Zinc oxide coated particles, compositions containing the same, and methods for making the same

a technology of zinc oxide and coated particles, which is applied in the direction of ball sports, electrical equipment, and mechanical instruments, can solve the problems of reduced rolling resistance of tires and reduced abrasion resistance of rubber compositions, and achieves improved aging resistance, high modulus, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

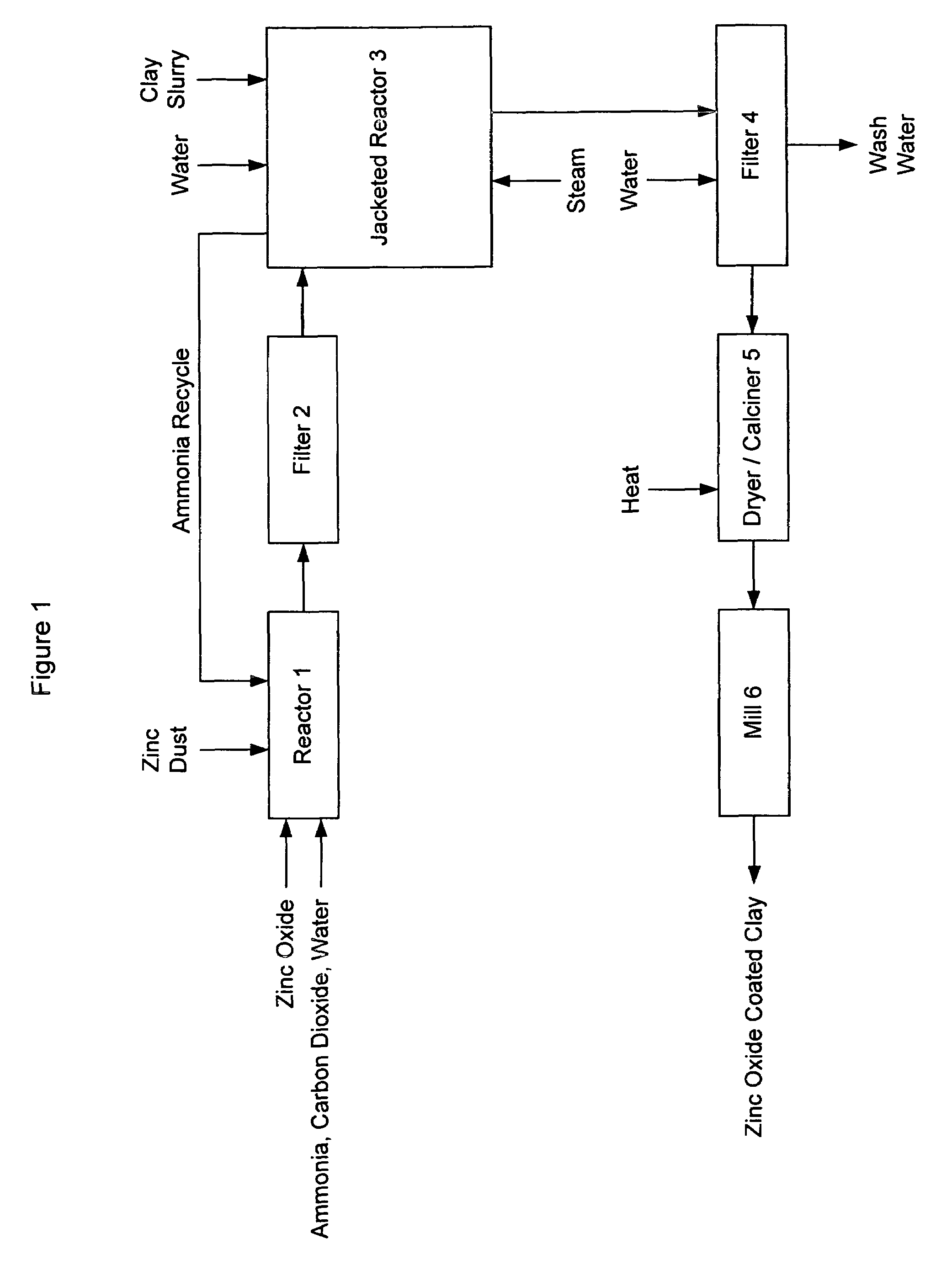

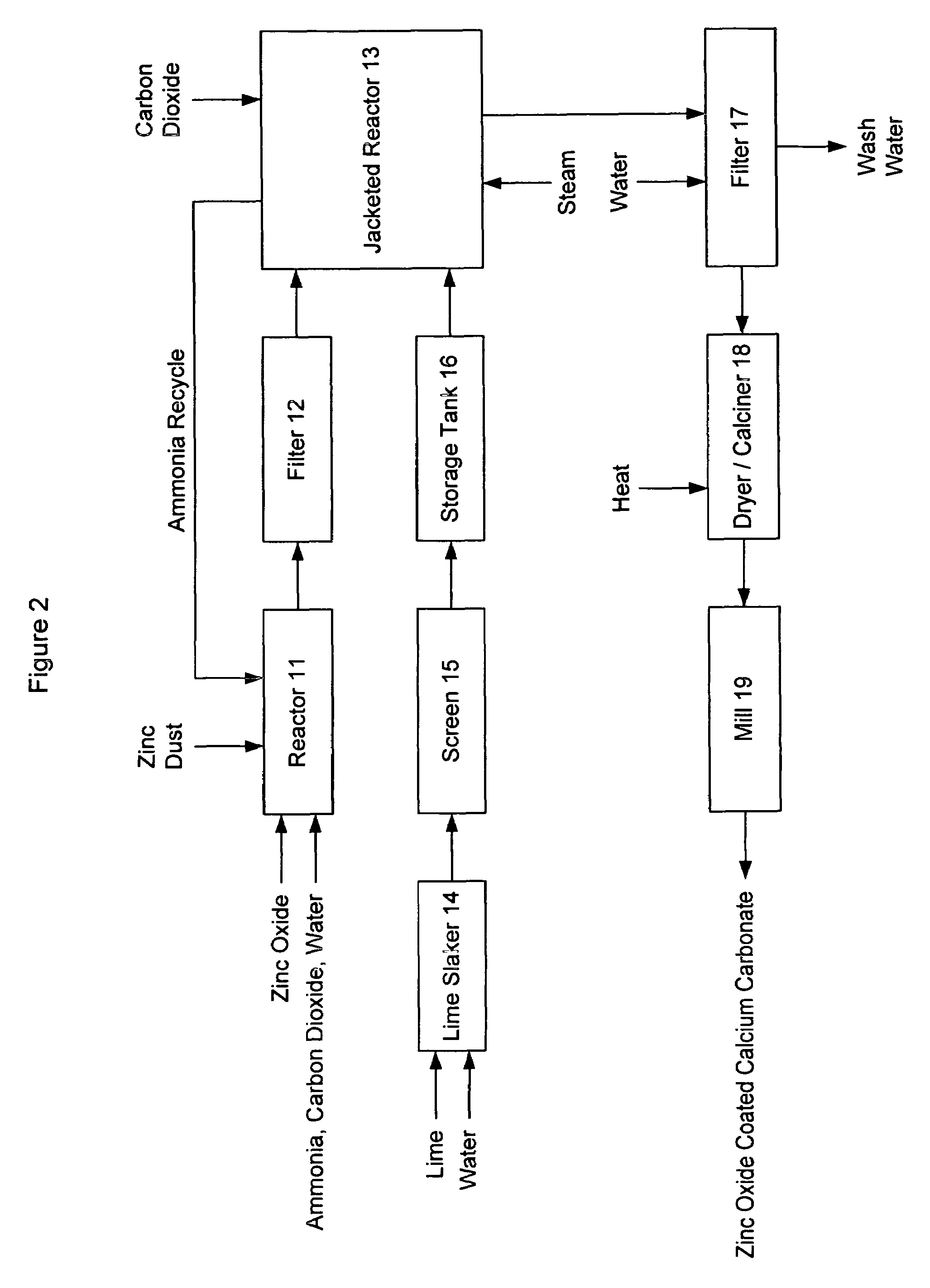

Method used

Image

Examples

example 1

Preparation of Zinc Ammonia Carbonate Complex Solution

[0054]Add 1,400 grams of French process zinc oxide into 10.5 kg of ammonium carbonate solution with 10.74% ammonia and 6.18% carbon dioxide. Agitate until all zinc oxide is dissolved. Add 40 grams of zinc dust with heavy agitation for 30 minutes then filter the resulting slurry. The filtrate is 11.1 kg of zinc ammonia carbonate complex solution with 9.78% Zinc, 9.48% ammonia, and 5.45% carbon dioxide. This is called solution A. The solution contains less than 1 ppm of heavy metal as lead and less than 2 ppm of iron.

example 2

Coating of Clay

