Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about "Horizontally conveying sausages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

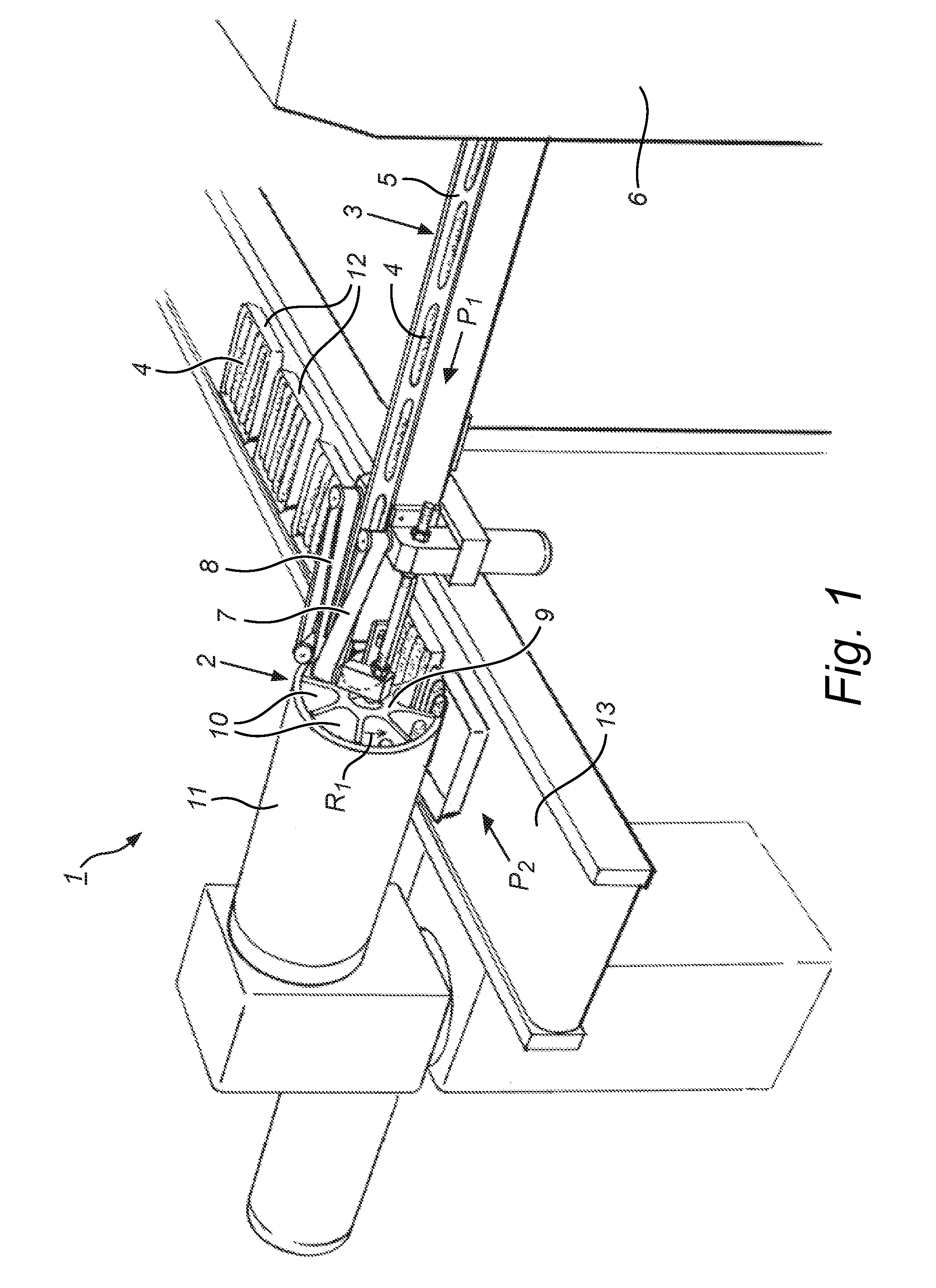

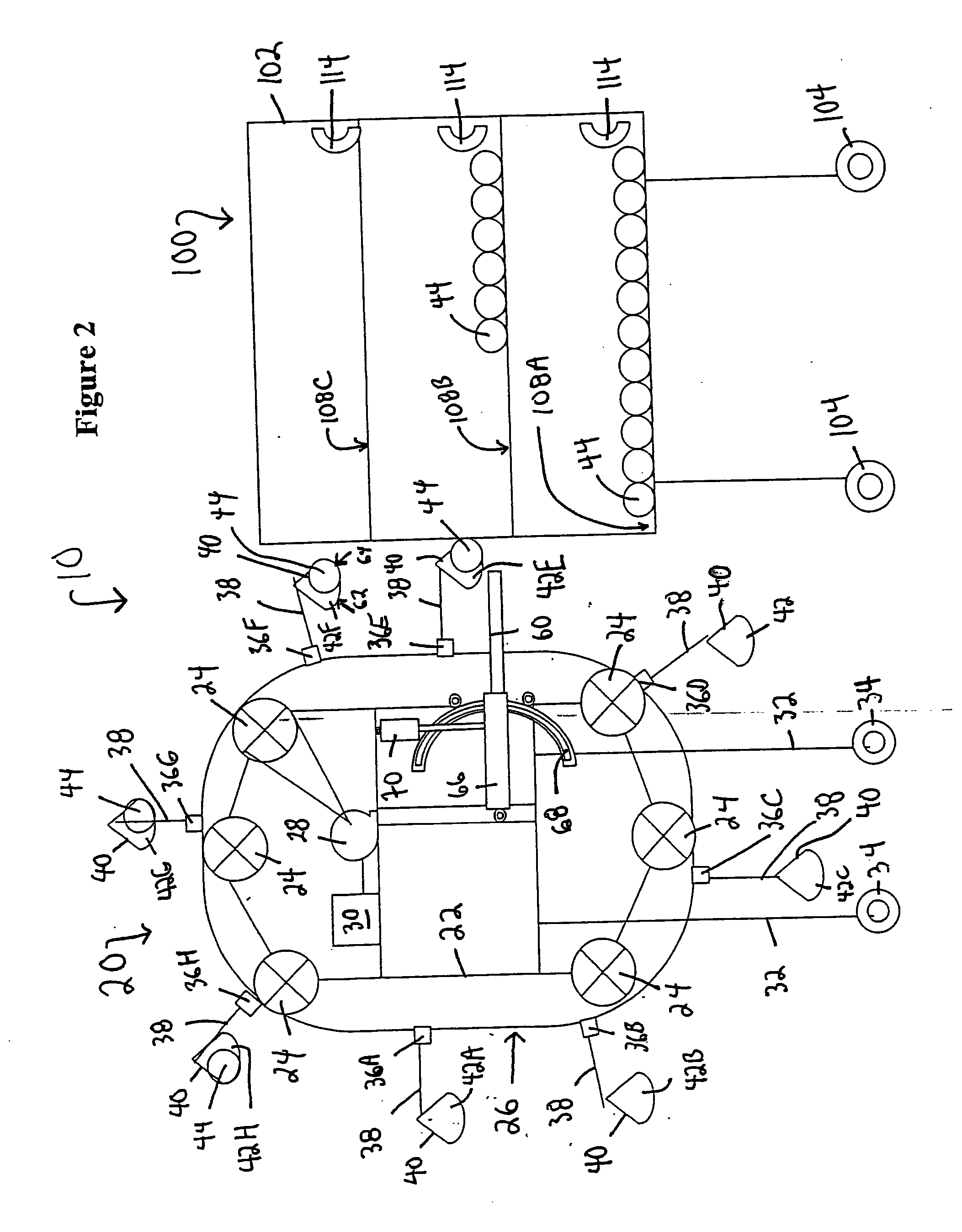

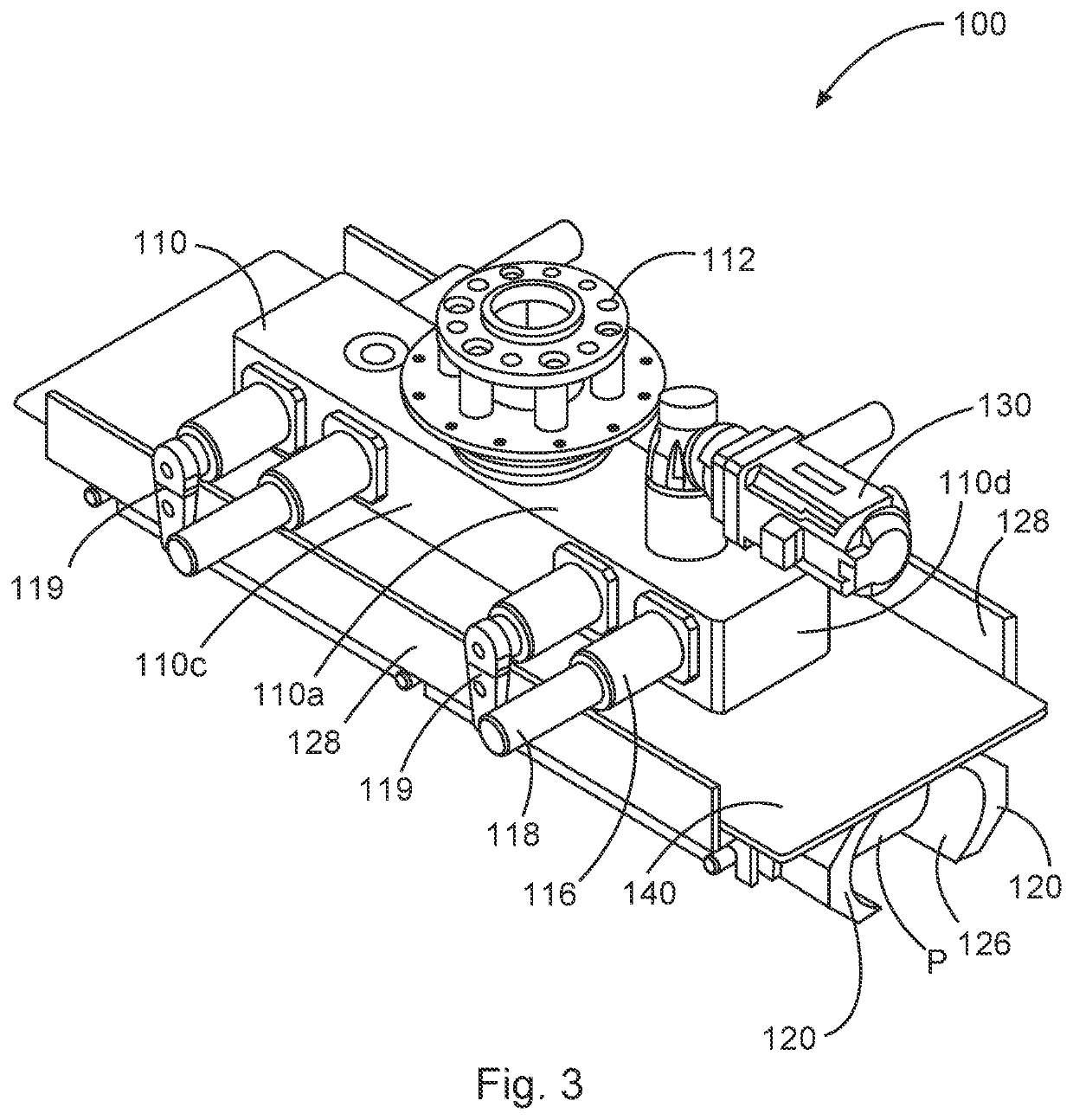

Automatic rack loader

An apparatus and system for loading items onto a rack is described. The rack loading apparatus is a conveyor having a loading side for receiving items and an unloading side for discharging items, a positioner to align a rack with the unloading side; and a load pusher to discharge the items from the unloading side onto the rack. The system is a sausage-making stuffer / clipper, a belt conveyor, a conveyor having a loading side for receiving sausages and an unloading side for discharging sausages, a positioner to align a rack with the unloading side; and a load pusher to discharge the sausages from the unloading side onto the rack.

Owner:POLY CLIP SYST

Device and method for the ordered deposition of parted sausage portions

ActiveUS7258604B2Accurate transferPrecise positioningMeat/sausage hanging-upHorizontally conveying sausagesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Process and Apparatus for Rapid Preparation of Dry Sausage

ActiveUS20120282372A1Meat/fish preservation by heatingHorizontally conveying sausagesMicrowaveEngineering

A process for manufacturing dry sausage. The process includes preparing a dry sausage meat mixture, stuffing the mixture into a casing or mould, fermenting the mixture, heat treating the mixture, cooling the mixture to a temperature sufficiently low to permit slicing, slicing the sausage, placing the sausage onto a conveyor, and passing the conveyor and sausage through a chamber. The process also includes introducing a supply of conditioned air into the chamber, the air having a relative humidity below about 60% and a temperature in the range of at least about 40° F. to 130° F., and introducing a supply of microwaves into the chamber. The air supply and microwaves are selected to reduce the moisture content of the meat to a predetermined moisture to protein ratio.

