CVD reactor and method for nanometric delta doping of diamond

a reactor and delta doping technology, applied in the direction of electrical equipment, semiconductor/solid-state device testing/measurement, electric discharge tubes, etc., can solve the problems of insufficient thermal activation energy barrier, inability to demonstrate the theoretically expected performance of delta doping of diamond with boron, and relatively low concentration of free carriers, so as to minimize turbulence and gas mixing, the effect of constant loads or “impedances”

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

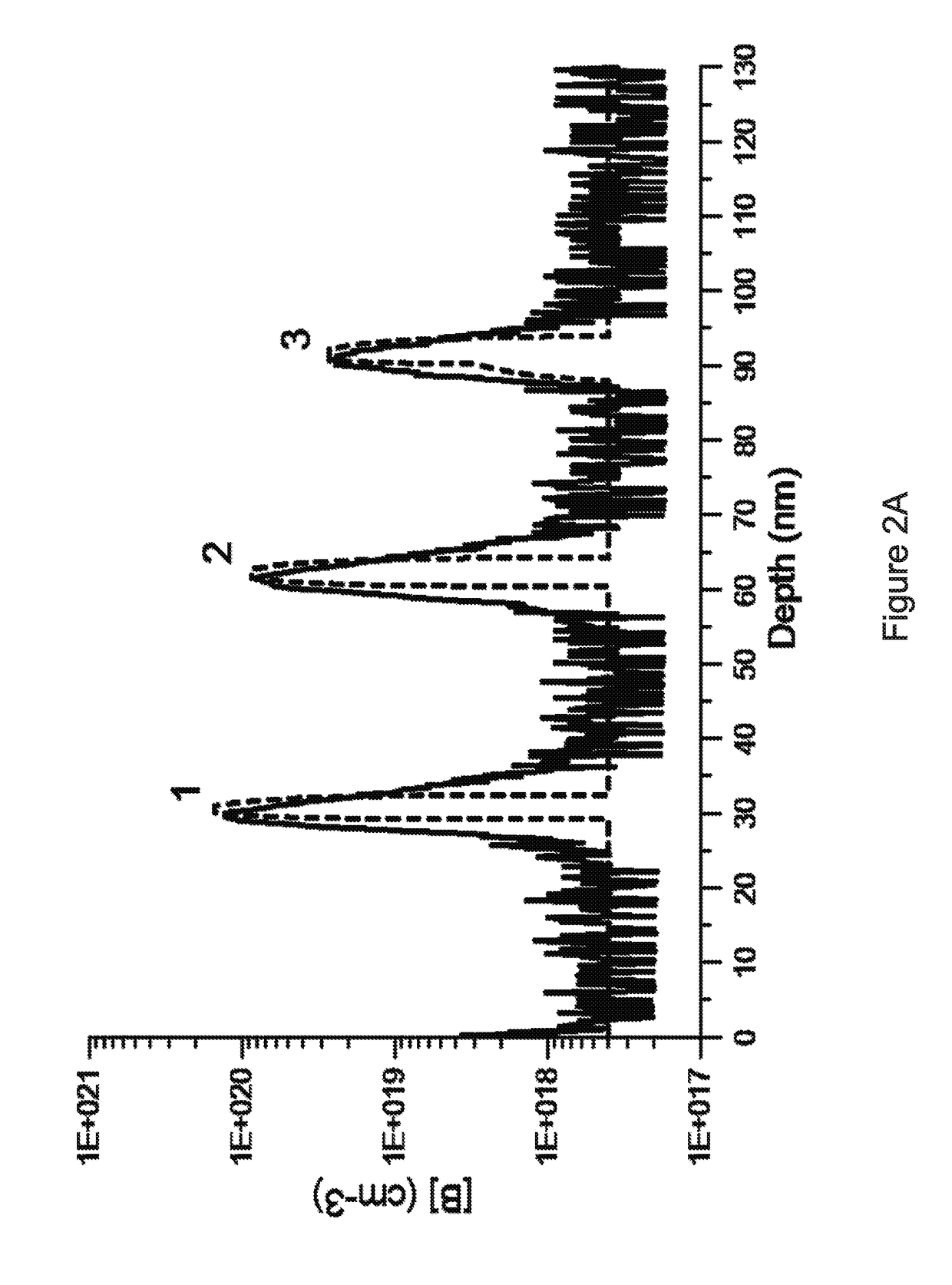

[0043]The present invention is an apparatus and method for creating nanometric delta doped layers in epitaxial diamond with interfaces between the doped and high mobility layers that are sufficiently abrupt and smooth to provide at least 100 cm2 / Vsec carrier mobility and 1013 cm−2 carrier concentration.

