Line-narrowed gas laser system

a laser system and gas laser technology, applied in laser details, microlithography exposure apparatus, active medium materials, etc., can solve the problems of not having an option, not being so often used by catadioptric systems as conventional dioptric systems, and chromatic aberration correction, etc., to achieve the effect of improving the capability of line narrowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

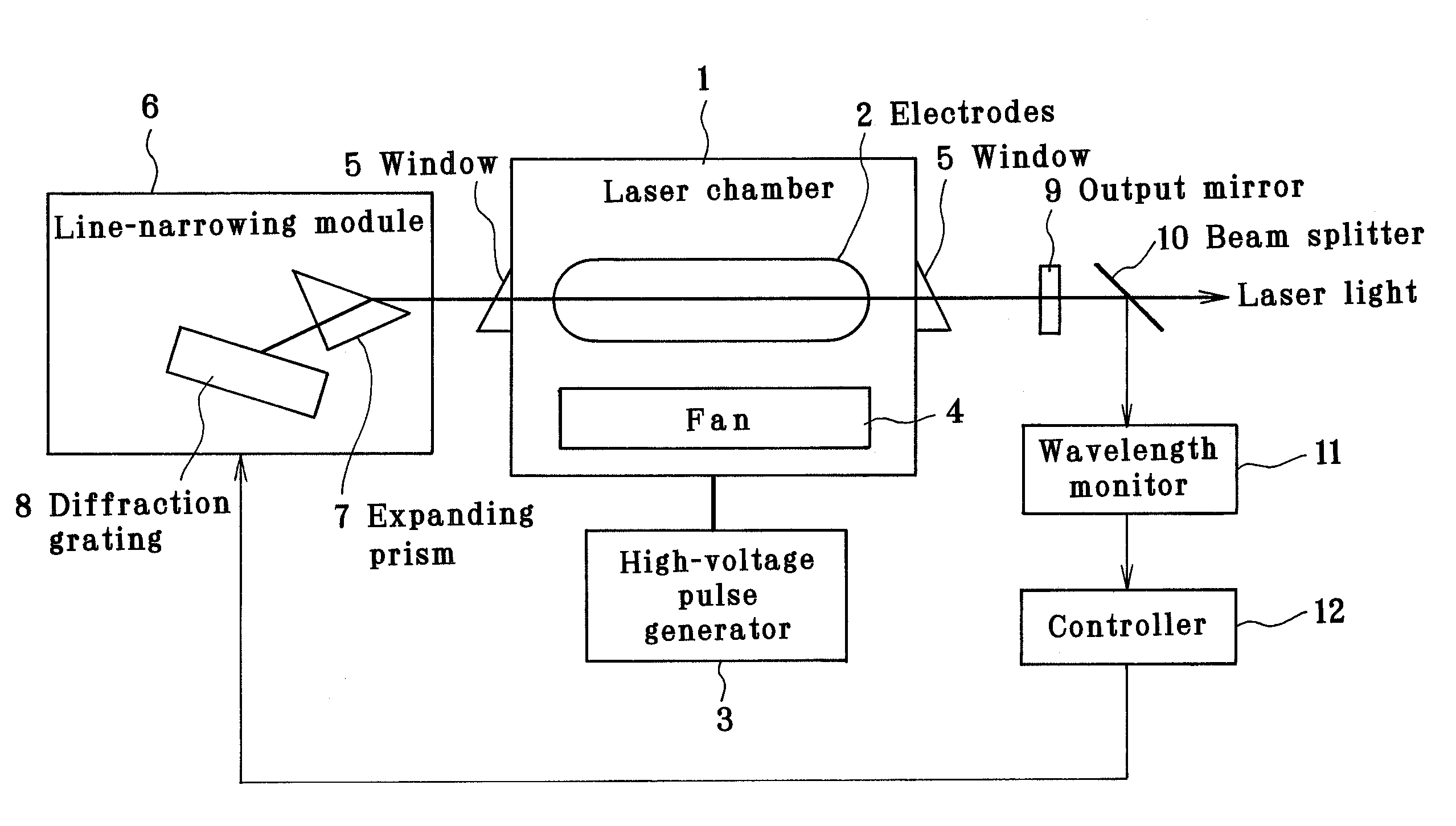

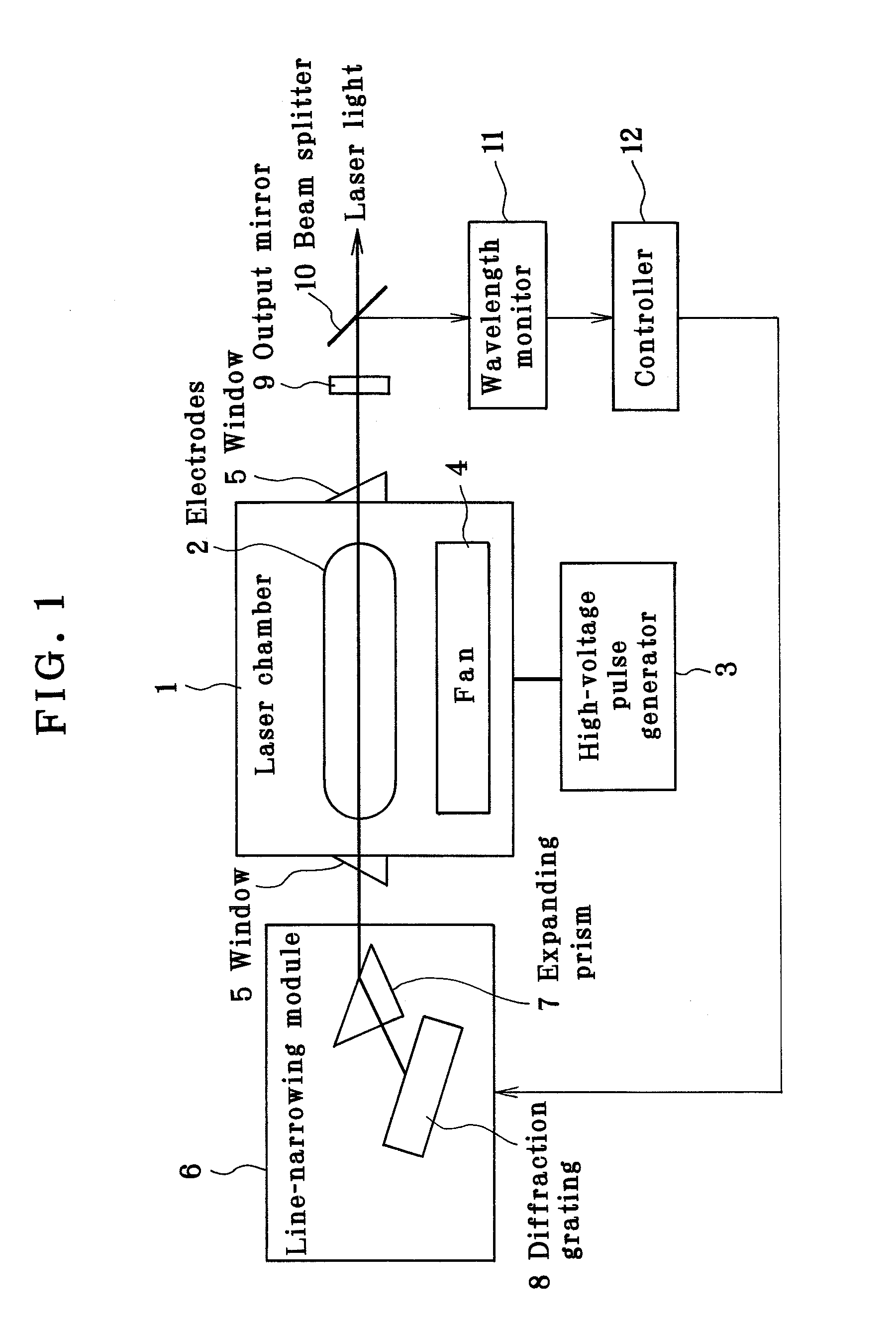

[0113]From the summary of the invention, it is understood that to achieve a spectral linewidth of 0.2 pm or less and a spectral purity of 0.5 pm or less, it is required to cut off or remove the ASE component from light emitted out of the line-narrowed F2 laser system. It is also understood that to improve line-narrowing capability, it is necessary to cut off or remove the ASE component light emitted out of the line-narrowed KrF or ArF laser system.

[0114]As a consequence of intensive and extensive studies made by the inventors, it has now been found out that to cut off or remove the ASE component from light emitted out of a line-narrowed F2 laser system such as one shown in FIG. 1, it is effective to make the rise of laser gain gentle and delay the rise starting point of time of a laser pulse. This is also found to hold true for line-narrowed KrF, and ArF laser systems. The present invention is now explained specifically with reference to the line-narrowed F2 laser system.

[0115]FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com