Owner:SMITHFIELD FOODS

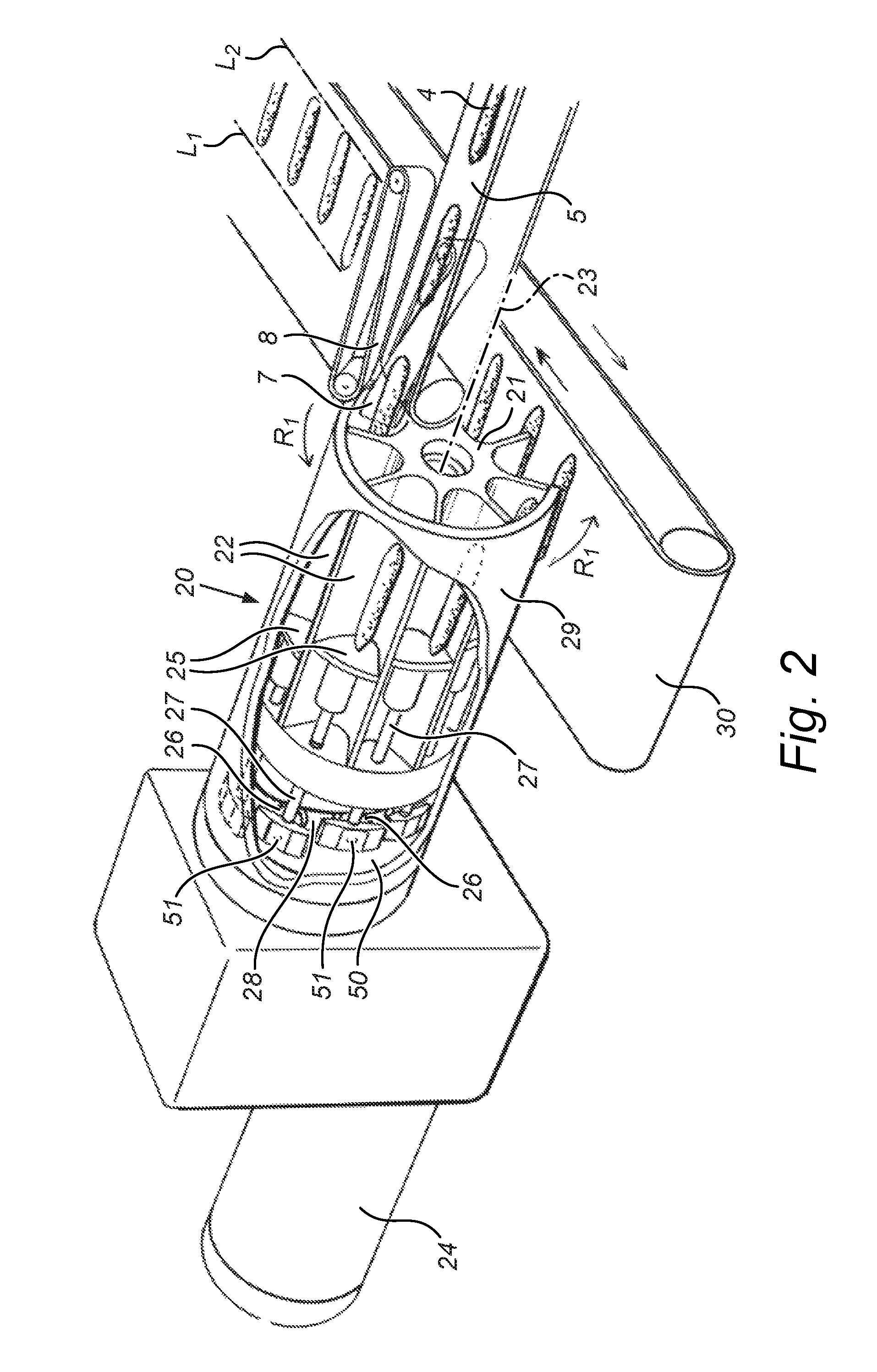

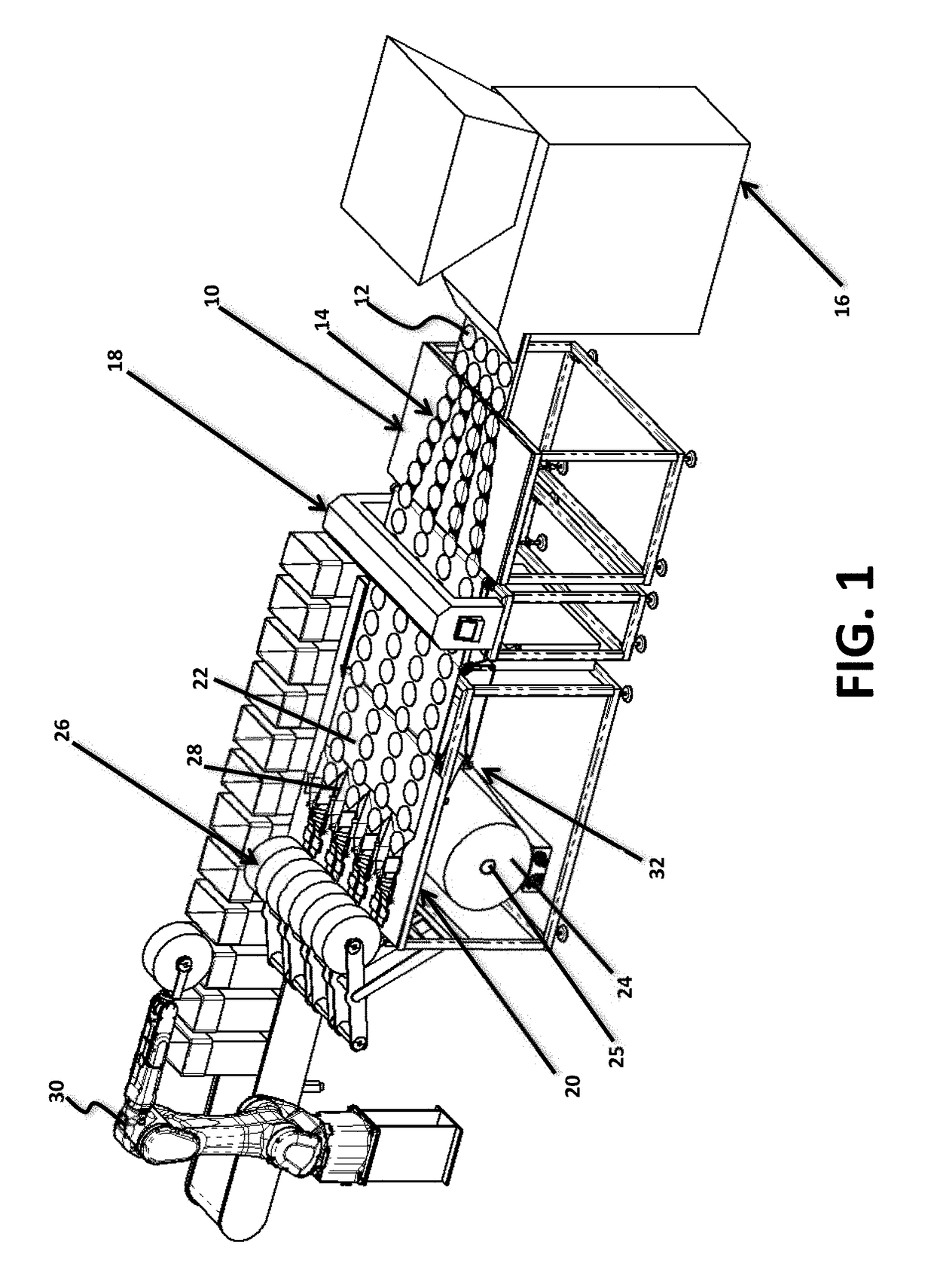

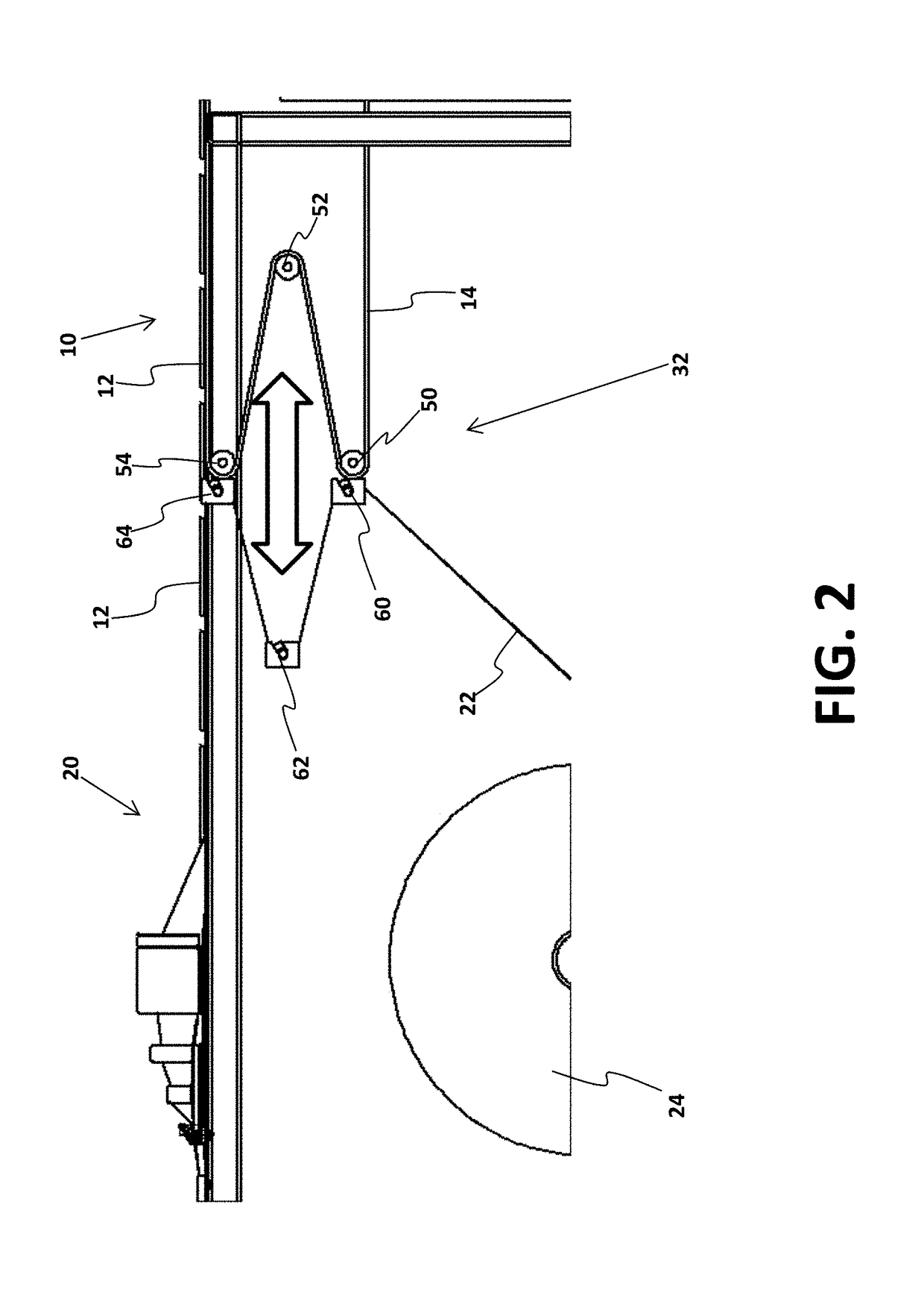

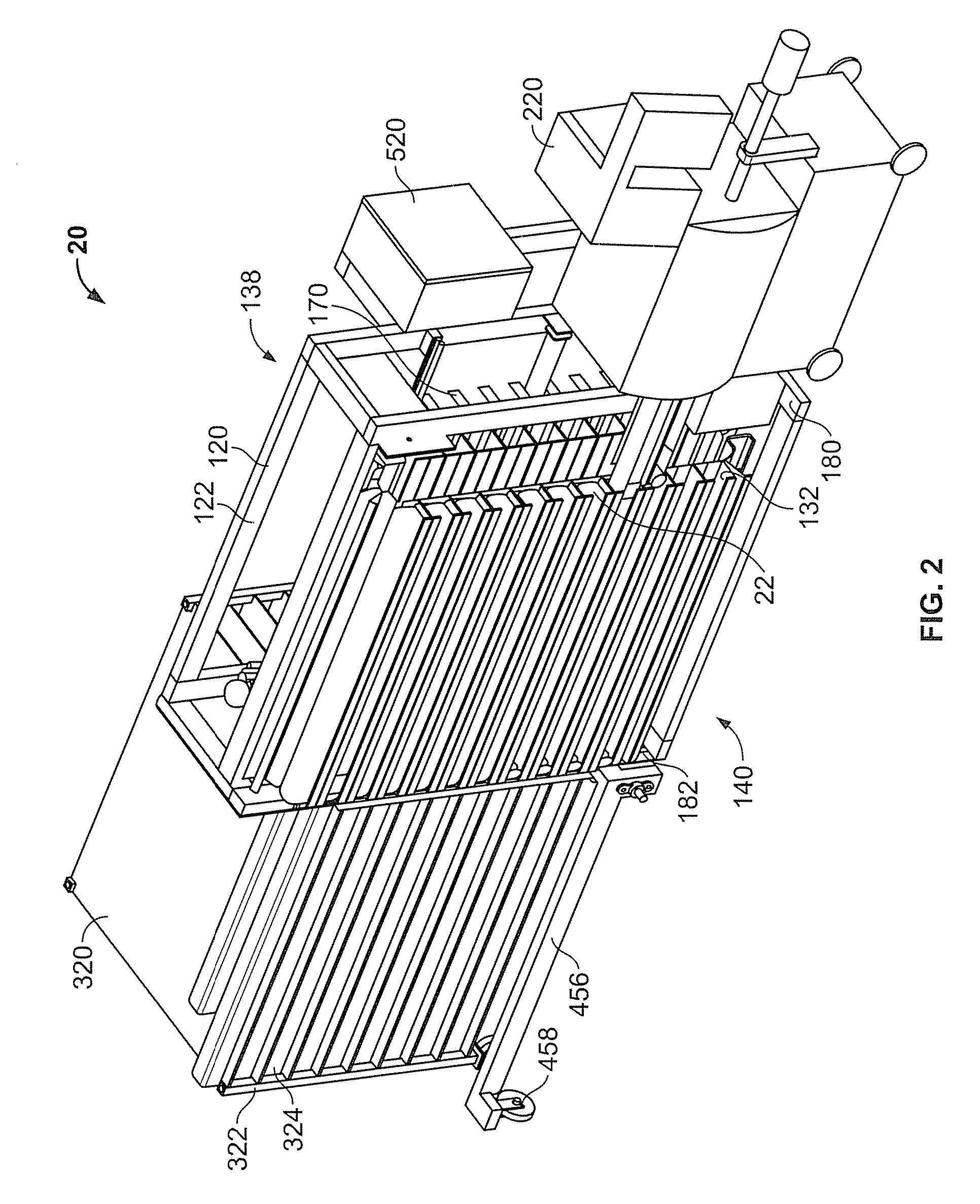

Automatic rack loader

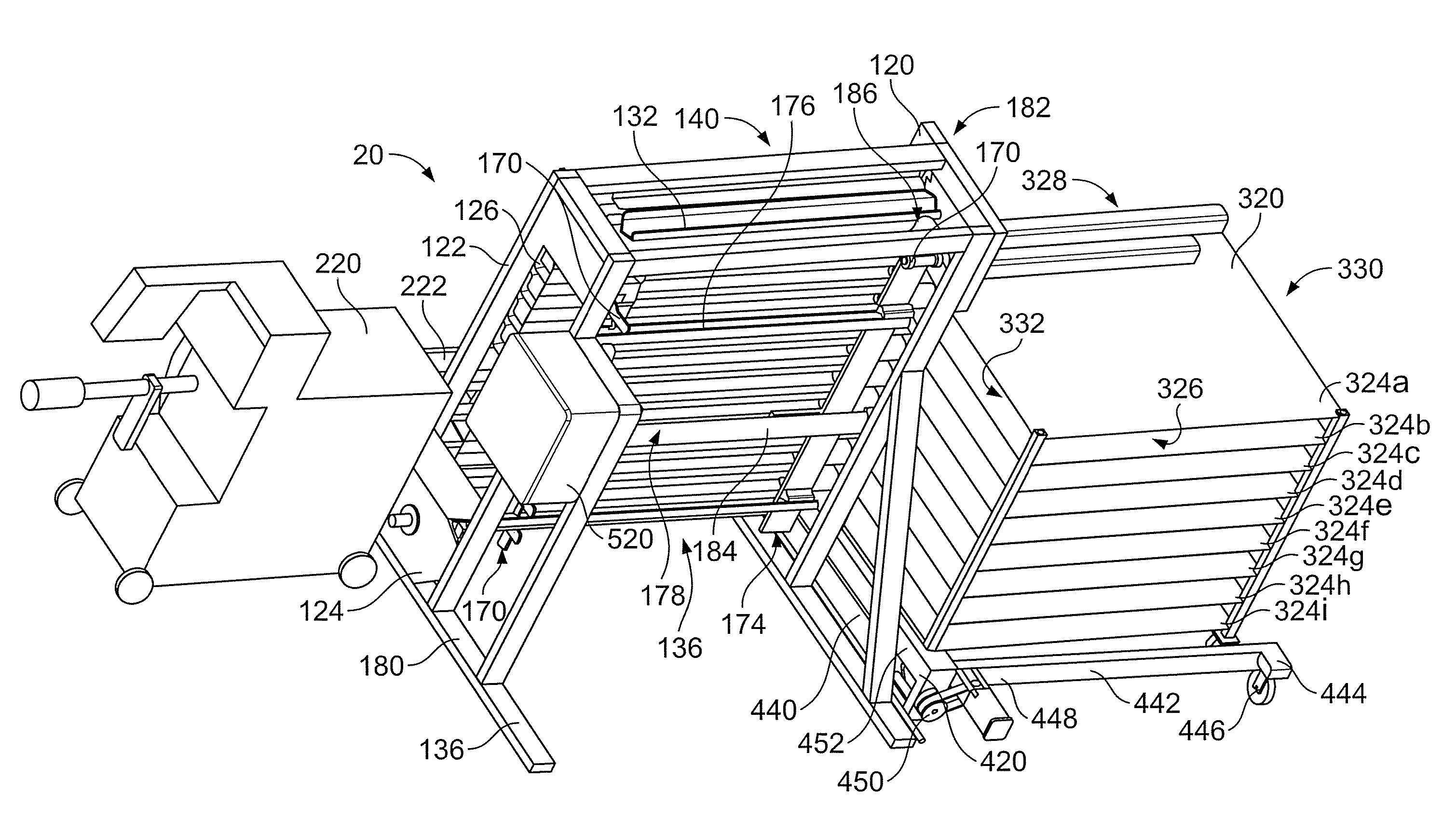

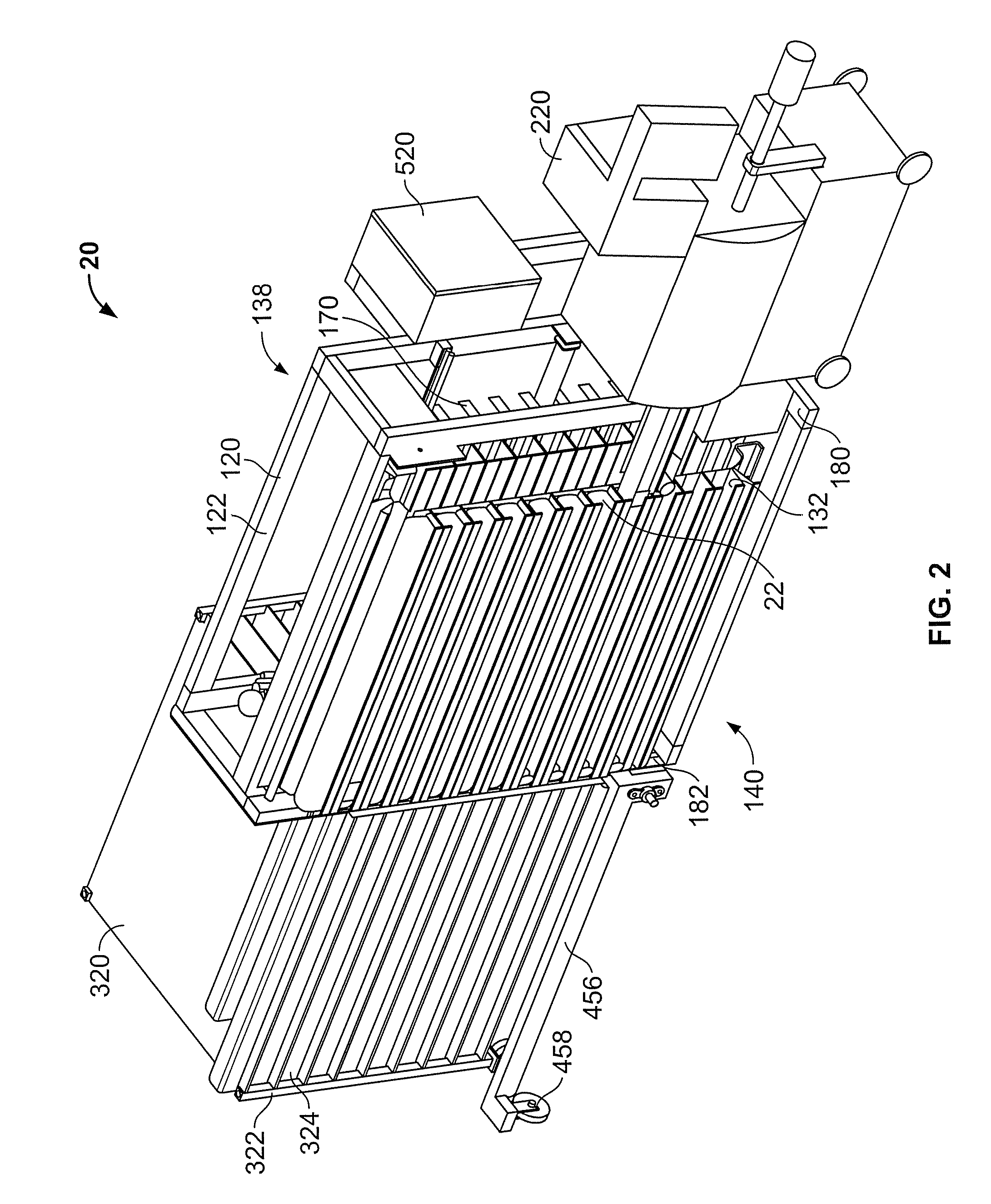

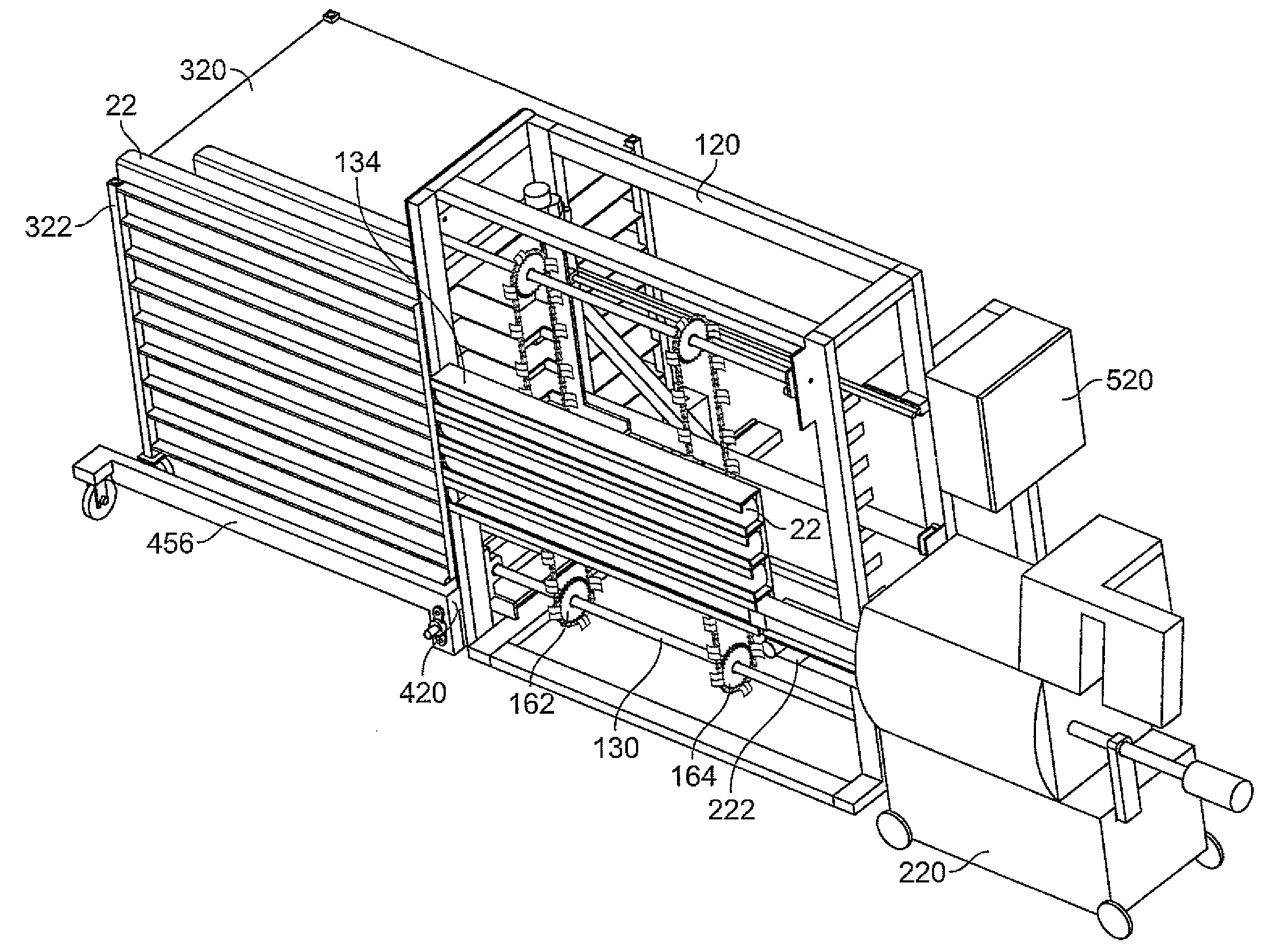

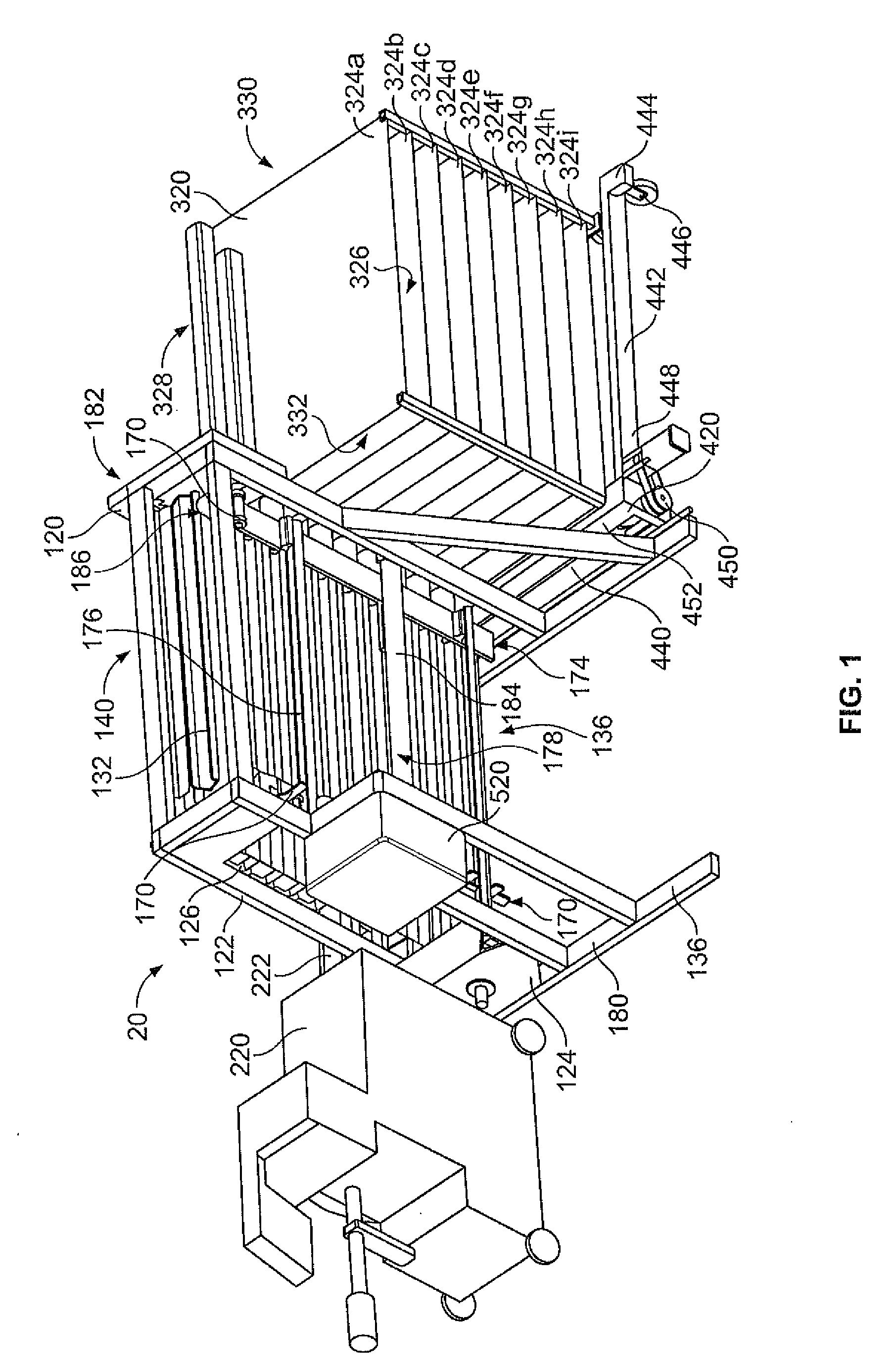

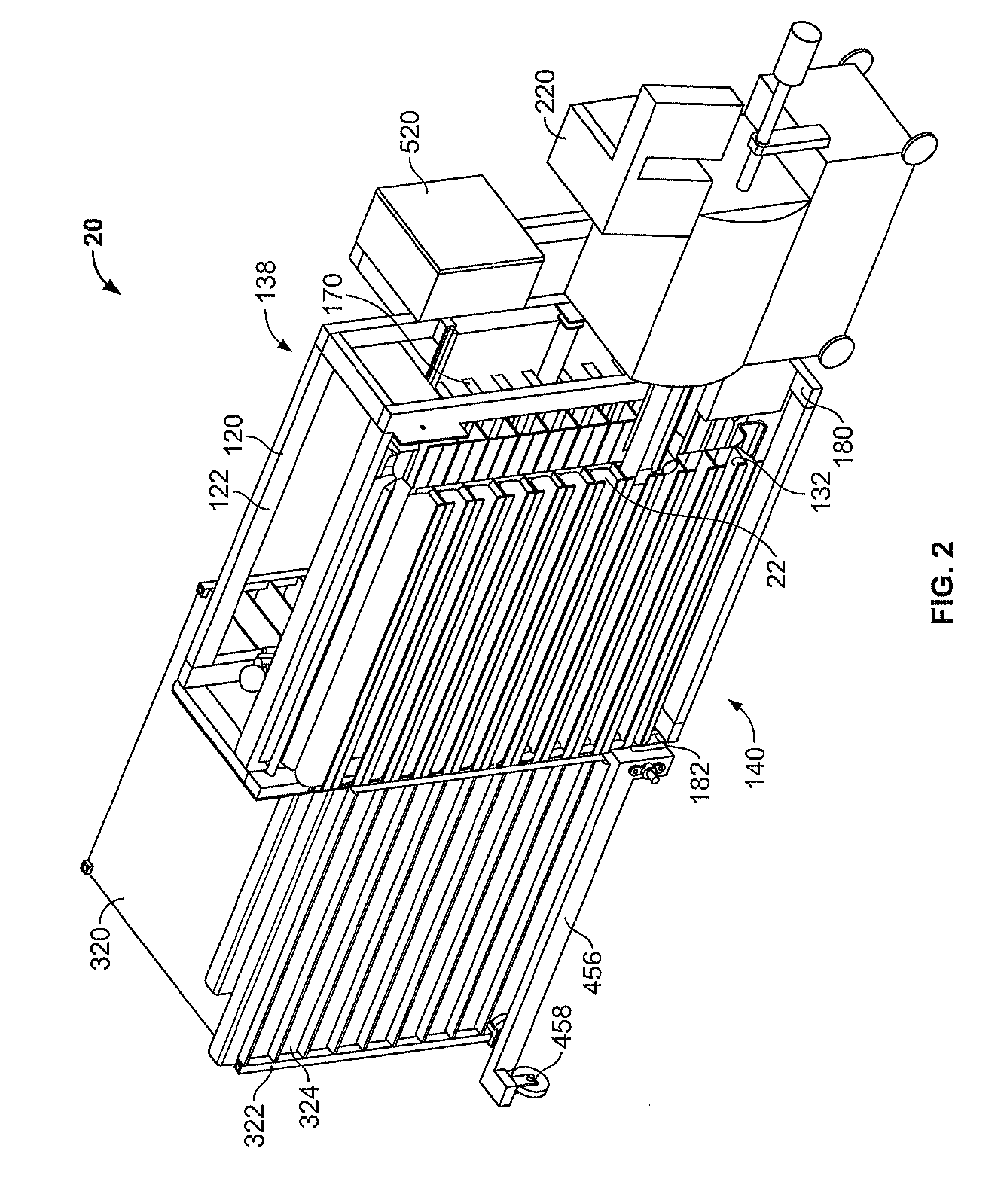

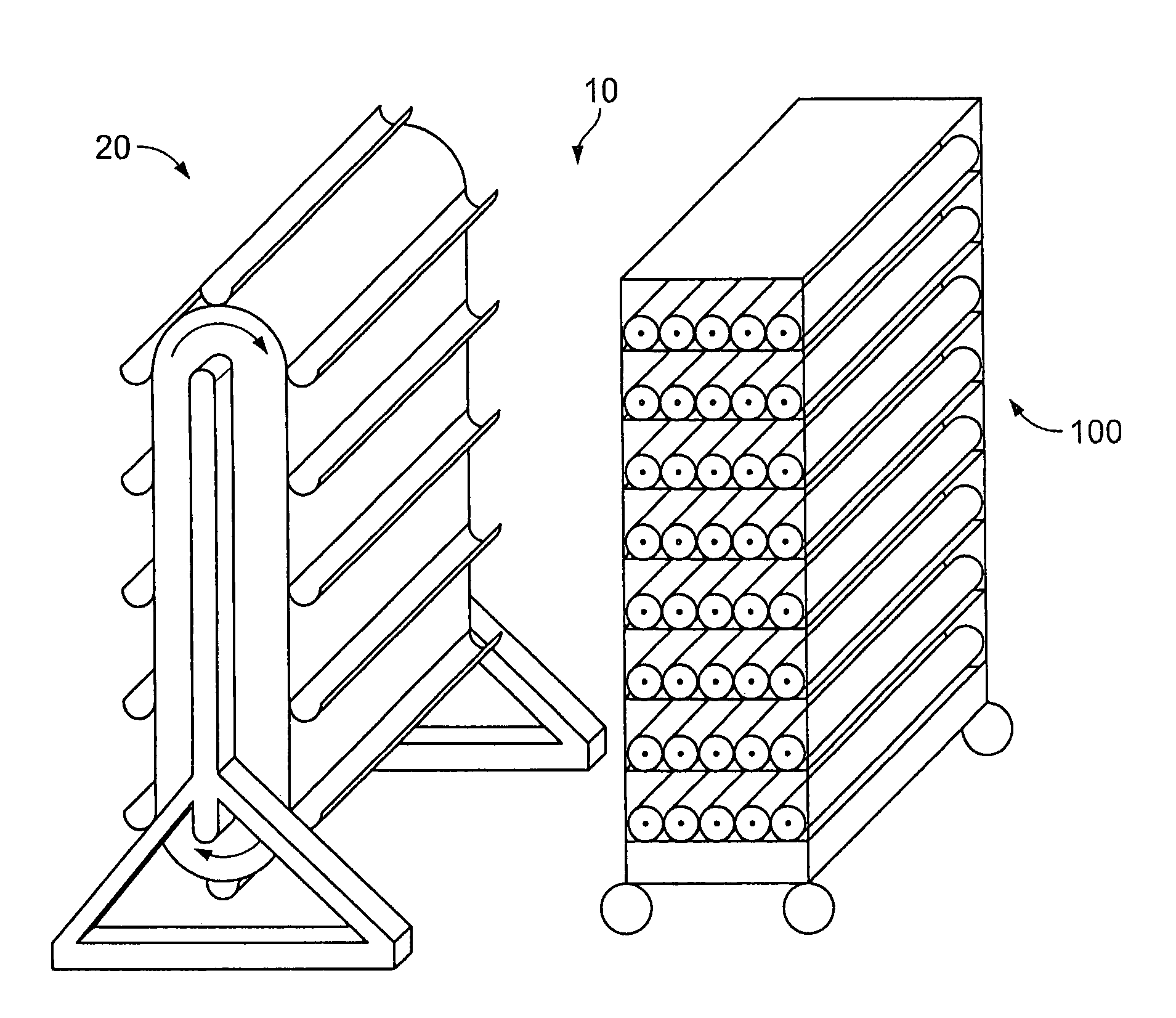

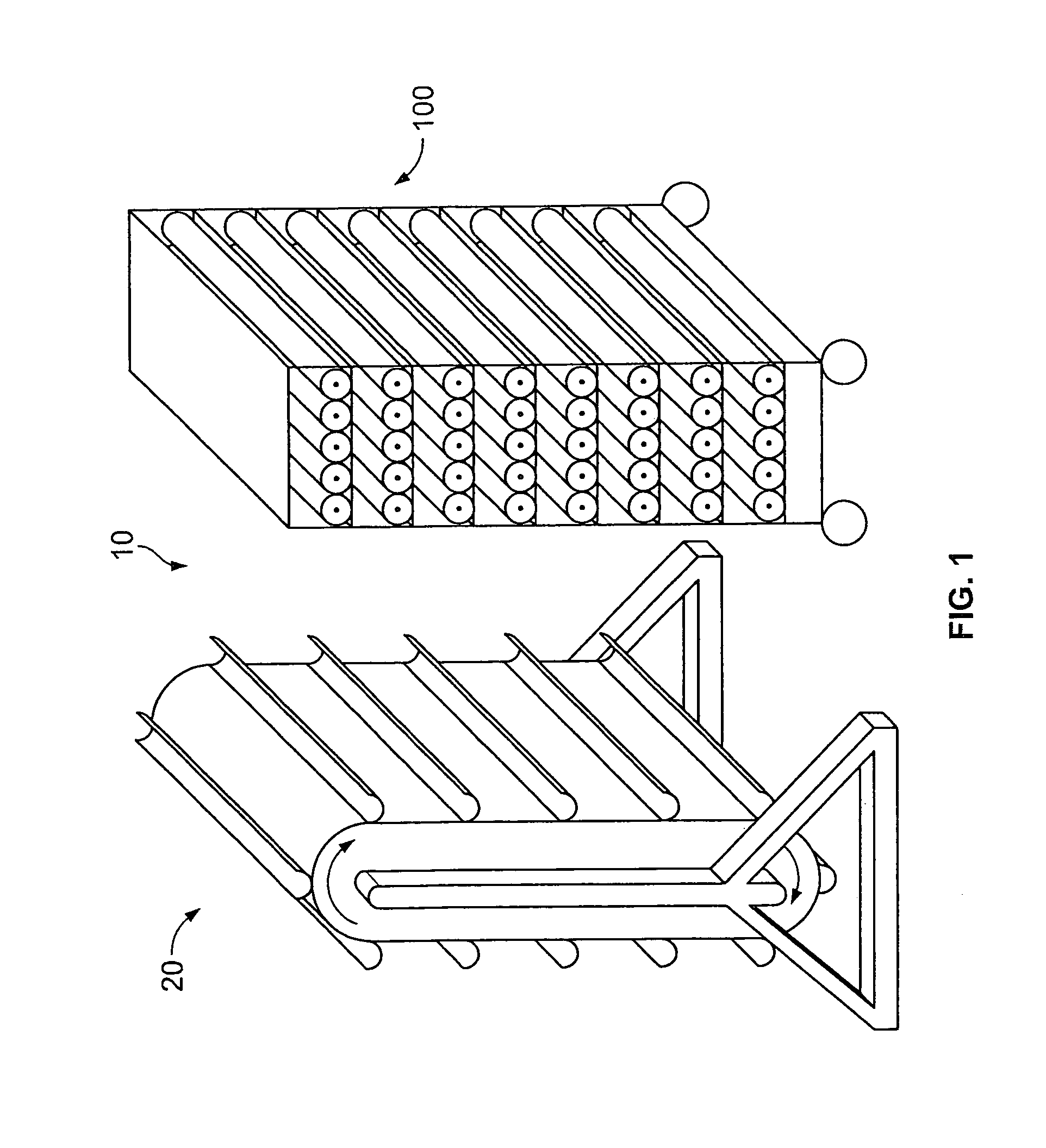

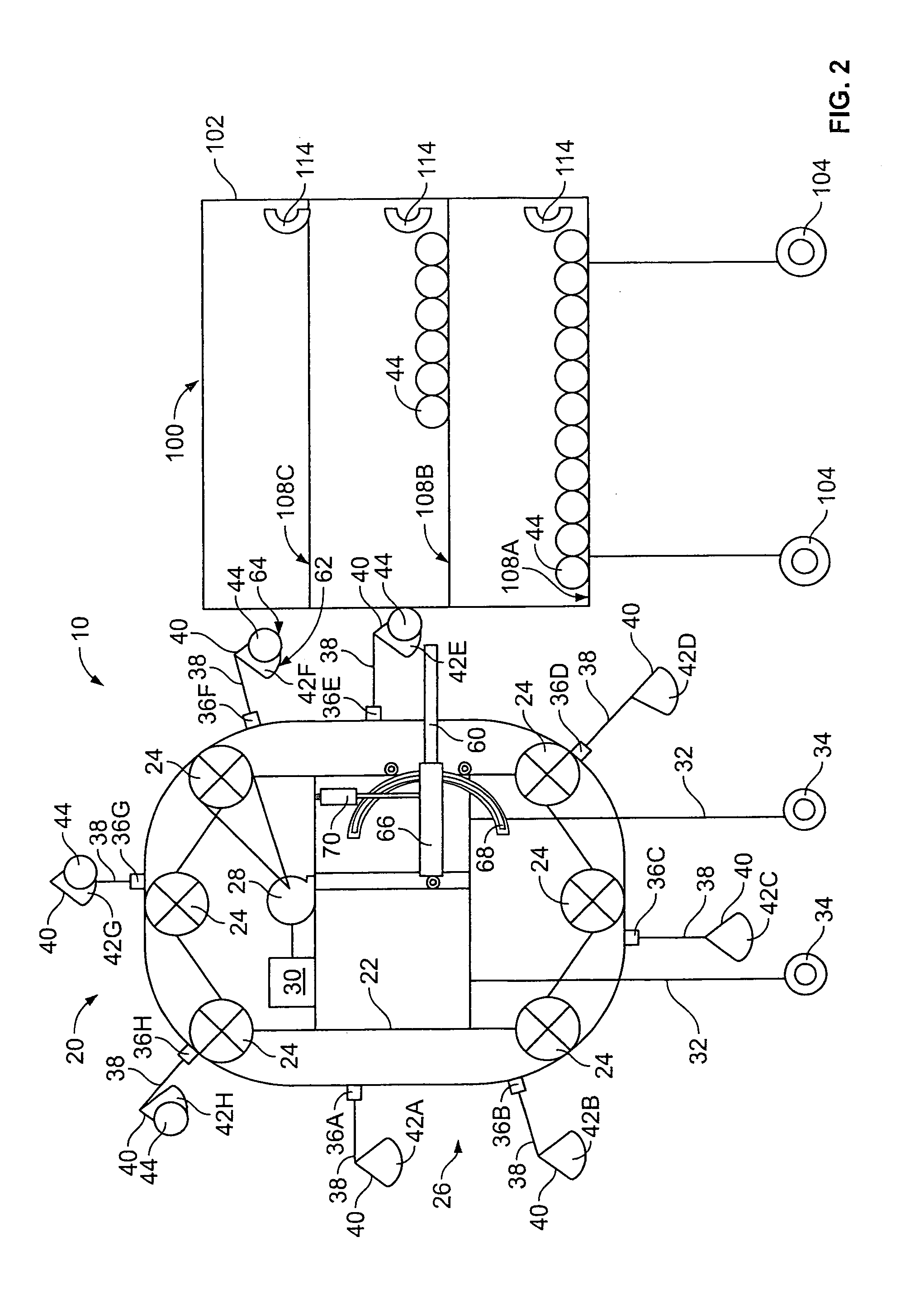

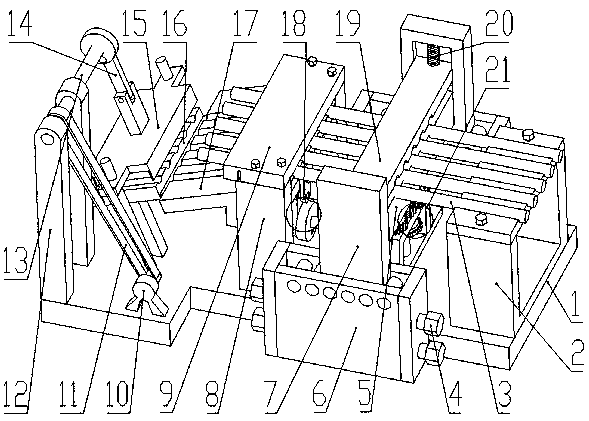

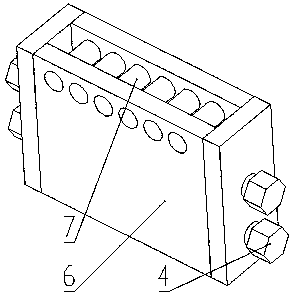

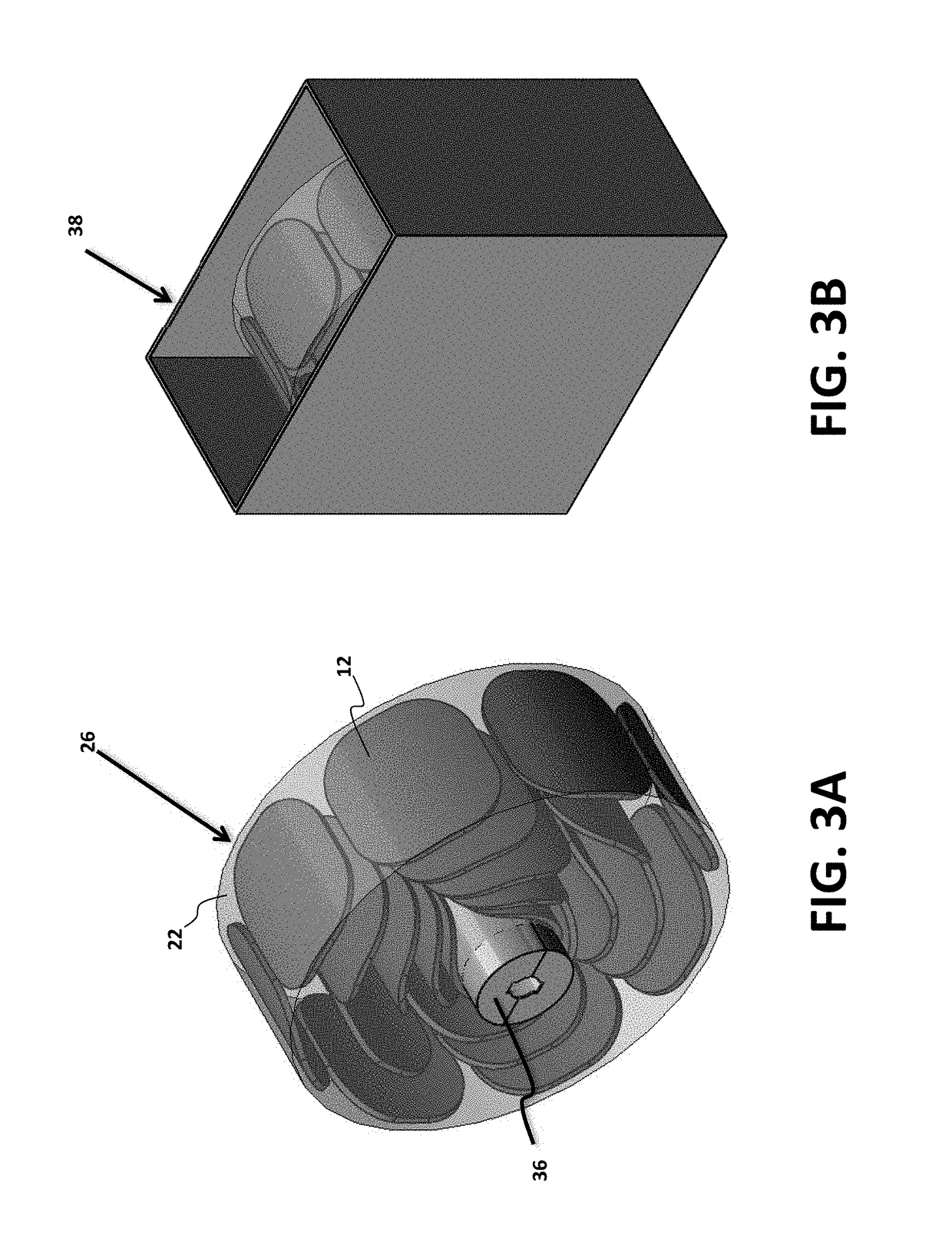

An apparatus and system for loading items onto a rack is described. The rack loading apparatus is includes a stuffer / clipper for making sausages, a belt conveyor for receiving a sausage from the stuffer / clipper and conveying the sausage to a rotary conveyor, the rotary conveyor comprising a plurality of stages and having a loading side for receiving a sausage and an unloading side for discharging a sausage, a rack comprising a frame supporting a plurality of trays, a positioner to align the rack with the unloading side, a controller to cause the rotary conveyor to align a one of the plurality of stages on the loading side with the belt conveyor to receive a sausage from the stuffer / clipper and to rotate the rotary conveyor to align the one of the plurality of stages on the unloading side with a one of the plurality of trays, and a load pusher to discharge the sausage off the one of the plurality of stages and onto the one of the plurality of trays, the pusher comprising a plurality of tabs extending on a rotatable arm. In another embodiment, a rack loading apparatus for loading other manufactured items is described.

