Grafted polymer surfaces for dropwise condensation, and associated methods of use and manufacture

a polymer surface and dropwise condensation technology, applied in the field of grafted polymer surface, to achieve the effects of reducing thermal resistance, reducing drop shedding size, and reducing degradation ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment c

Film Characterization Experiment C

Surface Roughness Measurements

[0160]Surface roughness was measured using atomic force microscopy (AFM, MP3D-SA, Asylum) in tapping mode. The advancing and receding contact angles were measured using a goniometer (Model 590 Advanced, ramé-hart). The hysteresis was also measured during condensation on the grafted polymer sample as the difference between the receding and advancing ends of a drop immediately before departure. Contact angles during condensation on the silanized sample could not be measured due to the film covering the surface.

Dropwise Condensation Experiment A

Nucleation and Shedding Comparison

[0161]In addition to CAH, the dropwise condensation heat transfer depends on a number of complex factors including nucleation site density and population distribution. To investigate the behavior of these surfaces during condensation, saturated pure water vapor at 800 Pa was condensed while cooling the surface with a Peltier device to a supersaturat...

experiment b

Dropwise Condensation Experiment B

Aluminum Substrate Experiment

[0162]Commercial condensers are typically constructed using alloys of metals such as titanium, stainless steel, copper, and aluminum. To test a prototype that was most similar to an industrial condenser, a 40 nm film of p(PFDA-co-DVB) was grafted onto 50 mm diameter aluminum substrates via iCVD. The additional roughness imparted by the metal surface (RMS=118±33 nm) was apparent in the AFM height scans (shown in FIGS. 3a and 3b). As expected on a rougher surface in a Wenzel state, the CAH measured during condensation at 6.9 kPa was similar (37°±5°) and accordingly, the size of a departing drop (4.2±0.1 mm) was larger than that on a silicon substrate (as shown in FIG. 3c).

Dropwise Condensation Experiment C

Effect of Grafting

[0163]In this Example, coated substrates were tested for condensation performance in the apparatus described below and shown in FIG. 6. The flow loop of the test apparatus is shown in FIG. 7. Saturated s...

