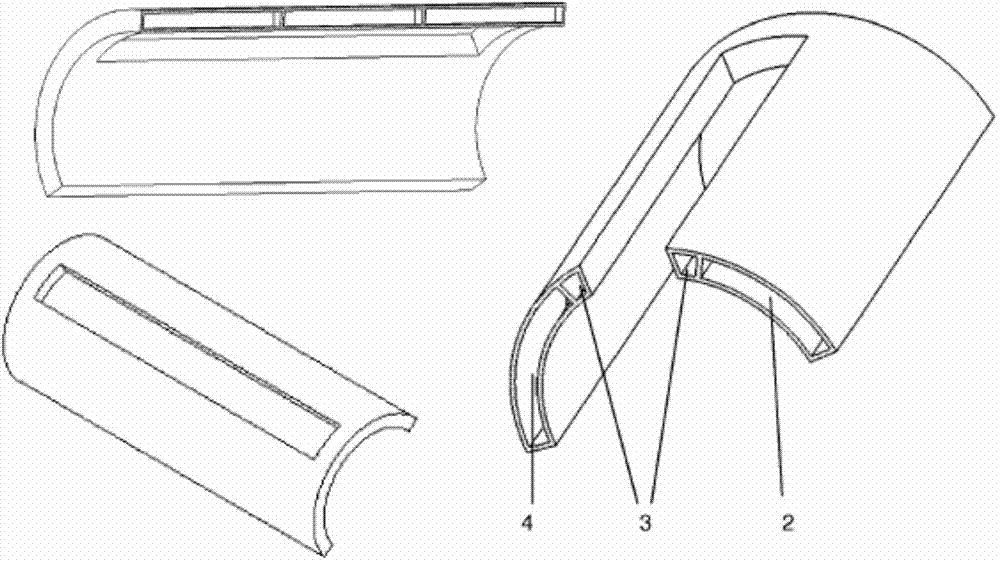

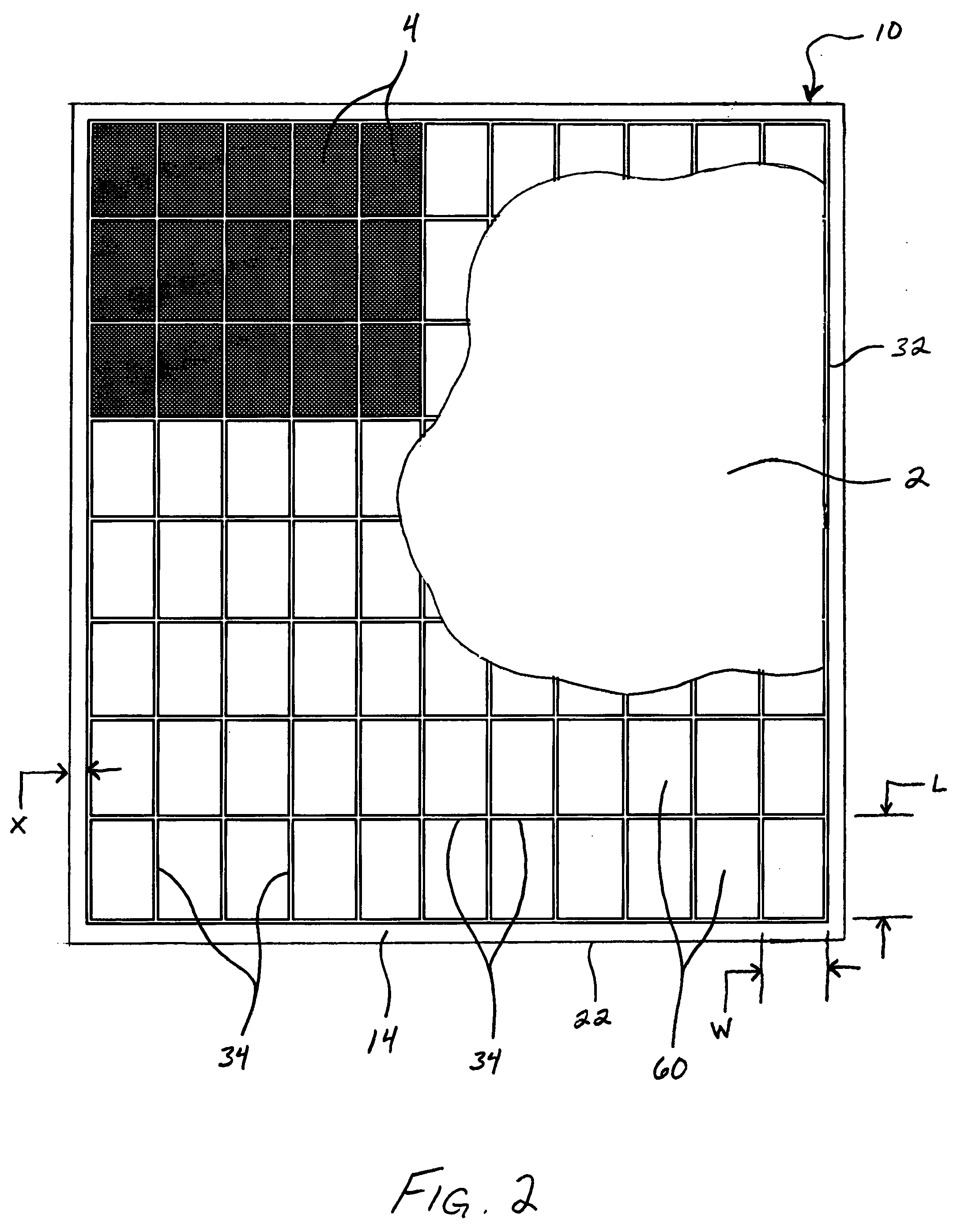

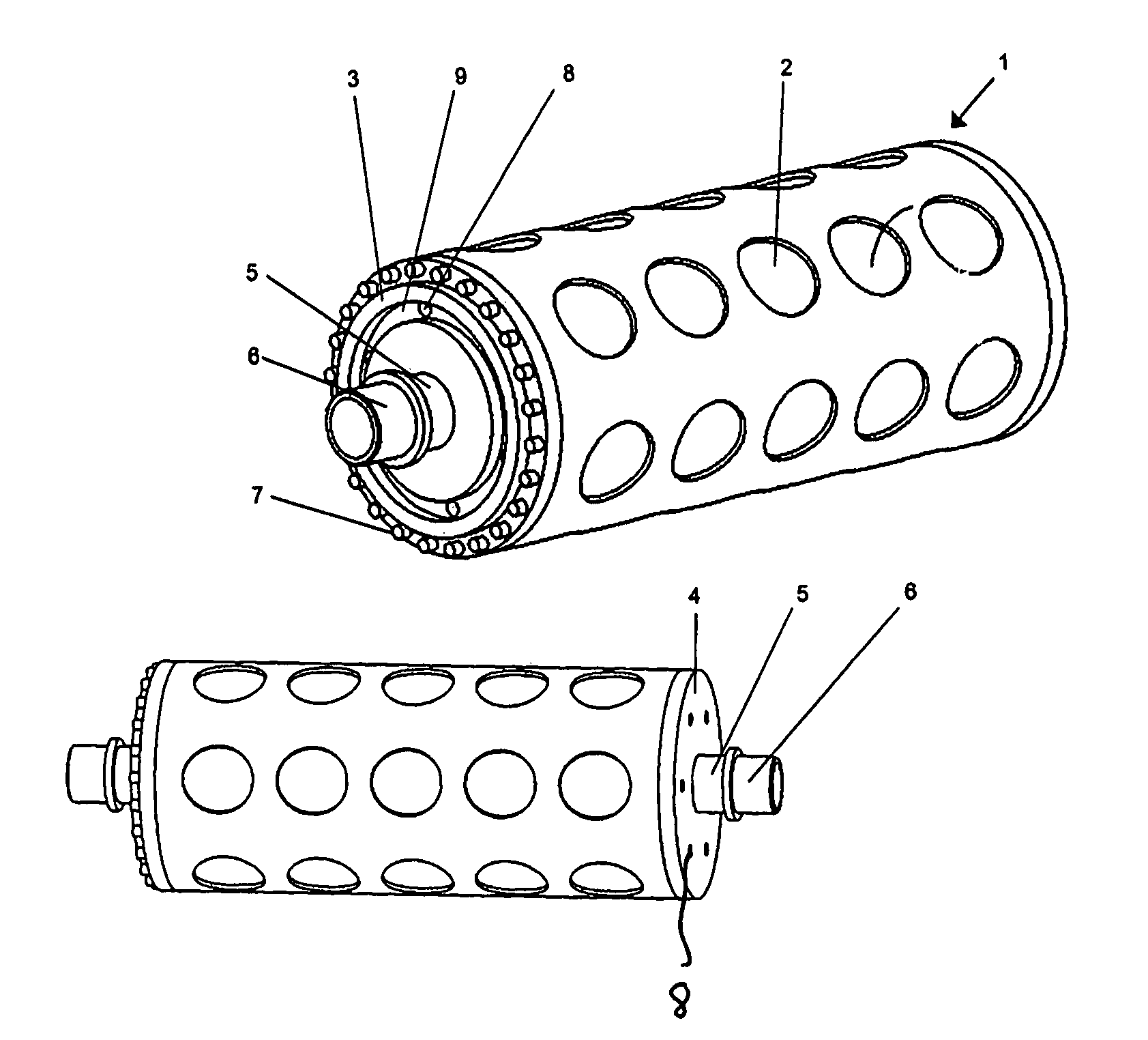

ActiveUS9162375B2Easy dischargeQuick conversionBearing assemblyMeat pressingCavity wallMechanical engineering

The present invention relates to a mold drum for molding products from a mass of food starting material. The mold drum comprises one or more cavities with a mold cavity wall having at least partially a porous structure, whereas each cavity is connected to a passage. The present invention further relates to a cleaning apparatus for the inventive mold drum with supporting means for supporting the axis of the drum. Additionally, the present invention relates to a process for cleaning the inventive drum.

Owner:CFS BAKEL

Processing equipment of meatball food

InactiveCN107518050ADoes not interfere with molding manufacturingGuaranteed cleaning effectMeat pressingCleaning using toolsHydraulic cylinderEngineering

The invention relates to a processing equipment of a meatball food. The processing equipment comprises a forming preformed hole and a fixing trapezoidal hole, wherein a stress dispersing baseplate is arranged at the bottom of the main body of the processing equipment; a buffer skidproof base is fixedly mounted at the bottom of the stress dispersing baseplate through a bolt; supporting fixing plates are respectively mounted at the front part and the rear part of the top of the stress dispersing baseplate through bolts; a bearing top plate is arranged at the top between the supporting fixing plates; a shaping water tank in a front-and-rear direction is fixedly mounted at the middle part of the top of the stress dispersing baseplate; and shaping water circulation interfaces with filter screens are respectively formed at the middle part of a front end surface and a rear end surface of the shaping water tank. According to the processing equipment disclosed by the invention, a fixed washing steel pipe and a washing rotating shaft are arranged, so that cleaning of residual raw materials adhered to a forming semi-spheroidal groove is facilitated; through the rotation of the washing rotating shaft, a washing banister brush is driven for rotary cleaning; besides, spraying is performed by three rows of washing spray heads on the fixed washing steel pipe; and the cleaning hydraulic cylinder moves up and down, and the washing rotating shaft canlift to the topmost through the cleaning hydraulic cylinder, so that the forming and making of the meatballs are not influenced.