Owner:POLY CLIP SYST

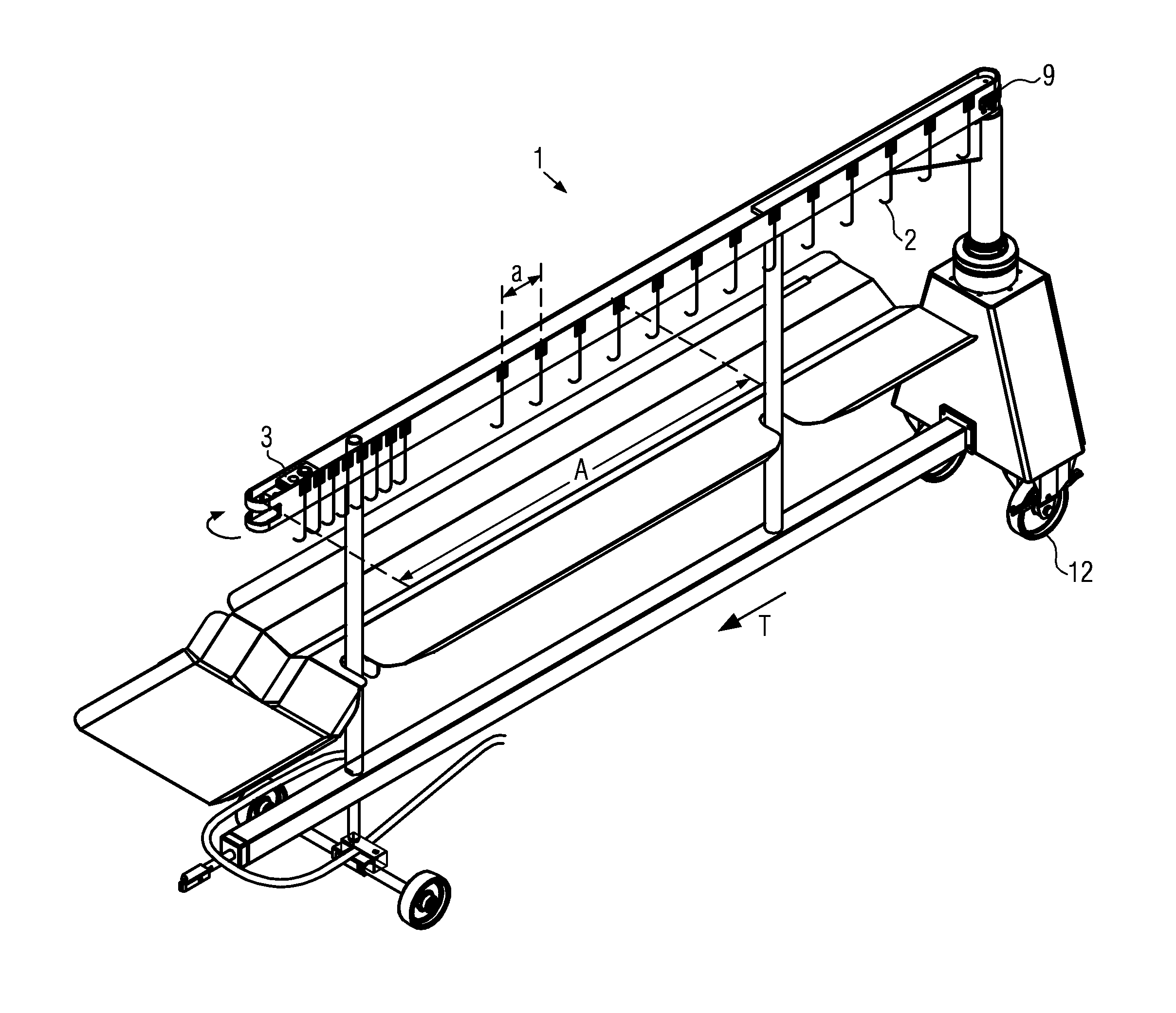

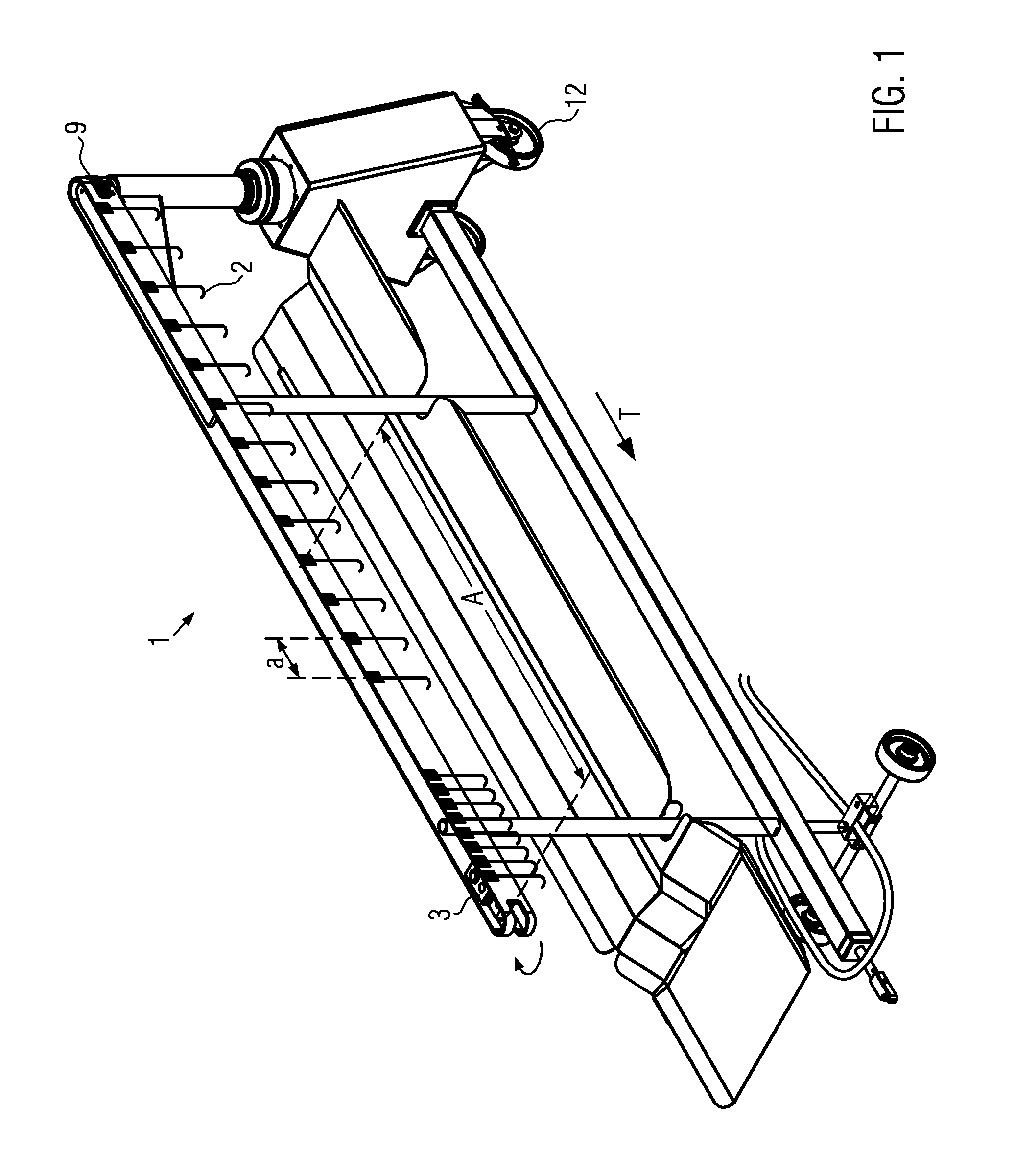

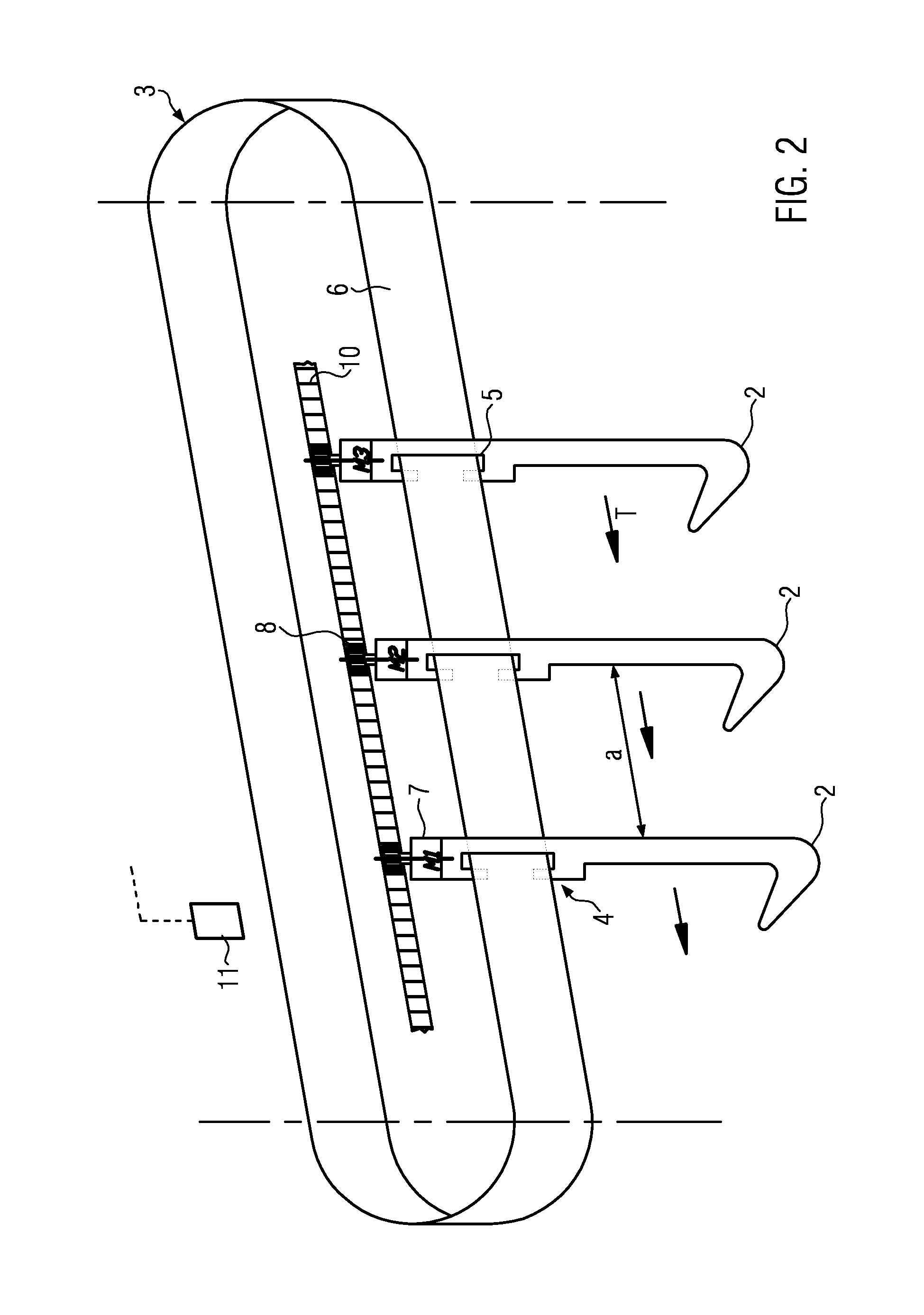

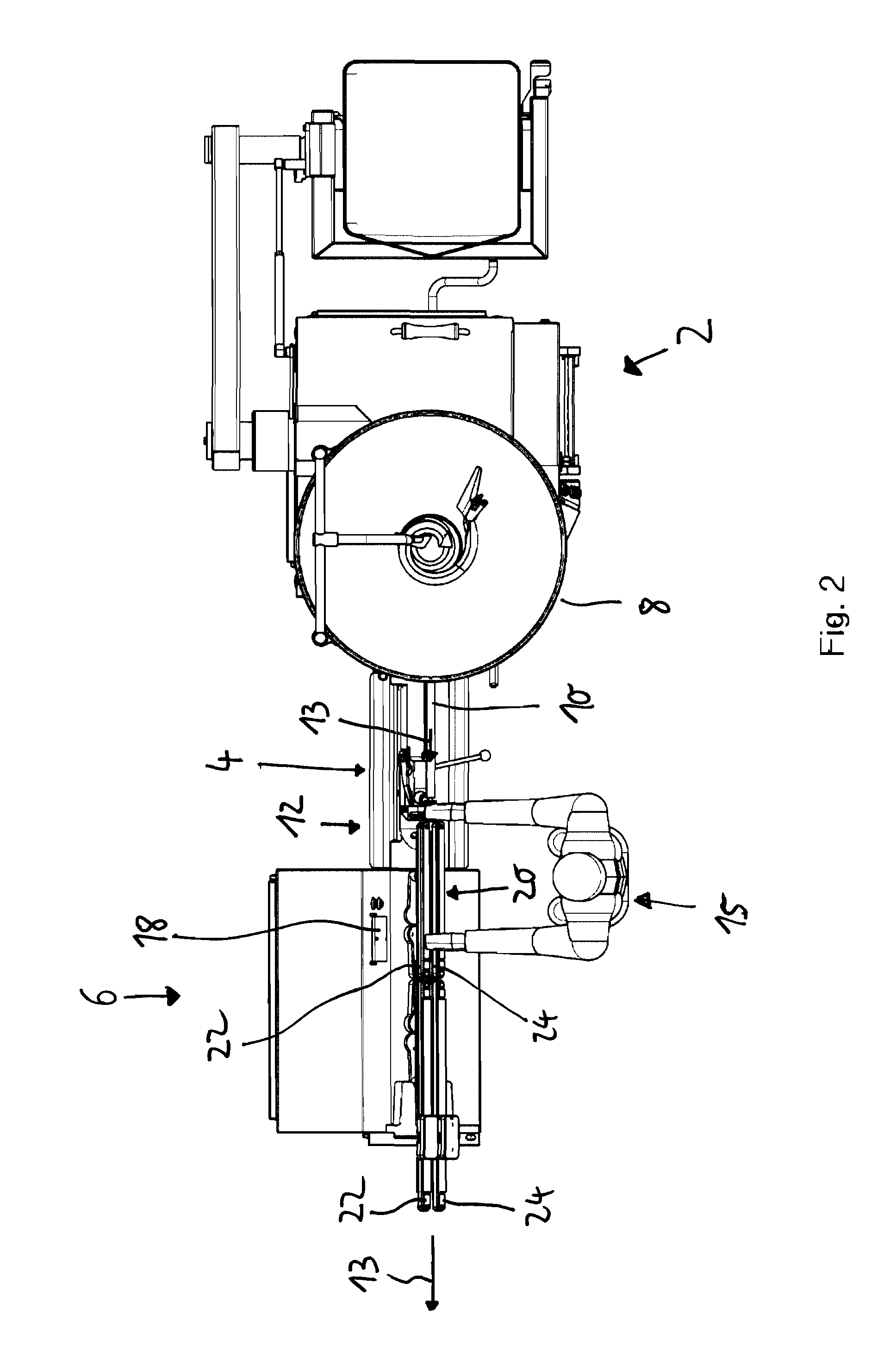

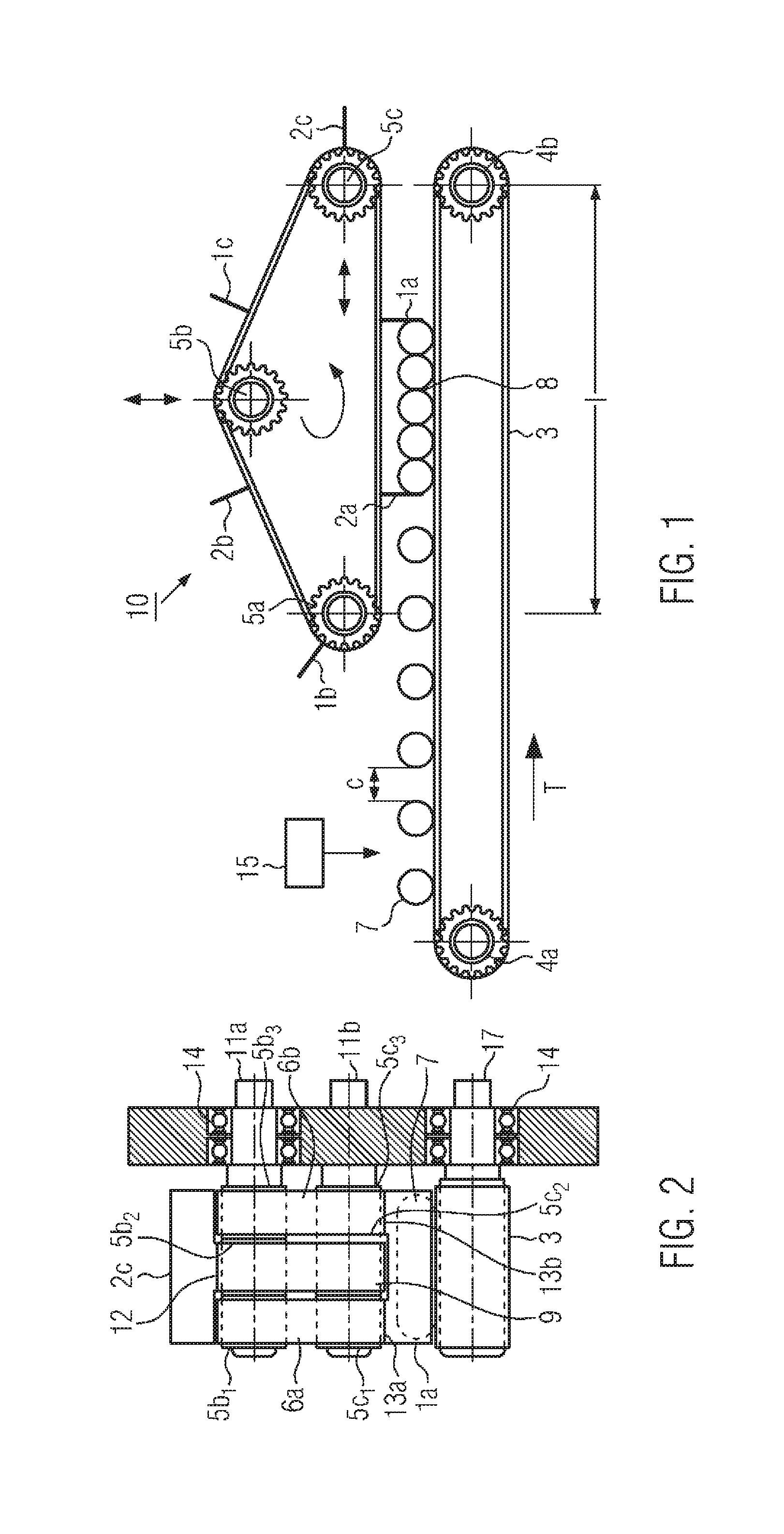

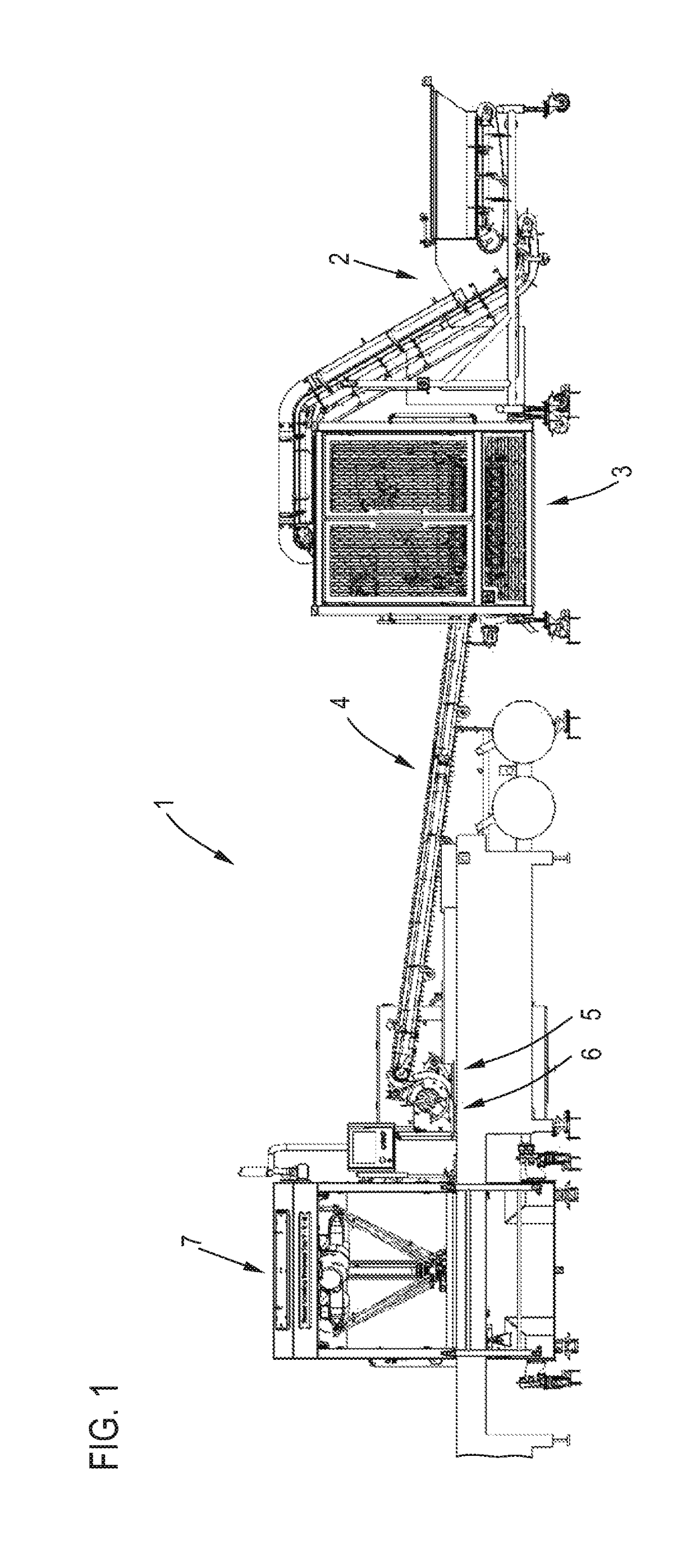

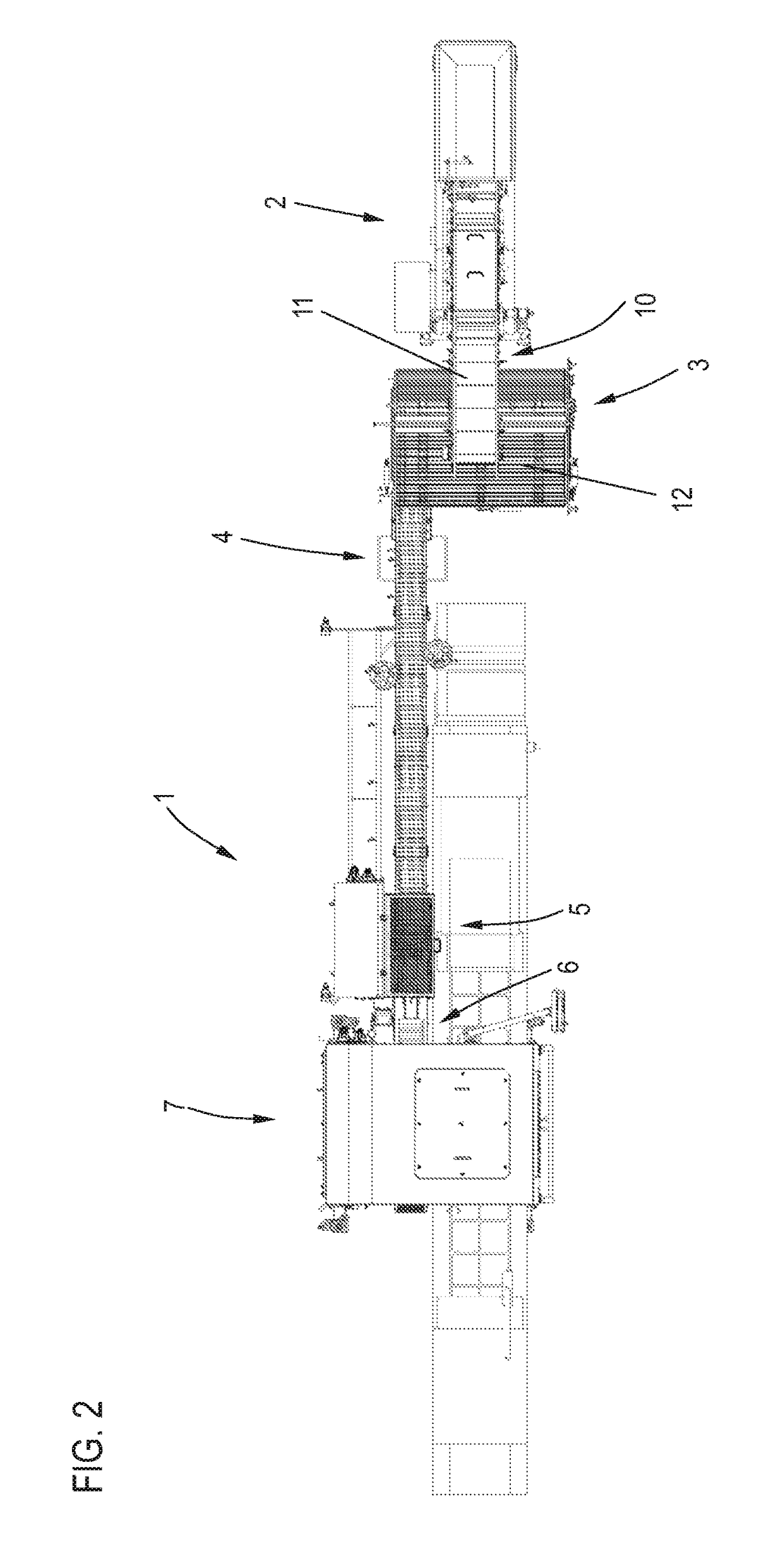

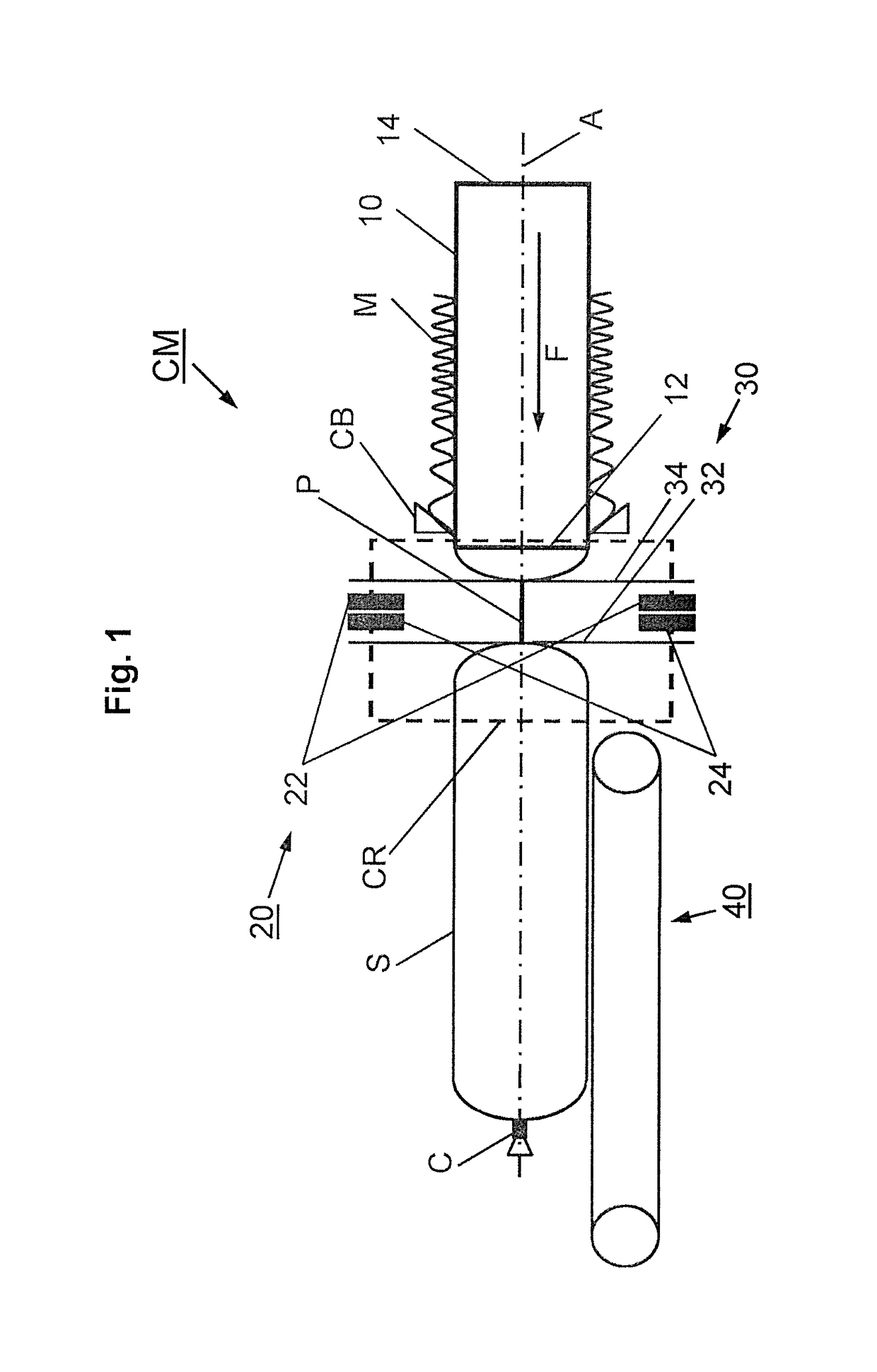

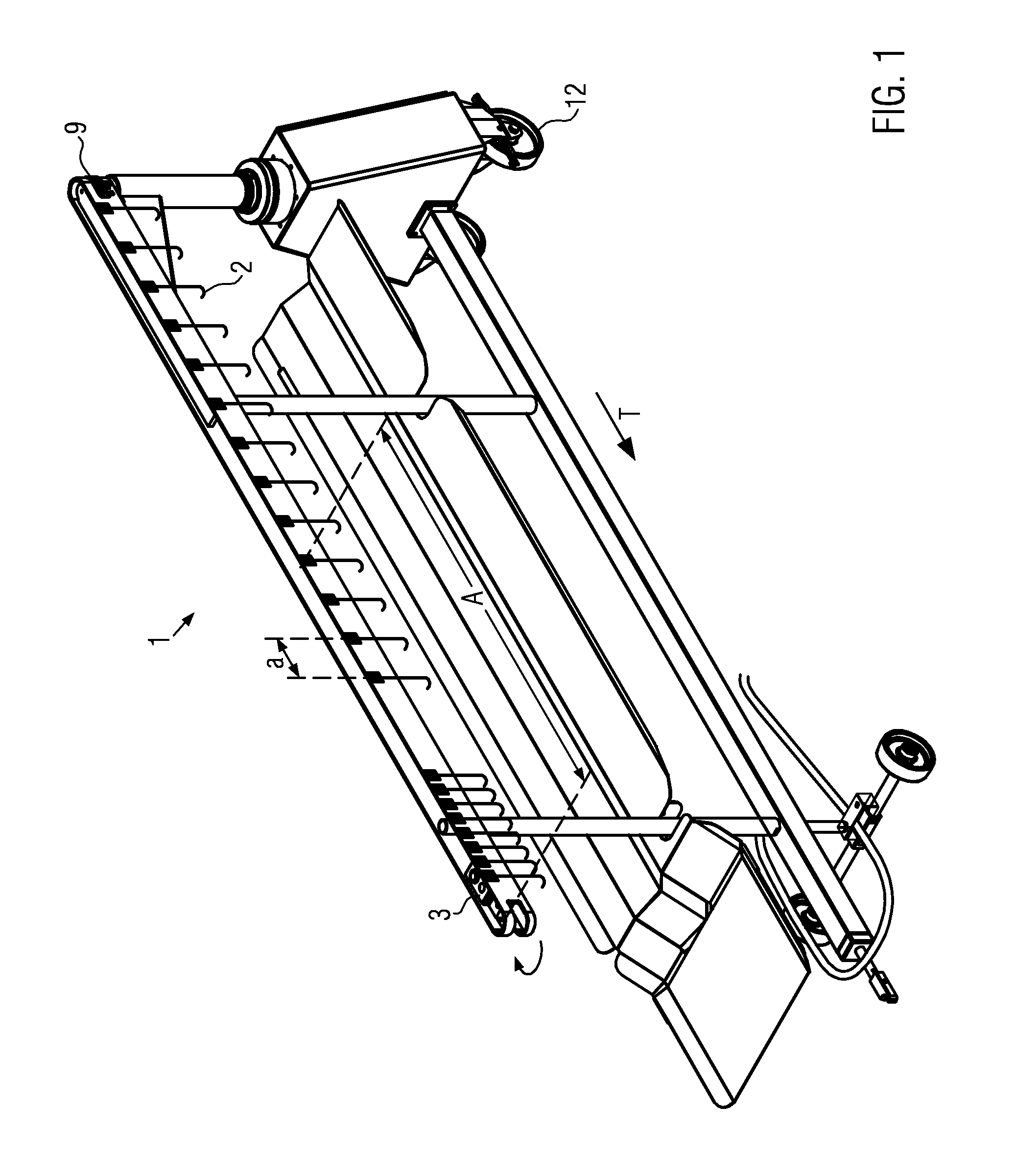

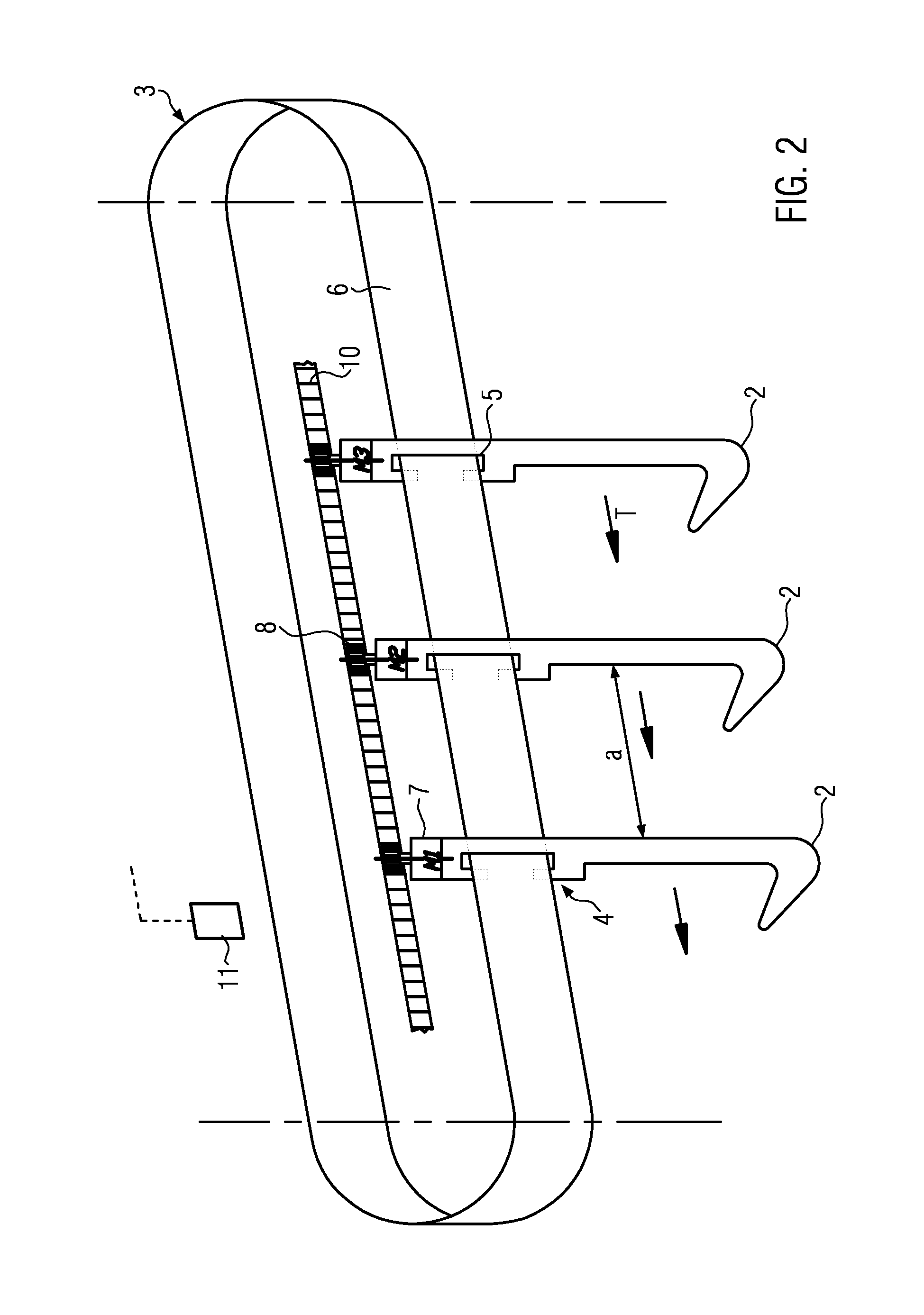

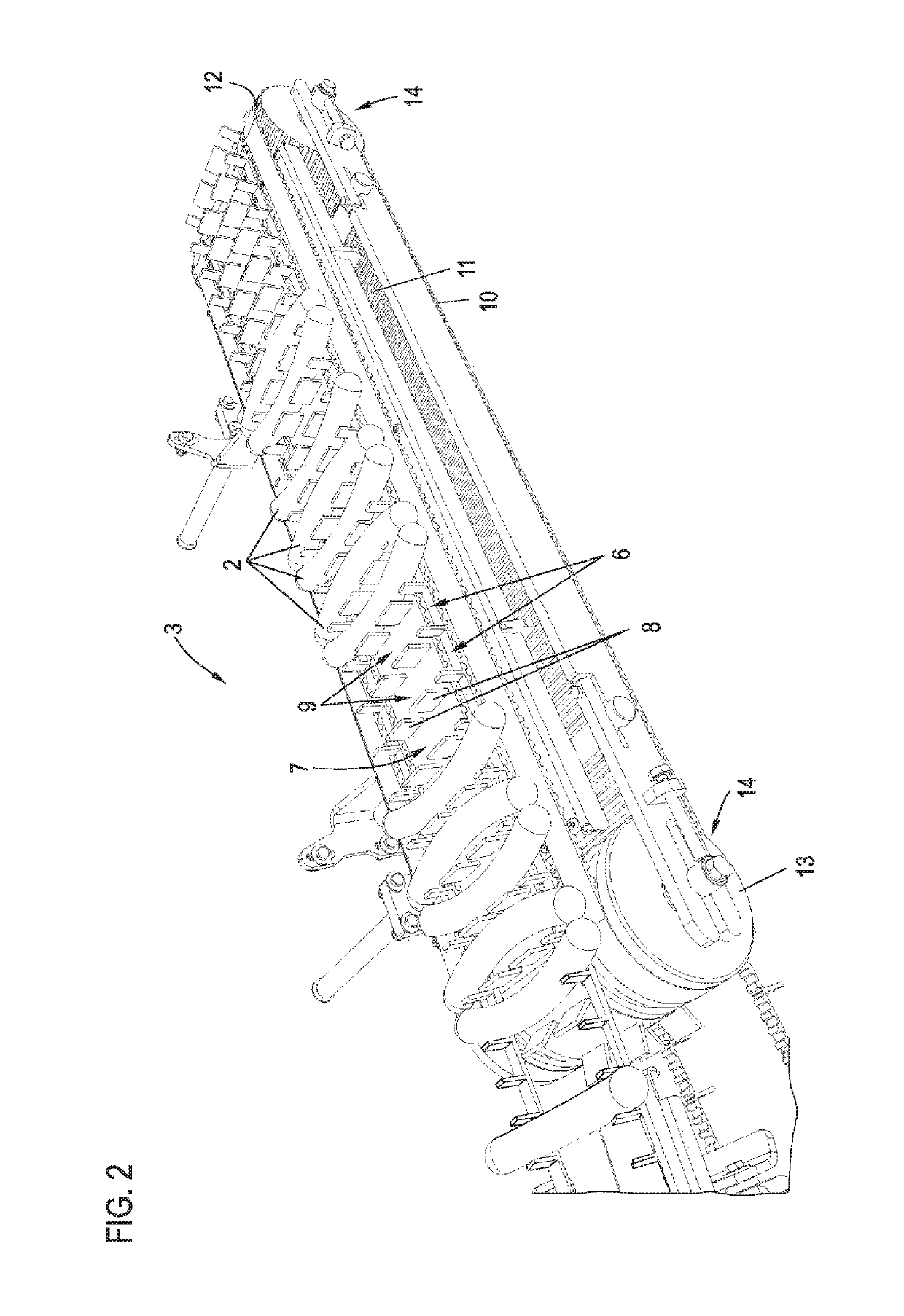

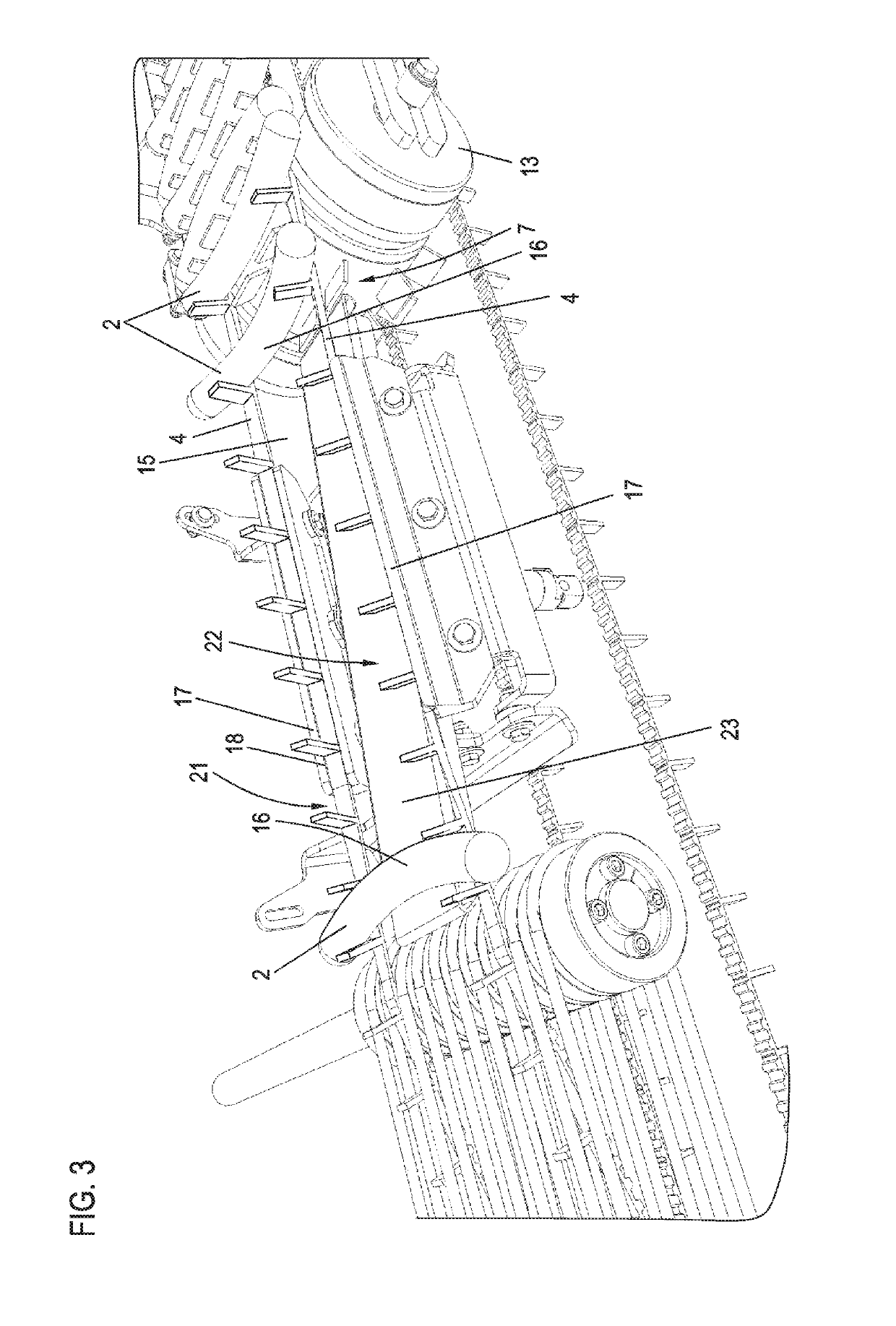

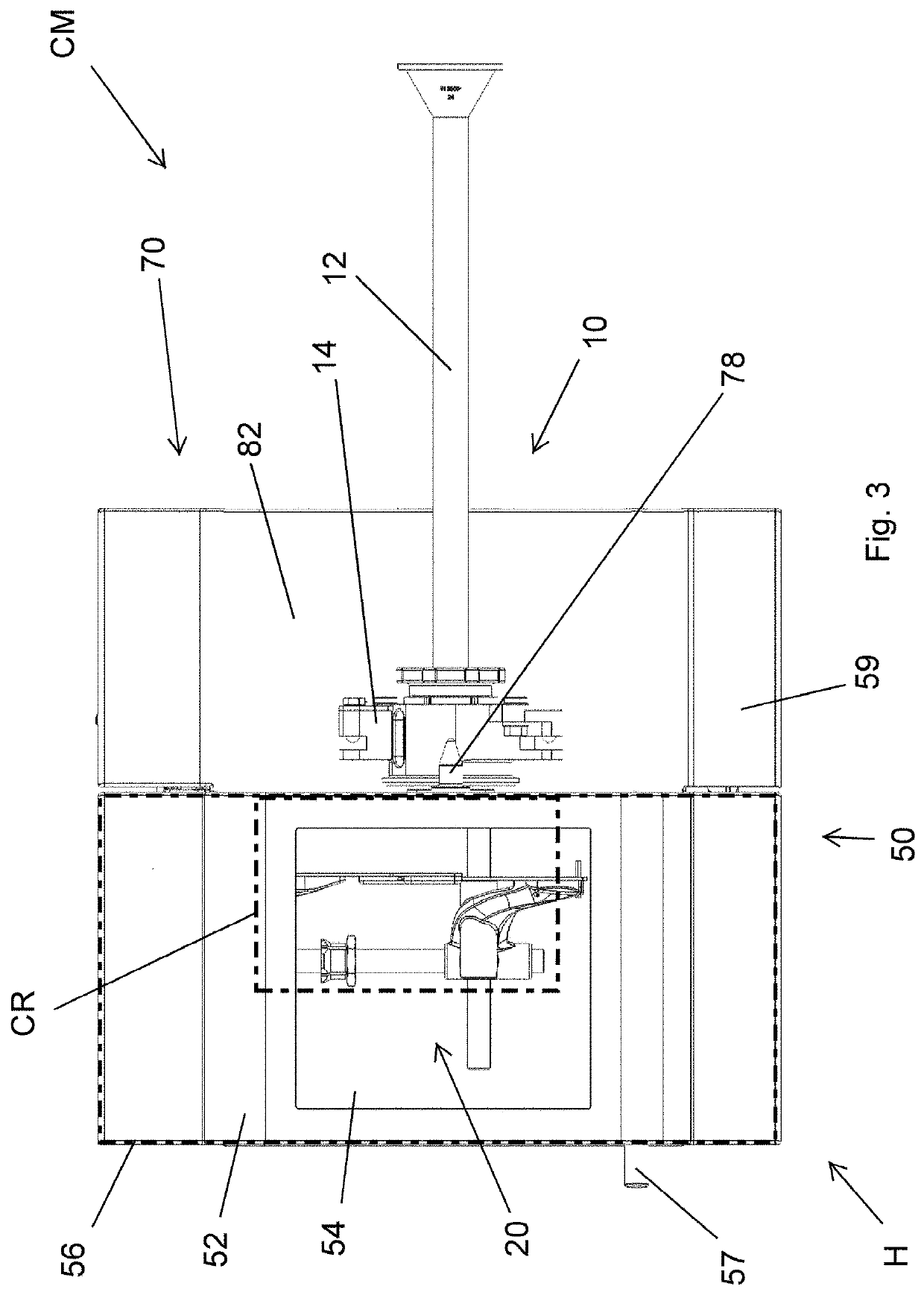

Continuous automatic rack loader

ActiveUS7121940B2Meat/sausage hanging-upHorizontally conveying sausagesEngineeringMechanical engineering

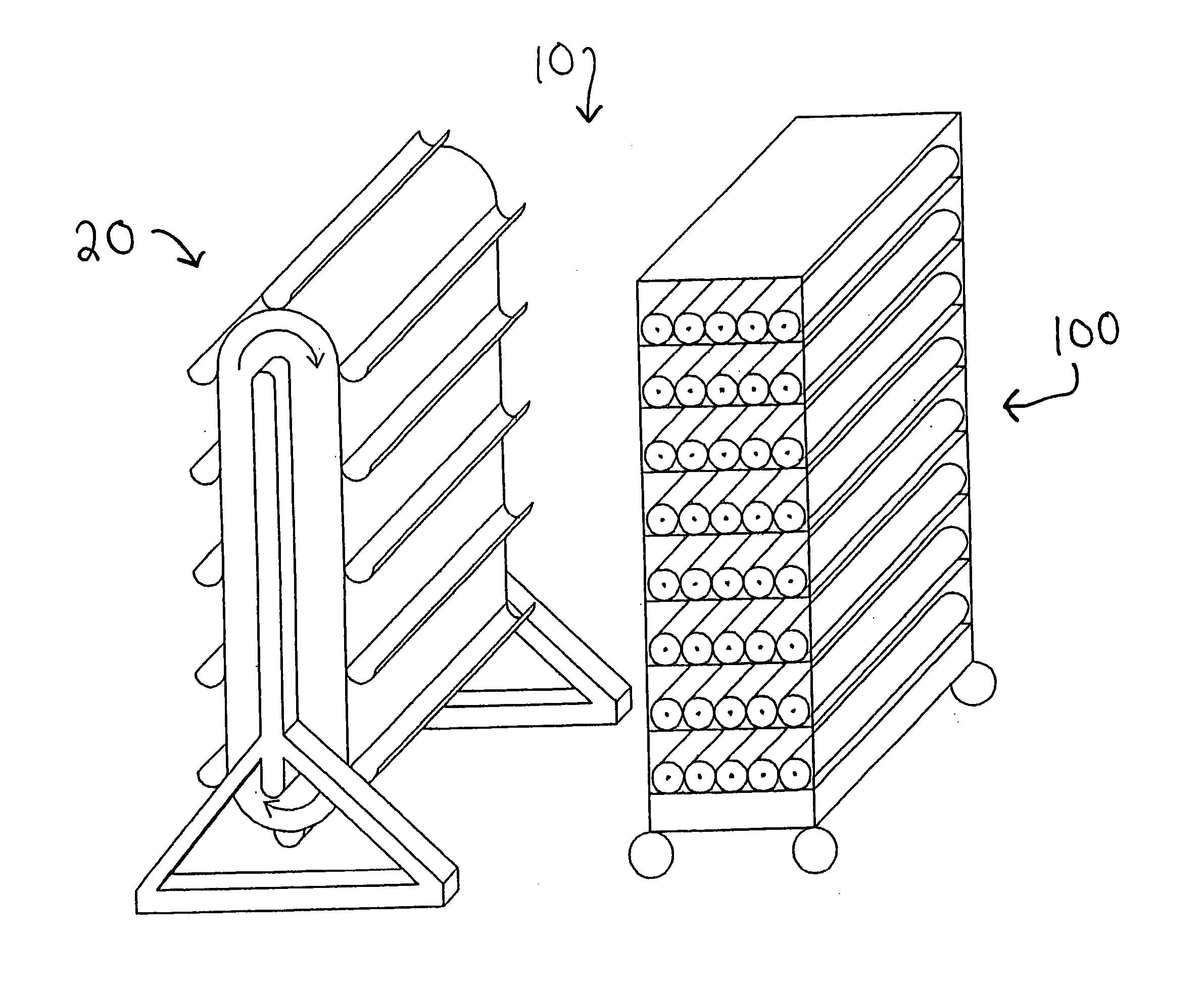

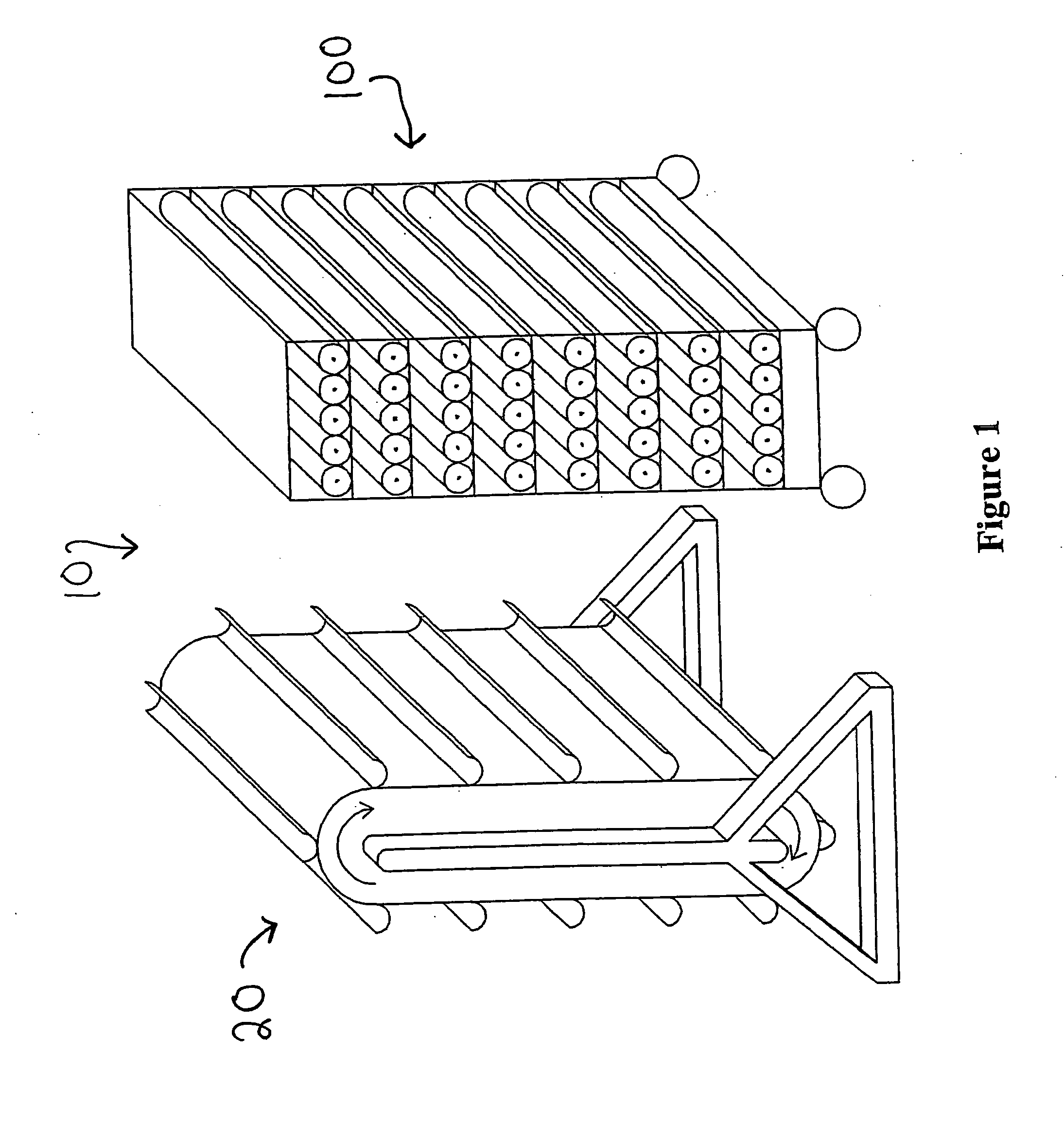

An apparatus for automatically delivering raw sausages to a smokehouse rack is described. A continuous rotating conveyor holds a plurality of half-tubular trays hung on gimbals. Sausages are extruded into a tray at a loading station, and the tray is carried around by the conveyor to an unloading station, where an arm causes the tray to tilt and to roll the sausage onto a smokehouse rack.