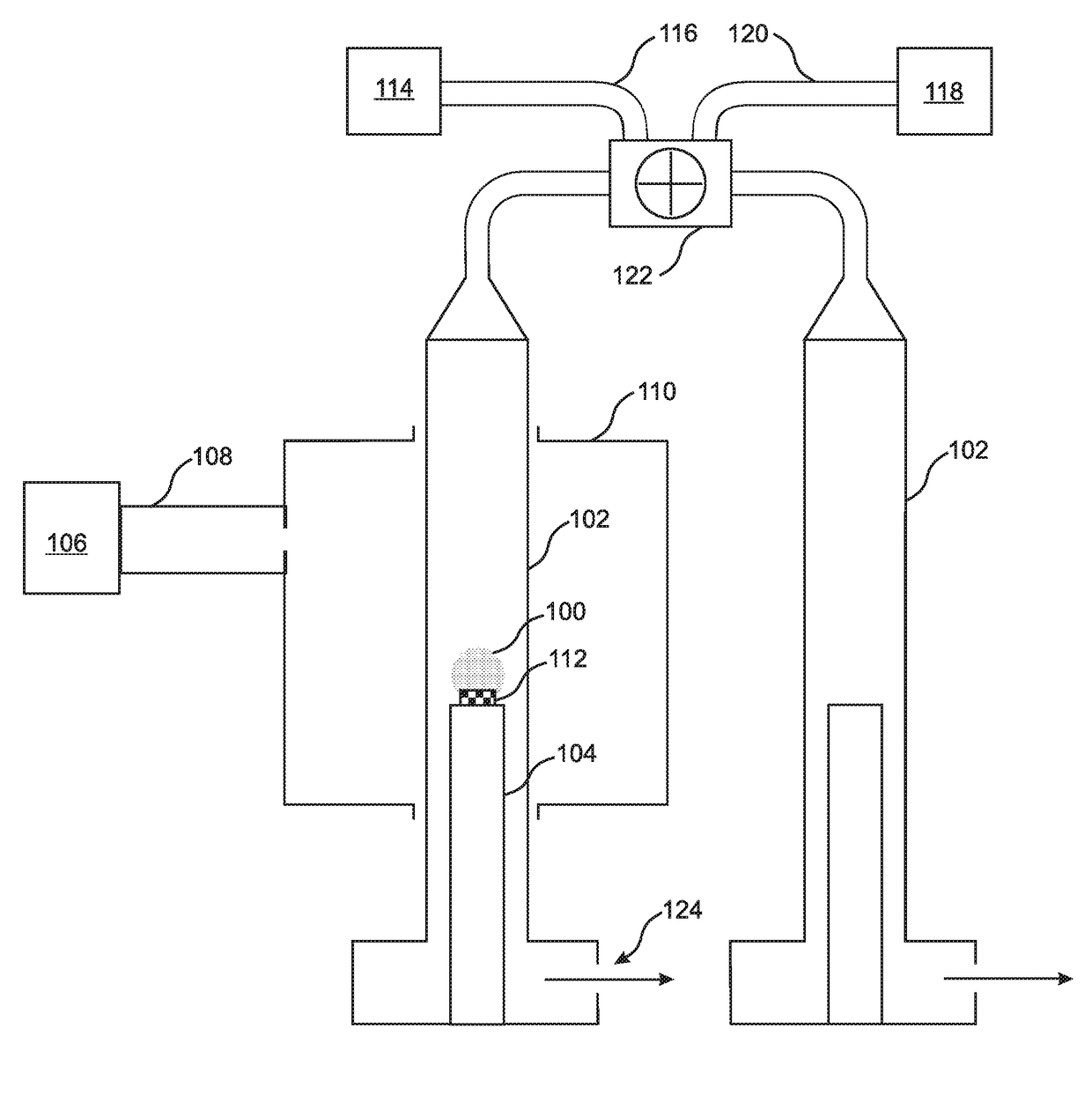

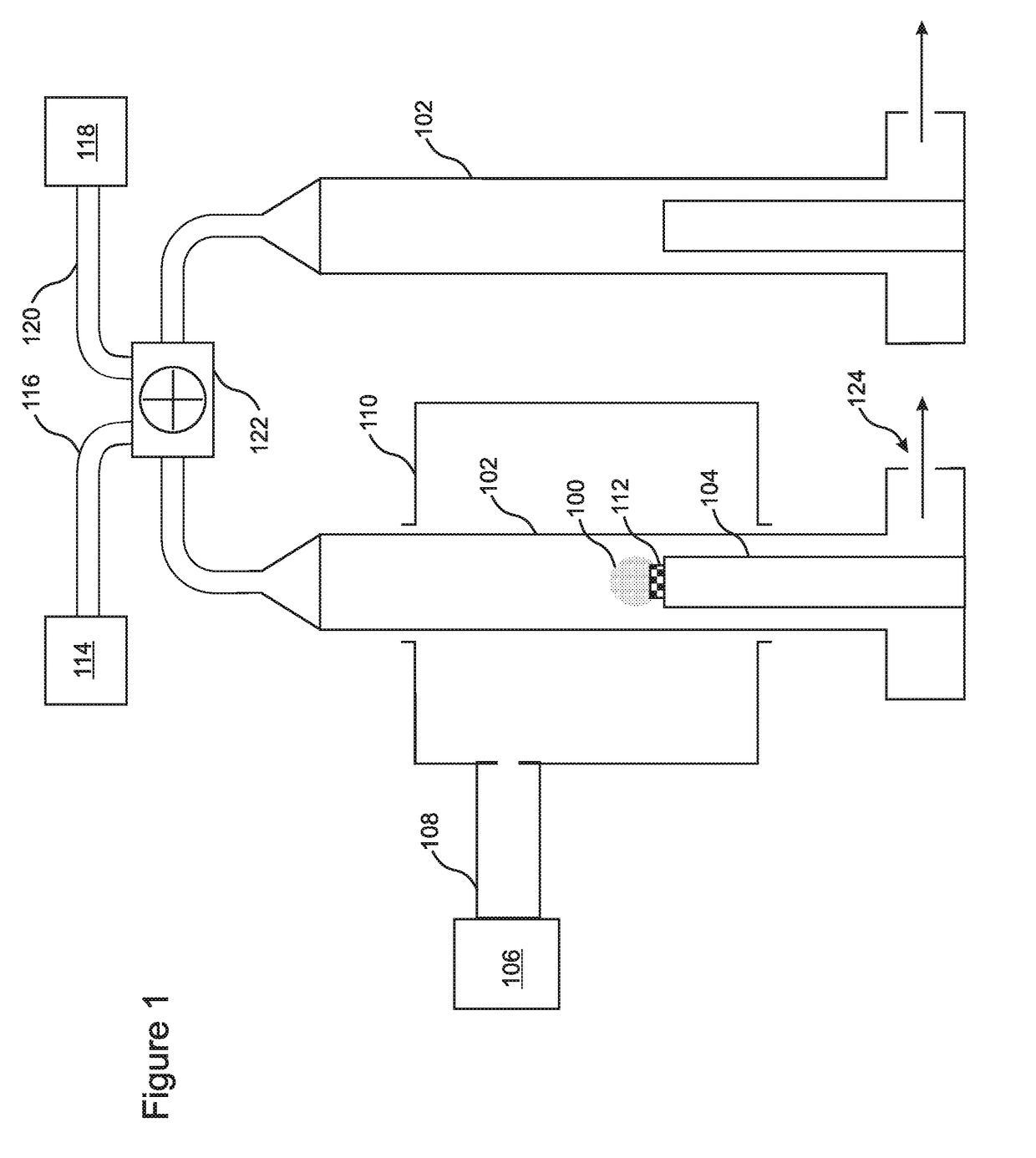

[0044]The apparatus of the present invention is a CVD reactor that is able to create nanometric delta-doped layers with ultra-sharp interfaces between doped / undoped material. FIG. 1 is a schematic illustration of an embodiment of the disclosed reactor, in which a microwave plasma excitation zone 100 surrounds a substrate 112 supported by a substrate holder 104 in a reduced pressure region of a vertical quartz tube growth chamber 102. In various embodiments the growth chamber is a fused silica tube 102. In embodiments, the substrate holder 104 can heat the substrate 112 to a temperature of between 700 and 1100° C. as desired.

[0045]The plasma in this embodiment is produced by electromag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| roughness Sa | aaaaa | aaaaa |

| roughness Sa | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com