Owner:徐美娣

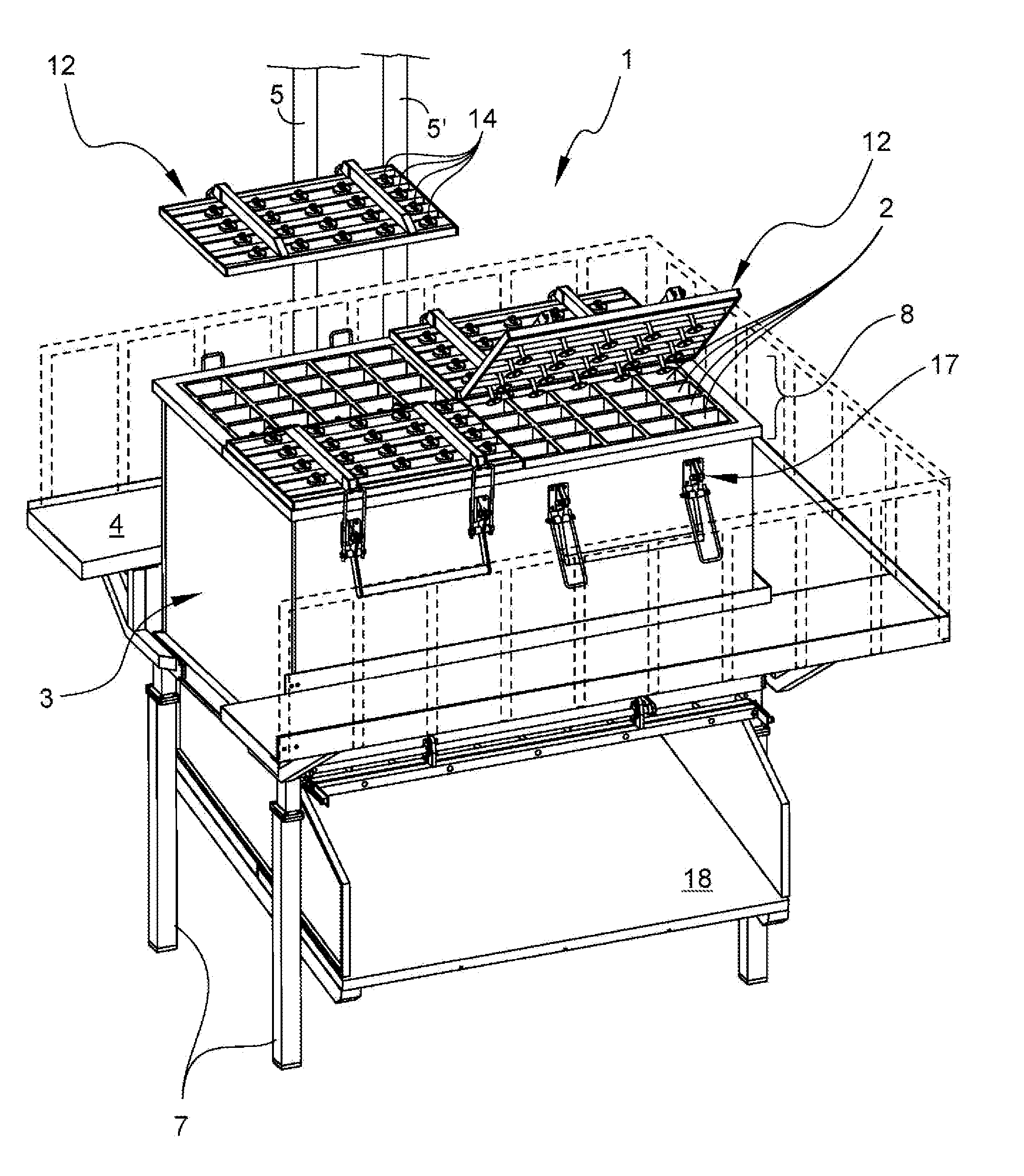

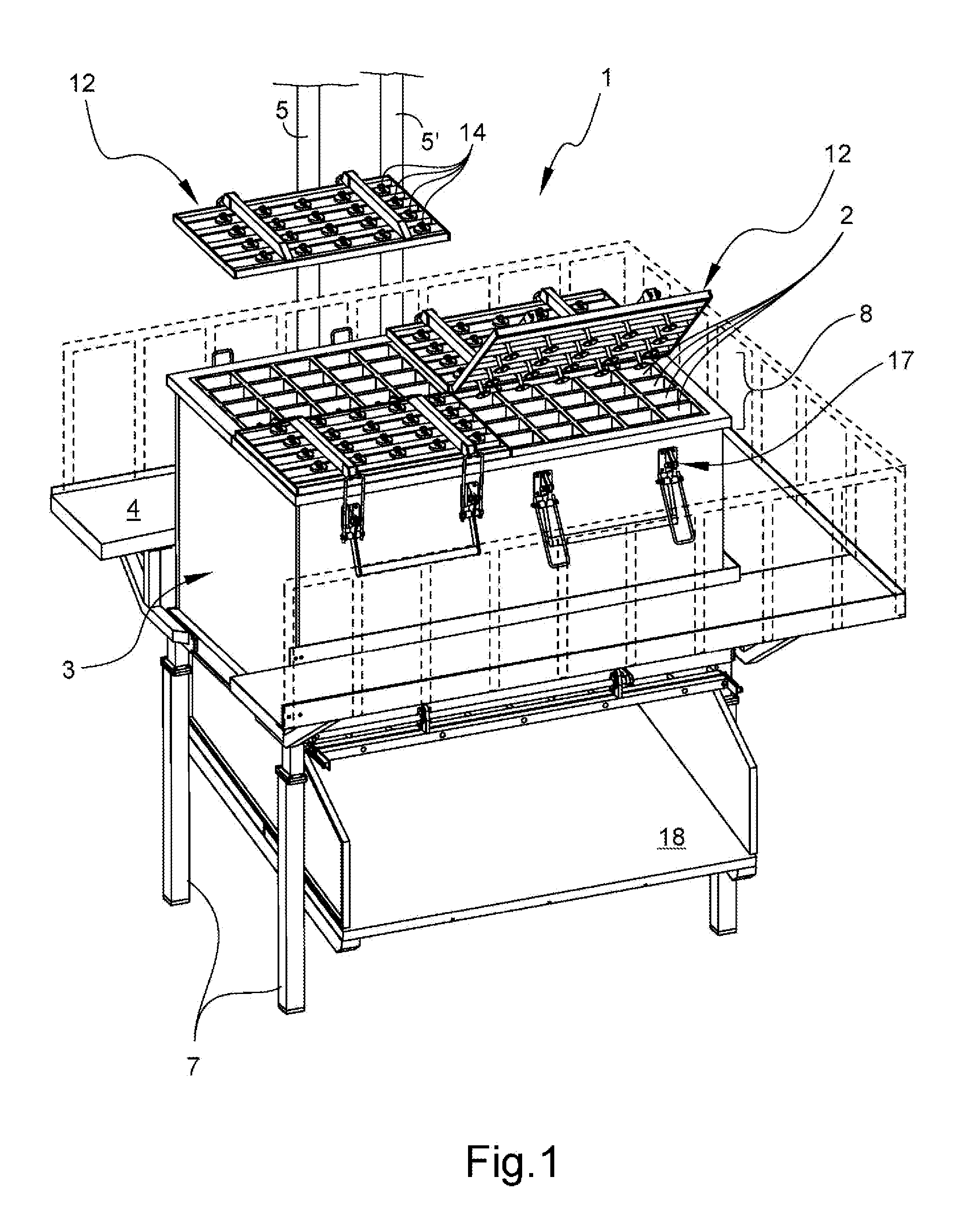

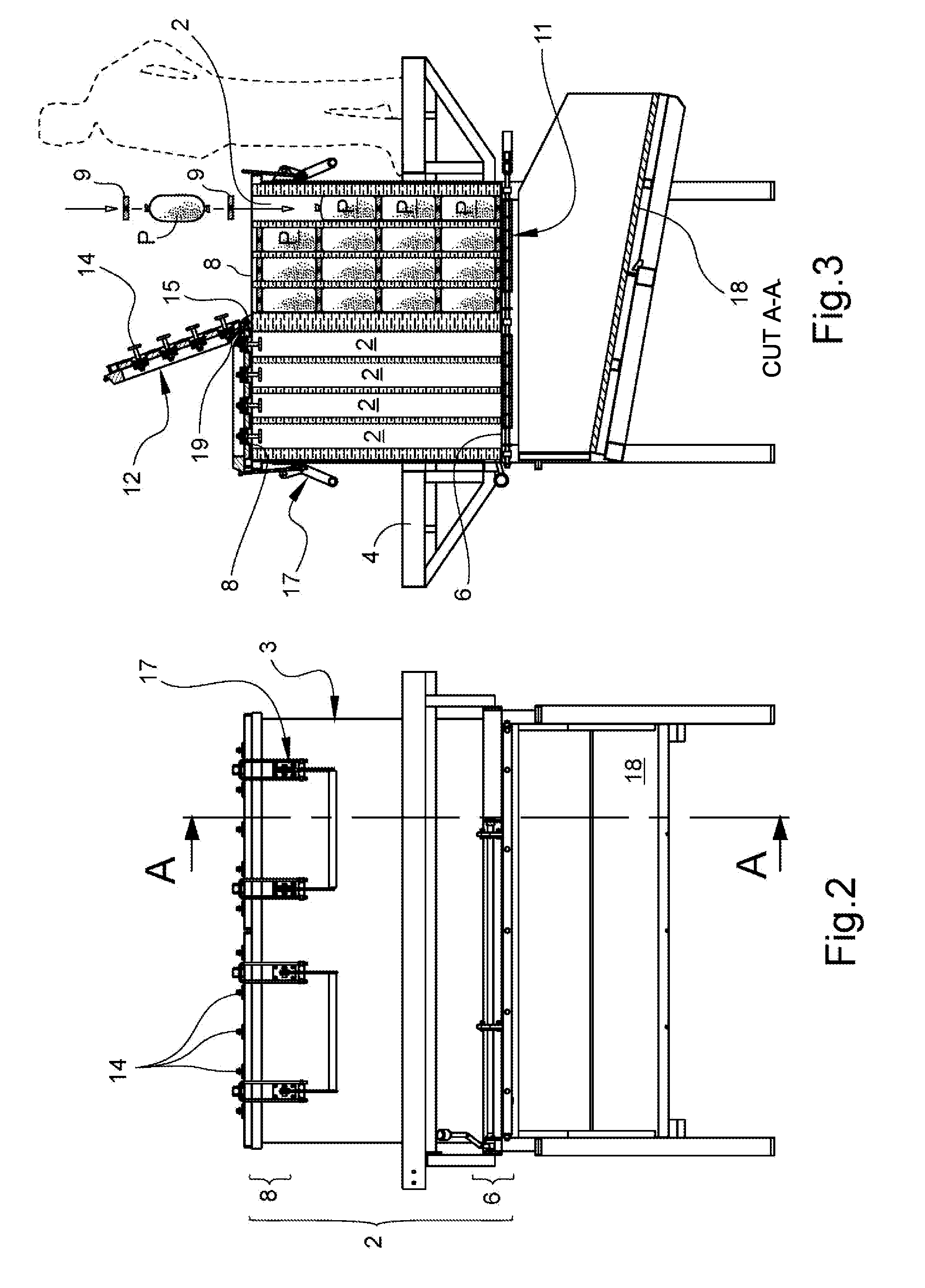

Apparatus and procedure for the molding and cooking of stuffed food products

ActiveUS20150010684A1Cook the filled piece safely and efficientlyEasy to shapeConfectioneryMeat pressingMechanical engineeringFood products

A molding and cooking apparatus for pieces of stuffed product such as cooked hams, which includes one or more molding cavities long enough so that more than one piece of stuffed product can be introduced in the same molding cavity, inserting separators which help to shape the ends of the pieces of vacuum stuffed product, both ends of the cavities are open and are sealed during product cooking, which permits a quick discharge of the already cooked and cooled pieces when the cavities bottoms are unsealed, and permits the product to fall because of gravity onto a collecting tray, likewise a procedure is revealed on the efficient use of this apparatus herein disclosed.