Owner:POLY CLIP SYST

Method and apparatus for suspending sausages

ActiveUS20130280996A1Suitable for applicationEasy to adjustMeat/sausage hanging-upHorizontally conveying sausagesEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

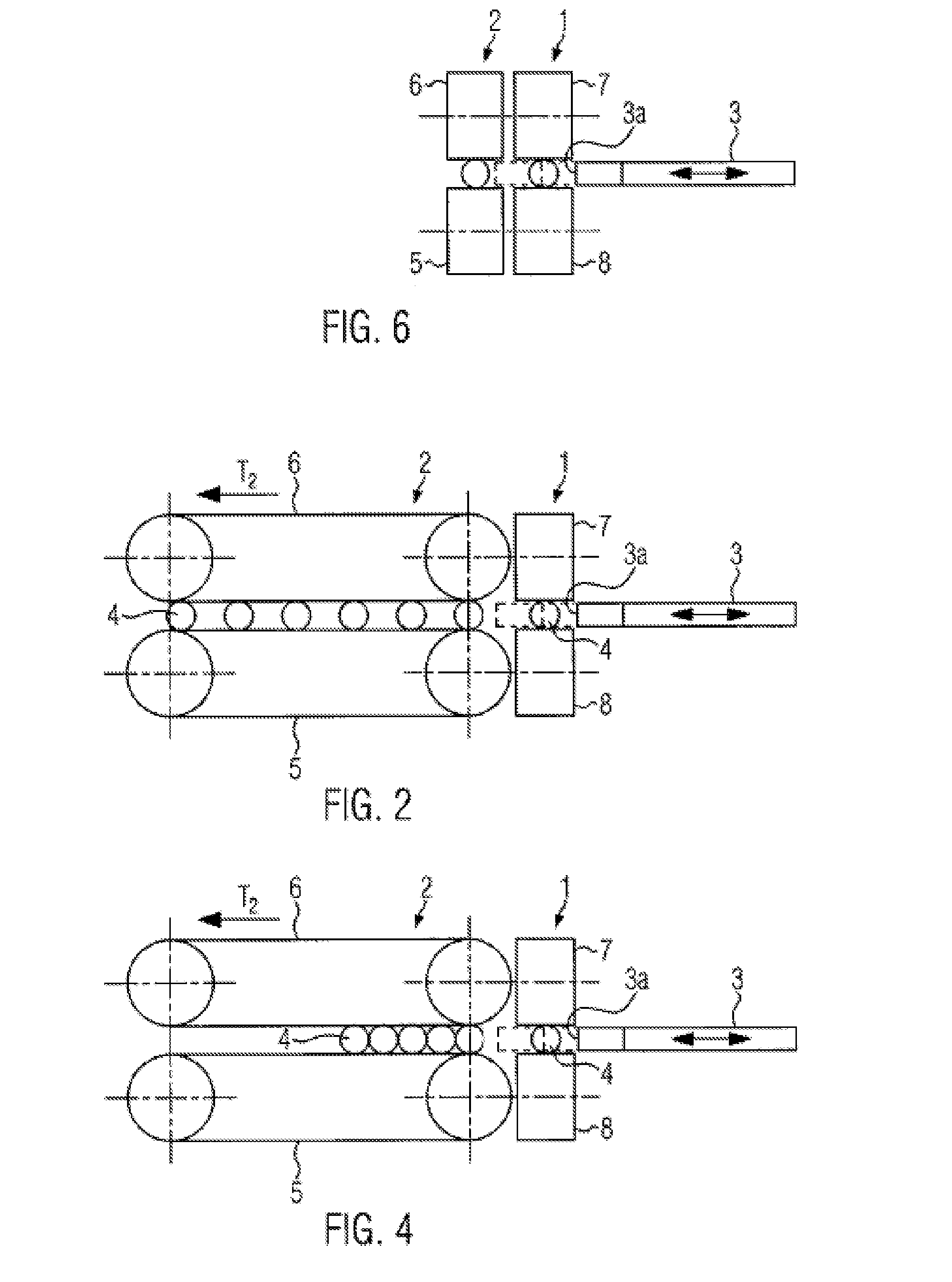

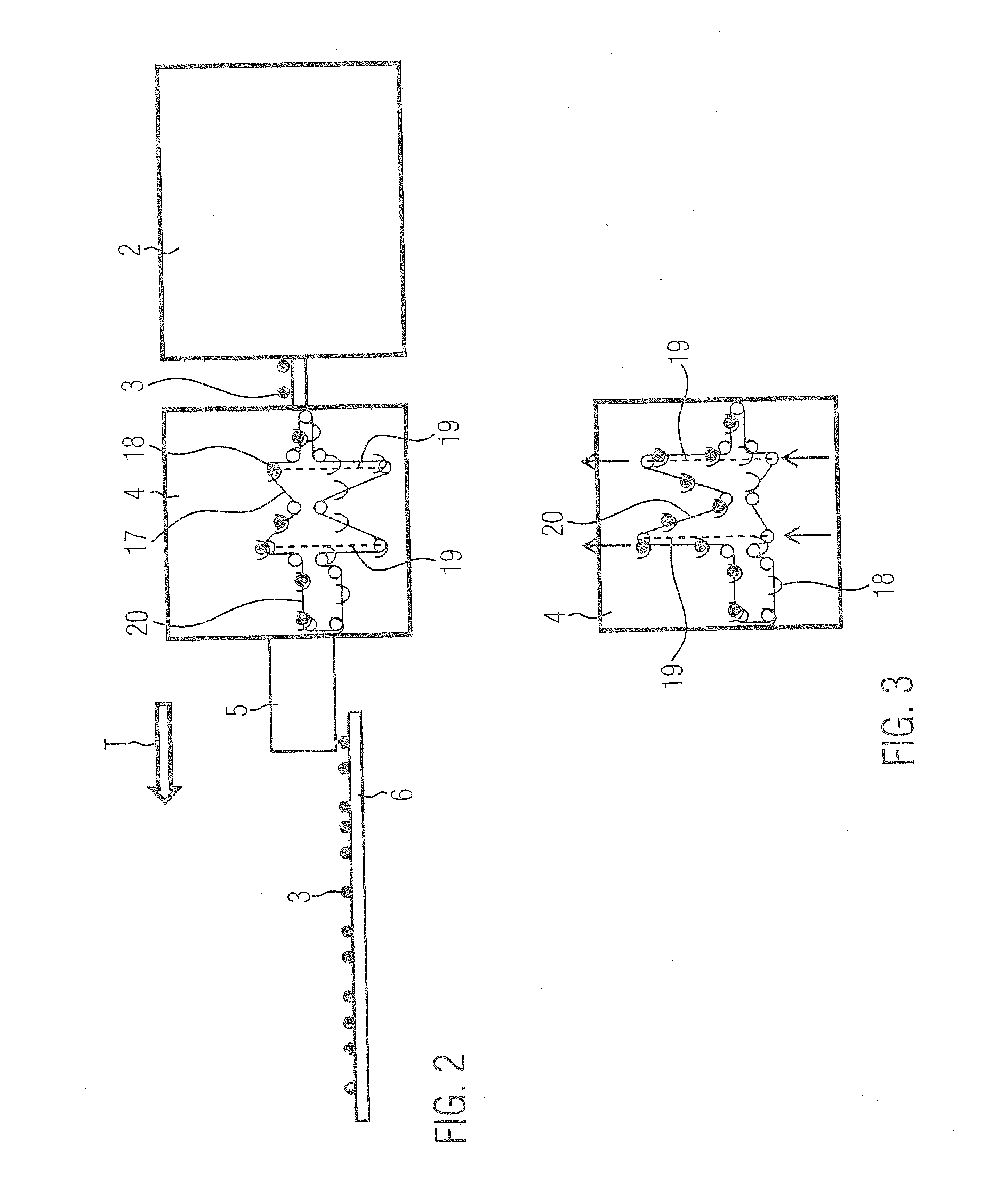

Device and method for transferring longitudinally supplied elongate food products

ActiveUS9504263B2Precise positioningGreat speed/forceMeat/sausage hanging-upHorizontally conveying sausagesEngineeringFood products

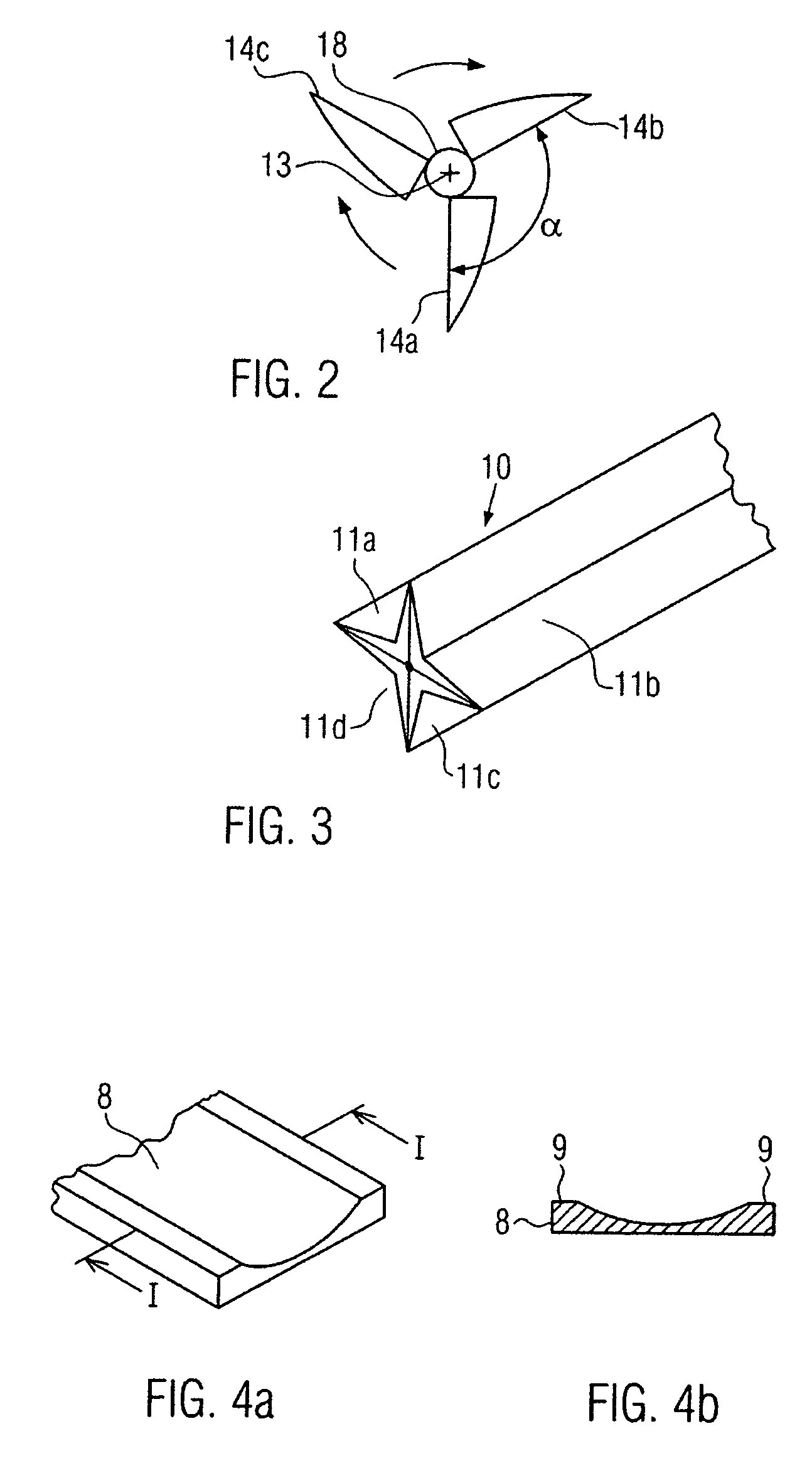

The invention relates to a device (2) for transferring longitudinally supplied elongate food products (4), such as for instance sausages. The sausages are placed here in a recess (10) of a rotatable holder body (9) and subsequently set down in lateral direction. The invention further relates to an assembly (1) of such a transfer device and a feed conveyor (3) for sausages connecting to the transfer device. The invention moreover relates to a method for transferring elongate food products such as sausages.

