High moisture edible compositions and methods of preparation thereof

a technology of edible compositions and compositions, applied in the field of food products, can solve the problems of unfavorable food additives, unfavorable food additives, and relatively rapid spoilage of certain fresh fruits, such as mangoes, and achieve the effects of reducing the risk of spoilage, reducing the shelf life of edible compositions, and reducing shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

fection Produced in a Batch Microwave Method

[0143]A packaged fresh mango confection was prepared as follows (Example 1): ripe mango was peeled, stoned and chopped into a coarse product (68.43 wt. %, 1.5 kg). PARADISE® mango paste (78 brix) (27.24 wt. %), unipectin LM (CARGILL® PG225C) (3.09 wt. %), mango flavor (0.33 wt. %), ascorbic acid (0.20 wt. %), calcium lactate (0.36 wt. %), and pectin methyl esterase (NOVOSHAPE®) (0.36 wt. %) were added, and the mixture was blended into a smooth paste.

[0144]The blended mixture was placed in a microwave suitable pressure cooker and heated at full power (1000 W kitchen microwave) for six to seven minutes. The pressure cooker was cooled enough to safely open. The still warm composition was immediately transferred into suitable, single serving plastic cups (100 to 120 g per package), sealed and cooled to ambient temperature.

example 2-5

Confections Produced by a Continuous Flow Microwave Method

[0145]Packaged, fresh mango-apple confections were prepared as follows: the ingredients (approximately 0.7 kg scale) as illustrated in Table 1 were combined and blended into a homogeneous, pumpable mixture. The mixture was pumped through a continuous flow, Aseptia, Inc. microwave system as described in U.S. Pat. No. 8,574,651, which is fully incorporate by reference herein, with a single heating time period of 33 seconds. The final composition was packaged in single-serve packages (100 to 120 g per package), sealed and cooled to ambient temperature.

TABLE 1Mango-Apple Confection Recipes Preparedby a Continuous Flow Microwave MethodExampleExampleExampleExampleIngredients2345Fresh mango puree68.4367.9568.2970.25 (yellow variety)Paradise ® Apple Paste27.2429.4627.2028.33 (78 brix)Cargill ® Unipectin LM,3.09—3.09—PG225SMango flavor0.33 0.390.420.42Ascorbic acid0.20—0.200.20Calcium Lactate0.36—0.400.40Novoshape ® PME0.36—0.400.40Ag...

