In manufacturing, the actual materials and equipment used are costly, but these costs are substantially determined by those responsible for

product design before manufacturing even begins.

First, regarding wear surfaces,

centrifuge interiors in general and particularly the interior surface of the outer wall of a centrifuge, are an extremely punishing and hostile environment for any chosen construction materials.

To put this yet another way, a centrifuge outer wall of a given outer

diameter ("x" inches) operating at its maximum burst strength RPM's will likely experience

structural failure if that centrifuge's rotational speed is further increased.

And, conversely, a given centrifuge operating at its maximum outer wall burst strength at a fixed RPM will also likely fail at that RPM if its design

diameter is further increased.

The well-documented strength ceilings for steel,

titanium and

alloy metal used in centrifuge outer walls, and the well-known ratios of rotational speed /

centrifugal force times

diameter which are governed by those limitations, have created widely accepted limitations for the use of centrifuges.

What appears not to be possible using the decades-old metal based methods of construction and assumptions inherent to all conventional centrifuges is the

processing of comparatively large volumes of fluid at centrifugal forces well above approximately 2,500 to 3,000 gravities.

This cannot presently be done because metals cannot provide sufficient hoop or

bursting strength to contain the heavier, high volumes, in large diameters, at higher gravities.

Many of today's most pressing environmental problems present very high

processing volumes combined with extremely fine, light (and often very dangerous, i.e.,

cryptosporidium cysts in

water supply) particles requiring separation.

However the very high

initial cost of and extensive ongoing maintenance required by each of these centrifuges has so far inhibited their use in large arrays of many of such devices, as would be required, for example, to continuously treat all the drinking water for a large

metropolitan area.

In addition, more and more long-term health disadvantages of the use of chemicals in water, both individually and from the side-effects of their combinations, are coming to light.

These widespread and intractable disadvantages further underscore the desirability of cost, strength, volume and operating breakthroughs in centrifuge design generally, as dictated by centrifuge outer wall design specifically.

Those disk centrifuges which use stacked disk cores to amplify gravitational separation can separate quite

small particles from fluids, in industrial size quantities, due to that amplification technique allowing the use of rotational forces below 3,000 gravities; however, such extremely complex, and maintenance-intensive devices cost many hundreds of thousands of dollars each.

Again, they have not been adopted for large scale fluid separation such as

water treatment, most likely because they are not cost-effective for such

mass use.

Finally, commercial decanting centrifuges' upper centrifugal limits in the 2,500 gravity range, lacking the

amplifier effect of stacked disks, cannot remove particles below approximately 3 to 5 microns.

And, large volume Decanters are also extremely expensive, approaching one million dollars apiece.