Owner:MAREL TOWNSEND FURTHER PROCESSING

Production line for continuously cutting off and packing meat sausages

ActiveCN108077387AUniform lengthImprove work efficiencyPackaging meatLinked sausage separationProduction lineEngineering

The invention provides a production line for continuously cutting off and packing meat sausages. The production line also comprises a first supporting plate, a cutting off device and a packing device,wherein the first supporting plate is fixedly arranged on the upper end surface of a bottom plate and used for supporting the meat sausages to move; the cutting off device which is arranged on the front side of the first supporting plate and can cut off the meat sausages; the packing device is used for packing the cut-off meat sausages; the cutting off device comprises a clamping mechanism for clamping the meat sausages to move forwards, a driving mechanism for driving the clamping mechanism to move and a cutting mechanism which is driven by the driving mechanism and can cut the meat sausages; and the cutting mechanism is connected with the packing device. Through the adoption of the production line disclosed by the invention, a plurality of the meat sausages which are arrayed in parallelcan be cut off at the same time, and the meat sausages of which the length is uniform are obtained; the working efficiency is improved; and the labor intensity of workers is reduced.

Owner:NEW HOPE LIUHE

Continuous automatic rack loader

ActiveUS20060178101A1Meat/sausage hanging-upHorizontally conveying sausagesEngineeringMechanical engineering

An apparatus for automatically delivering raw sausages to a smokehouse rack is described. A continuous rotating conveyor holds a plurality of half-tubular trays hung on gimbals. Sausages are extruded into a tray at a loading station, and the tray is carried around by the conveyor to an unloading station, where an arm causes the tray to tilt and to roll the sausage onto a smokehouse rack.

Owner:POLY CLIP SYST

Portioning and/or transport device for portioning and/or transporting elongated sausage or other food products

Owner:VEMAG MASCHENBAU

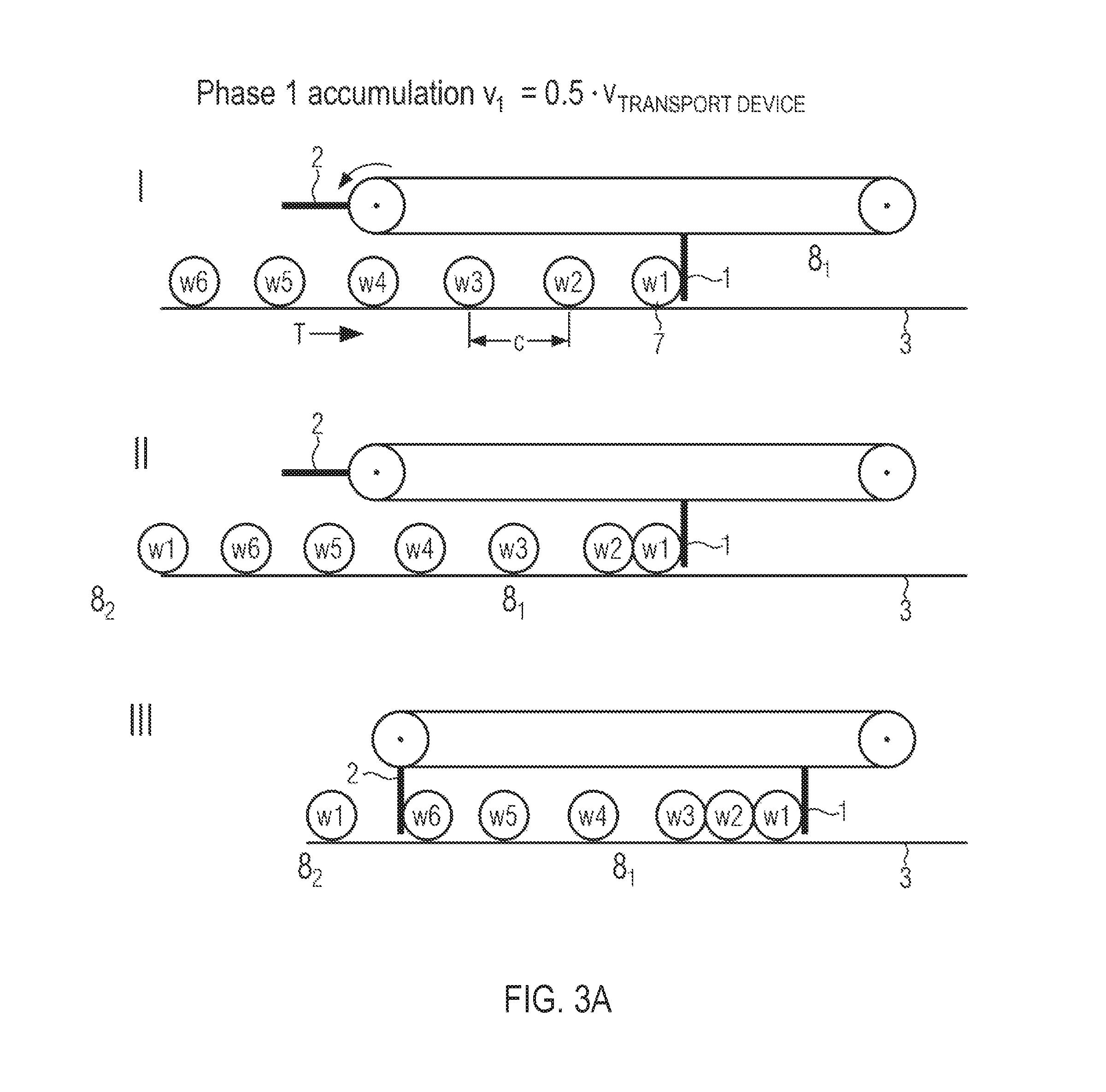

Sausage collating device and method for collating sausages to form sausage groups

Owner:ALBERT HANDTMANN MASCHFABRICK

Device and method for transferring sausage portions

ActiveUS20160143300A1Reduce gapShorten speedMeat packaging/handling/transportingHorizontally conveying sausagesEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Device for the treatment of individual sausages

ActiveUS9944471B2Improve grouping and placementHigh-precision movementProgramme-controlled manipulatorConveyorsEngineeringConveyor belt

Owner:SINGER & SOHN

System and method for processing food product

InactiveUS20190061981A1Packaging meatWrapping material feeding apparatusCollection systemProcess engineering

A system and method are provided for processing and packaging food product. The system includes at least a transportation system configured to move food product on a conveyor belt, and a collection system configured to receive the food product from the transportation system on a disposable conveyor sheet, and further configured to package the disposable conveyor sheet with the food product thereon on and / or in a dispenser pack.

Owner:F R DRAKE

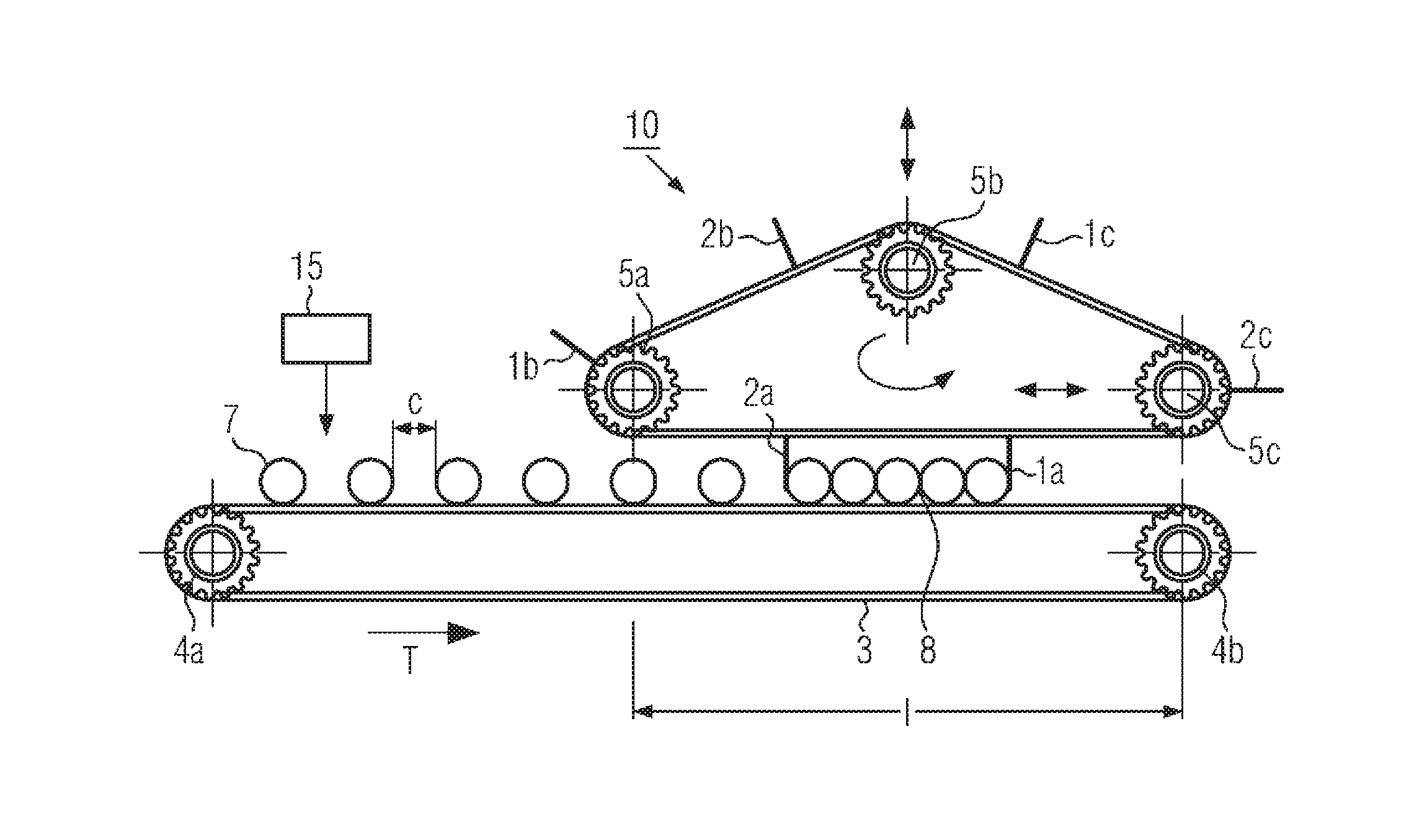

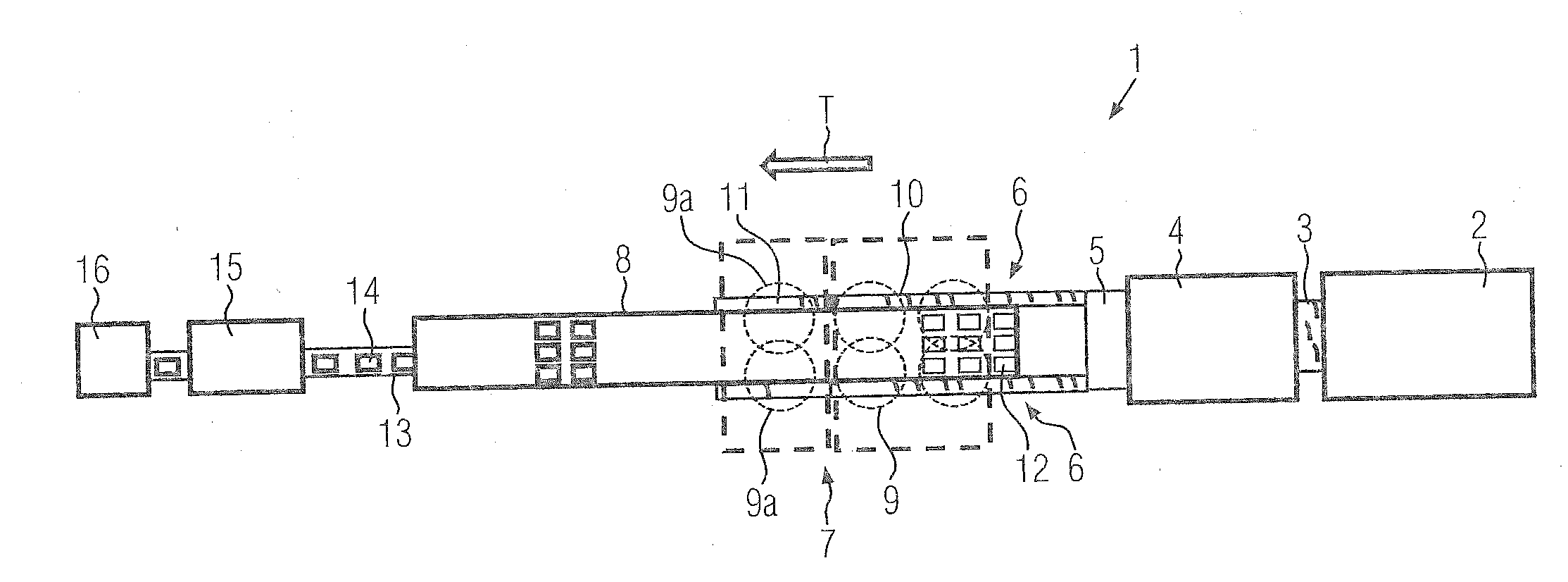

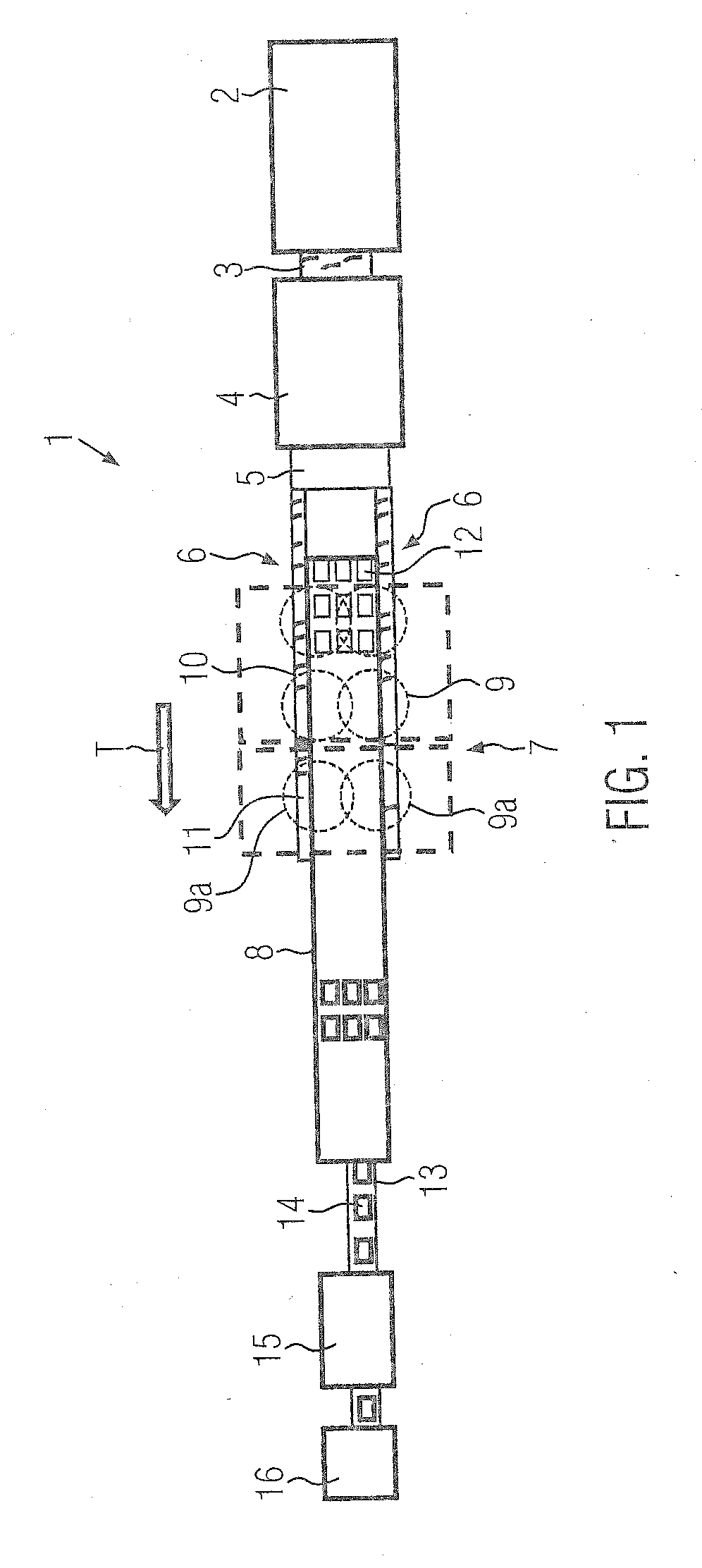

Packaging plant

ActiveUS8979619B2Improve packaging effectReduce distanceHorizontally conveying sausagesRod-shaped articlesBiomedical engineeringInsertion device

The invention relates to a packaging plant for packing sausages or other objects, comprising a manufacturing device, a buffer device, a feeding device, an insertion device, and a packaging machine, the buffer device comprising a length-variable transport section, and a method for operating a packaging plant according to the invention.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