Owner:PAGANINI COMBA HERMANOS Y COMPANIA

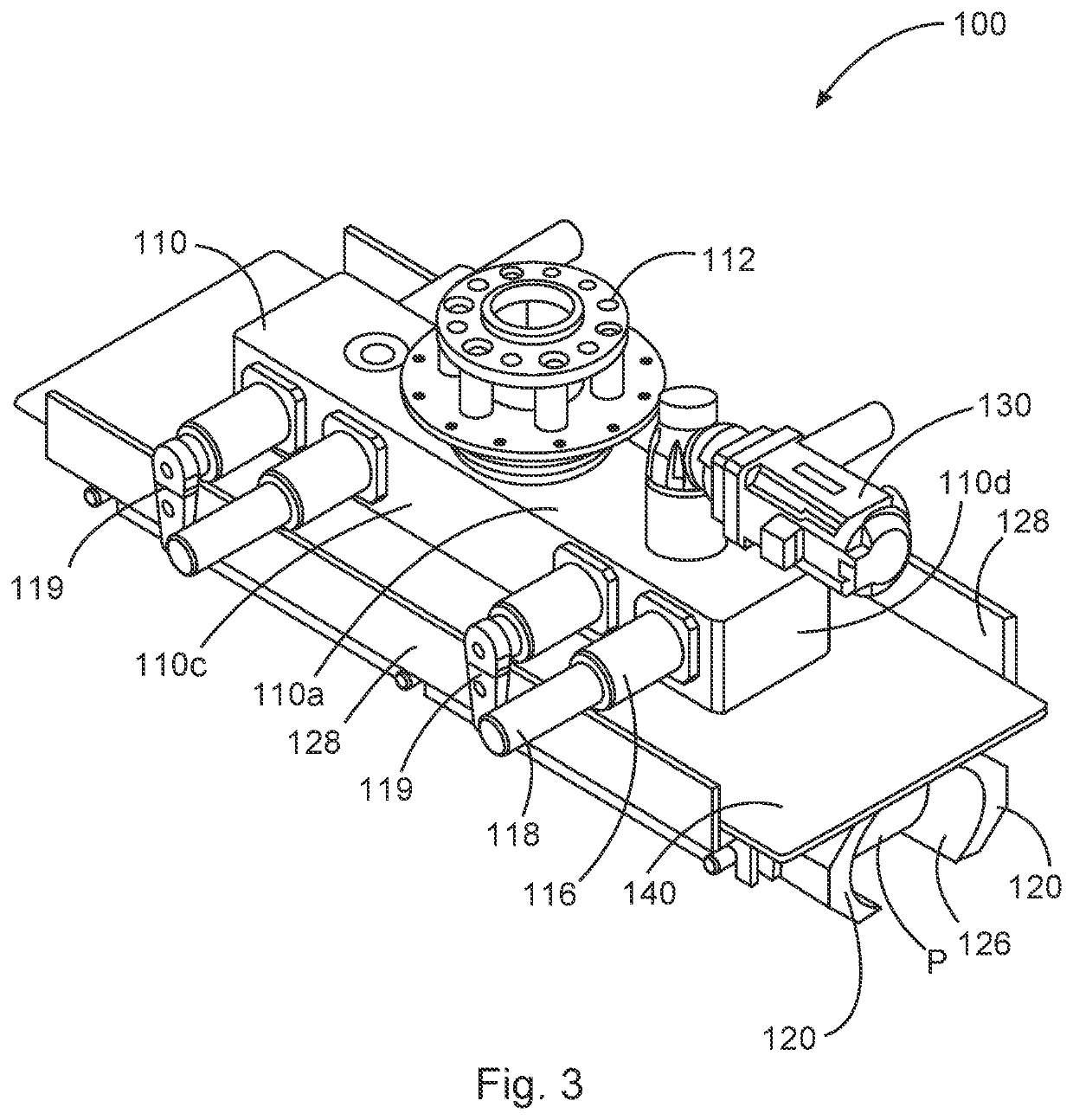

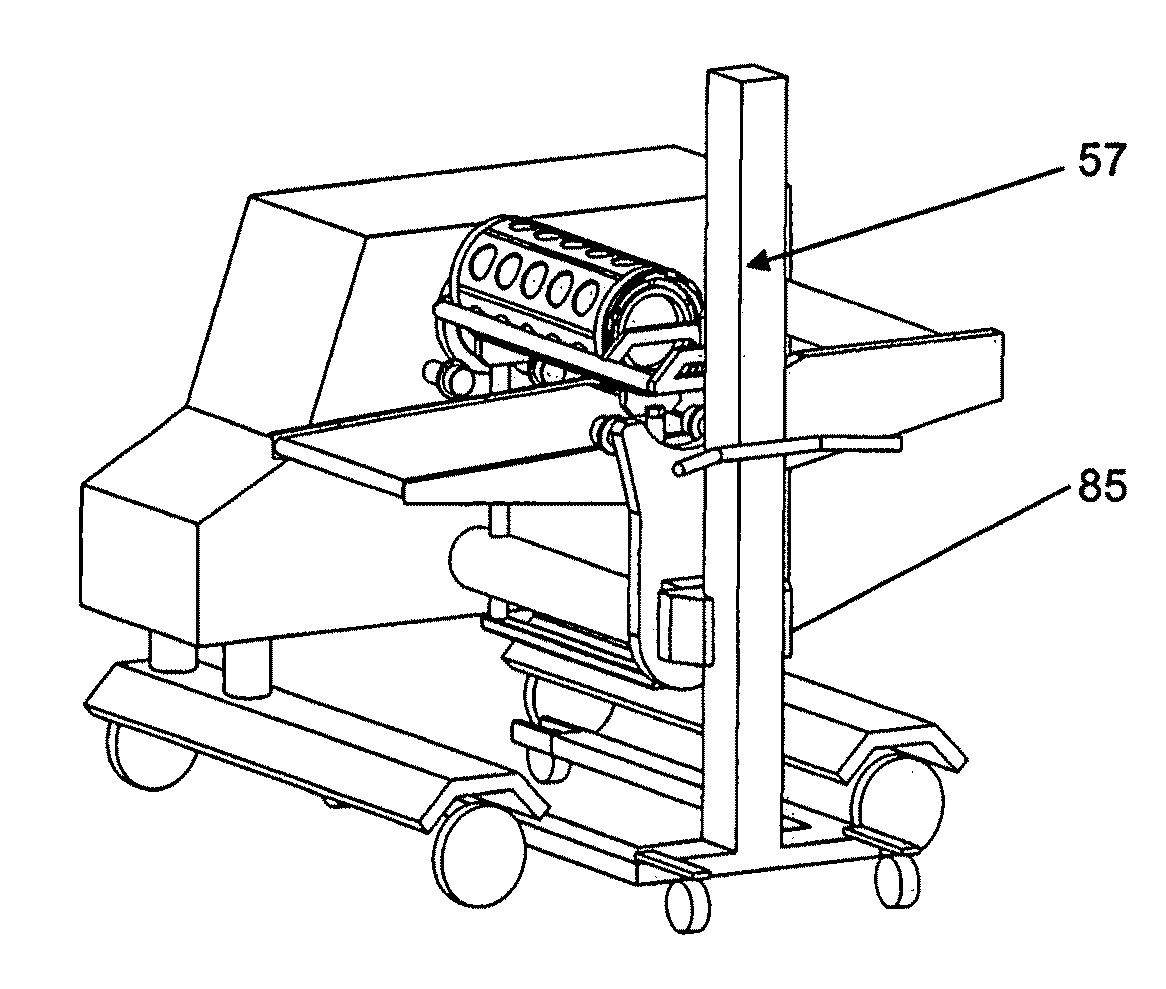

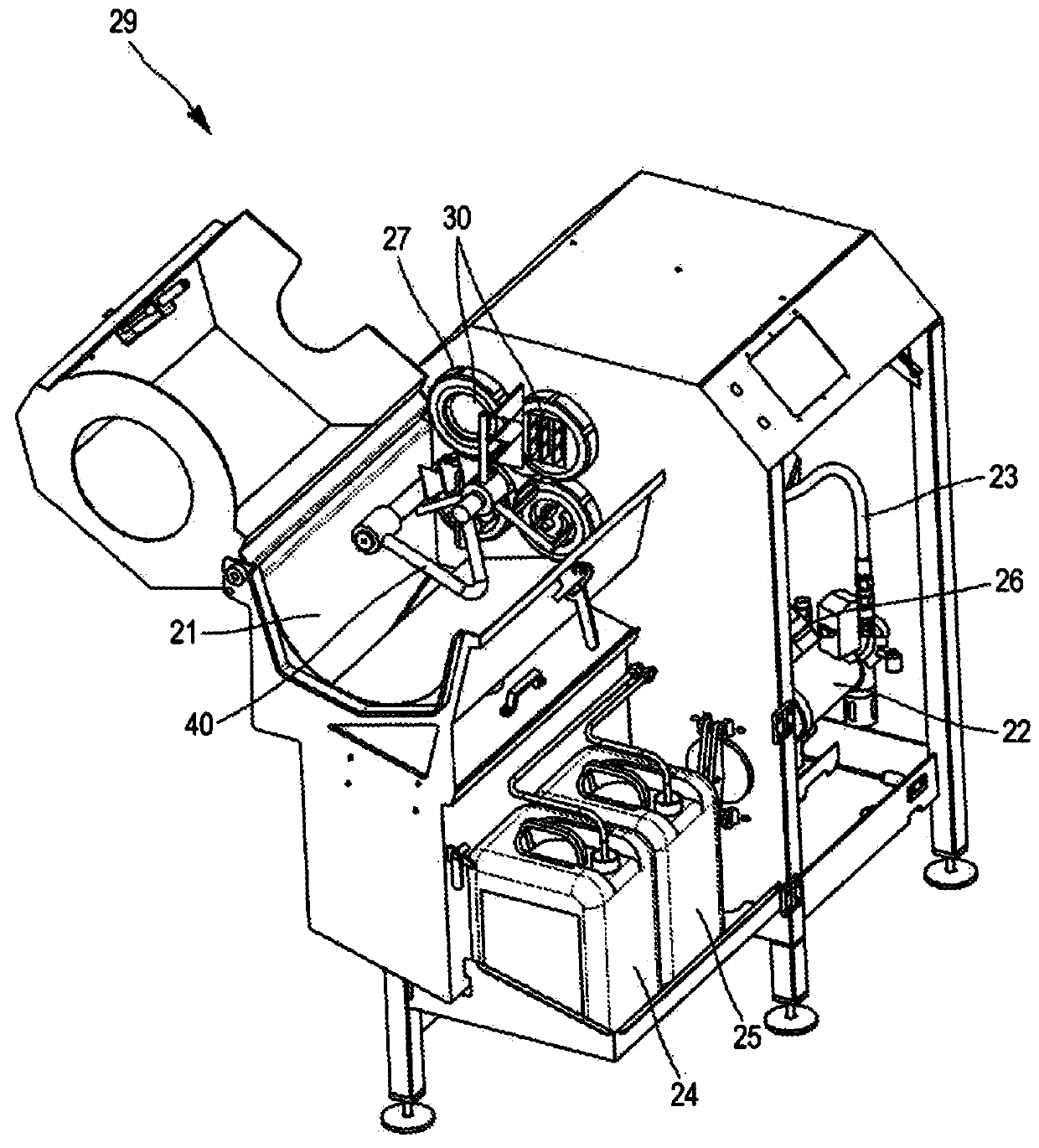

Movable unit for transport of a mould drum and methods thereof

ActiveUS20150344275A1Easy dischargeQuick conversionBearing assemblyMeat pressingEngineeringCavity wall

The present invention relates to a mould drum for moulding products from a mass of food starting material. The mould drum comprises one or more cavities with a mould cavity wall having at least partially a porous structure, whereas each cavity is connected to a passage. The present invention further relates to a cleaning apparatus for the inventive mould drum with supporting means for supporting the axis of the drum. Additionally, the present invention relates to a process for cleaning the inventive drum.