experiment d

Dropwise Condensation Experiment D

Film Thickness & Heat Transfer Coefficient

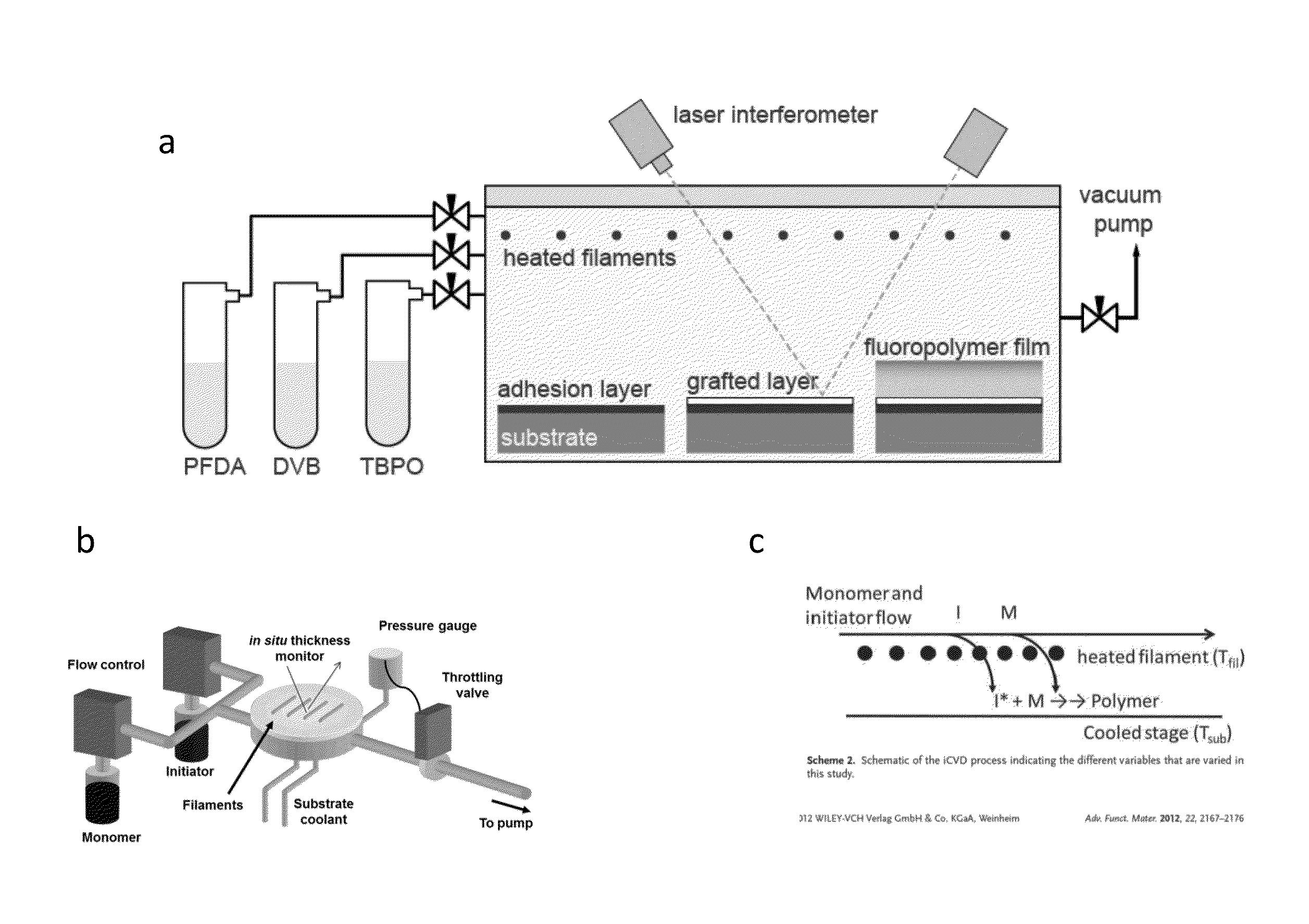

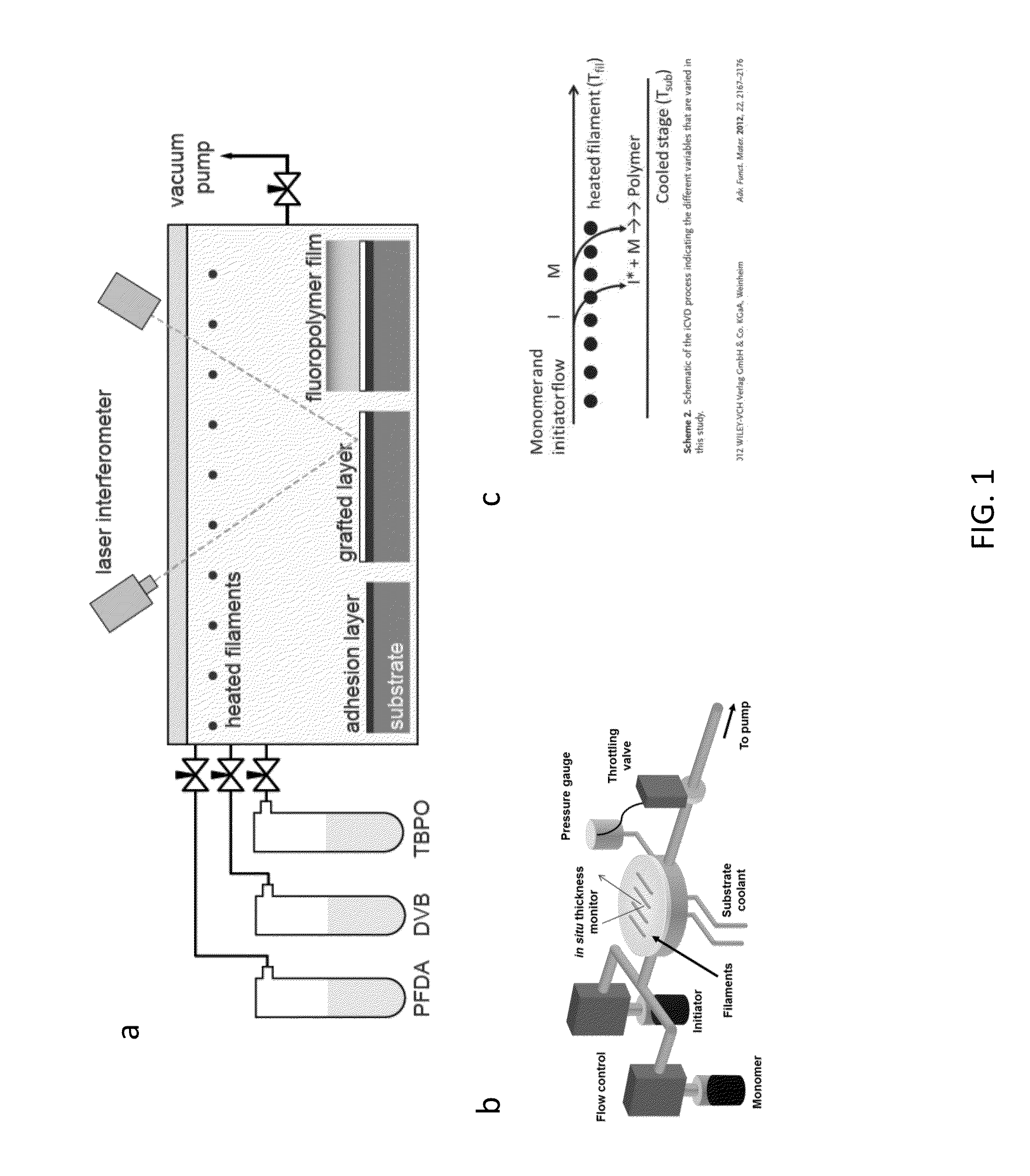

[0166]Referring now to FIG. 1a, monomer and initiator species are flowed into a reactor at controlled rates, where the monomer and initiator species encounter heated filaments and a cooled substrate, as shown in FIG. 1b. The locally heated zone around the filaments thermally cleaves the initiator species (tert-butyl peroxide, TBPO). The produced radical fragments initiate vinyl polymerization of the monomers absorbed on the surface, which is held at a lower temperature. The functional groups, such as the perfluorinated side chain of PFDA, are fully preserved after polymerization.

[0167]The film thickness is measured in-situ during deposition, so that the process can be stopped when the thickness reaches the desired value. In some embodiments, the iCVD copolymer layers are ultra-thin (˜40 nm), leading to an estimated contribution to total thermal resistance of less than 0.001%. To verify that the film thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com