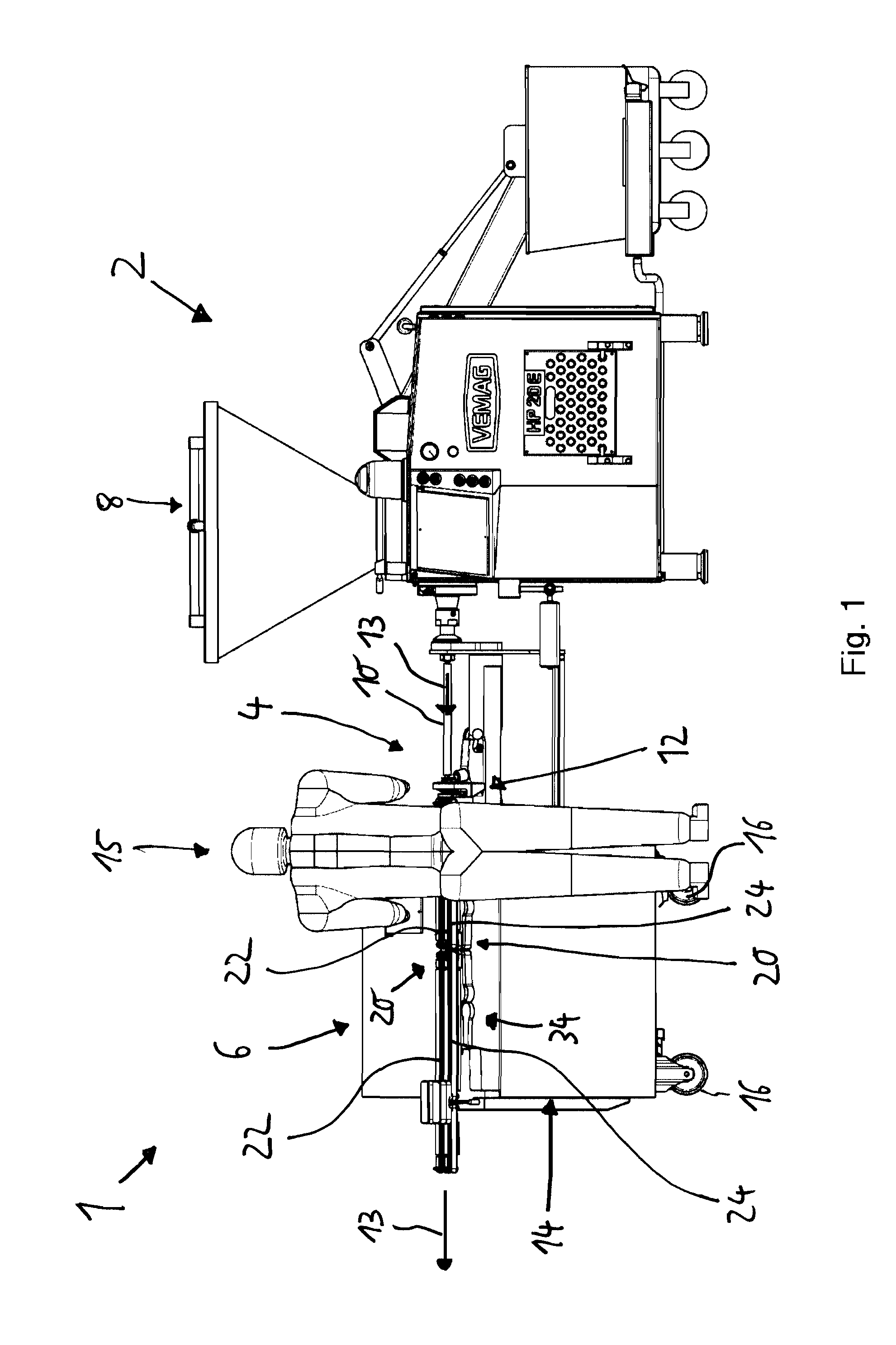

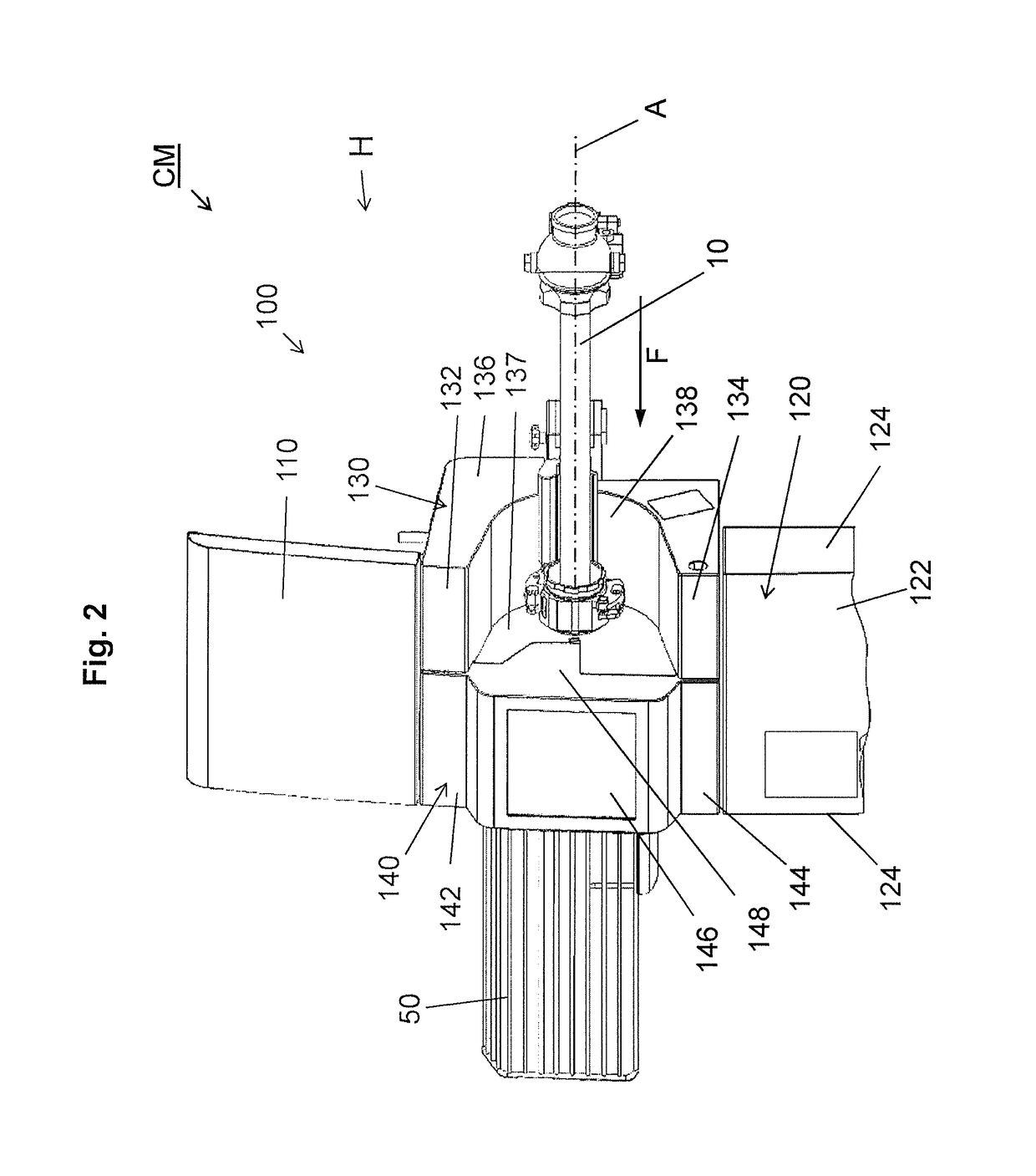

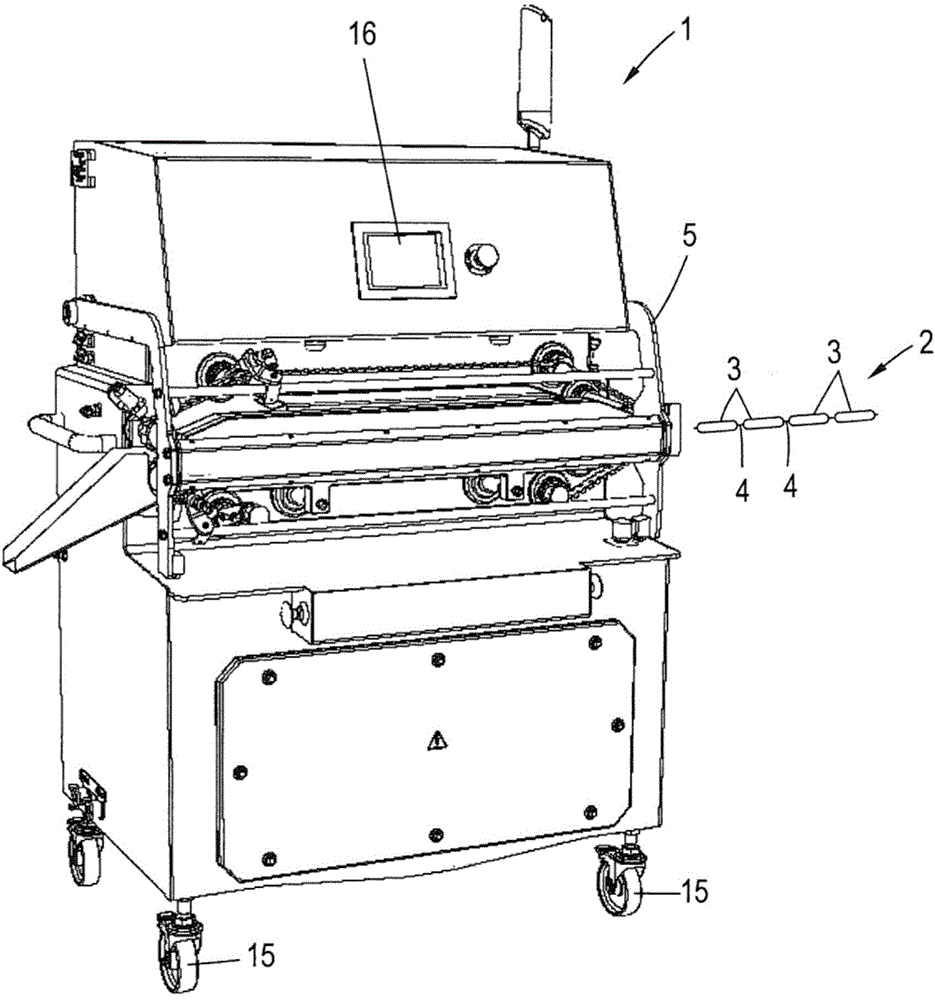

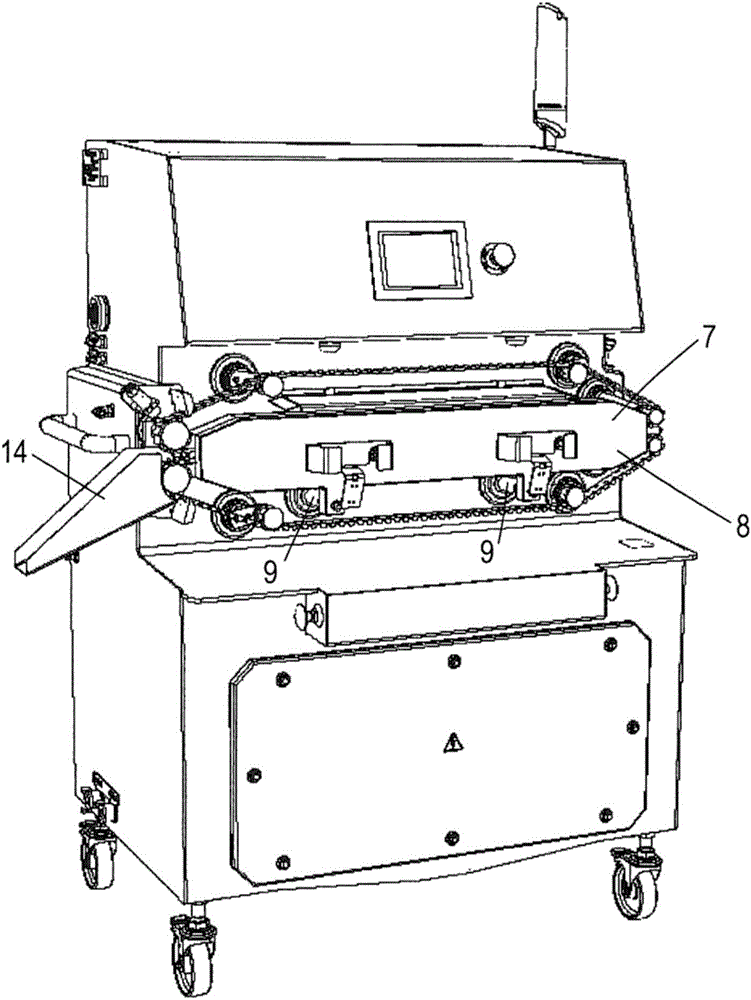

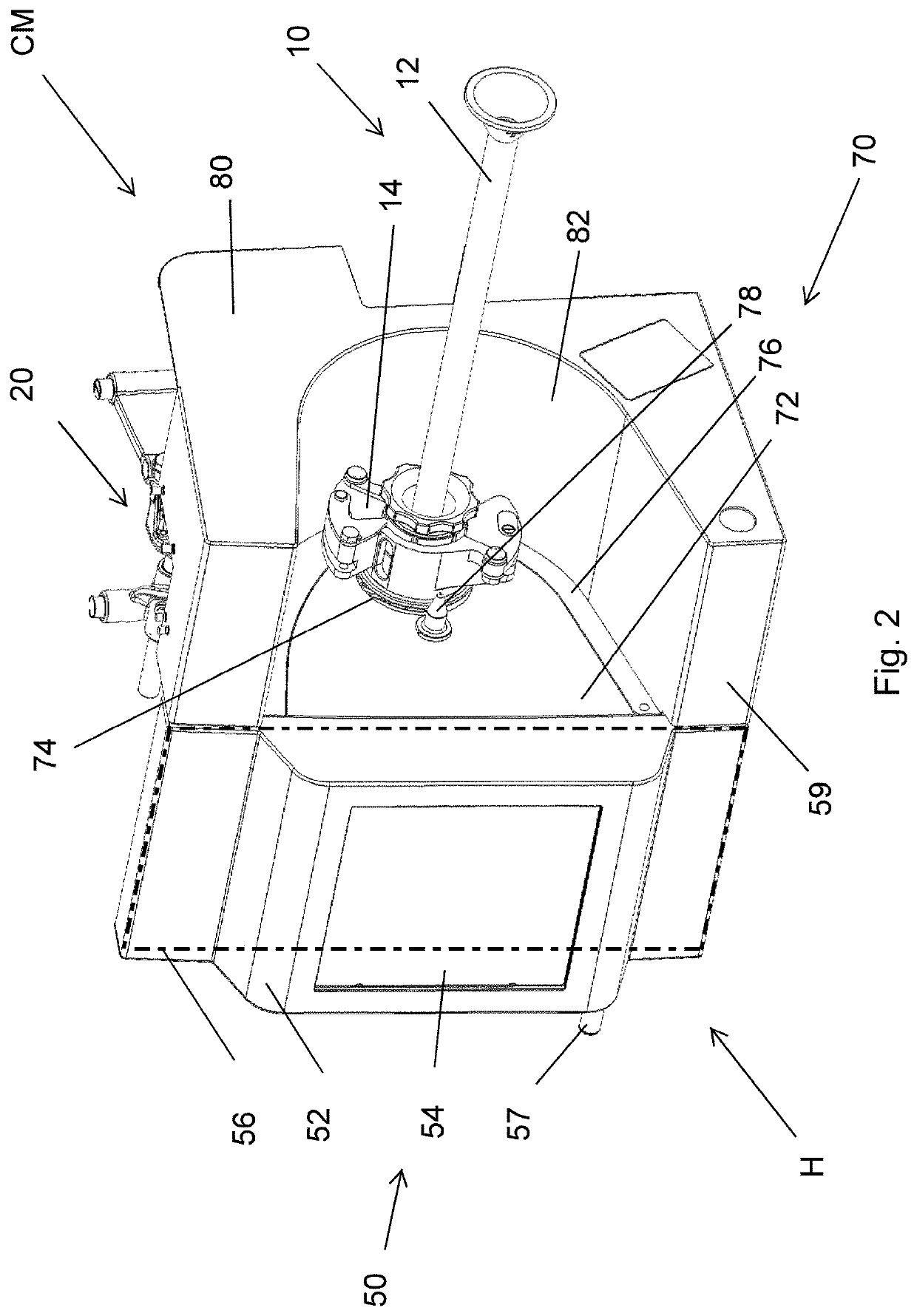

Clipping machine with easy access

ActiveUS9986744B2Reduce stepsPrecise positioningHorizontally conveying sausagesWrapper twisting/gatheringFilling materialsEngineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, by filling a tubular or bag-shaped packaging casing with filling material and closing said filled tubular or bag-shaped packaging casing. The clipping machine includes a filling tube through which the filling material is fed into said tubular or bag-shaped packaging casing which is stored on said filling tube, a casing brake assembly arranged on the filling tube for limiting the movement of the tubular packaging casing at least while being filled, gathering means for gathering said filled tubular packaging casing and for forming a plait-like portion thereto, and a clipping device for applying at least one closure means, like a closure clip, to the plait-like portion formed on the filled tubular or bag-shaped packaging casing in a closing region. The clipping machine further comprises a housing defining at least a front wall, a rear wall, and two side walls of the clipping machine, for enclosing at least the clipping device and the gathering means. The housing includes at least one housing element arranged in the front wall of the housing for covering at least the closing region, wherein the at least one housing element is coupled to the clipping machine by a linking device including a shifting mechanism for reversibly shifting the housing element relative to the clipping machine, in a shifting direction, for granting access to the closing region of the clipping machine.

Owner:POLY CLIP SYST

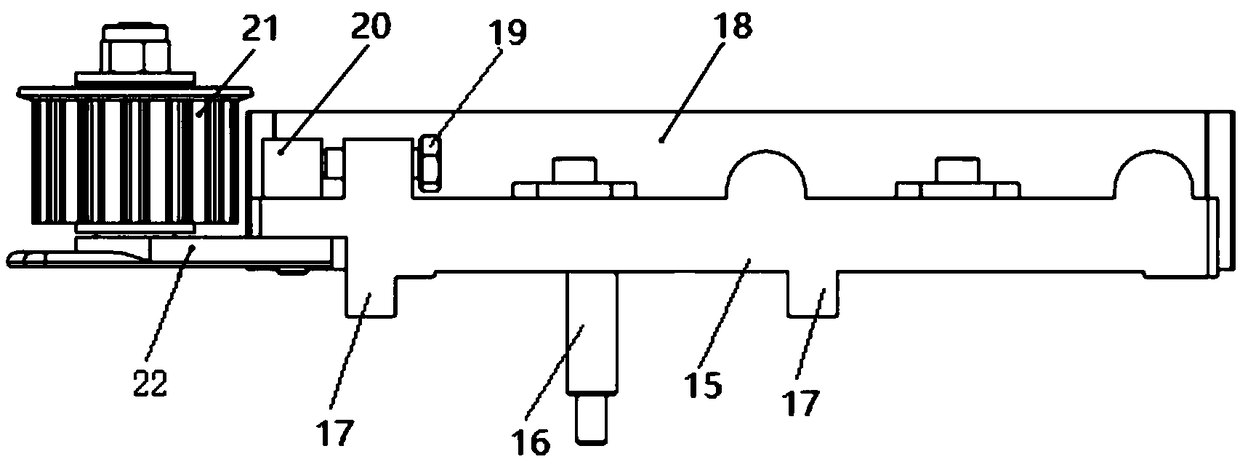

Traction adjusting device of wire tying machine

PendingCN109122793AThe distance is easy to adjustThe appearance is standard and beautifulHorizontally conveying sausagesSausage skin tying apparatusEngineering

The invention relates to the technical field of sausage manufacturing, in particular to a traction adjusting device of a wire tying machine. The traction adjusting device of the wire tying machine comprises a left traction guide mechanism, a right traction guide mechanism, a screw rod supporting seat, a screw rod, a first sliding seat, a second sliding seat, a screw rod fixing seat, a rotating rodand a hand wheel, wherein the screw rod is a positive-negative tooth screw rod; a right-hand thread is arranged at the position where the screw rod contacts with the first sliding seat; a left-hand thread is arranged at the position where the screw rod contacts with the second sliding seat; when the screw rod rotates, the first sliding seat and the second sliding seat arranged on a positive and negative tooth are driven to move in opposite directions or in reverse directions so as to drive column pins on the left traction guide mechanism and the right traction guide mechanism to move in a column pin guide groove and realize adjustment of the distance between the left traction guide mechanism and the right traction guide mechanism; two wire tying machine traction adjusting devices can be arranged side by side on a panel to work at the same time; and the sausage traction machine device provided by the invention can adjust the distance between synchronous belts simply and conveniently and is very suitable for traction of sausages with different diameters.

Owner:佛山市奥楷机械科技有限公司

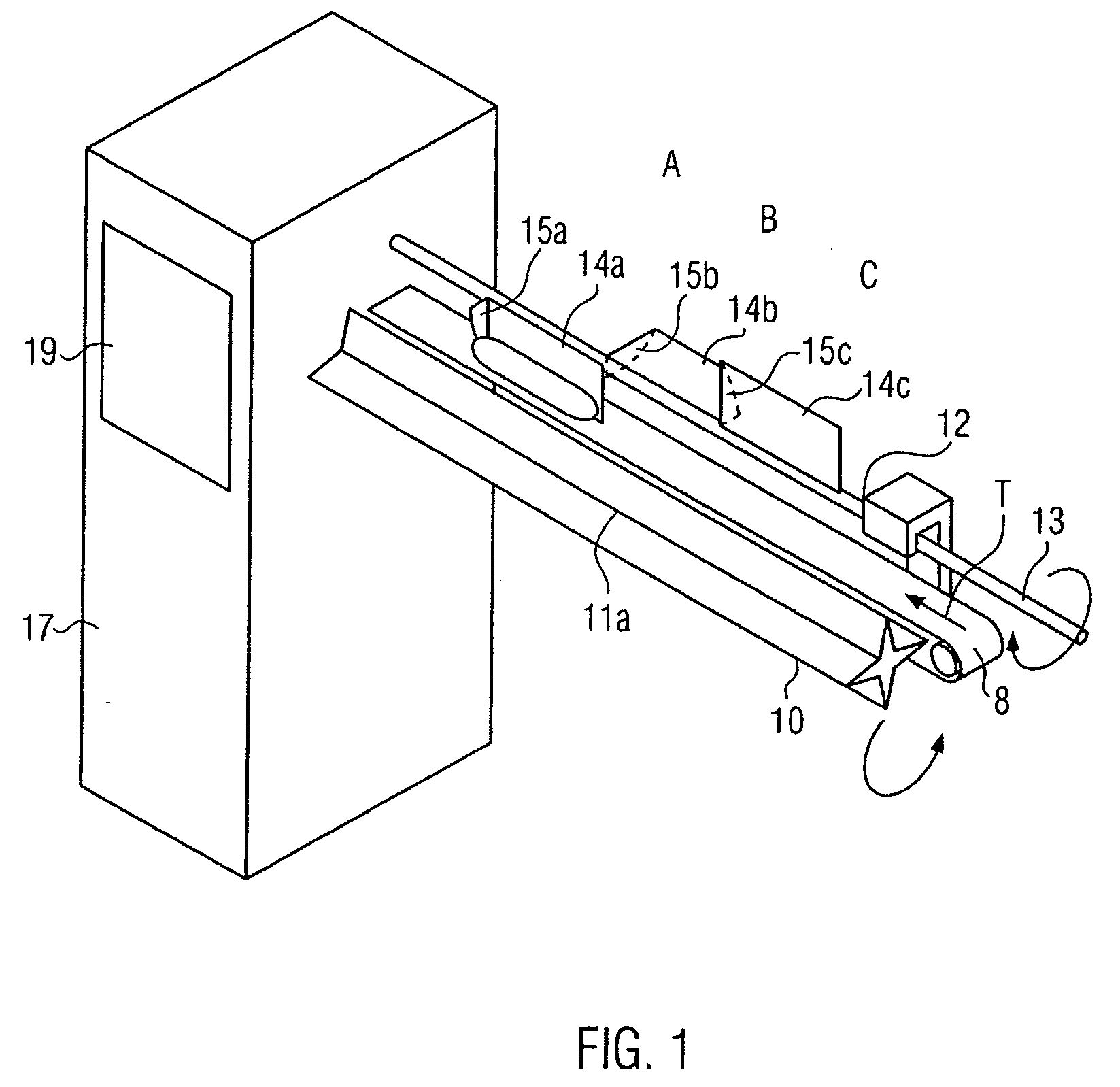

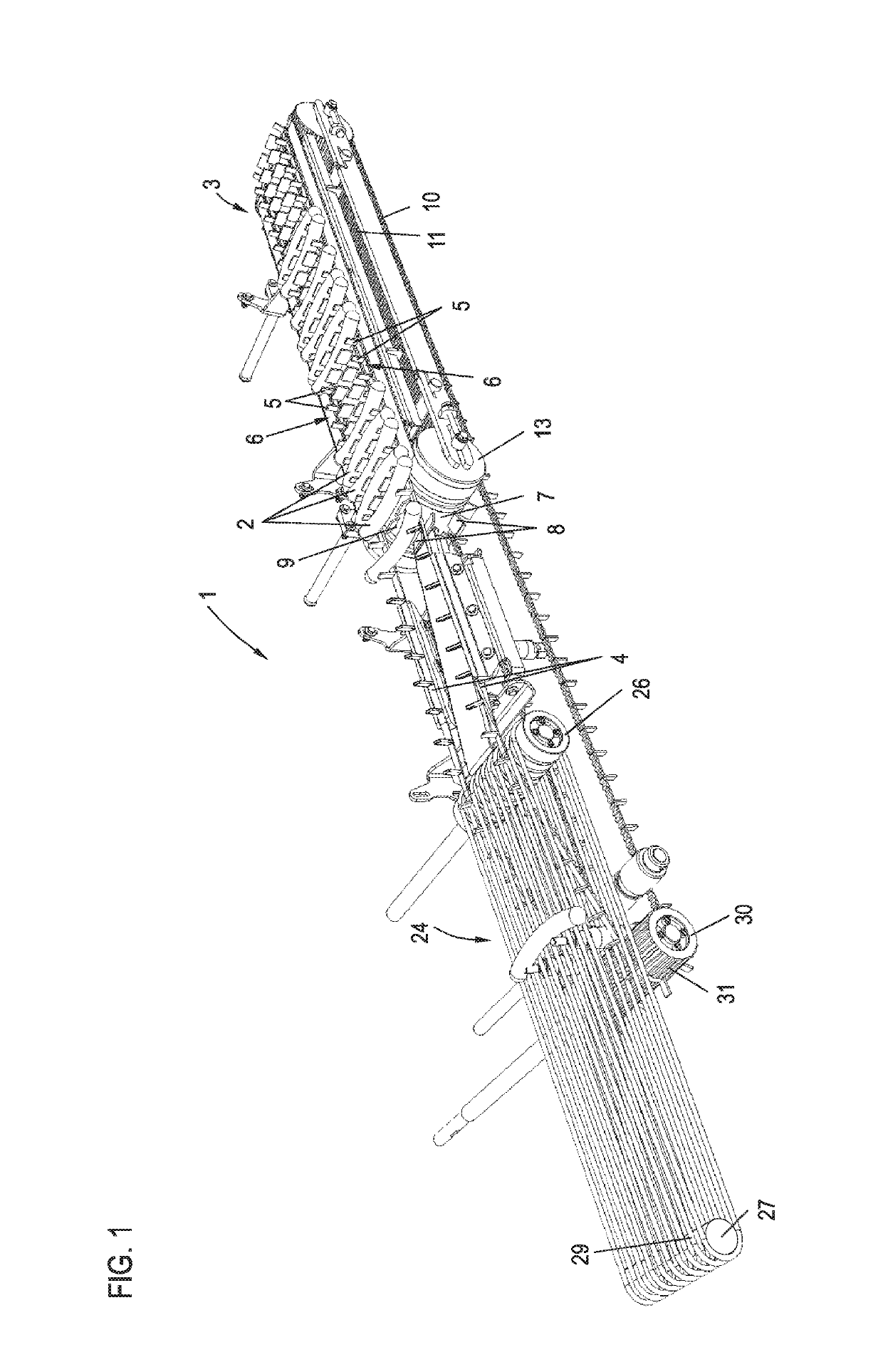

Device and method for the ordered deposition of parted sausage portions

ActiveUS20060240754A1Accurate transferPrecise positioningMeat/sausage hanging-upHorizontally conveying sausagesEngineeringAcceleration Unit

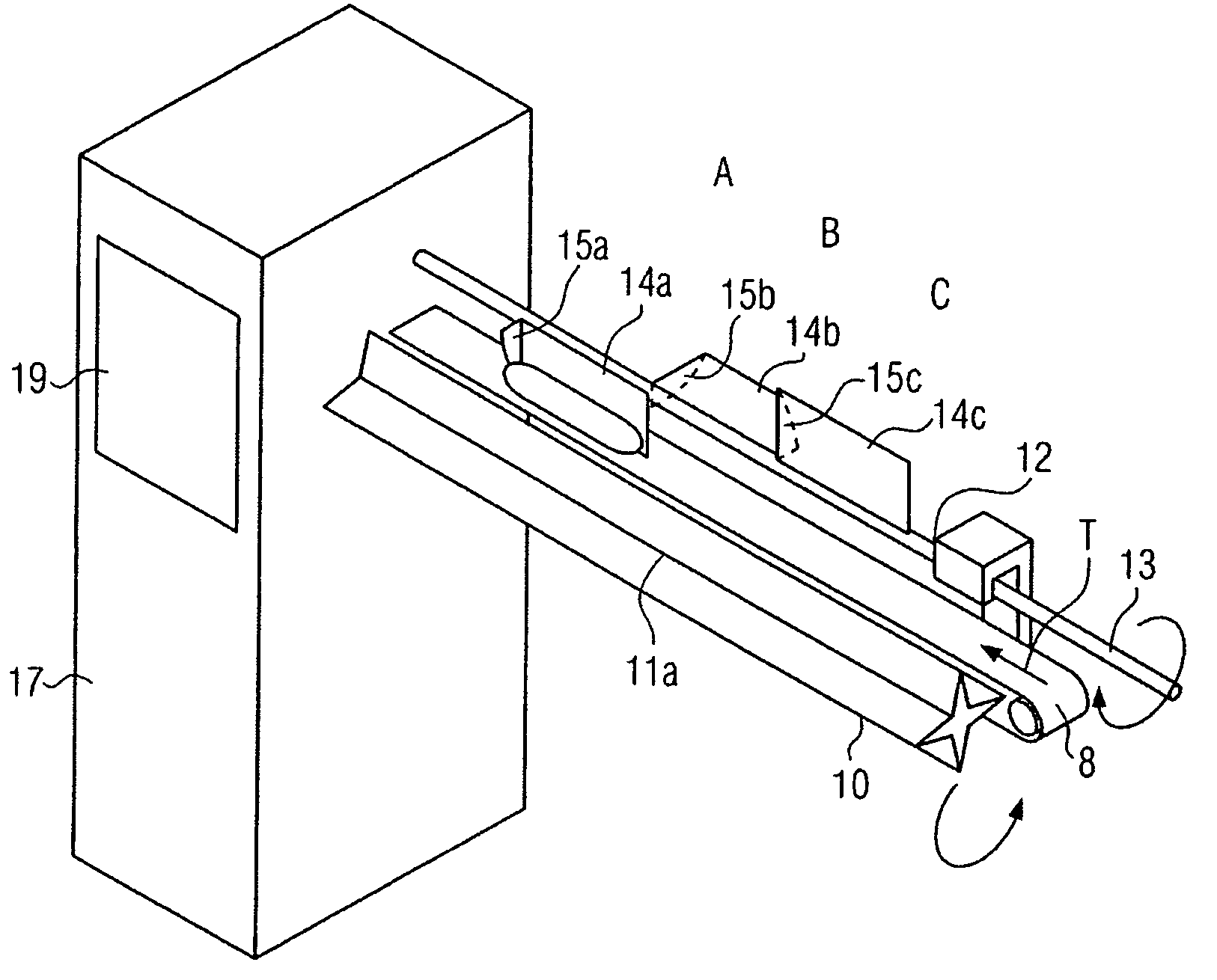

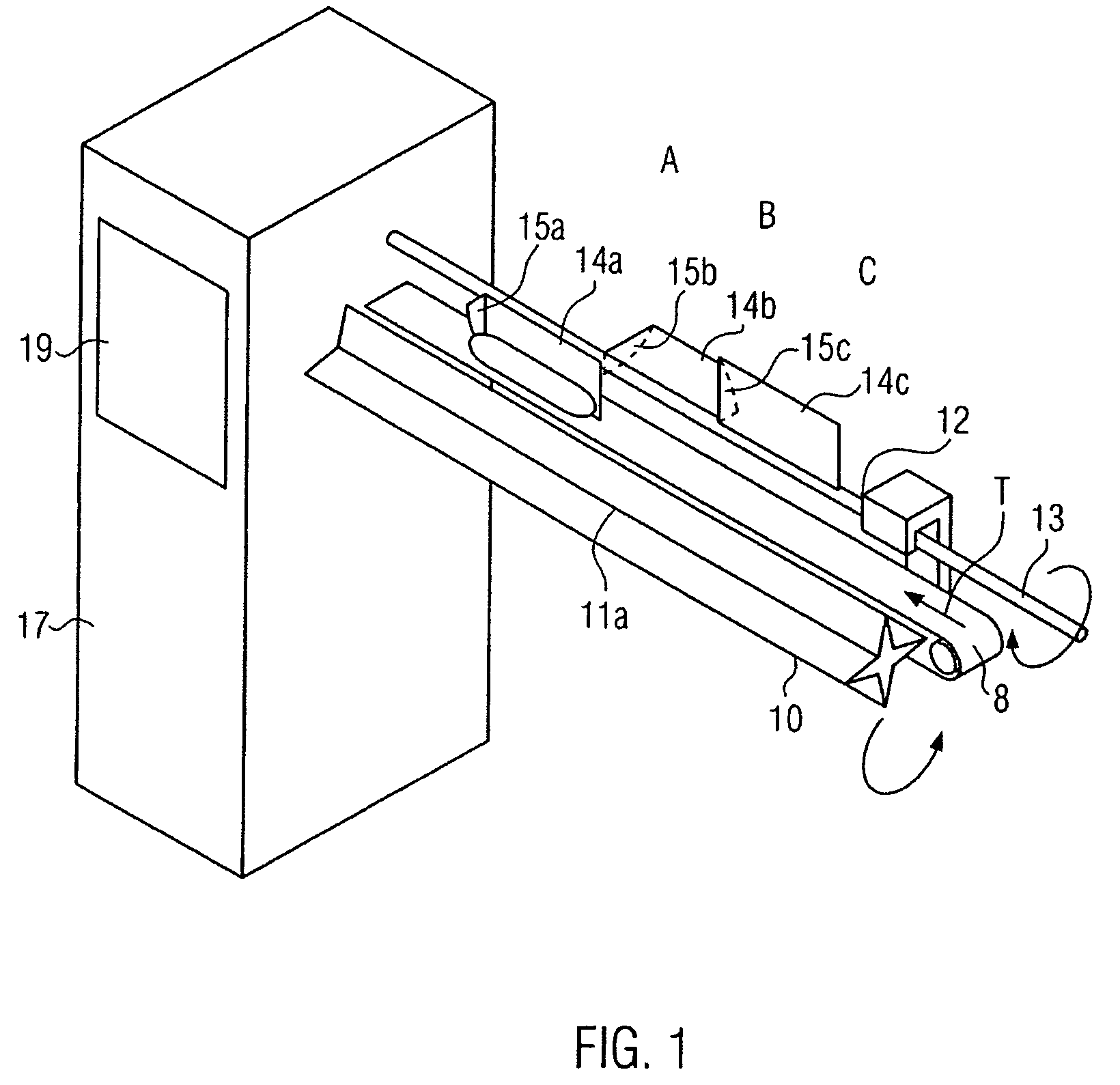

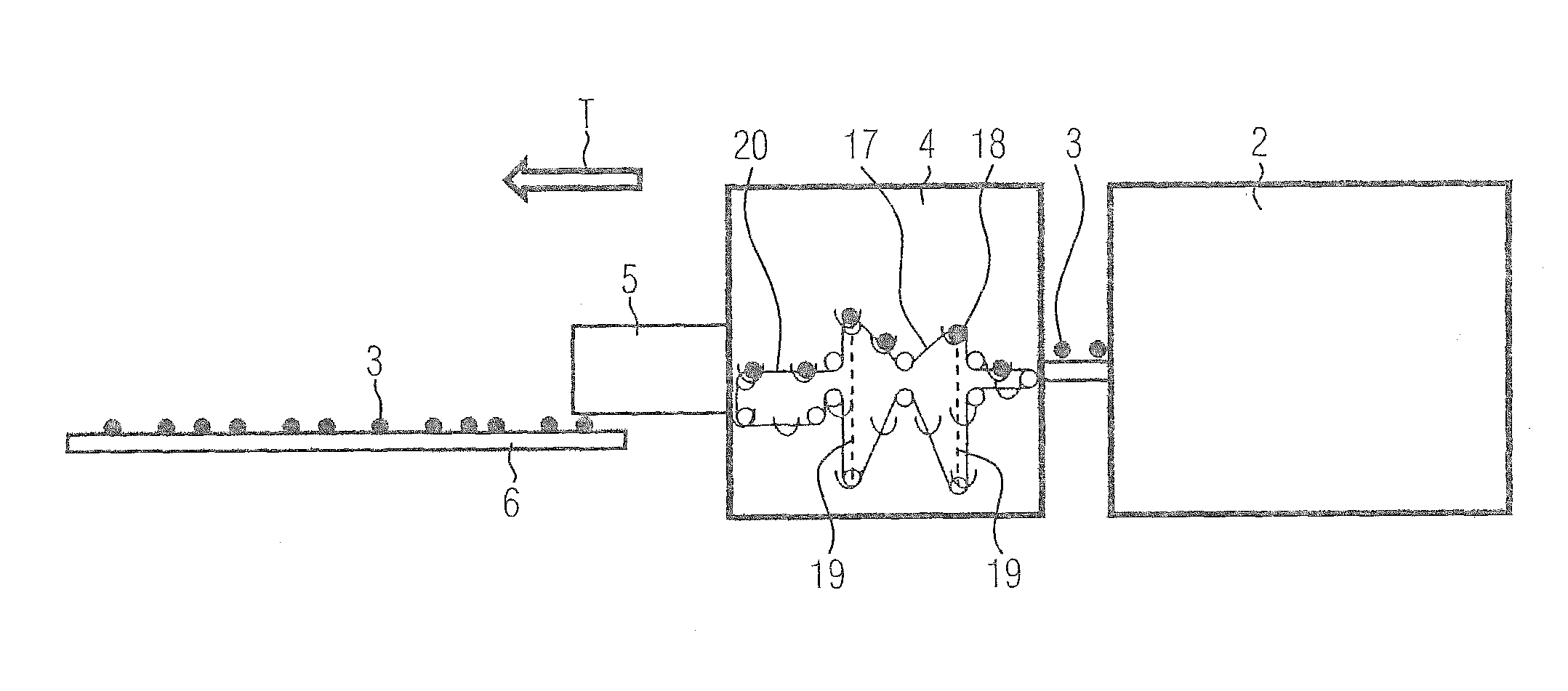

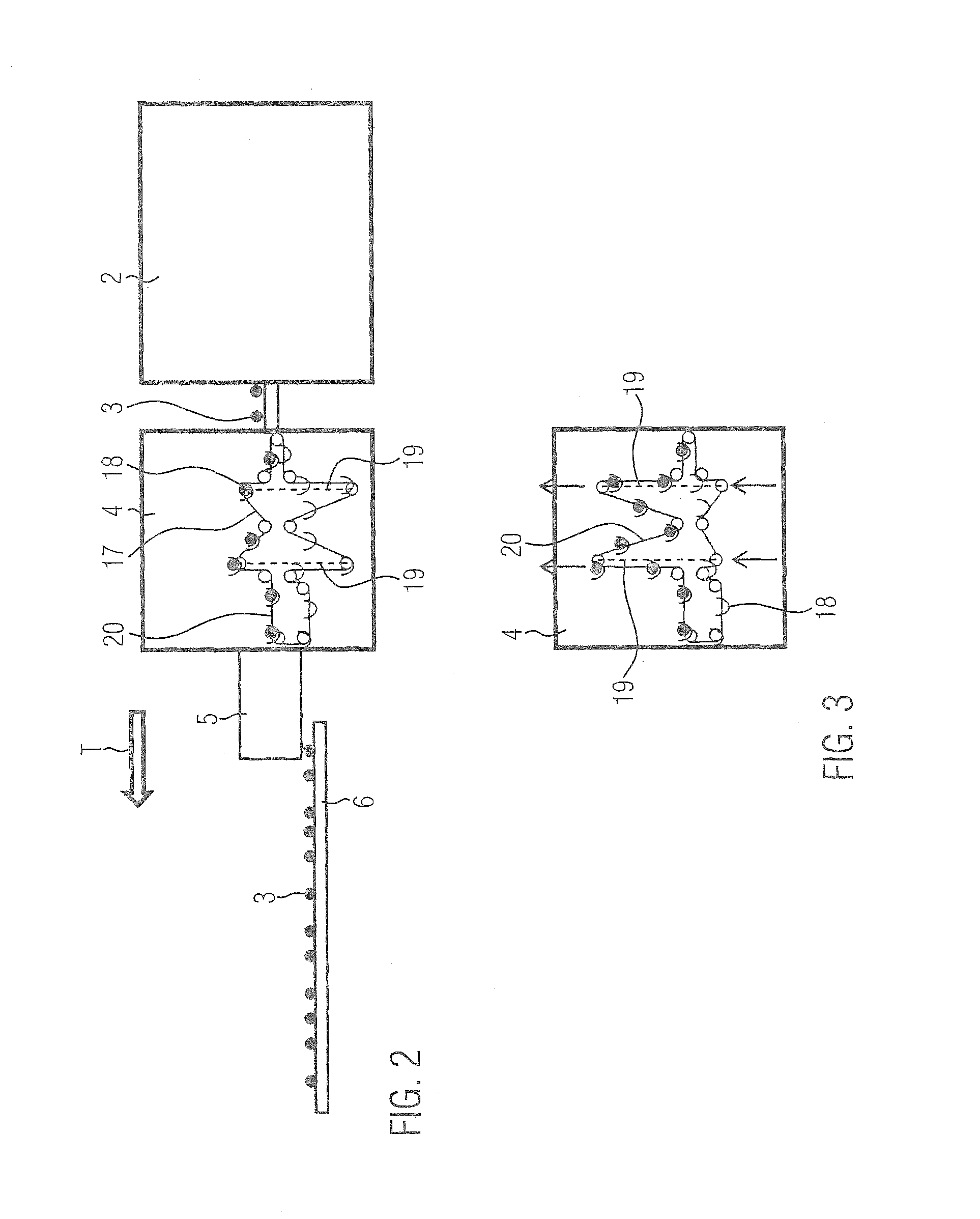

In order to be able to accept single sausage portions after leaving the filling machine and to be able to deposit them in an ordered manner with respect to quantity and position, an acceleration device for accepting the sausage portions from a filling machine in a row and for conveying them further, and a transfer device for pushing the single sausage portions sideways from the acceleration device at defined positions.