Owner:GEA FOOD SOLUTIONS BAKEL

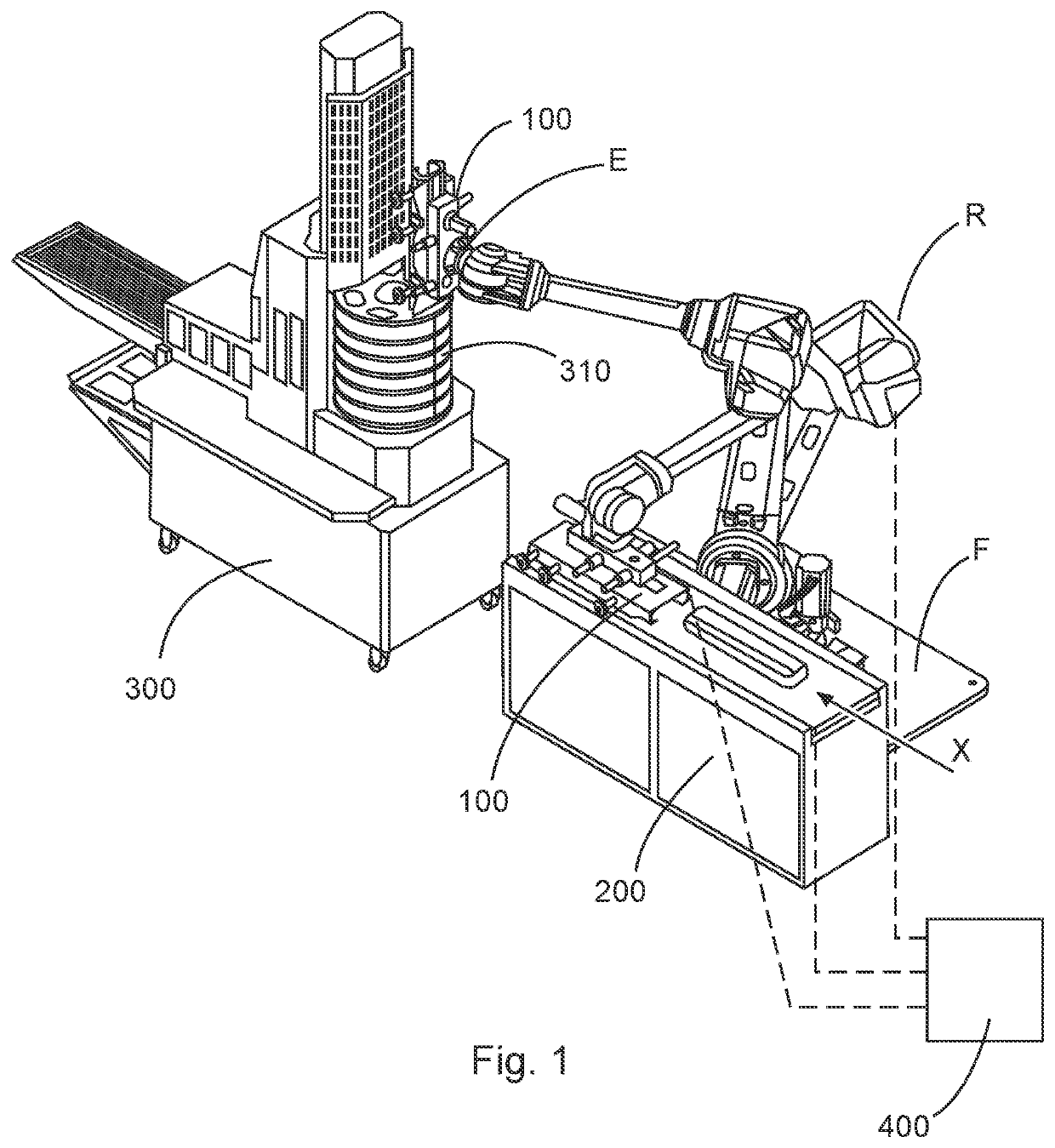

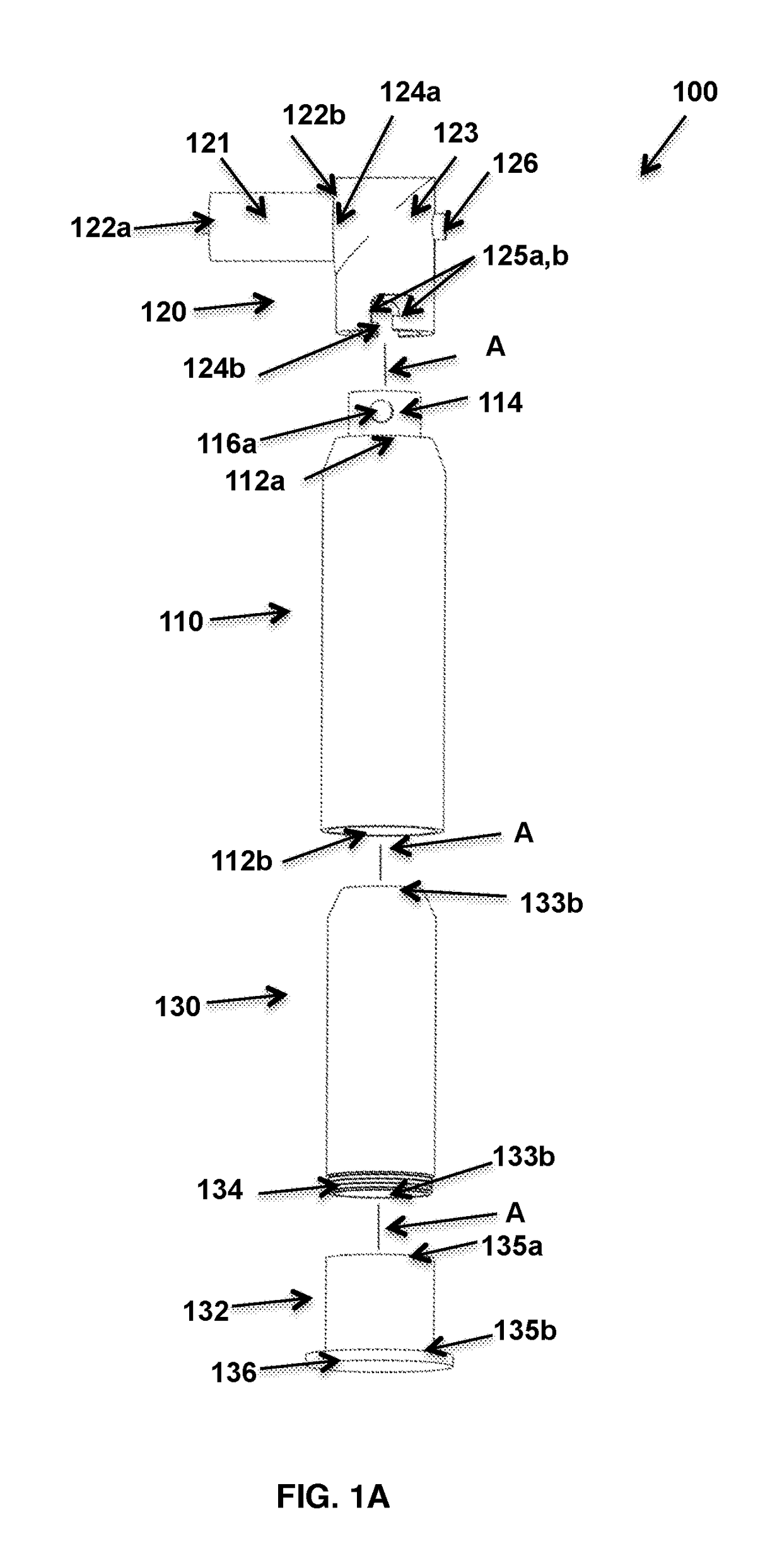

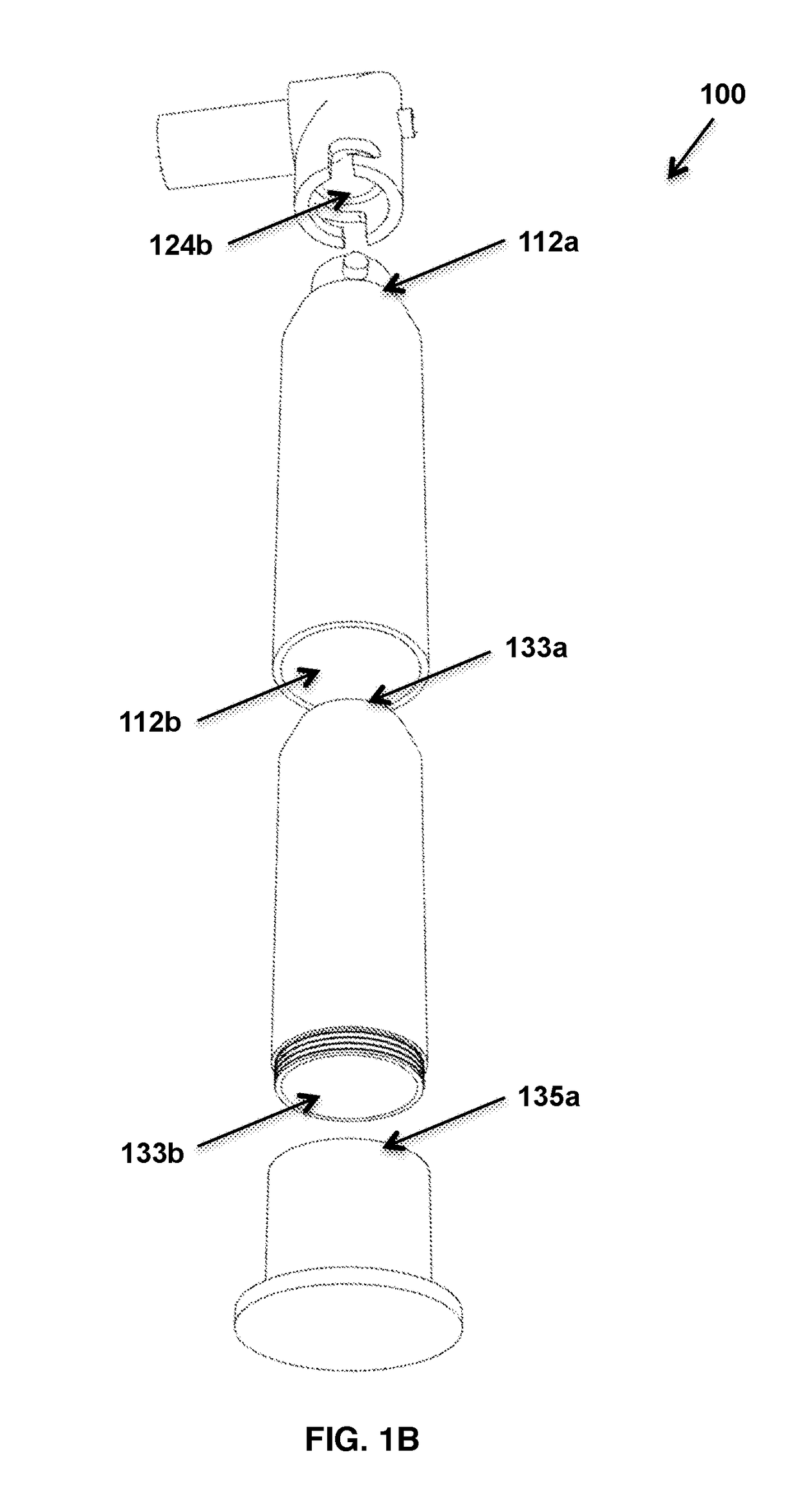

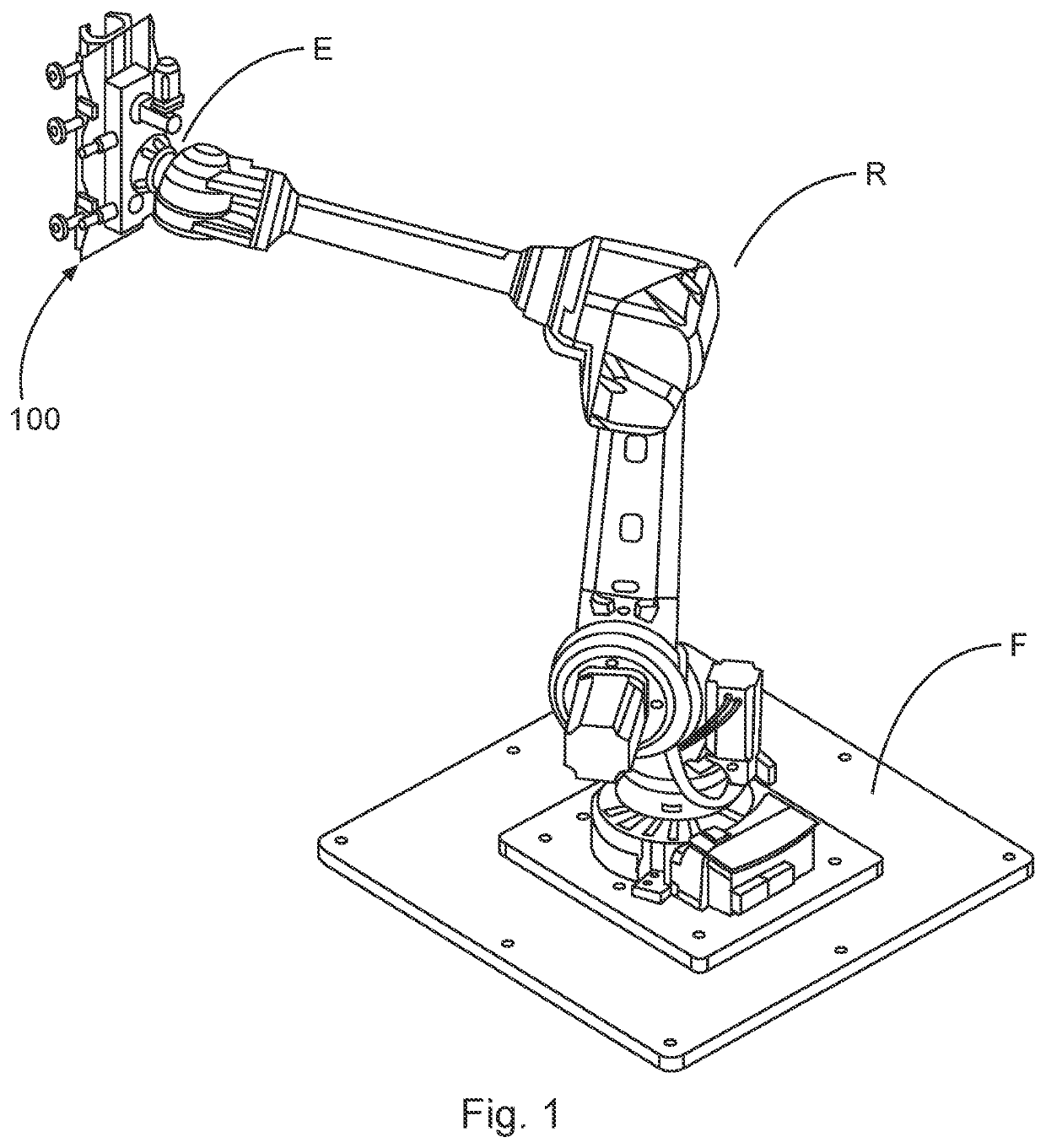

System for picking up, conveying, and delivering a product, and method of controlling such system

PendingUS20220072730A1Quick exchangeImprove stabilityProgramme-controlled manipulatorGripping headsControl cellProcess engineering

The present invention relates to a system for picking up, conveying, and delivering a foodstuff product to a processing machine which preferably has an upright magazine tube, said system including: a handling device, a gripping device releasably attachable to the handling device, a transporting apparatus, and a control unit; wherein the transporting apparatus has a transporting portion on which the foodstuff product that is to be picked up by the gripping device may be positioned in a pick-up position allowing the foodstuff product to be picked up by the gripping device, and the control unit is connected at least to the handling device of the gripping device and to the transporting apparatus; wherein the control unit is configured for detecting when the foodstuff product to be picked up has reached the pick-up position.

Owner:POLY CLIP SYST

Apparatus and methods for cleaning a mould drum

ActiveUS20150343671A1Easy dischargeQuick conversionBearing assemblyMeat pressingEngineeringCavity wall