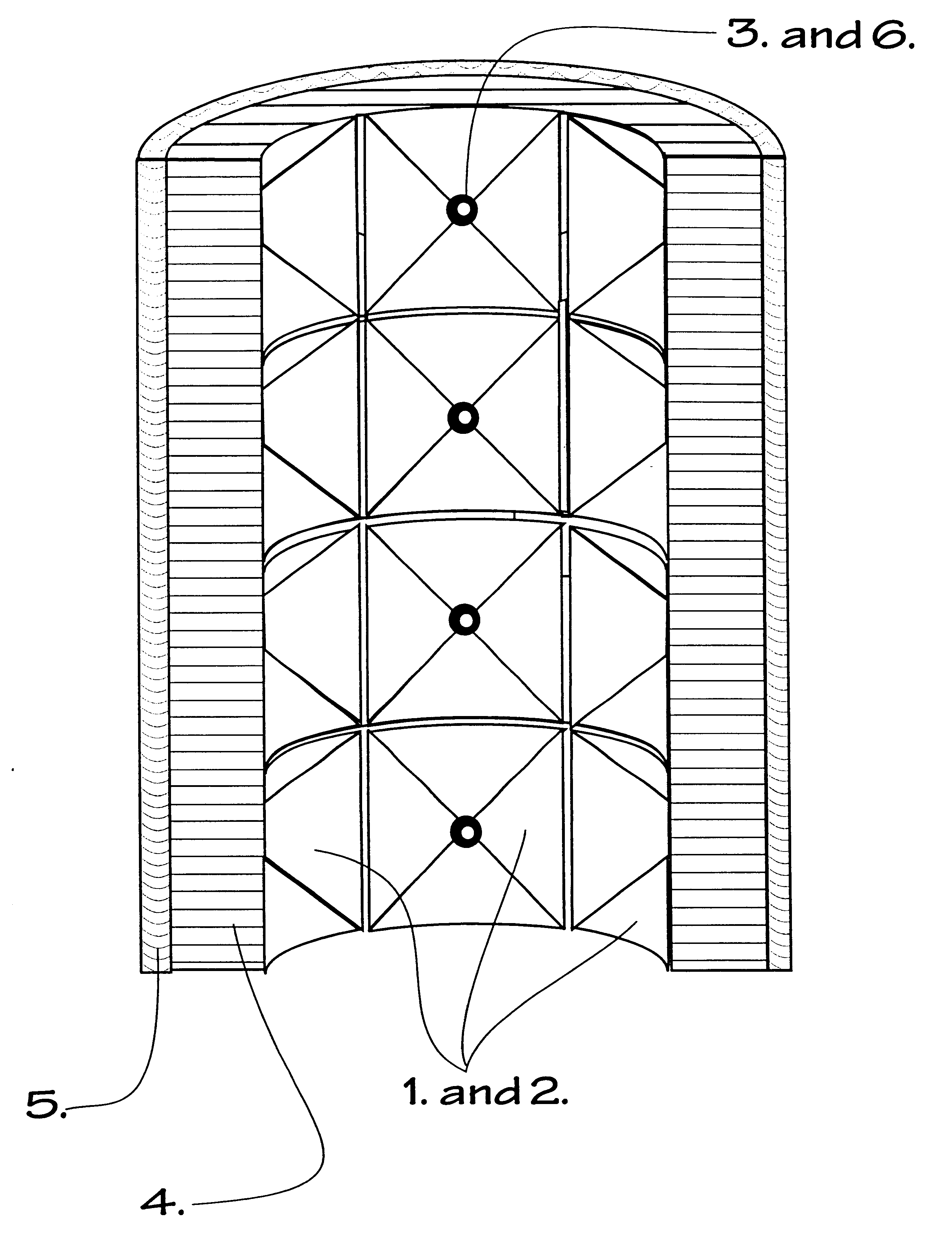

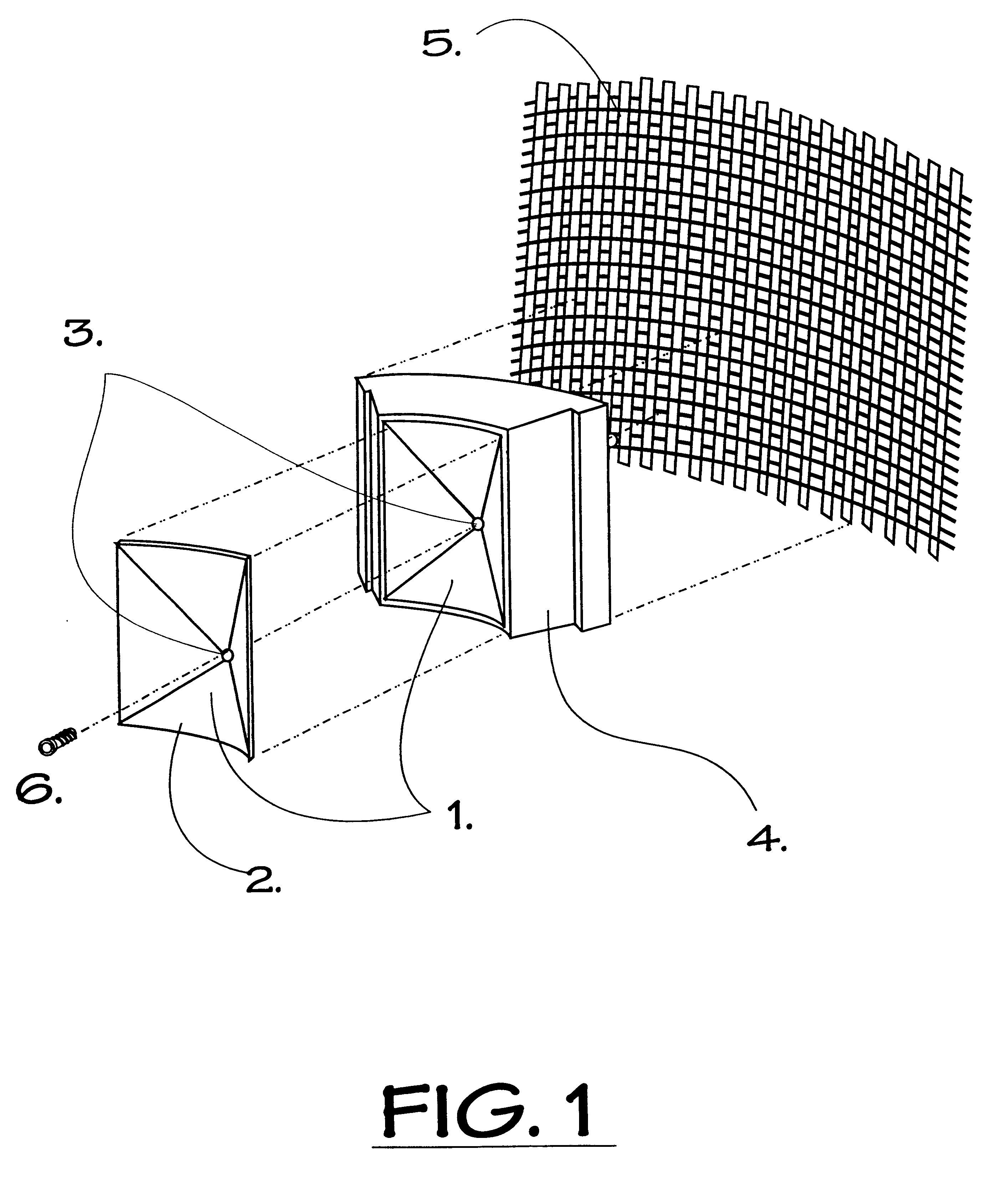

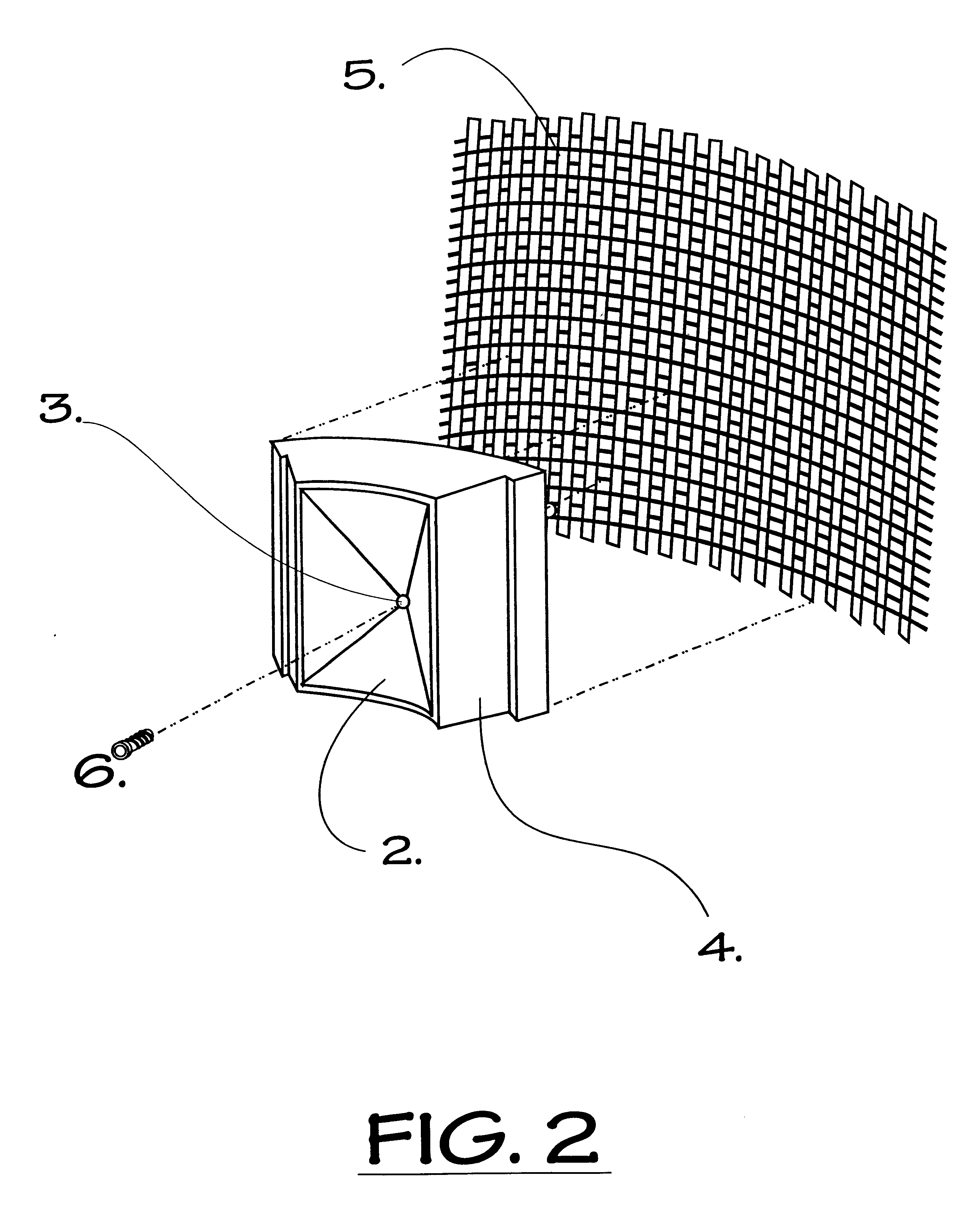

First, the thin wear layer would need incompressible physical support by means of the layer immediately outside or behind it.

This is the case because the wear layer is not only being bombarded with many extremely heavy,

abrasive individual particles being thrown from the centrifuge, but also because it is being subjected to immense, deforming,

centrifugal force.

As stated previously in this application, centrifuges

spinning at high speed have extremely low tolerance for weight or density imbalances across the axis of spin.

In addition, for some applications, such middle-layer members can be made of extremely incompressible but comparatively lightweight materials such as cast

ceramic.

Until now, the limitations of metal-fabricated wall strength available in commercial centrifuges has drawn a line in the sand regarding how large they can be, and how fast they can spin.

And, as stated above, until now their limitations have governed centrifuge development.