Owner:ALBERT HANDTMANN MASCHFABRICK

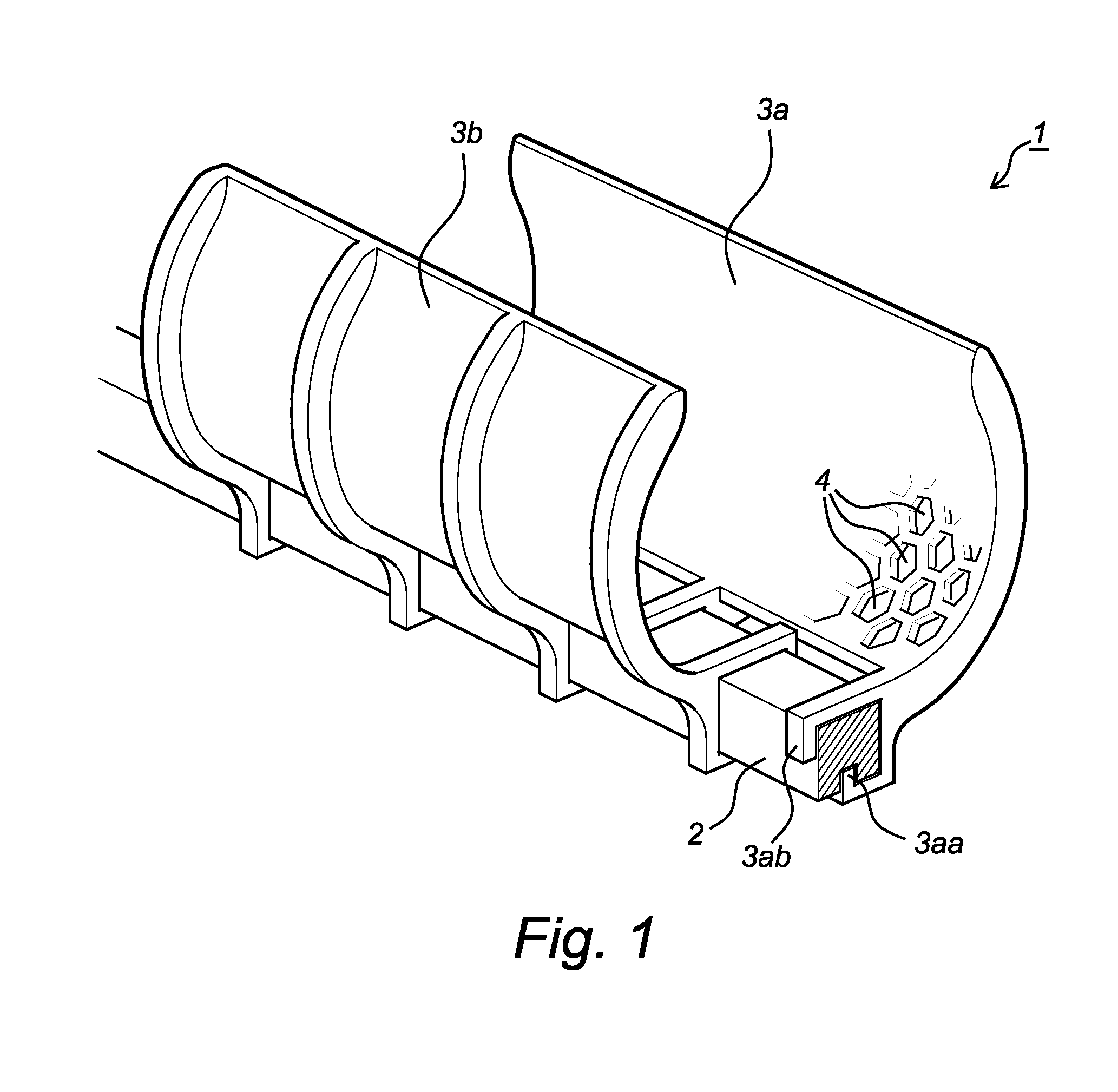

Device for treating a string of sausages

InactiveCN104604998AMonitor fireEasy to cleanMeat/fish preservationLinked sausage separationEngineeringRadiation

Device for treating a string of sausages composed of a plurality of sausages which are disposed so as to be behind one another, having a sausage casing from an organic material which in the region between two sausages displays in each case a twist, wherein at least one microwave applicator which has at least one application chamber and is assigned at least one microwave generation unit for generating the microwave radiation to be supplied to the application chamber, and which has at least one conveying unit for conveying the string of sausages through the at least one application chamber is provided, wherein at least one measuring unit (28, 29) for identifying at least one measured value which represents a measure of the temperature prevailing in the application chamber (11) is provided.

Owner:赫魏香肠公司

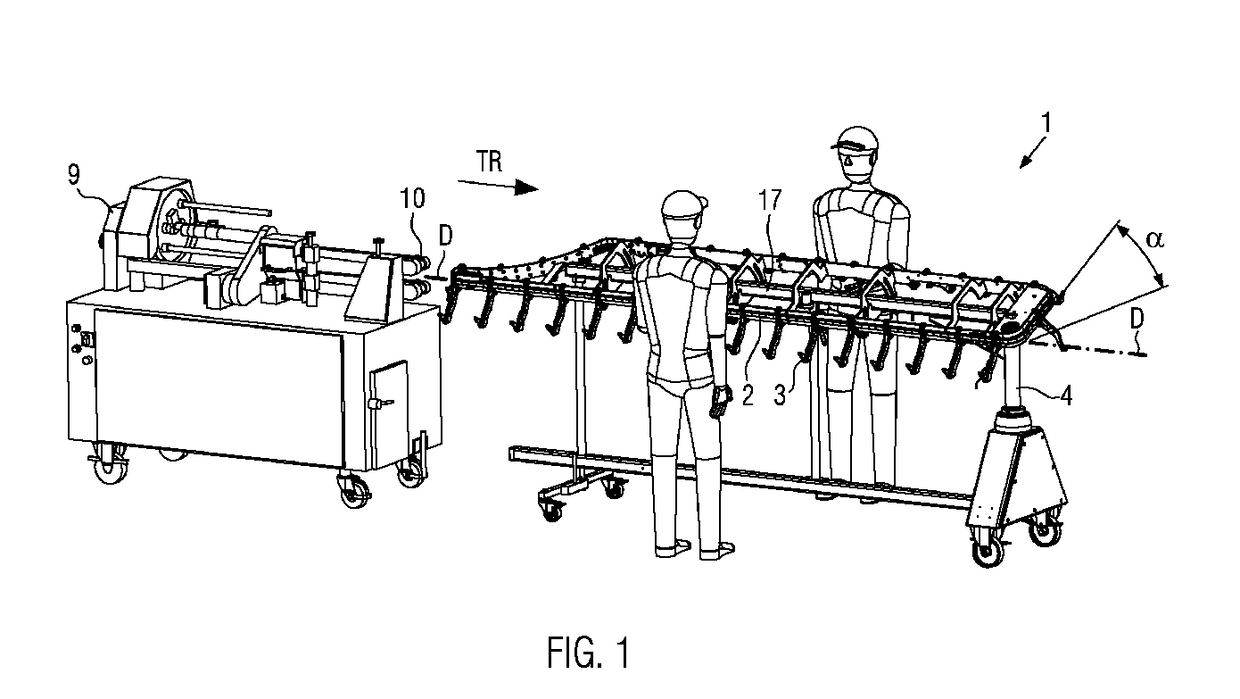

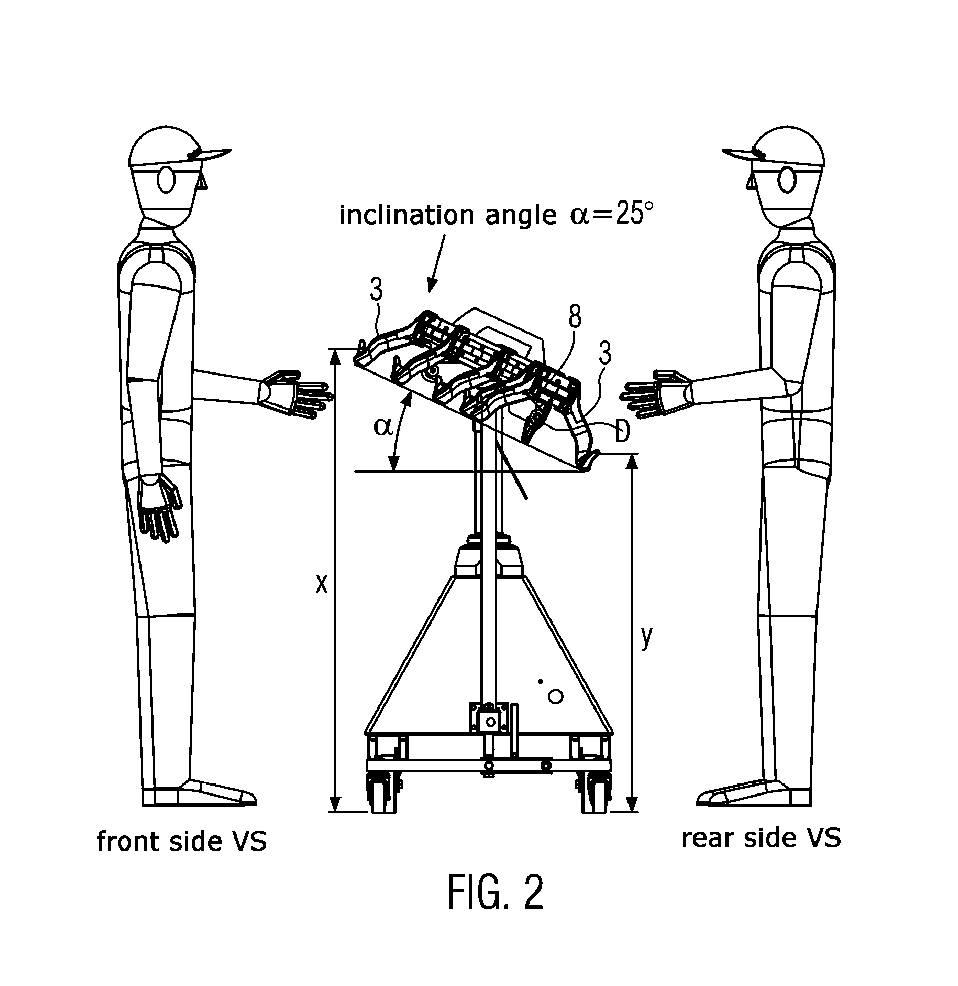

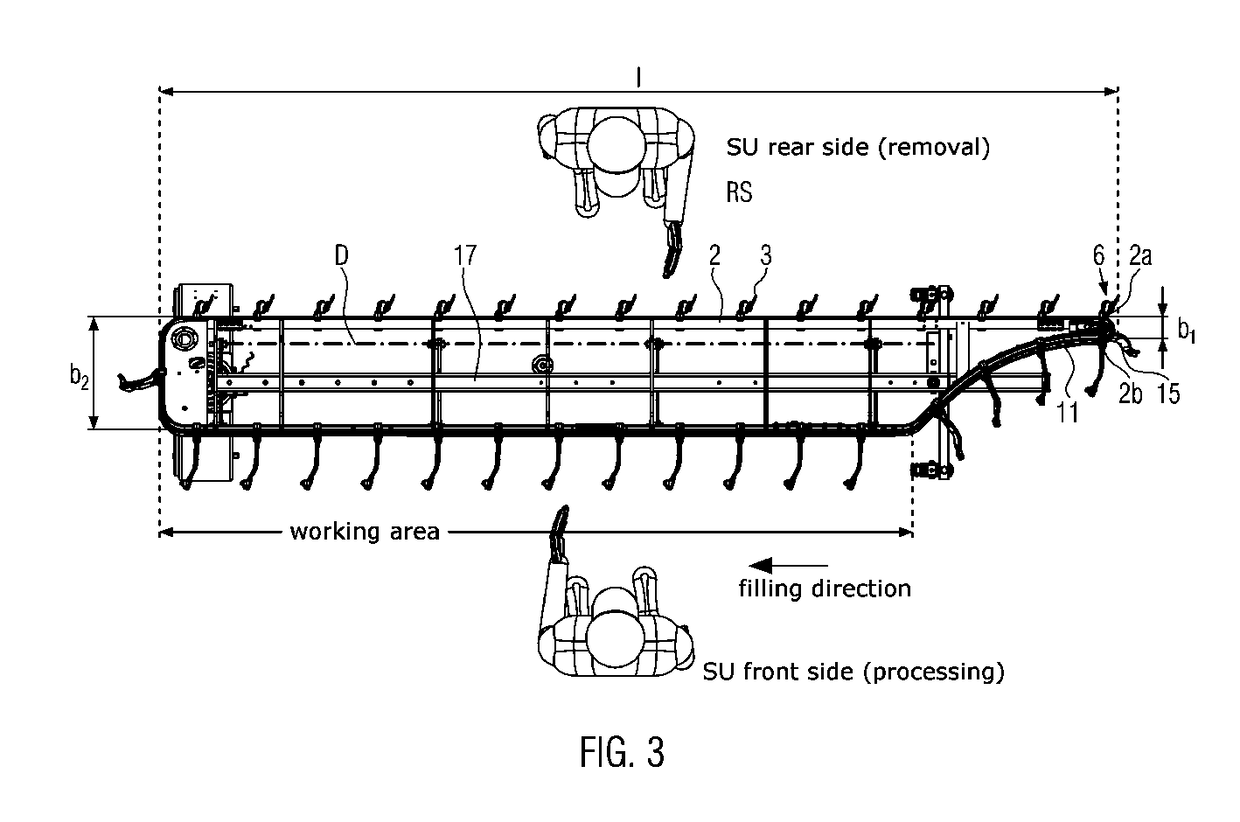

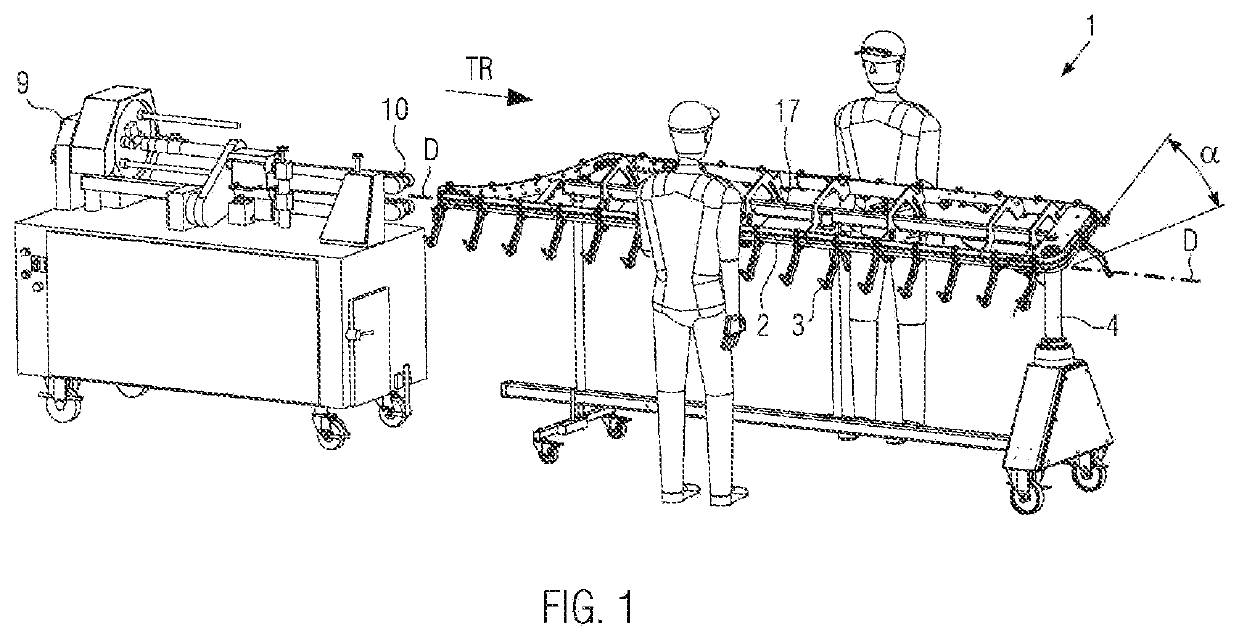

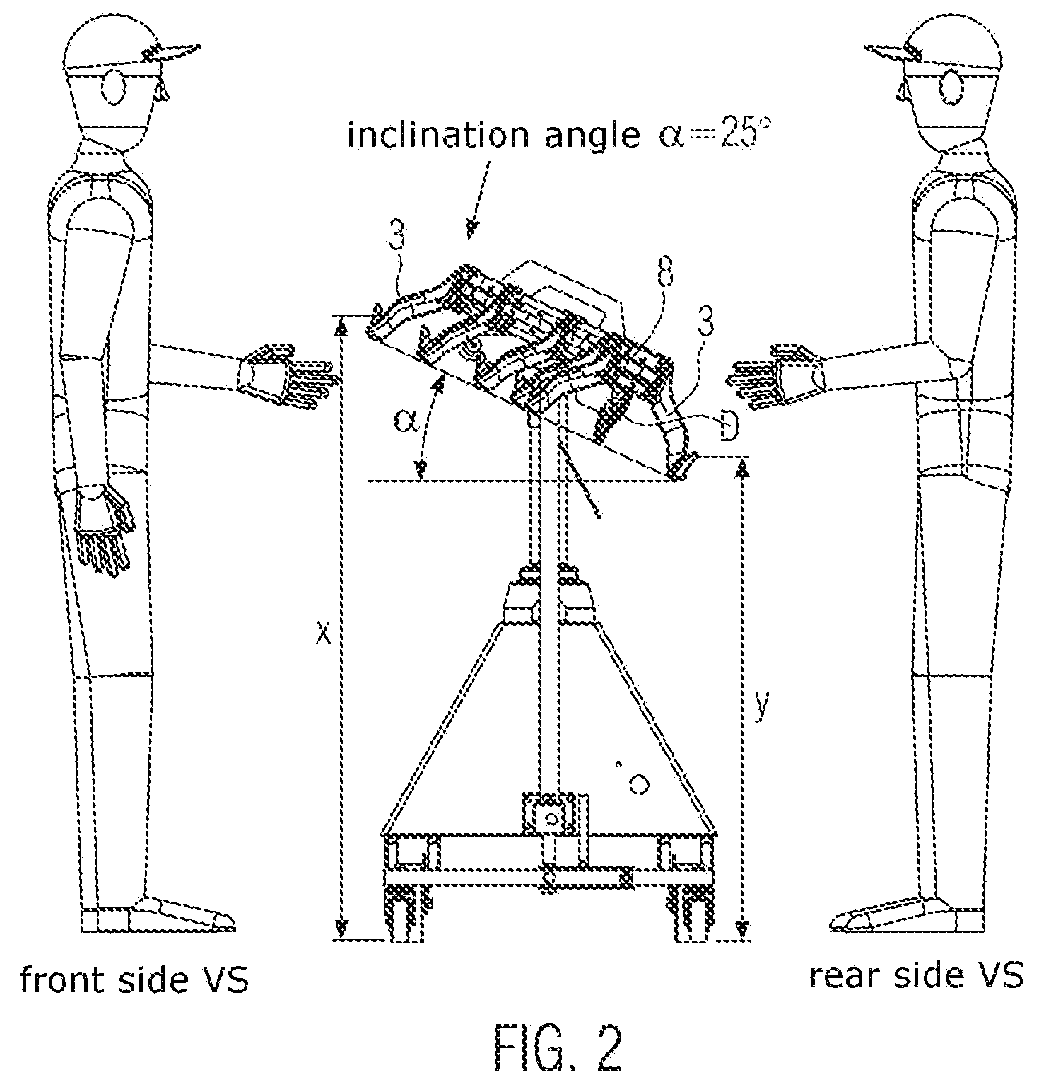

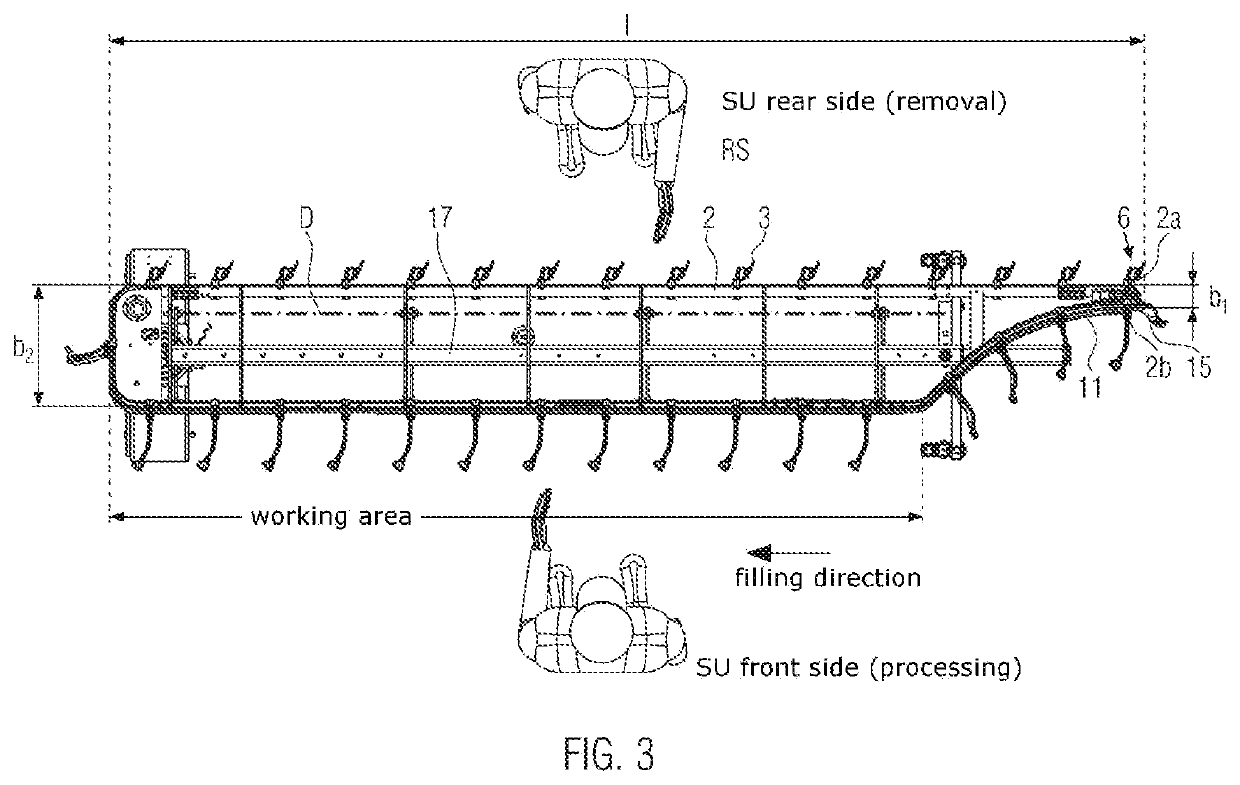

Suspension unit with inclined guide rail

ActiveUS20190000093A1Easy to disassembleImprove ergonomicsMeat/sausage hanging-upHorizontally conveying sausagesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Automatic rack loader

An apparatus and system for loading items onto a rack is described. The rack loading apparatus is a conveyor having a loading side for receiving items and an unloading side for discharging items, a positioner to align a rack with the unloading side; and a load pusher to discharge the items from the unloading side onto the rack. The system is a sausage-making stuffer / clipper, a belt conveyor, a conveyor having a loading side for receiving sausages and an unloading side for discharging sausages, a positioner to align a rack with the unloading side; and a load pusher to discharge the sausages from the unloading side onto the rack.

Owner:POLY CLIP SYST

Method and apparatus for suspending sausages

ActiveUS8894473B2Easy to adjustMaximum flexibilityMeat/sausage hanging-upHorizontally conveying sausagesEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Clipping machine with easy access

ActiveUS20170172164A1Improve functionalityImprove reliabilityHorizontally conveying sausagesWrapper twisting/gatheringFilling materialsEngineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, by filling a tubular or bag-shaped packaging casing with filling material and closing said filled tubular or bag-shaped packaging casing. The clipping machine includes a filling tube through which the filling material is fed into said tubular or bag-shaped packaging casing which is stored on said filling tube, a casing brake assembly arranged on the filling tube for limiting the movement of the tubular packaging casing at least while being filled, gathering means for gathering said filled tubular packaging casing and for forming a plait-like portion thereto, and a clipping device for applying at least one closure means, like a closure clip, to the plait-like portion formed on the filled tubular or bag-shaped packaging casing in a closing region. The clipping machine further comprises a housing defining at least a front wall, a rear wall, and two side walls of the clipping machine, for enclosing at least the clipping device and the gathering means. The housing includes at least one housing element arranged in the front wall of the housing for covering at least the closing region, wherein the at least one housing element is coupled to the clipping machine by a linking device including a shifting mechanism for reversibly shifting the housing element relative to the clipping machine, in a shifting direction, for granting access to the closing region of the clipping machine.

Owner:POLY CLIP SYST

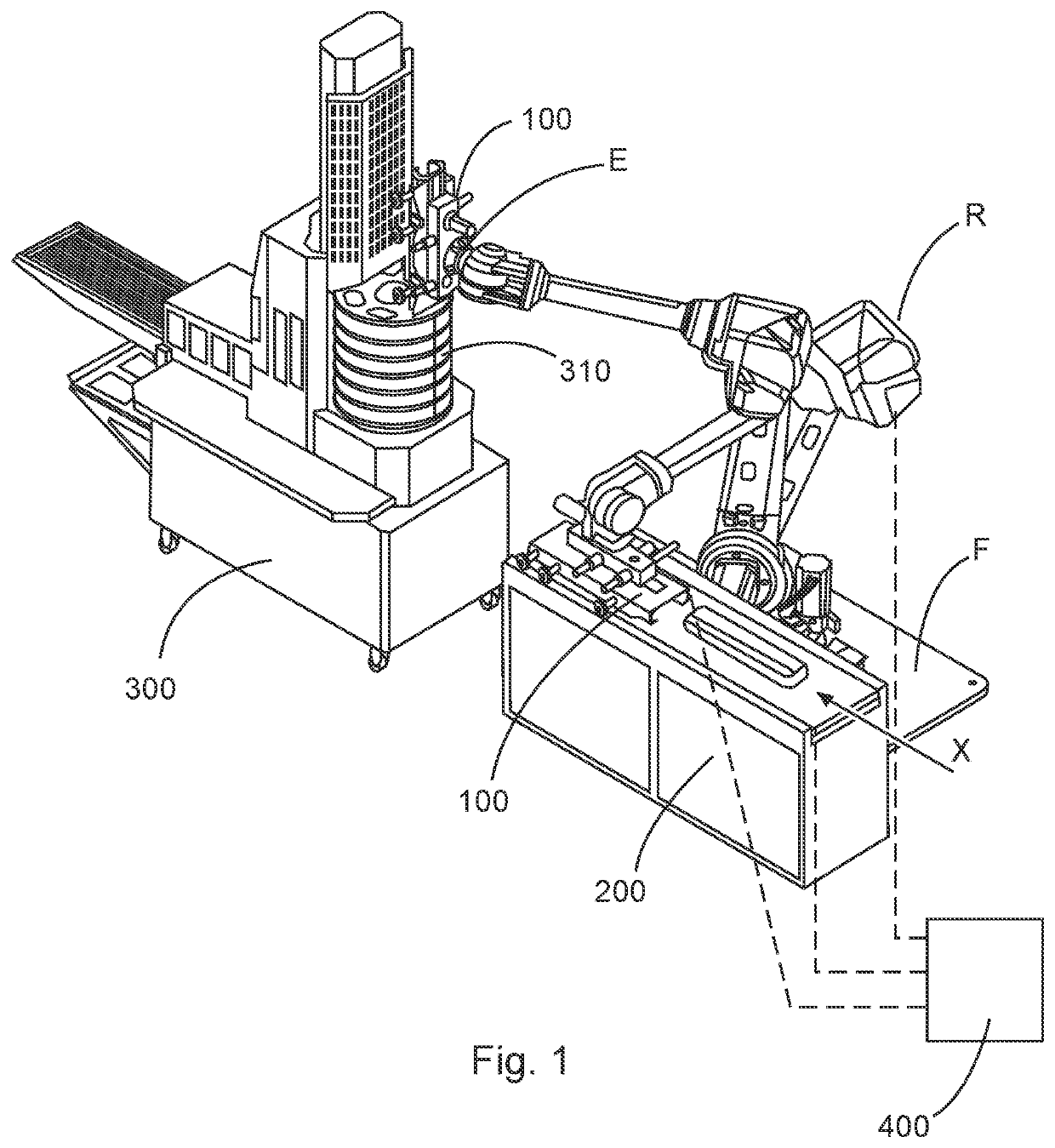

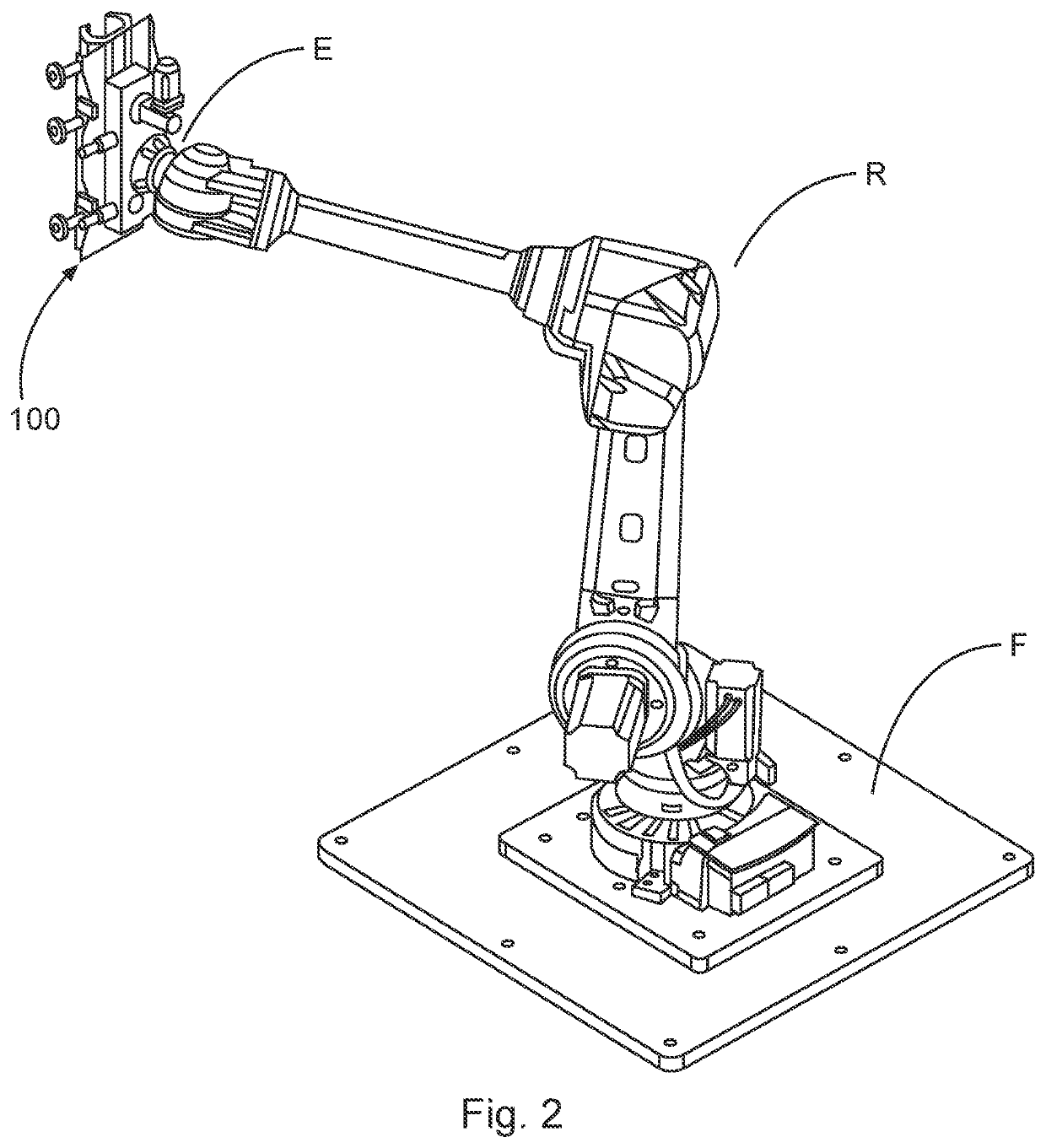

System for picking up, conveying, and delivering a product, and method of controlling such system

PendingUS20220072730A1Quick exchangeImprove stabilityProgramme-controlled manipulatorGripping headsControl cellProcess engineering

The present invention relates to a system for picking up, conveying, and delivering a foodstuff product to a processing machine which preferably has an upright magazine tube, said system including: a handling device, a gripping device releasably attachable to the handling device, a transporting apparatus, and a control unit; wherein the transporting apparatus has a transporting portion on which the foodstuff product that is to be picked up by the gripping device may be positioned in a pick-up position allowing the foodstuff product to be picked up by the gripping device, and the control unit is connected at least to the handling device of the gripping device and to the transporting apparatus; wherein the control unit is configured for detecting when the foodstuff product to be picked up has reached the pick-up position.