Owner:GEA FOOD SOLUTIONS BAKEL

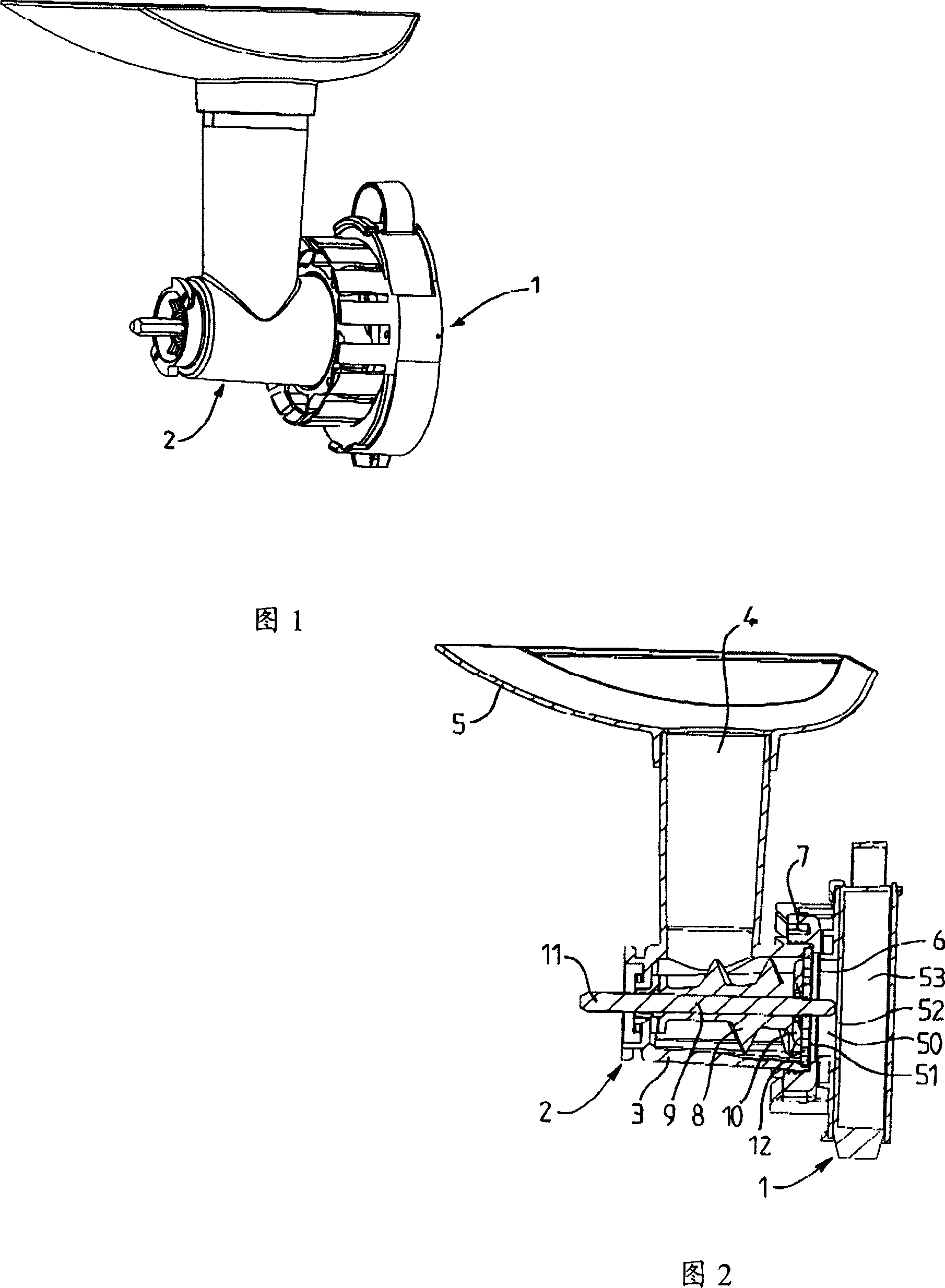

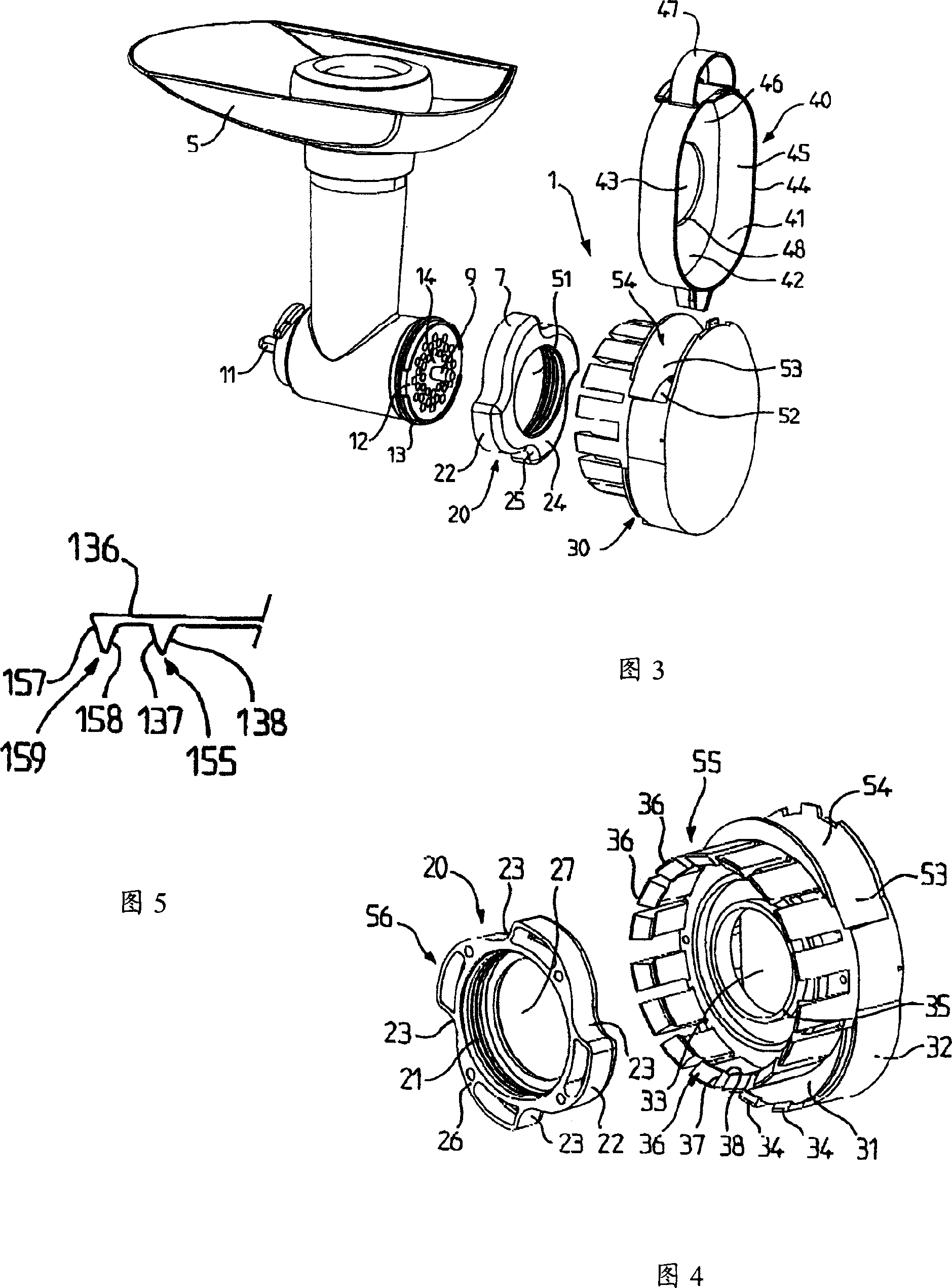

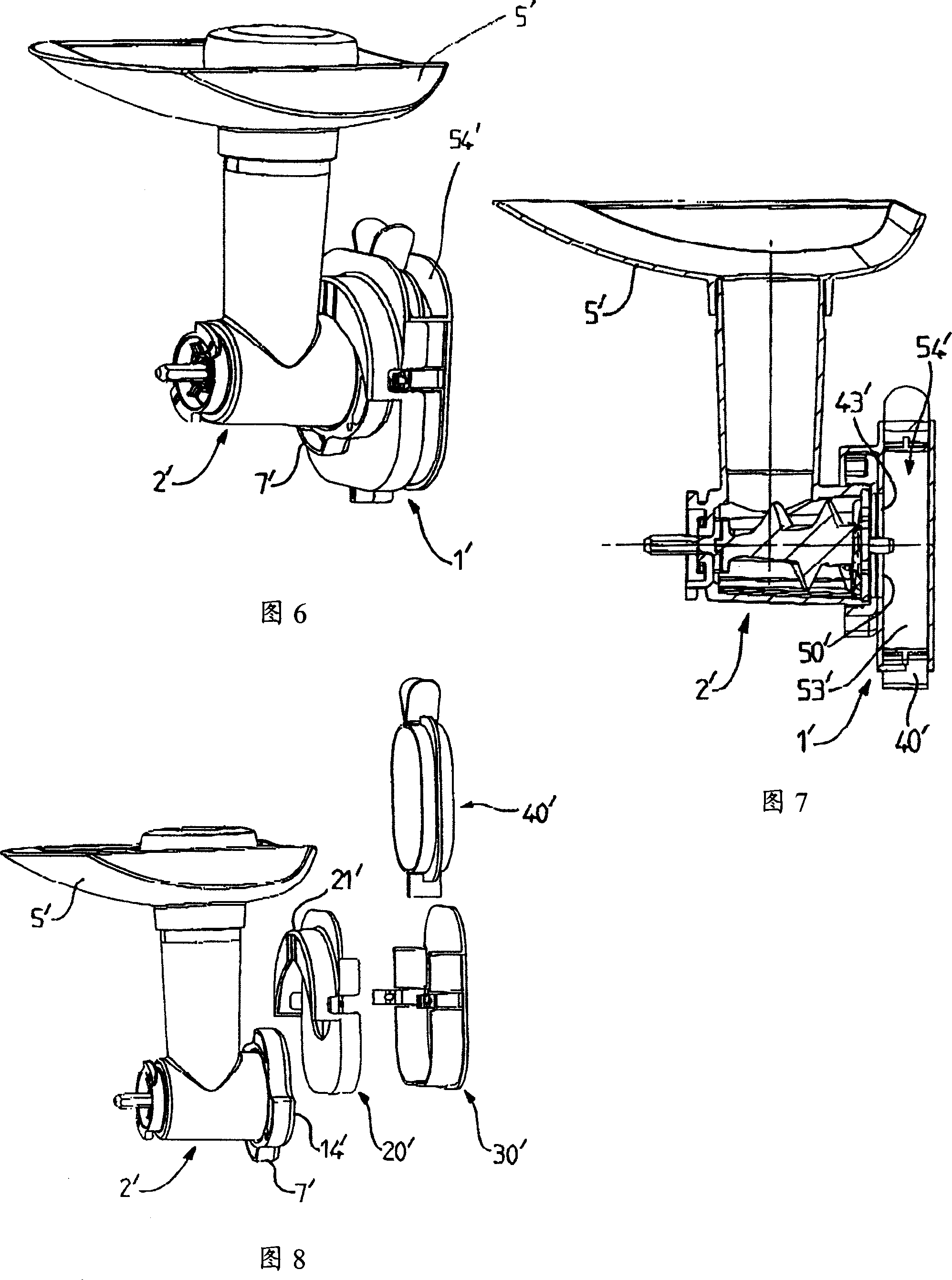

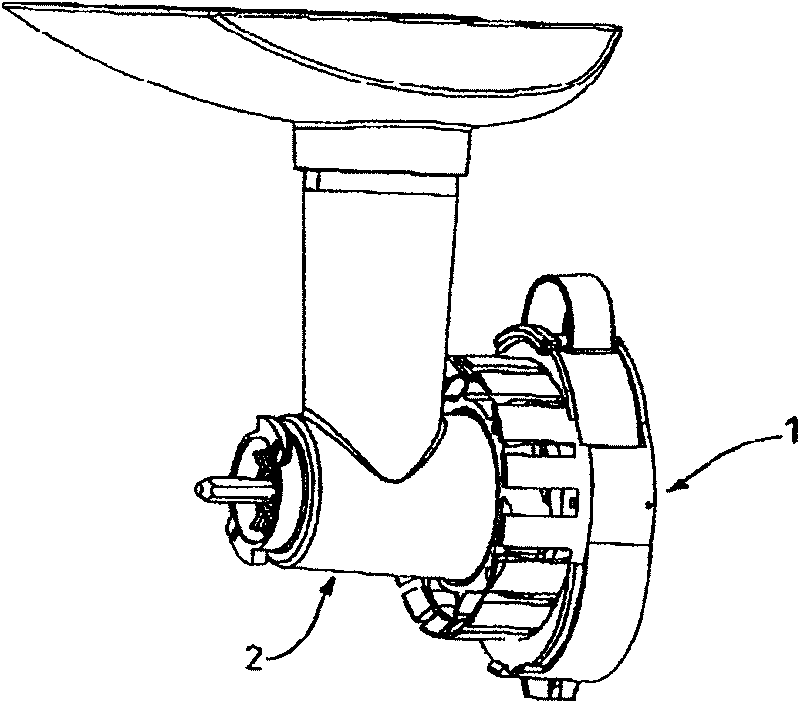

Device for moulding chopped preparations

Owner:SEB SA

Device for Molding a Foodstuff

Owner:AL QUDAH SOHAIB +1

Finished product forming integrated device for meat food processing and forming method

The invention discloses a finished product forming integrated device for meat food processing and a forming method, and relates to the technical field of meat food processing. Pressing and demolding are convenient. The device specifically comprises a rotating motor, the output end of the rotating motor is rotationally connected with a rotating spindle, evenly-distributed supporting rods are fixed to the side wall of the top end of the rotating spindle, and a bearing seat is arranged at one ends of the supporting rods. The method comprises the following steps: mounting a corresponding die holder to the bottom of an extrusion plate according to requirements; and supplying meat food materials through a conveying pipe and then outputting the meat food materials into a molding cavity through an output head. By arranging the bearing seat, the bottom plate, a jacking spring and other structures, when meat food materials are placed on the bottom plate in the molding cavity, mutual attraction of a second magnetic attraction block and a first magnetic attraction block, working of a hydraulic cylinder and pressing forming can be utilized, after pressing is finished, the rotating motor drives the bearing seat to continue to rotate, and under the resilience force effect of the jacking spring, the food formed in the molding cavity is upwards ejected out.

Owner:安徽靖童科技农业发展有限公司

Movable unit for transport of a mould drum and methods thereof

ActiveUS9637365B2Easy dischargeQuick conversionBearing assemblyMeat pressingEngineeringFood material

The present invention relates to a mold drum for molding products from a mass of food starting material. The mold drum comprises one or more cavities with a mold cavity wall having at least partially a porous structure, whereas each cavity is connected to a passage. The present invention further relates to a cleaning apparatus for the inventive mold drum with supporting means for supporting the axis of the drum. Additionally, the present invention relates to a process for cleaning the inventive drum.

Owner:GEA FOOD SOLUTIONS BAKEL

Device for molding a foodstuff

Owner:AL QUDAH SOHAIB +1

Mass-distributing device and moulding device comprising a mass-distributing device of this type

ActiveUS20150250226A1Avoid a lotPrevent leakageMeat pressingFood shapingContact pressureFood material

A mass-distributing device for supplying a mass of foodstuff starting materials suitable for consumption, in particular a meat mass, to one or more mould cavities of a moulding member for moulding three-dimensional products from the mass is provided. The device comprises a housing, which has an open side which can be turned towards the moulding member, in which a flexible abutment element for the housing to abut the moulding member is arranged. In the housing, a through-passage for the mass extends from an introduction opening in the housing to a discharge, which discharge opens at the open side of the housing. Pressure means are provided in order to position the flexible abutment element under pressure against the plane of the moulding member comprising one or more mould cavities, the pressure means being designed to set contact pressures in separate zones of the flexible abutment element.

Owner:MAREL TOWNSEND FURTHER PROCESSING

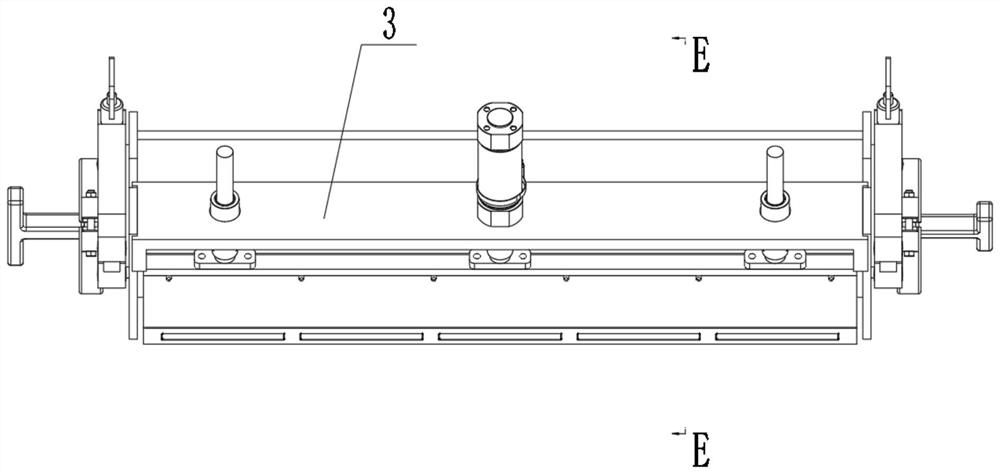

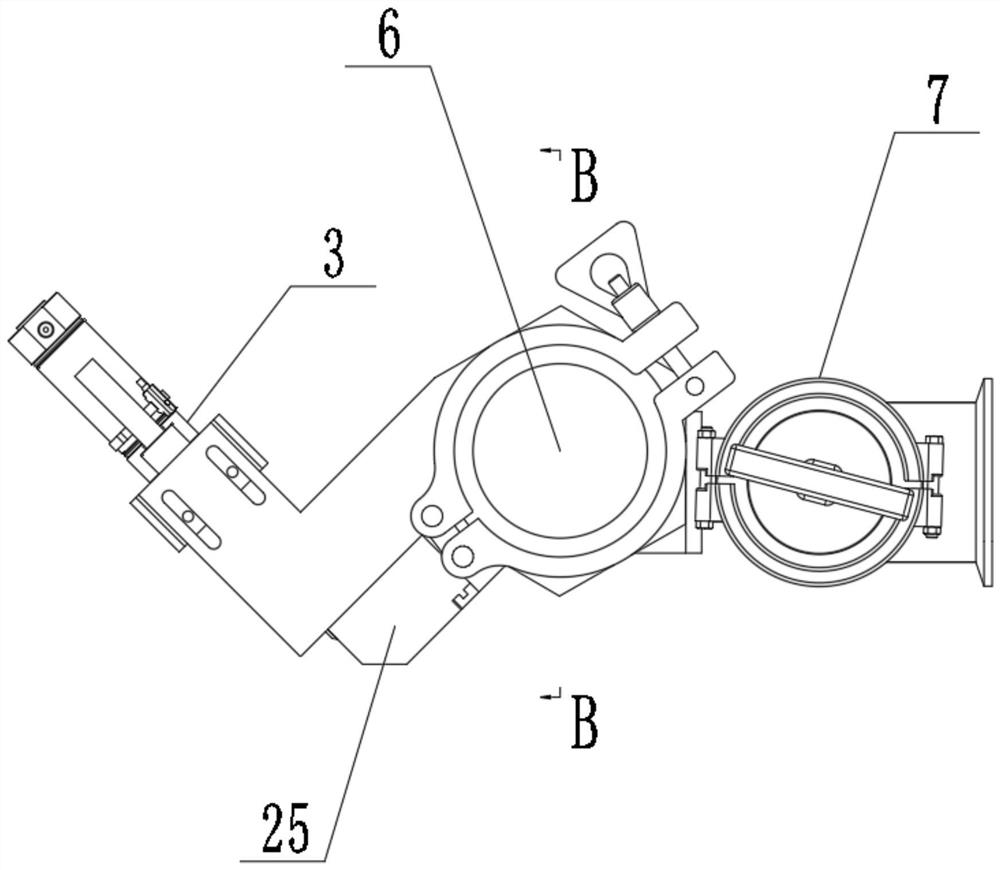

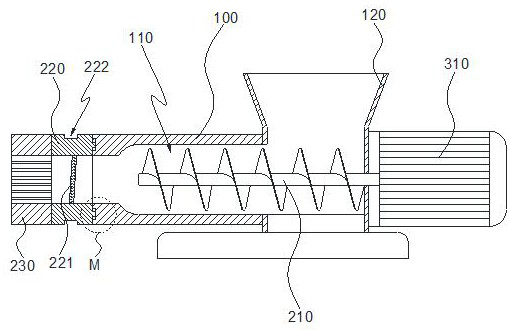

Material distributing device for meat strip extruder

ActiveCN113940368ALarge discharge pressureHighlight substantive featuresMeat pressingMetal working apparatusMeat pasteEngineering

