Magnetic random access memory with switable switching assist layer

a random access memory and assist layer technology, applied in the field of sttmram elements, can solve the problems of devices that cannot scale beyond 65 nanometer (nm) process nodes, more complex cell architectures with high write current, and poor scalability attributed to the process used to manufacture these devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In the following description of the embodiments, reference is made to the accompanying drawings that form a part hereof, and in which is shown by way of illustration of the specific embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized because structural changes may be made without departing from the scope of the present invention. It should be noted that the figures discussed herein are not drawn to scale and thicknesses of lines are not indicative of actual sizes.

[0035]In the various STTMRAM elements to follow, a MTJ is employed with perpendicular magnetic anisotropy material(s) with improved stability in non-writing modes and easier switching during writing mode.

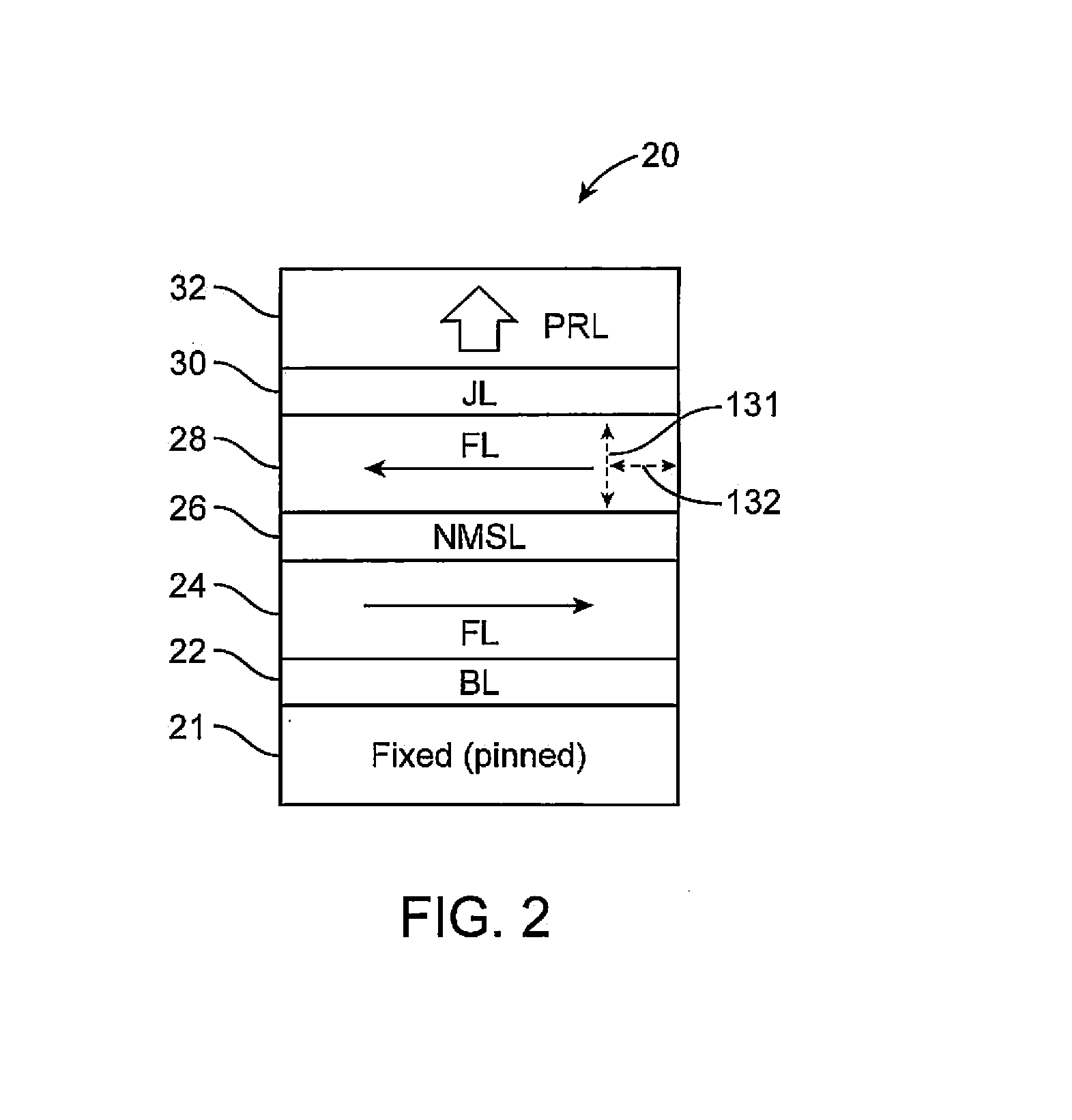

[0036]FIG. 2 shows relevant layers of a STTMRAM element 20 in accordance with an embodiment of the present invention. The STTMRAM element 20 is shown to include a fixed layer (sometimes referred to herein as a “reference layer (RL)”) 21 on top of which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com