Electron-accepting compound and composition for charge-transporting film, and luminescent element using same

a charge-transporting film and electron-accepting compound technology, applied in the direction of organic compounds of group 3/13 elements, identification means, instruments, etc., can solve the problems of increasing the demand for organic electroluminescent elements, reducing the operating voltage, and increasing the operating voltage at continuous operation. , to achieve the effect of excellent thermal stability, high hole injection/transporting ability, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthetic example 1

Synthesis of (B-1)

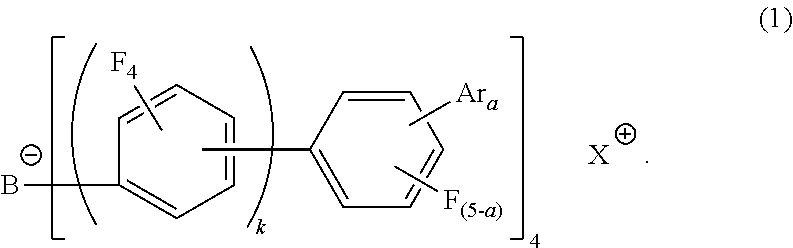

[0276]Cumyltolyliodonium chloride (26 g) was added to a methylene chloride (900 ml) solution of lithium tetrakis(nonafluorobiphenyl)boron (89.5 g) and the whole was reacted at room temperature for 5 hours. The methylene chloride layer was washed with purified water several times and, after treated with active carbon, was concentrated under reduced pressure. The residue was recrystalized to obtain an objective substance (B-1) (31 g).

[0277]The structure of the synthesized compound was identified by MS analysis and NMR. The measurement conditions for the MS analysis are as follows.

[0278]Measurement conditions for MS analysis: ionization method: ESI (+ / −)

[0279]Cation: C16H18I+ (337.0)

[0280]Anion: C48BF36− (1271.0)

synthetic example 2

Synthesis of (B-18)

[0281]A mixed solution of 3-bicyclo[4.2.0]octa-1,3,5-trieneboronic acid (30.3 g), 1,4-dibromo-2,3,5,6-tetrafluorobenzene (125.9 g), 1,2-dimethoxyethane (1 L), and a 2.0M aqueous tripotassium phosphate solution (0.26 L) was deaerated with argon. Thereafter, tetrakistriphenylphosphine palladium(0) (7.3 g) was added thereto and the whole was heated and stirred at an inner temperature of 73° C. for 7.5 hours.

[0282]After cooling to room temperature, purified water (0.25 L) was added and extraction was performed with toluene (1.8 L). After the organic layer was washed sequentially with purified water (0.5 L) and saturated aqueous sodium chloride solution (0.5 L), the layer was dried with anhydrous magnesium sulfate and filtrated and the filtrate was concentrated. The residue was purified by silica gel column chromatography to obtain 3-(4-bromo-2,3,5,6-tetrafluorophenyl)bicyclo[4.2.0]octa-1,3,5-triene (45.5 g).

[0283]Under an argon stream, a dry diethyl ether (760 mL) sol...

synthetic example 3

Synthesis of (B-20)

[0285]Under an argon stream, 4-isopropyl-4′-methyldiphenyliodonium chloride (4.24 g, 1.00 eq.) was slowly charged portionwise at an inner temperature of 8° C. under stirring into a methanol (330 mL) solution of lithium tetrakis(4′-(1,2-dihydrocyclobuta[a]naphthalen-4-yl)-2,2′,3,3′,5,5′,6,6′-octafluoro-1,1′-biphenyl-4-yl)borate (25.6 g) and dichloromethane (80 mL). After stirring at an inner temperature of 8 to 9° C. for 2 hours, methanol was distilled off under reduced pressure. The residue was again dissolved in dichloromethane (150 mL) and, after inorganic salts were filtrated off, the filtrate was concentrated.

[0286]The residue was purified by silica gel column chromatography (hexane / dichloromethane=1 / 2 to 1 / 4) to obtain an objective substance (B-20) (20.9 g, yield 85.6%). The structure of the synthesized compound was identified by NMR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ra | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com