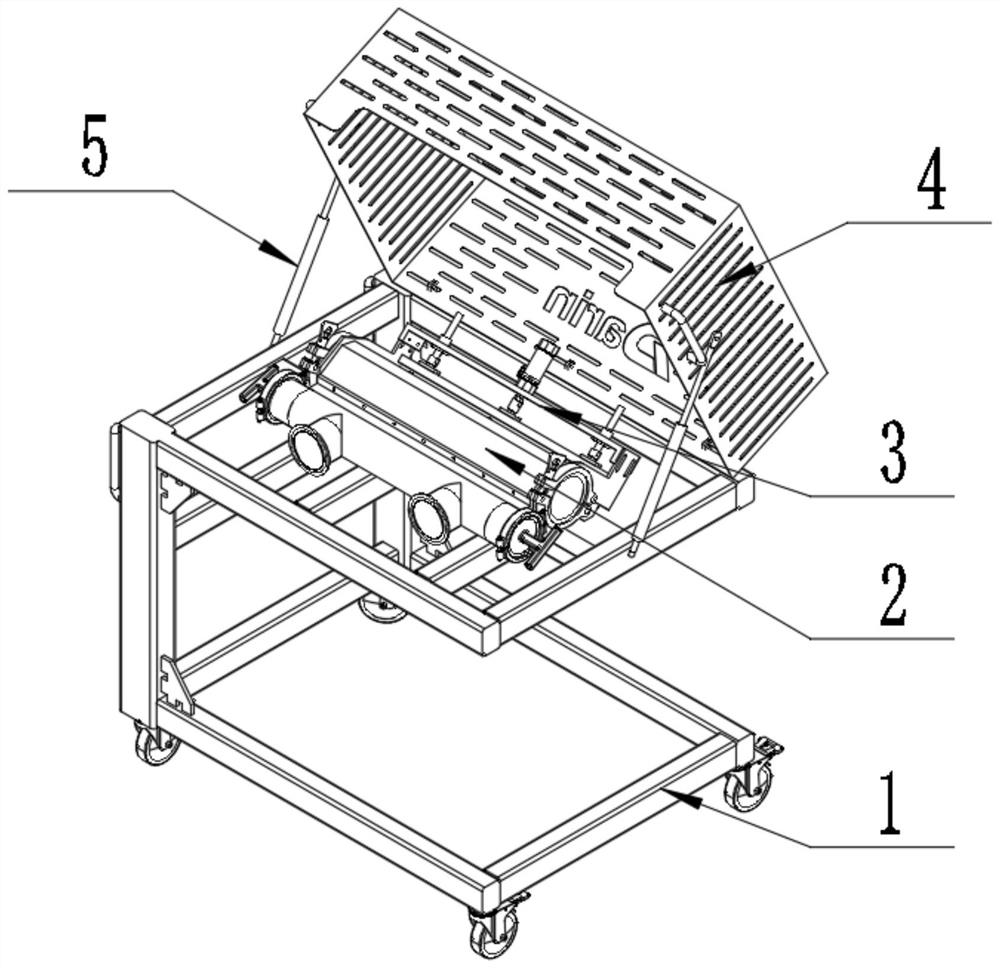

The invention provides a material distributing device for a meat strip extruder. The material distributing device comprises a support, a protective cover, a material distributing mechanism, a cutting mechanism and a controller; the support serves as an installation and supporting foundation of the protective cover, the material distributing mechanism and the cutting mechanism; one side of the protective cover is hinged to the support, and the protective cover protects the material distributing mechanism and the cutting mechanism; the material distributing mechanism comprises a material cavity, a material distributing cavity and a forming die; the outlet end of the material cavity communicates with the inlet end of the material distributing cavity; a material distributor assembly is fixed in the material distributing cavity; after meat paste enters the material cavity through the inlet end of the material cavity, the material cavity is filled with the meat paste; after the material cavity is filled with the meat paste, the meat paste enters the material distributor assembly of the material distributing cavity from the material cavity under the pressure of a feeding screw of the extruder, and the material distributor assembly continuously brings the meat paste to the forming die; and the cutting mechanism is fixedly connected with the material distributing cavity and used for cutting meat strips formed through the forming die. The material distributing device for the meat strip extruder can meet the forming requirements of one or more meat strips in different shapes and different sizes, and the situation of material breakage is avoided.

Owner:济南达润机械有限公司

Food forming equipment with food supply member

The present invention relates to a food-forming-apparatus with: a rotating drum which comprises product cavities in which a food product is formed from a food mass and a food mass feed member, which comprises a housing with an infeed channel and at least one upstream sealing area and / or a downstream sealing area and a flexible pressure plate which is pressed against the outer surface of the drum and thereby provides a seal between the food mass member and the drum. The drum has at its outer surface a multitude of rows of cavities.

Owner:GEA FOOD SOLUTIONS BAKEL

Bacon product and method of making

A reconstructed bacon product includes meat sourced exclusively from pork bellies. The product includes a cohesive mass of compressed layers of pork belly fat trimmings and pork belly lean trimmings of whole muscle segments. A method of forming a reconstructed bacon product includes obtaining pork belly lean trimmings of whole muscle segments and pork belly fat trimmings, macerating the pork belly lean trimmings, layering the pork belly lean trimmings and pork belly fat trimmings, compressing the layers, heat processing the layers in a mold to form a cohesive mass, and demolding the cohesive mass.

Owner:SMITHFIELD FOODS

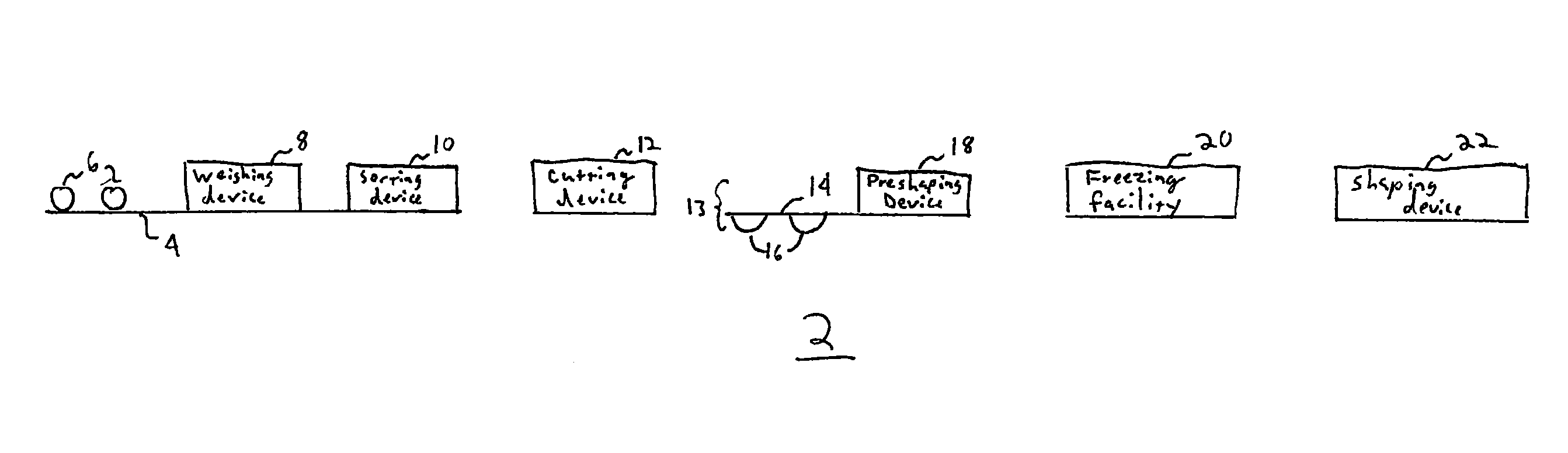

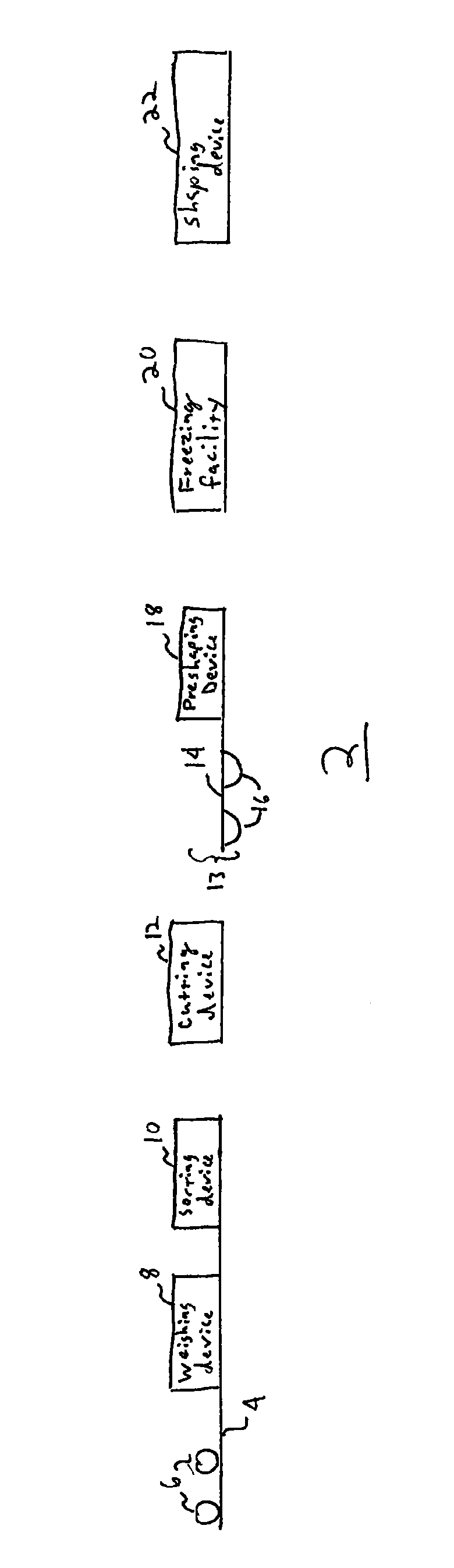

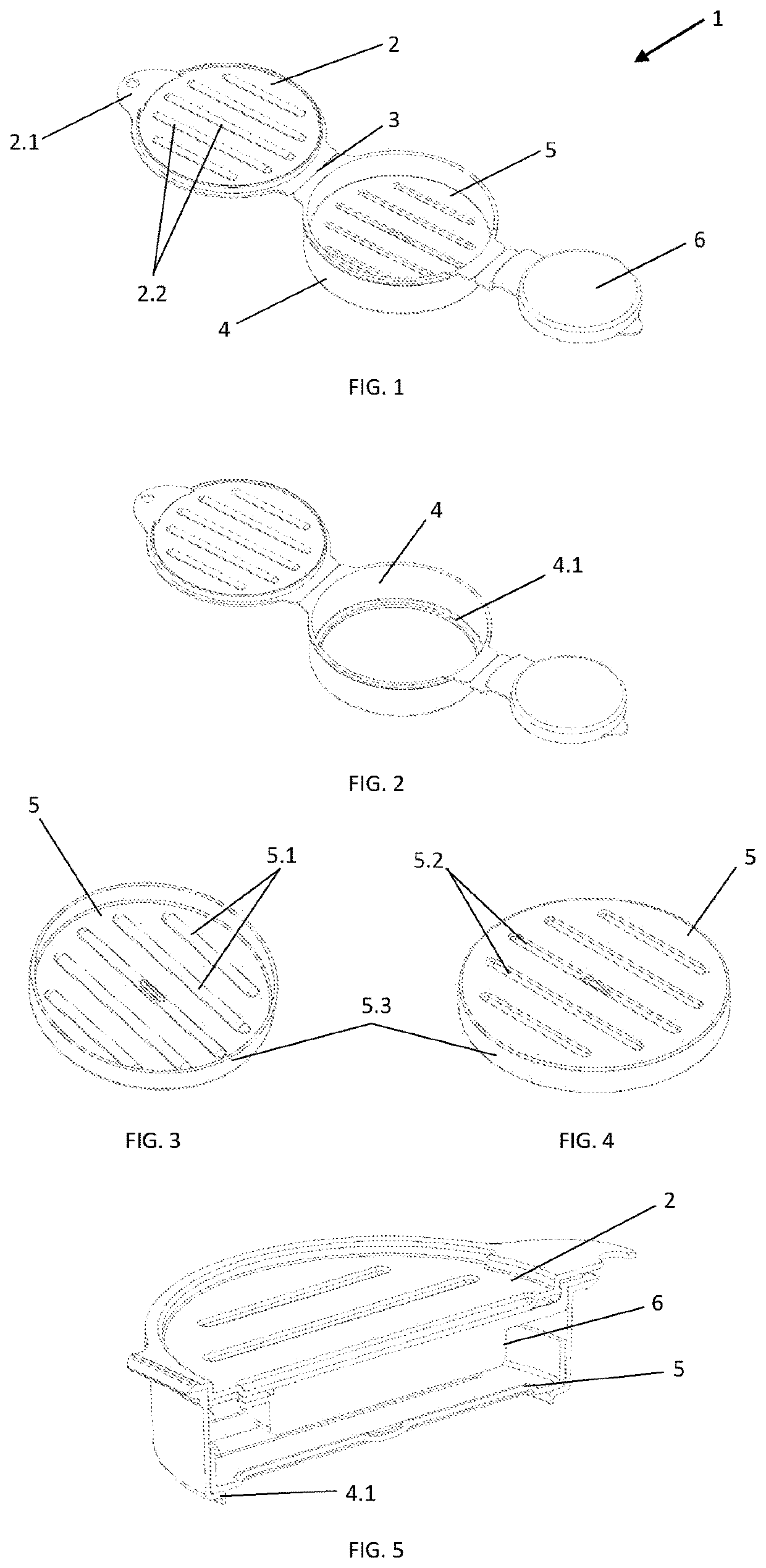

Method and device for producing shaped meat portions from whole natural meat pieces

ActiveUS8916222B2Great possible flexibilityMinimal restrictionPeptide/protein ingredientsConfectioneryControl mannerThree dimensional shape

A device for producing shaped meat portions, the device including a sorting device for sorting meat into a first set of pieces having a weight which is below a desired weight, a second set of pieces having a weight which corresponds to a desired weight, and a third set of pieces having a weight which is above a desired weight. The device further includes a cutting device which cuts each of the third set of pieces to a desired weight so that the cut pieces having a desired weight define a set of selected meat pieces. A transport device transports the set of selected meat pieces and a freezing facility through which the transport device conveys the set of selected meat pieces and which freezes the set of selected meat pieces. The device further including a shaping device which presses or presses and punches the frozen set of selected meat pieces in a mold and thus transforms the frozen set of selected meat pieces into a final shape or a plurality of final shapes, wherein the shaping device produces in a controlled manner meat portions having a predefined weight and a predefined three-dimensional shape.

Owner:NIENSTEDT GMBH

Hamburger mold

ActiveUS10682017B2Reduces and simplifies cleaning and handlingMeat pressingKitchen equipmentMechanical engineeringIndustrial engineering

Owner:BRAIDOTTI NELY CRISTINA

Machine and method for producing spiral sausages

ActiveUS9888695B2Easy to insertEasy to placeMeat pressingSausage filling/stuffing machinesEngineering

A device for making sausage spirals including a sausage blank attached with an end portion above a face of a vertically standing hub and wound into a sausage spiral by rotating it about the hub axis. The hub moves along a circumference of the rotating table wherein the following components are arranged behind one another along the circumference: an insertion station for the blank, a skewering station for skewering the finished sausage spiral and an ejection station for ejecting the sausage spiral from the machine.