Owner:POLY CLIP SYST

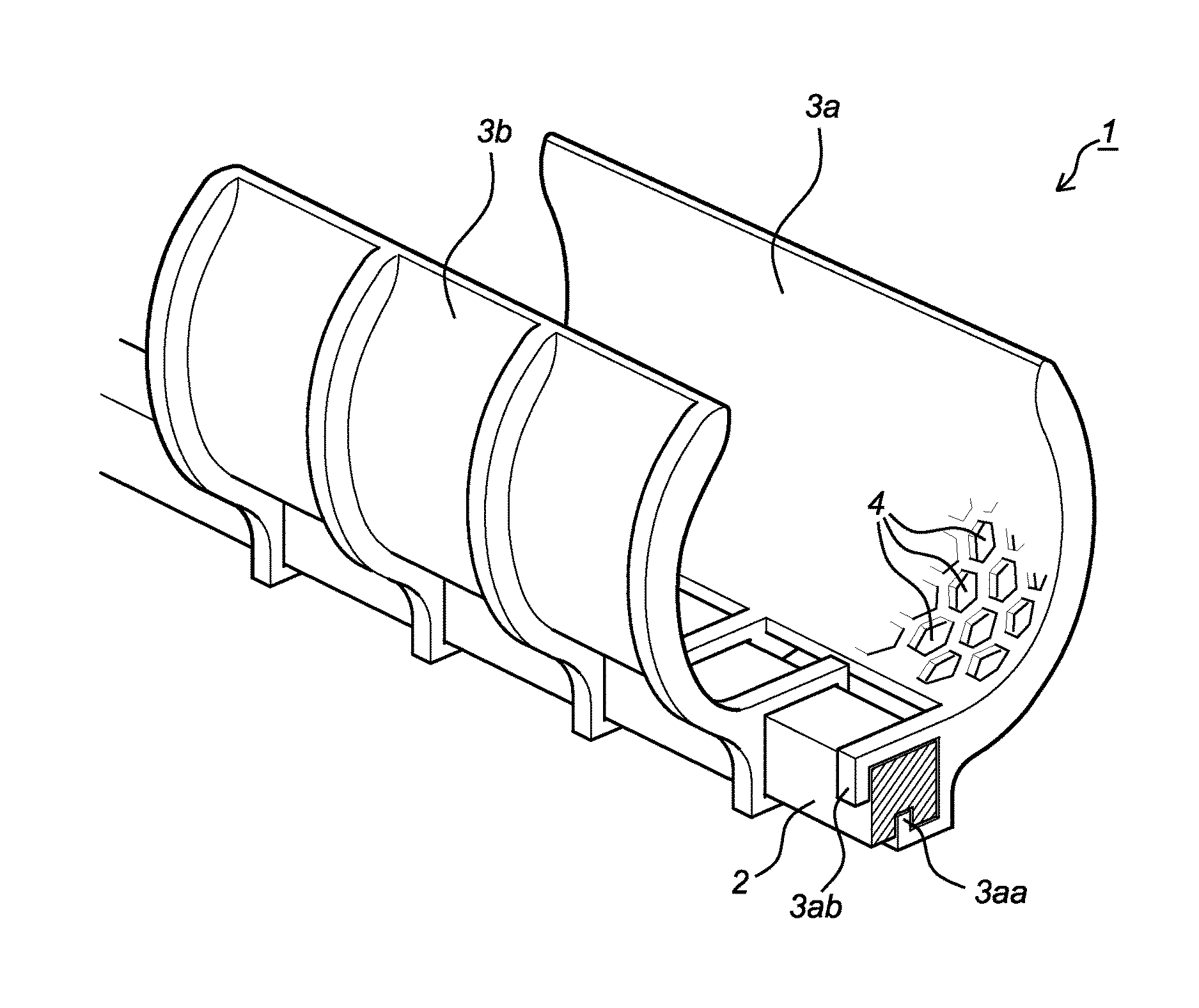

Product holder for holding food products

ActiveUS9550627B2Easy to cleanIncrease capacityHorizontally conveying sausagesMechanical conveyorsMechanical engineeringFood products

The present invention relates to a product holder (1) for holding food products to be transported through a processing room comprising: a carrier frame (2) having at least a longitudinal support structure and coupling ends connected to opposite sites of the longitudinal support structure; and a container formed by at least one curved contact segment (3a, 3b) for contacting the food products, wherein the at least one curved contact segment is detachably connectable to the carrier frame. The invention further relates to a transporting device comprising the product holder of the present invention and methods for assembling and disassembling the product holder of the present invention.

Owner:MAREL TOWNSEND FURTHER PROCESSING

Apparatus for transporting elongate sausages which have a curvature

ActiveUS10278402B2High frequencyPackaging meatHorizontally conveying sausagesEngineeringConveyor belt

A device for the transportation of elongate sausages exhibiting a curvature, the device having a first conveying device including two circulating conveyor belts or belt conveyors spaced apart from one another laterally, each having studs for randomly receiving the sausages. An end portion of a sausage can be received in two adjacent studs in each case. A free space is provided beneath the conveying belts or belt conveyors at least sectionally along the conveying path, in order to facilitate a swing-through of the sausages mounted on the conveyor belts or belt conveyors in the peripheral region so that they hang in the free space with the curvature facing downwards, said device has a lead component into which a sagging sausage runs, by which it is pivoted up in the direction of the conveying plane, and having a second conveying device for receiving the upwardly pivoted sausage.

Owner:SINGER & SOHN

Clipping Machine with Secured Access to the Clipping Region

ActiveUS20200329721A1Prevent openingLow bending stiffnessHorizontally conveying sausagesWrapper twisting/gatheringEngineeringStructural engineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, containing a flowable filling material in a tubular or bag-shaped packaging casing, the machine comprising filling means configured to feed filling material into the casing, and further comprises closing means arranged downstream the filling means, for closing the casing in a closing region. A housing is provided, enclosing at least the closing region, comprising at least a front wall and a first side wall, wherein the front wall is arranged at least substantially parallel to a longitudinally extending axis of the filling means, and further comprises an opening which can be closed by a movable door element, movable between an open position, allowing access to the closing region and a closed position, covering and blocking access to the closing region. The side wall faces the filling means and further comprises a movable housing element, movable between at least an open position and a closed position, wherein the movable housing element comprises an opening for passing through the sausage-shaped products, and wherein the movable housing element enables access from a side of the first side wall to the closing region when in the open position; and wherein the movable housing element covers and blocks access to the closing region when in the closed position.

Owner:POLY CLIP SYST

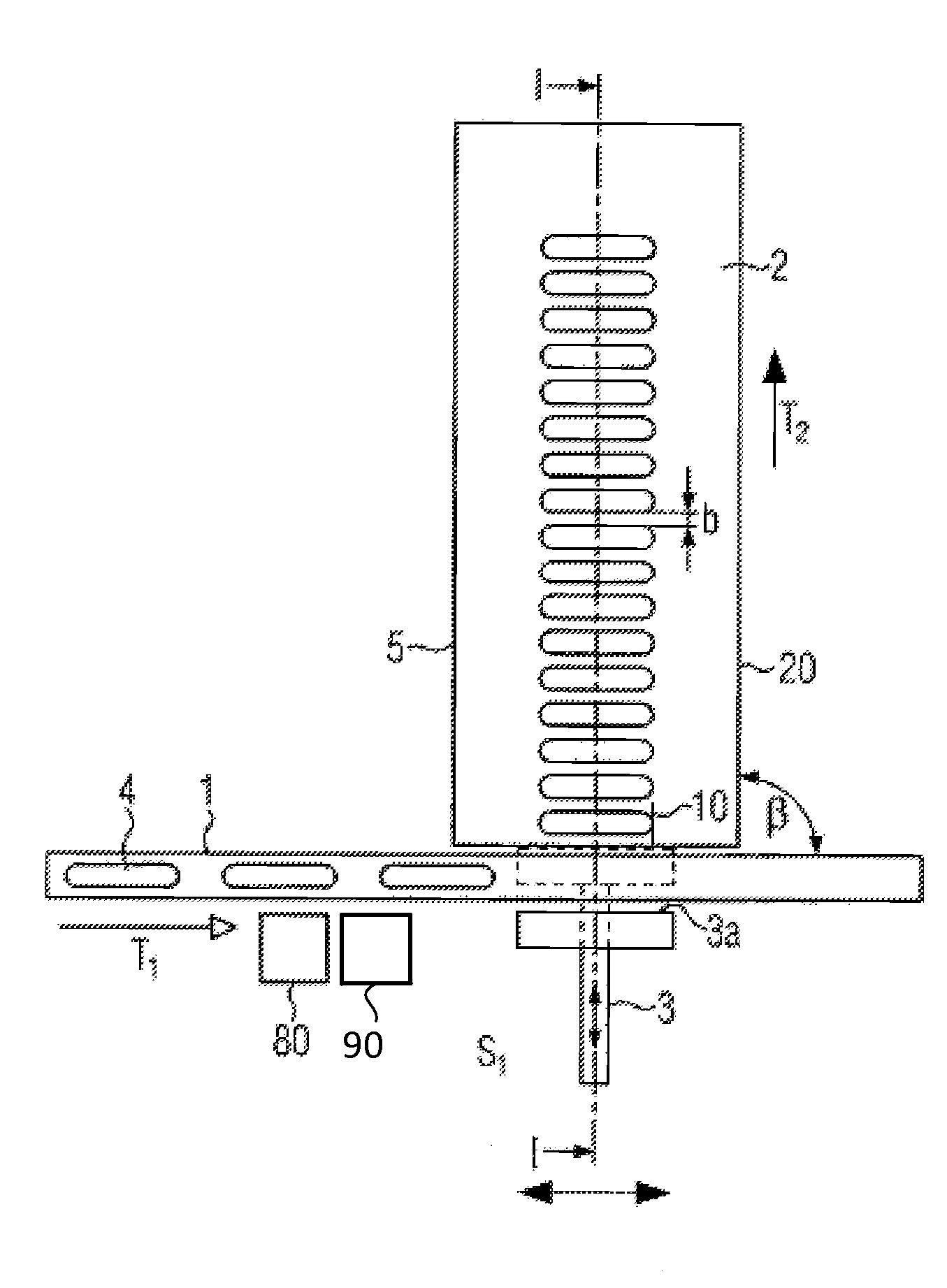

Packaging plant

ActiveUS20130324022A1Reduce distanceImprove efficiencyHorizontally conveying sausagesRod-shaped articlesBiomedical engineeringInsertion device

The invention relates to a packaging plant for packing sausages or other objects, comprising a manufacturing device, a buffer device, a feeding device, an insertion device, and a packaging machine, the buffer device comprising a length-variable transport section, and a method for operating a packaging plant according to the invention.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Suspension unit with inclined guide rail

ActiveUS20210352921A1Sufficiently spreadGood removal effectMeat/sausage hanging-upHorizontally conveying sausagesClassical mechanicsStructural engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

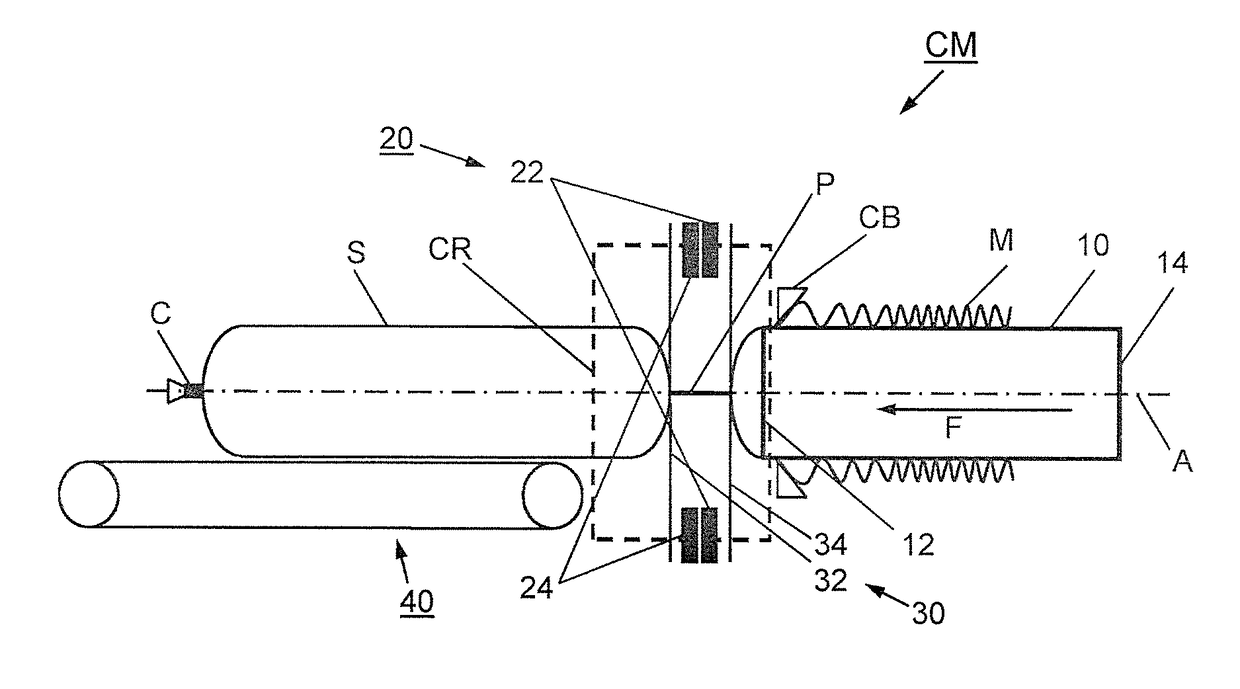

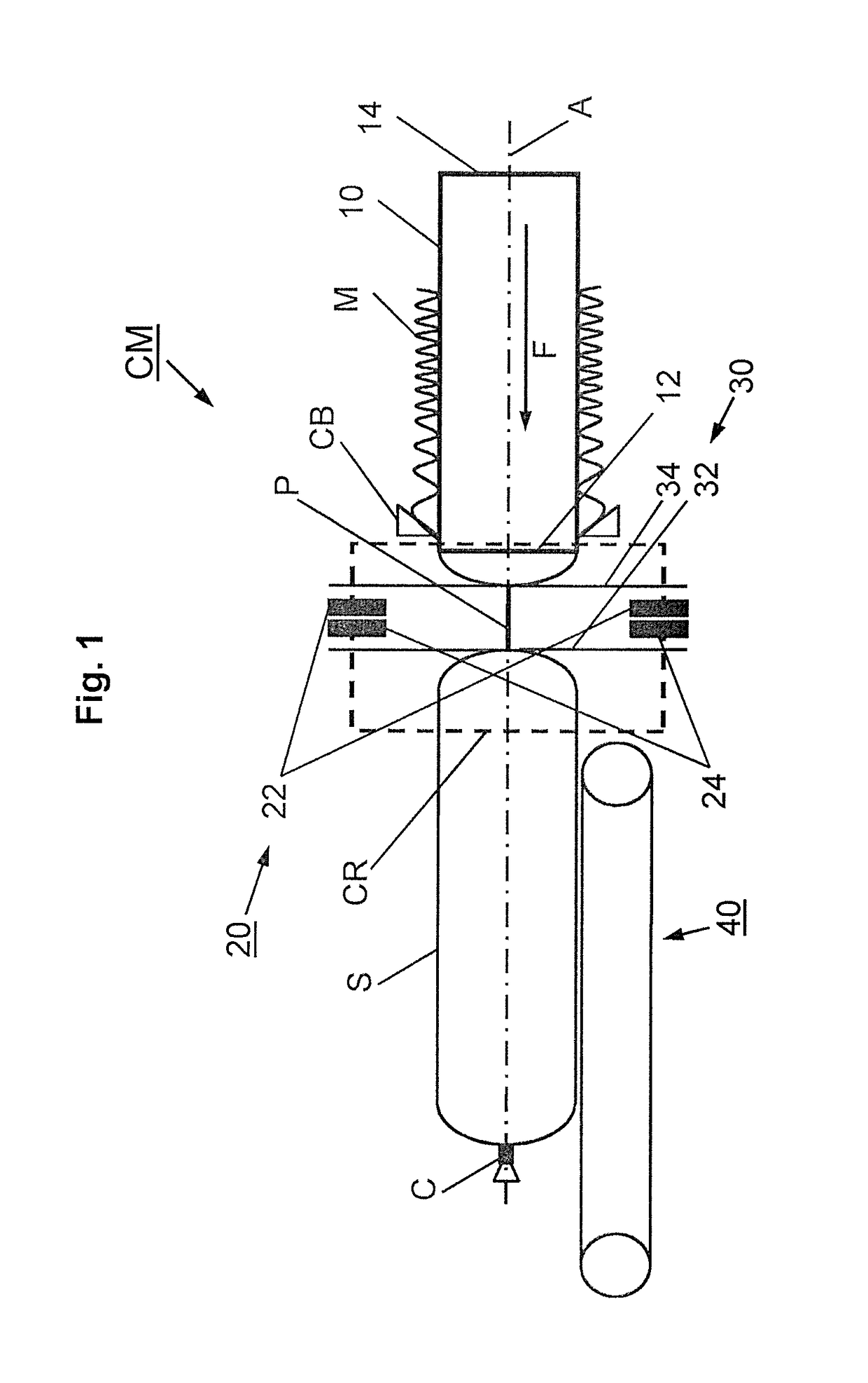

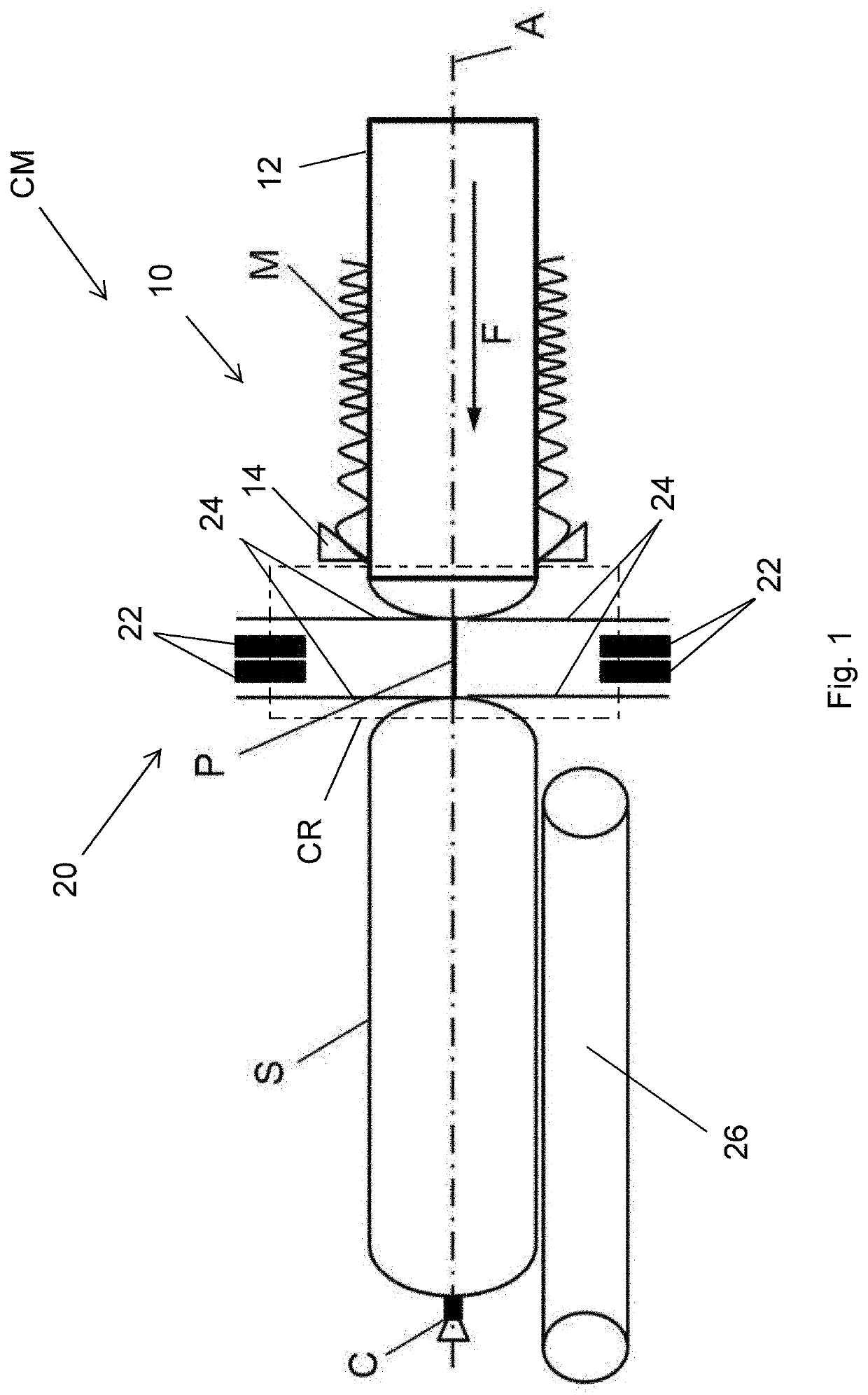

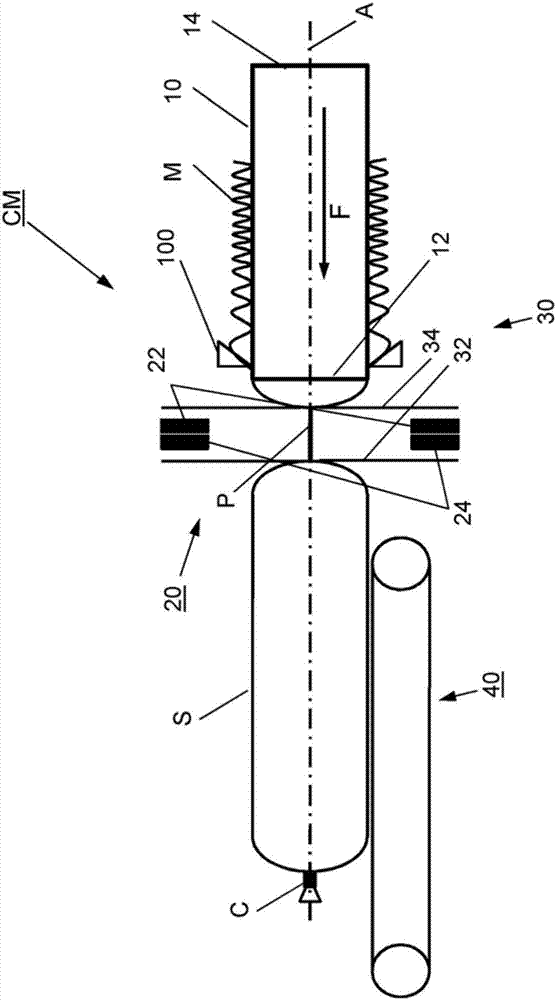

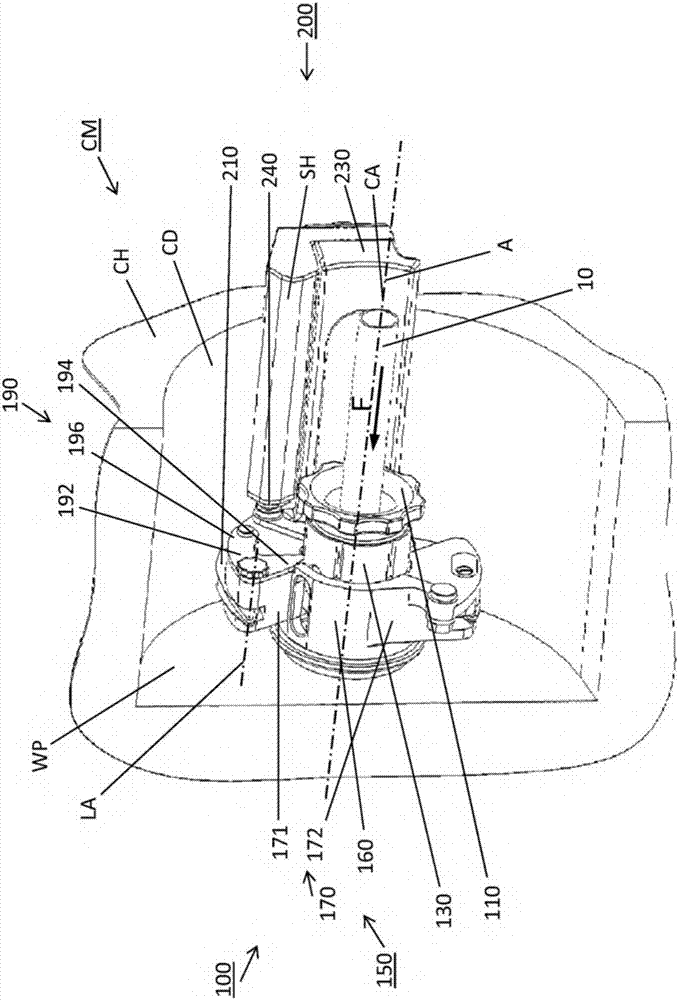

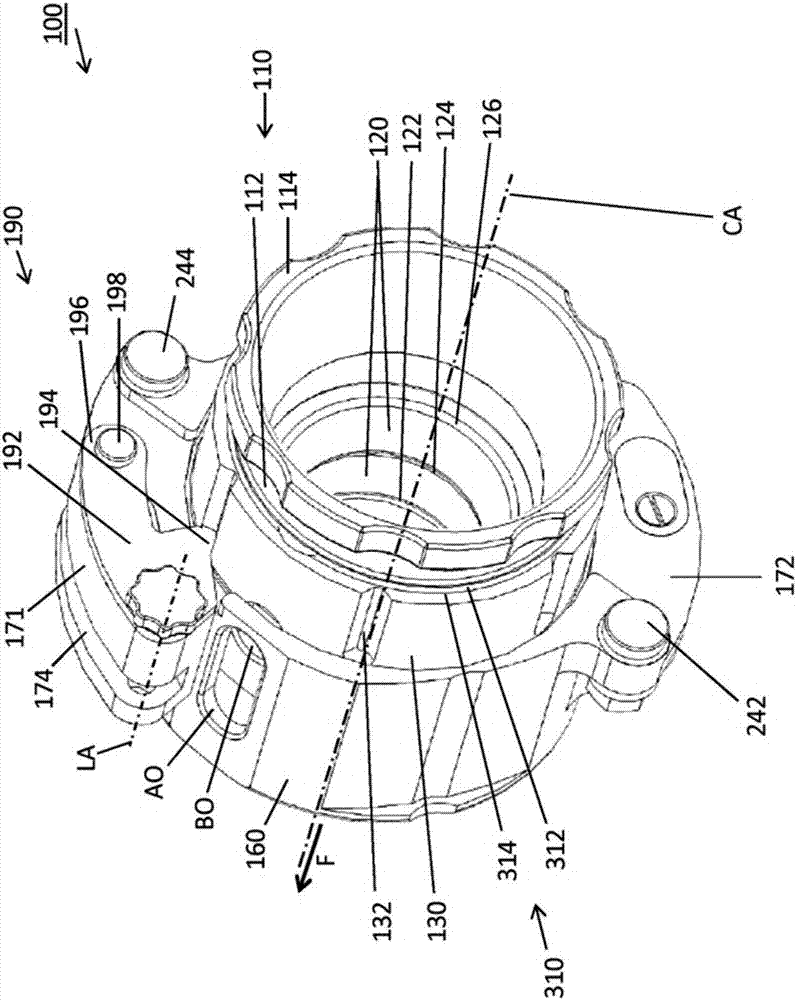

Casing brake assembly

ActiveCN106900822AHorizontally conveying sausagesSausage skin tying apparatusFriction forceBiomedical engineering

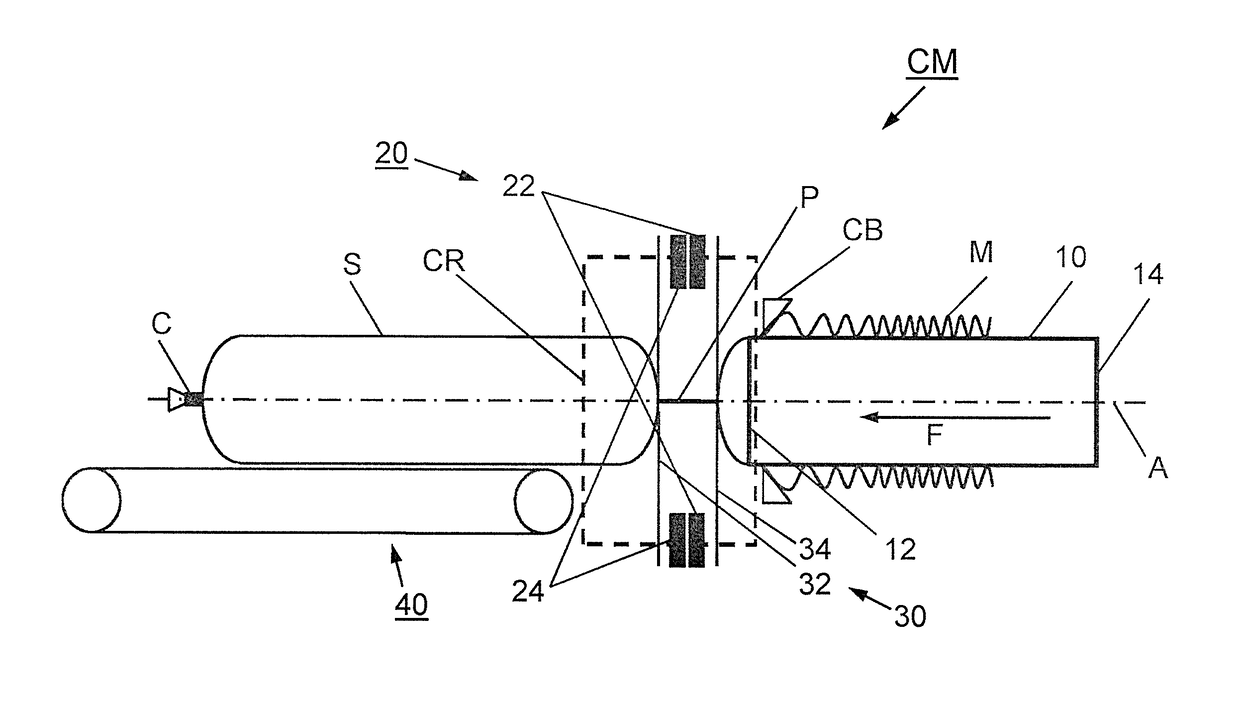

A casing brake assembly (100) is provided for applying a frictional force to a tubular casing being arranged on a filling tube (10) of a production apparatus (CM), which is used in the production of sausage-shaped products (S) and for limiting the movement of said tubular casing. The casing brake assembly (100) comprises tubular support means (110) for supporting at least one brake element having an at least approximately ring-shaped design. The casing brake assembly (100) further comprises a tubular bushing (130) for accommodating the tubular support means (110) and the brake element, and an attachment device (150) including a tubular accommodation portion (160) for accommodating the tubular bushing (130), and at least one attachment portion (170) configured for attaching the casing brake assembly (100) to the production apparatus (CM).

Owner:POLY CLIP SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com