[0055]For rubber or rubber latex products like tires, shoe soles, rubber bands, latex gloves, etc., the amount of zinc oxide activator added is usually about 1 to 5 phr. Fillers like carbon black, calcium carbonates, china clay, silica, talc, etc., are used to reduce cost and / or to modify properties. The total amount of the fillers is usually much higher than the amount of zinc oxide. It is around 5 to 10 phr for latex elastic thread and up to 80 phr for tires. Thus, the rubber composition may further include one or more optional additives, such as carbon black, calcium carbonate, a clay, silica, talc, an antioxidant, a retarder, a lubricant (e.g., a paraffin wax), an activator, sulfur, an accelerator, a processing oil (e.g., an aromatic oil), and a processing aid (e.g., a coumarone resin or styrene resin). If the zinc oxide coated clay is to be used as both an activator and a filler, the coating should be relatively thin so that not too much zinc oxide is added to th...

example 3

Coating Clay with Different Amounts of Zinc Oxide

[0059]Using the same method as Example 2, the following zinc oxide coated clay is prepared with clay S-40:

[0060]

BETpHsurfaceHeatingof 10%Wt. %Wt. %BulkareaMaterialTemperatureslurryZincClayDensity(m2 / gr)Powder D400° C.8.887.11900.4510.4Powder E400° C.8.9847.1370.2735.7Powder F400° C.8.6442.6440.3032.1Powder G400° C.7.3825.3670.3021.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com