Owner:TVI ENTWICKLUNG & PROD GMBH

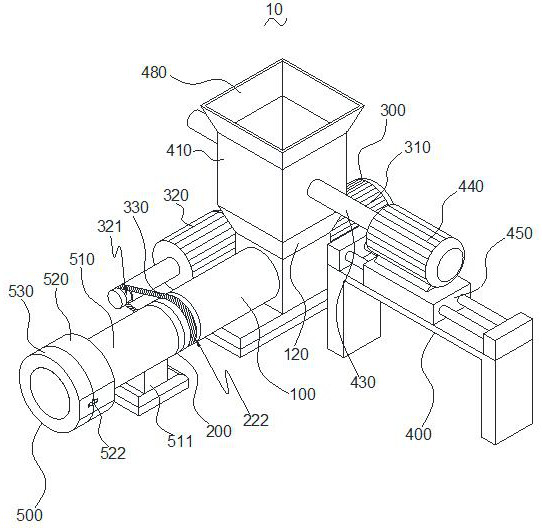

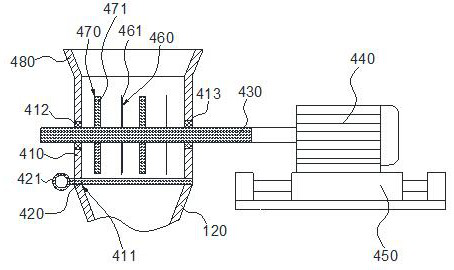

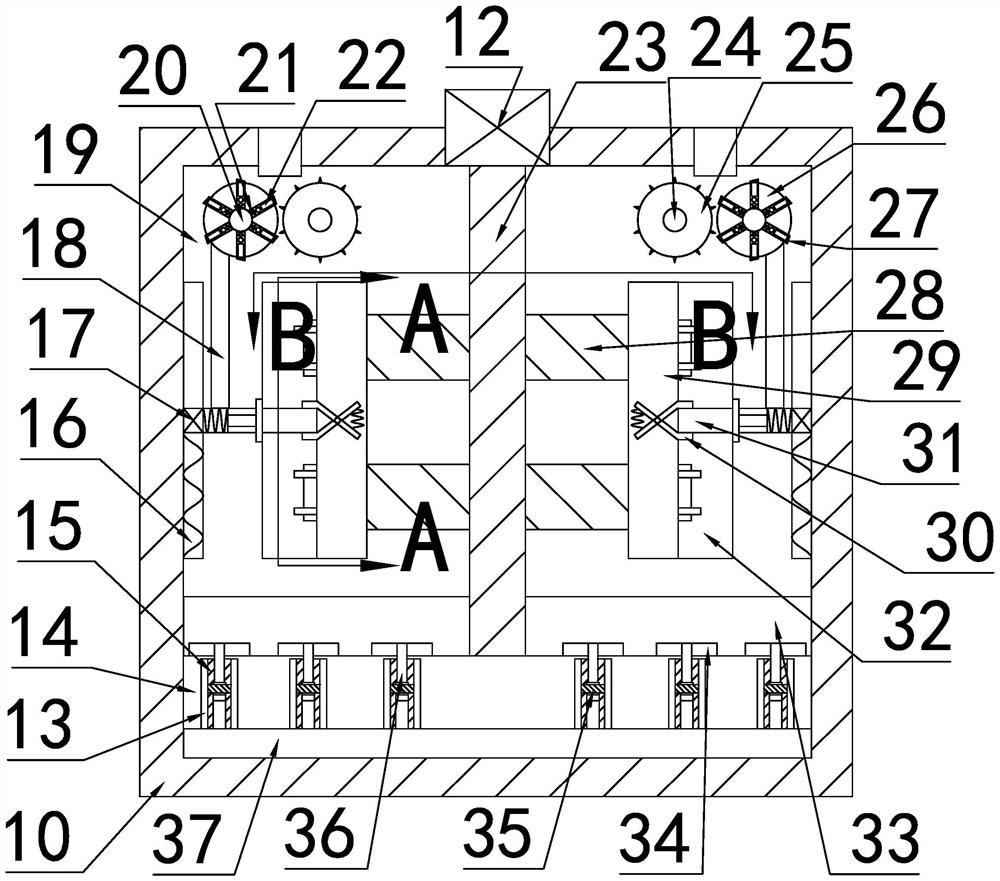

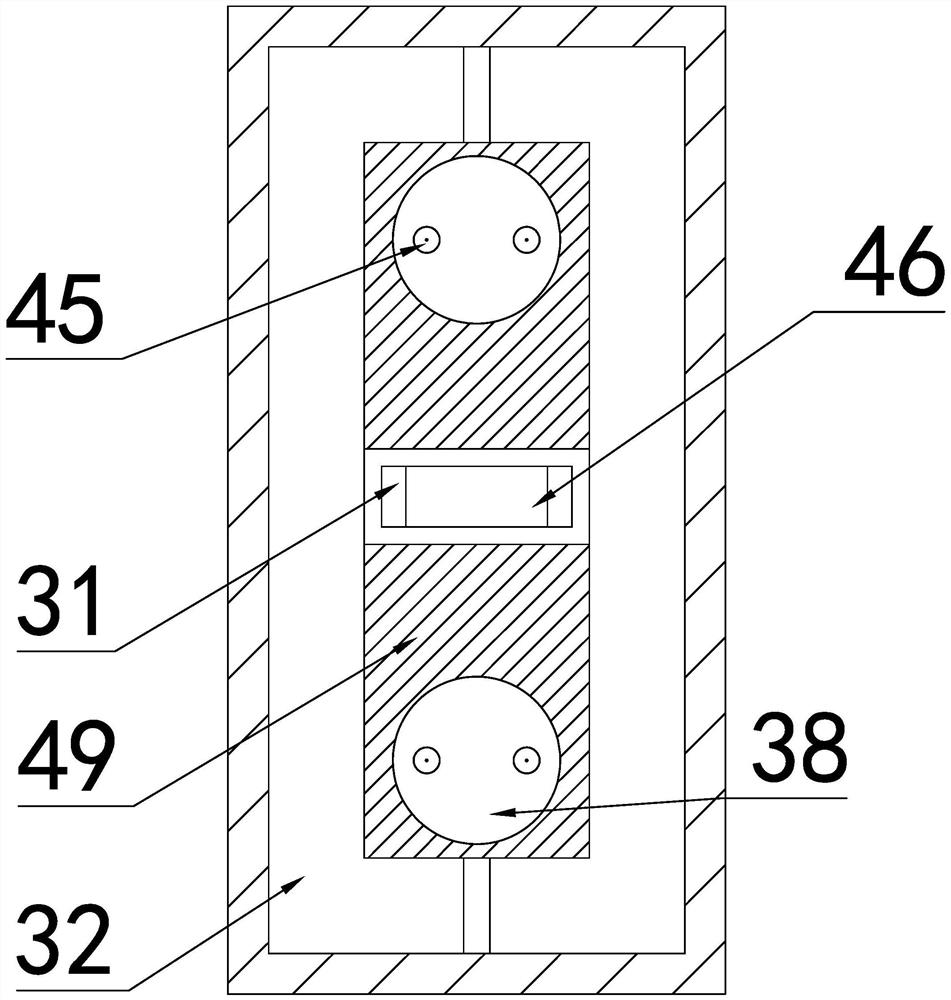

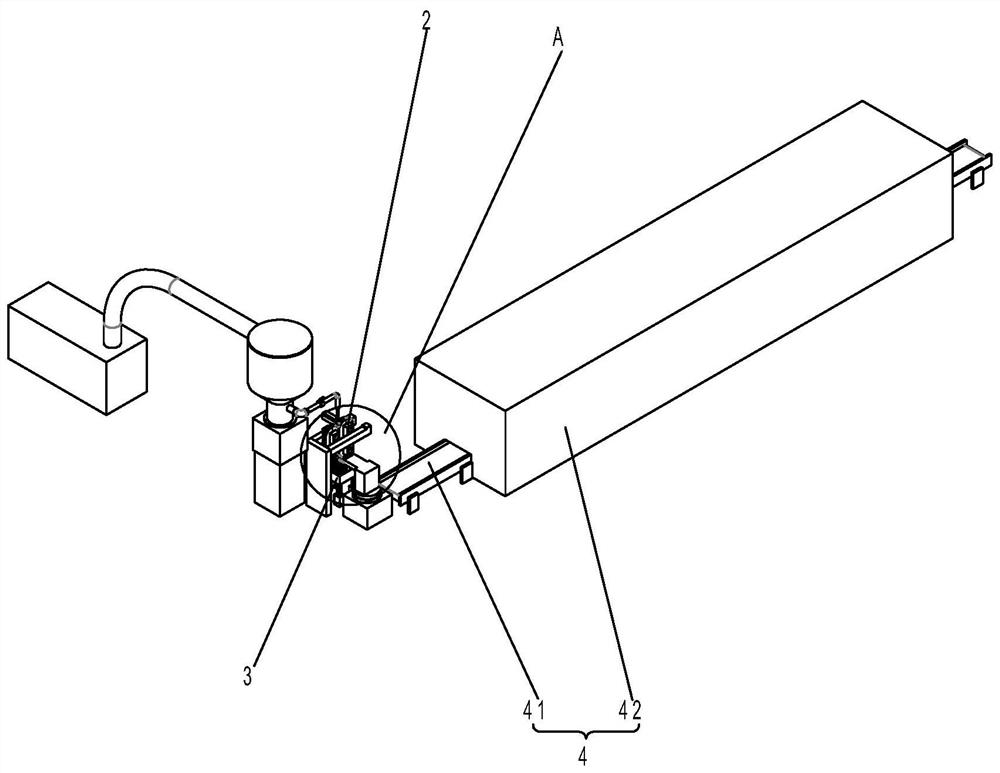

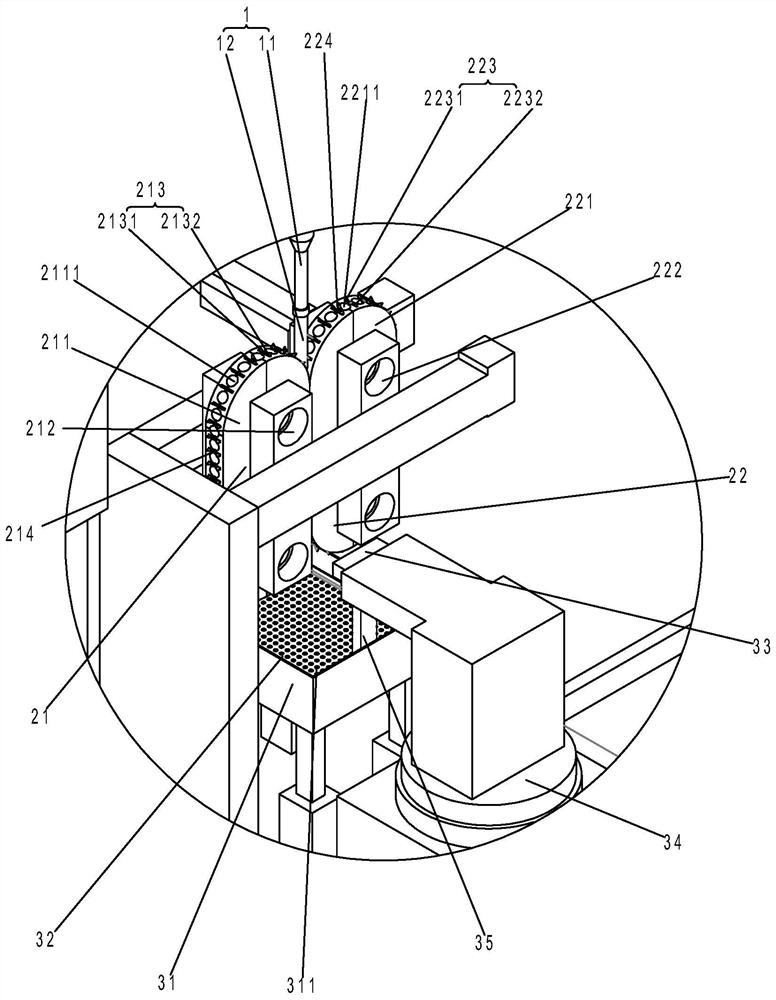

Automatic production equipment for meatball products

The invention provides an automatic production equipment for meatball products, which comprises a meat grinder, a reamer component, a driving component, a front component and a forming component. The reamer assembly includes the auger shaft, the cutter plate and the stuffing orifice plate. The meat-grinding cylinder is rotatably connected with the cutting board, and the cutting board is connected with the stuffing orifice board. The driving assembly includes a first driving motor and a second driving motor, the first driving motor is drivingly connected with the auger shaft, and the second driving motor is drivingly connected with the cutting board. The front assembly includes a stirring box, a baffle plate, a rotating rod, a rotating driving part, a reciprocating driving part, several cutting units and several stirring units. The rotating rod is rotated and slidably connected with the mixing box. The rotating drive member is drivingly connected with the rotating rod. The reciprocating drive is drivingly connected to the rotary drive. Each cutting unit and each stirring unit are arranged alternately, the cutting unit includes several cutting knives, and the stirring unit includes several stirring sticks. The above production equipment improves the production efficiency of meatball products.

Owner:广东华创展翔食品有限公司

Fish ball shaping and manufacturing equipment

The invention belongs to the related field of fish balls, and relates to fish ball shaping and manufacturing equipment which comprises a shell, a downward rolling cavity is formed in the upper end wall of the shell, a fish grinding and bone picking device is arranged on the downward rolling cavity, an extruding and rotating device is arranged at the lower end of the downward rolling cavity, meanwhile, fish bones on the inner side are effectively treated, and the fish bones are prevented from being scratched. The fish flesh can be effectively scraped by a fish flesh layer on the outer wall, so that the fish flesh can move downwards and slide, the fish flesh can be rotationally extruded, the fish flesh can fall off more sufficiently, a plurality of pieces of fish flesh can be quickly fleshed, and the fish flesh can be more effectively collected through extrusion and rotation; a clamping block can effectively scrape a fish meat layer on the outer wall, fish meat powder is more fully collected through fixing, the fish meat is moved downwards and slides, after the fish meat powder is effectively stirred, the fish meat powder is moved upwards to be collected, and after shaping is completed, the fish meat powder is collected.