examples 6-8

e Confections Produced in a UHP Method

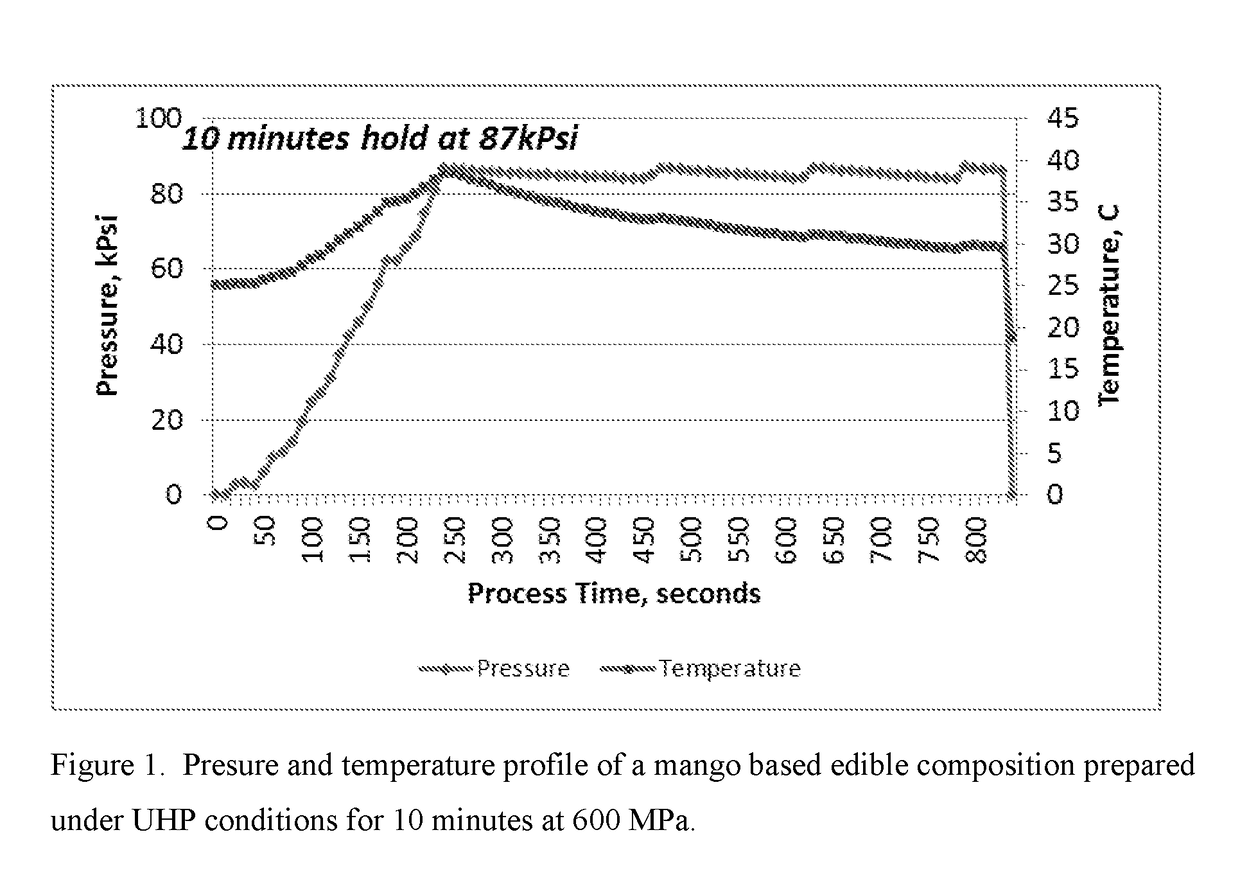

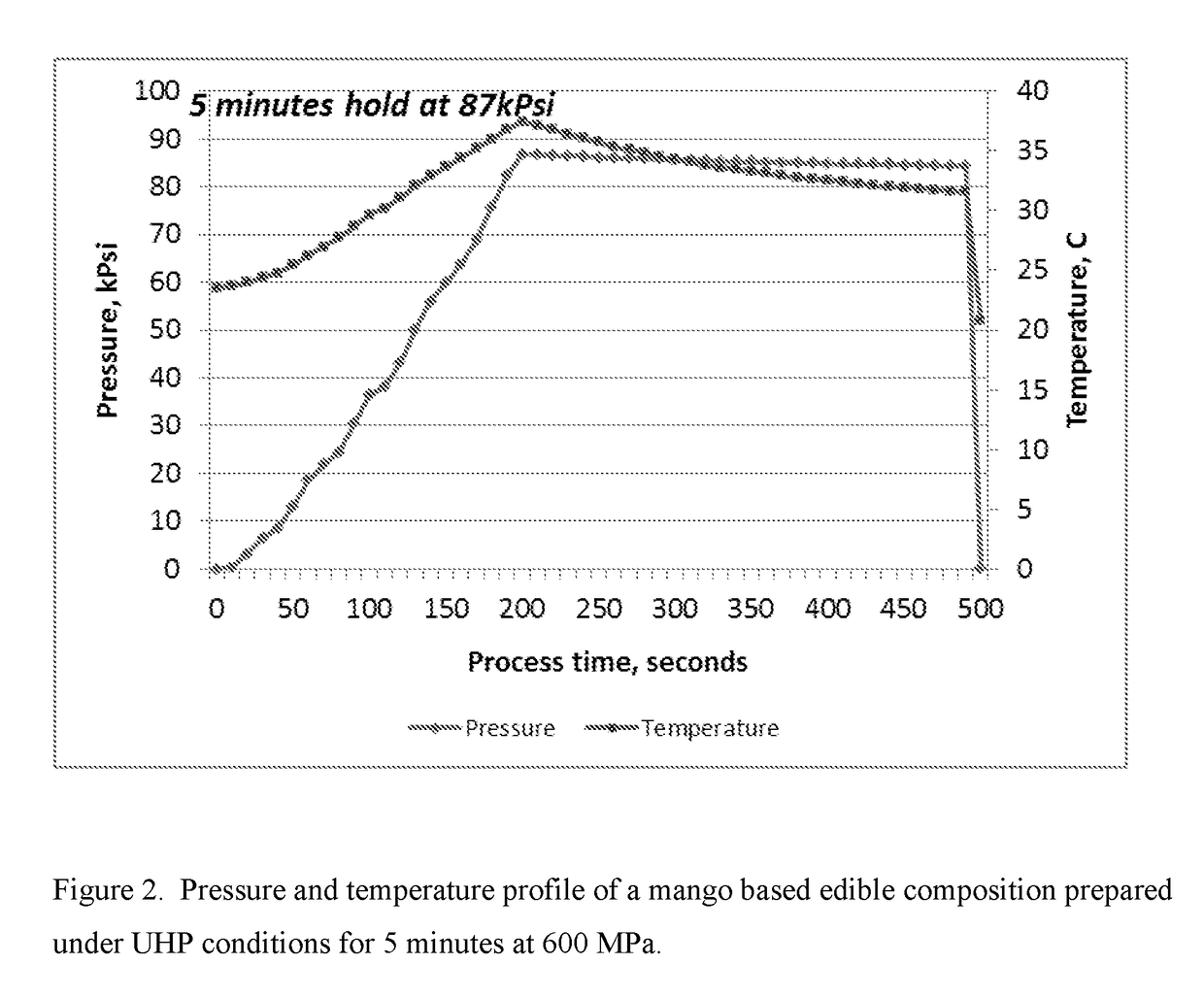

[0146]Packaged fresh mango confections were prepared as follows: the ingredients as illustrated in Table 2 below, were combined and blended into a homogeneous mixture. The mixture was packaged in single serving clear packages and vacuum sealed. The packages were then subjected to ultra-high pressure in a 2 L Avure Technologies UHP unit for from 5 to 10 minutes at approximately 600 MPa (87,000 psi). The temperature and pressure profile were monitored and representative examples are shown in FIGS. 1 and 2. Similar edible compositions were prepared using oranges and strawberries (ingredient list not shown).

TABLE 2Mango Confection Recipes Prepared in a UHP MethodExampleExampleExampleIngredients678Fresh mango puree48.9574.0248-50(yellow variety)Agar (GS 900 from1.713.061.4-1.7Prinova ®)Deionized Water24.47—24-26Treetop ® mango24.47—24-26concentrate (28 brix)mango flavor0.390.400.2-0.4Snopac Apple Juice—22.53—ConcentrateAll values are in weight % of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com