In those parts of such devices having high-strength requirements, such as all parts to be high-speed rotated out away from the axis of spin where

centrifugal force is the highest, metal parts is the final

assembly of conventional centrifuge walls are often laboriously x-rayed to uncover metal

crystal and / or

welding flaws which would compromise

bursting strength and lead to

catastrophic failure at speed.

The extremely high cost of steel and alloyed raw materials certified to have predictable, uniform

crystal structure, strength and other qualities, and the equally high cost of

casting, turning, finishing, testing and documenting such parts, is well known in the metal trades.

In large part because of the costs of raw materials and fabricating, a single large decanting centrifuge can cost a million dollars or more.

A single conventional disk centrifuge, also metal fabricated, can cost a quarter million dollars or more.

Smaller tubal centrifuges, again made of cast and carved metals, but of lesser cost because of their smaller sizes, can spin much faster and produce much higher gravities than the other devices, but only because of their deliberately small diameters, which keep the centrifugal forces produced within the available strength of the metals used, but also limit their use to fluids in test or extremely small production quantities.

In centrifugal devices designed to attain comparatively higher rotational speeds, another problem must be addressed, which is

harmonics.

In a centrifugal device,

spinning so as to produce 2,000 or 3,000 multiples of gravity, and filled with extremely heavy fluid whose heavier components are being thrown outwards at greatly increased weights due to

gravitational force,

harmonics or out-of-phase vibrational forces can quickly cause structural failures.

Centrifuge device assemblies for high-speed operation must therefore achieve precise

dynamic balance, and they must also be torsionally rigid, since twisting forces in a device, particularly during acceleration, can also induce destructive

harmonics.

Carbon fibers, although strongest, are also brittle;

Kevlar fibers, less strong, are far more flexible.

However, the use of

filament winding to dramatically strengthen centrifuge outer collecting walls is herein claimed as both novel and non-obvious to experts in the imperforate bowl field.

Login to View More

Login to View More