Owner:财聚福临茶业股份公司

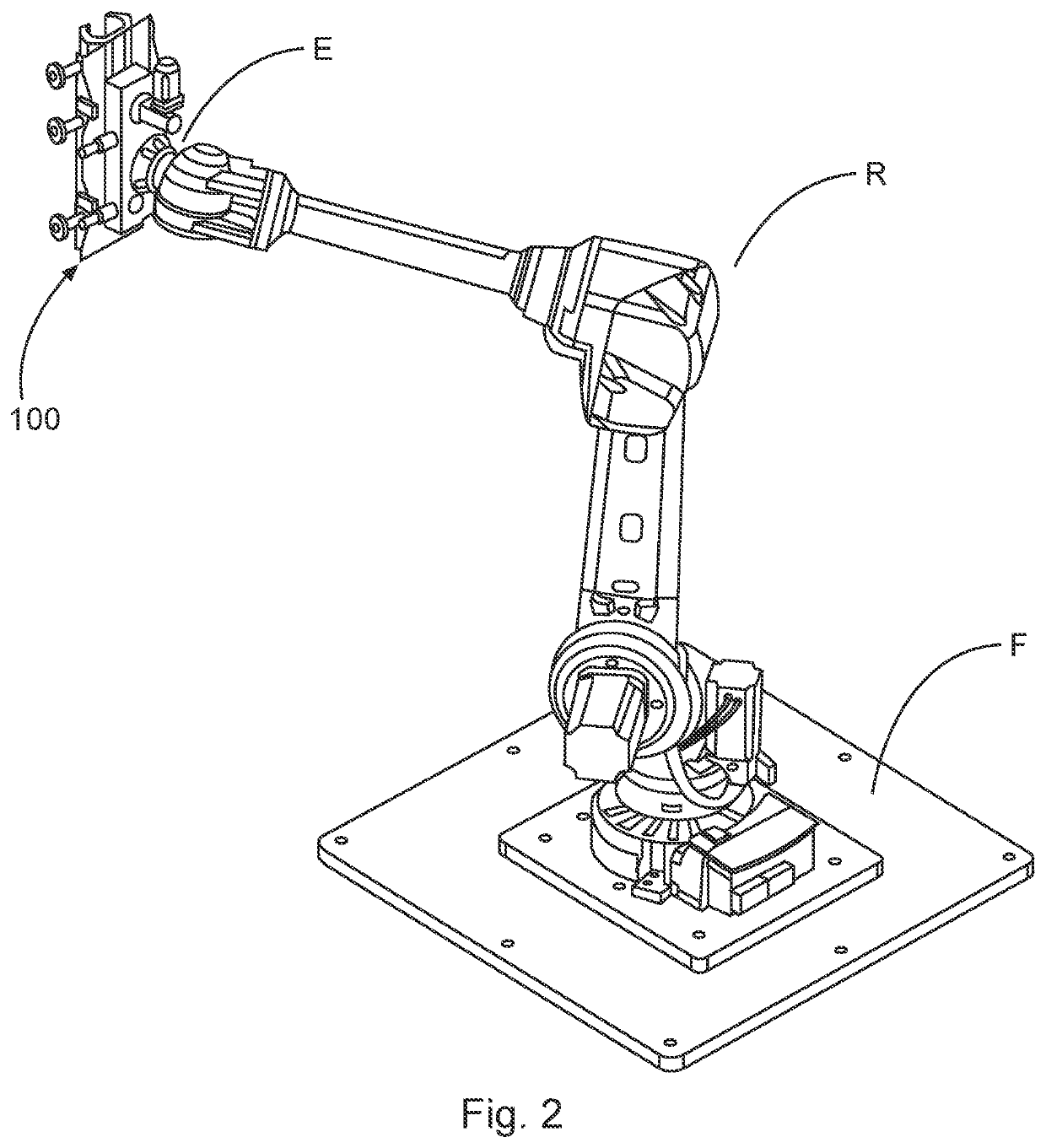

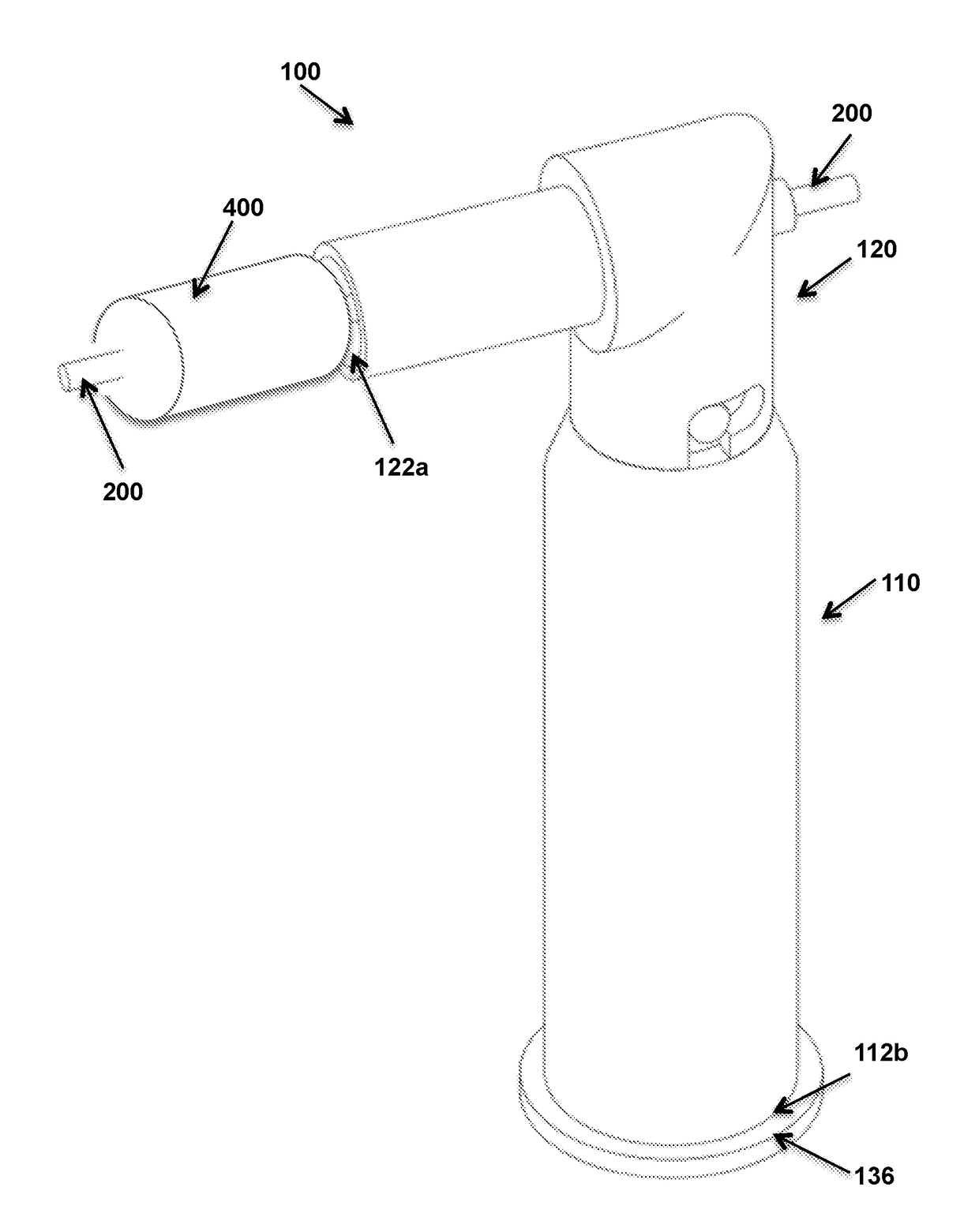

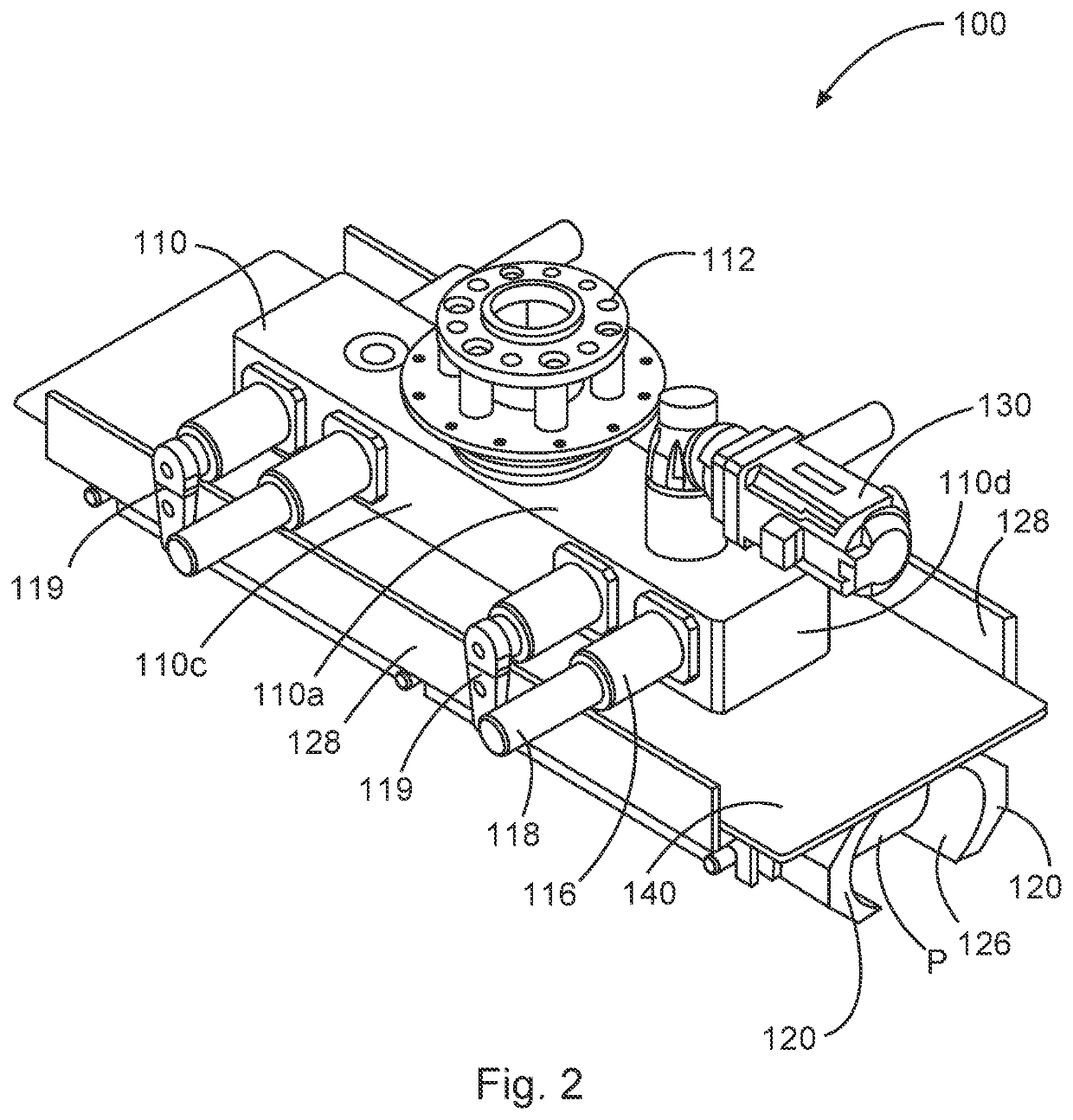

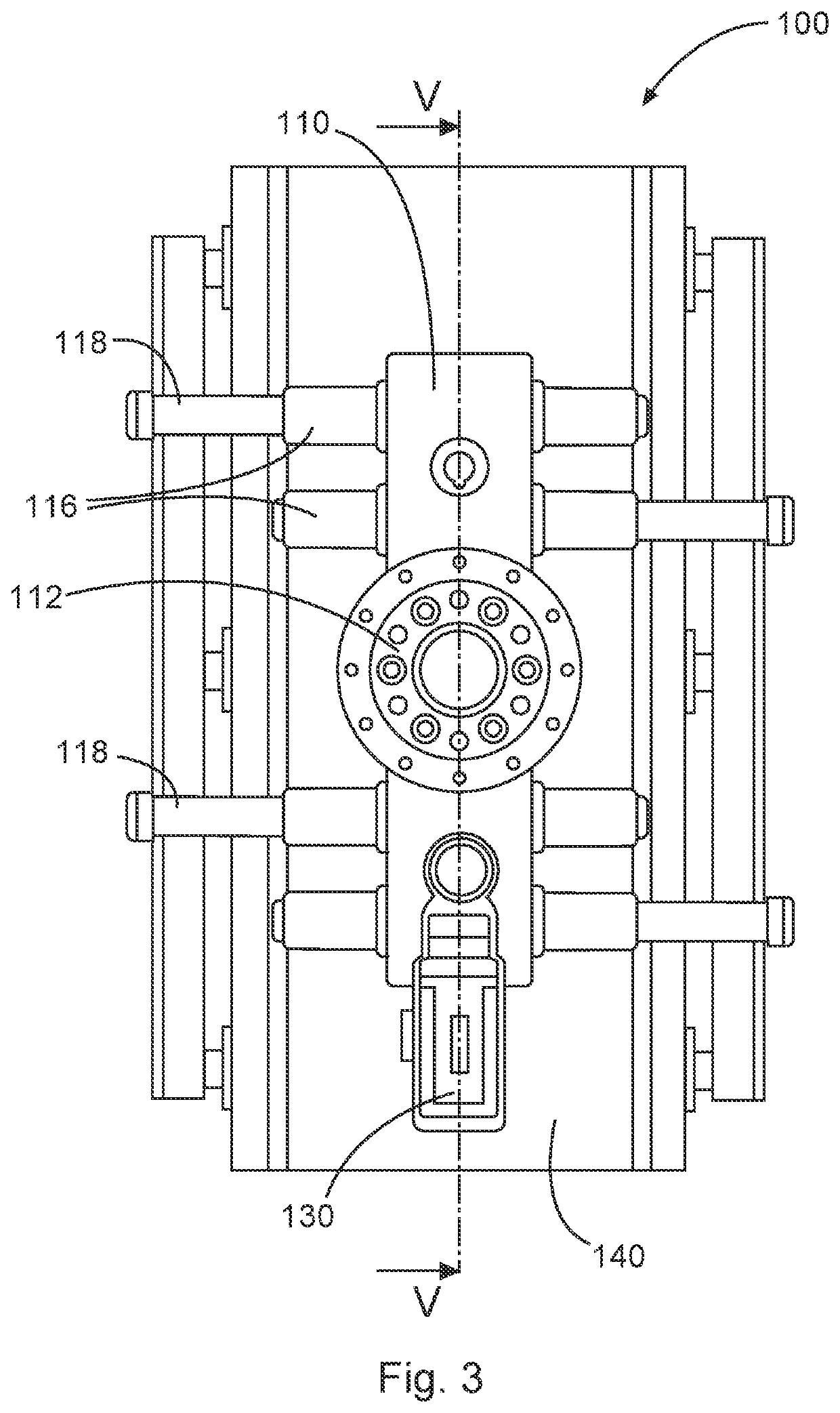

Gripping Device

PendingUS20220072718A1Reduce the burden onIncrease clock speedGripping headsMeat packaging/handling/transportingPinch gripCoupling

The present invention relates to a gripping device for picking up, conveying, and delivering a product, the gripping device including: a base structure which may be attached to a handling device by means of a coupling element, preferably so in a non-destructively detachable manner; at least two gripper members having each at least one bottom surface and at least one top surface, said top surface of the gripper members facing towards the coupling element and said bottom surfaces of the gripper members facing away from the coupling element; at least one drive means for reversibly moving the gripper members between a first position, in which the gripper members may be positioned on opposite sides of the product to be picked up, and a second position, in which the gripper members seize the product to be picked up; and an abutment plate which is at least approximately supported by the top surfaces of the gripper members.

Owner:POLY CLIP SYST

Device for moulding chopped preparations

Owner:SEB SA

Intelligent production equipment and production process for quick-frozen food

ActiveCN113575652AAvoid re-deformationEasy to sellConveyorsMeat pressingProcess engineeringThermal water

The invention provides intelligent production equipment for quick-frozen food. The intelligent production equipment comprises a conveying device for conveying stuffing, a forming device for forming the stuffing into balls, and a heat setting device for setting the balls; the output end of the conveying device is connected with the input end of the forming device, and the output end of the forming device is connected with the input end of the heat setting device; the heat setting device comprises a hot water accommodating part for accommodating hot water, a receiving part for receiving the shaped balls, and a lifting driving device for driving the receiving part to lift; a hot water containing cavity is formed in the upper surface of the hot water containing part, and the bearing part is arranged in the hot water containing cavity. The conveying device, the forming device and the heat setting device are sequentially arranged from top to bottom. The forming device is used for forming the formed balls, the formed balls are prevented from deforming again, and selling is facilitated. The invention further provides an intelligent production process of the quick-frozen food.

Owner:漳州丸滋食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com