Electrode for lead-acid battery and method for producing such an electrode

a lead-acid battery and electrode technology, applied in the field of electrodes for lead-acid batteries, to achieve the effect of improving mechanical and electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

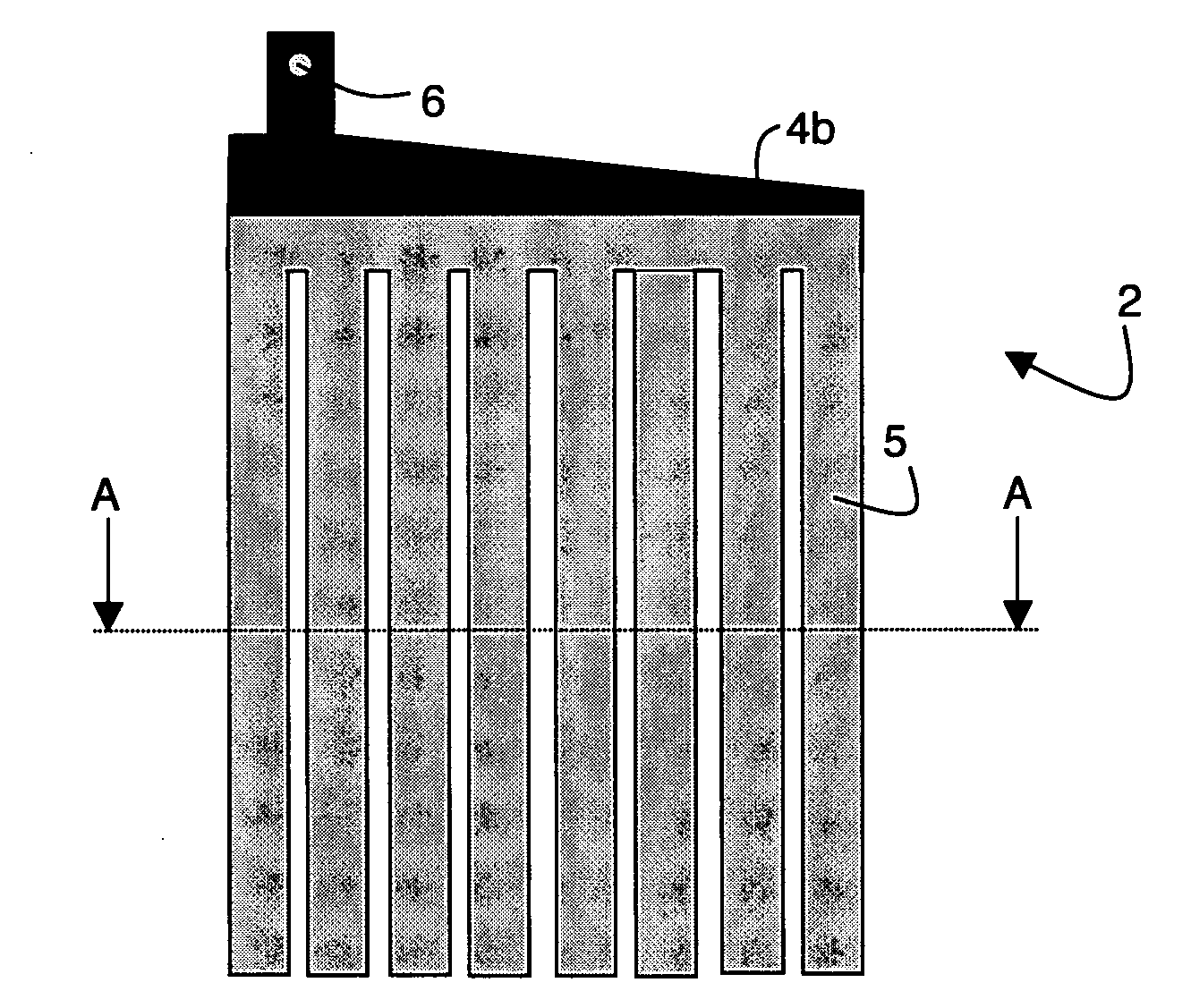

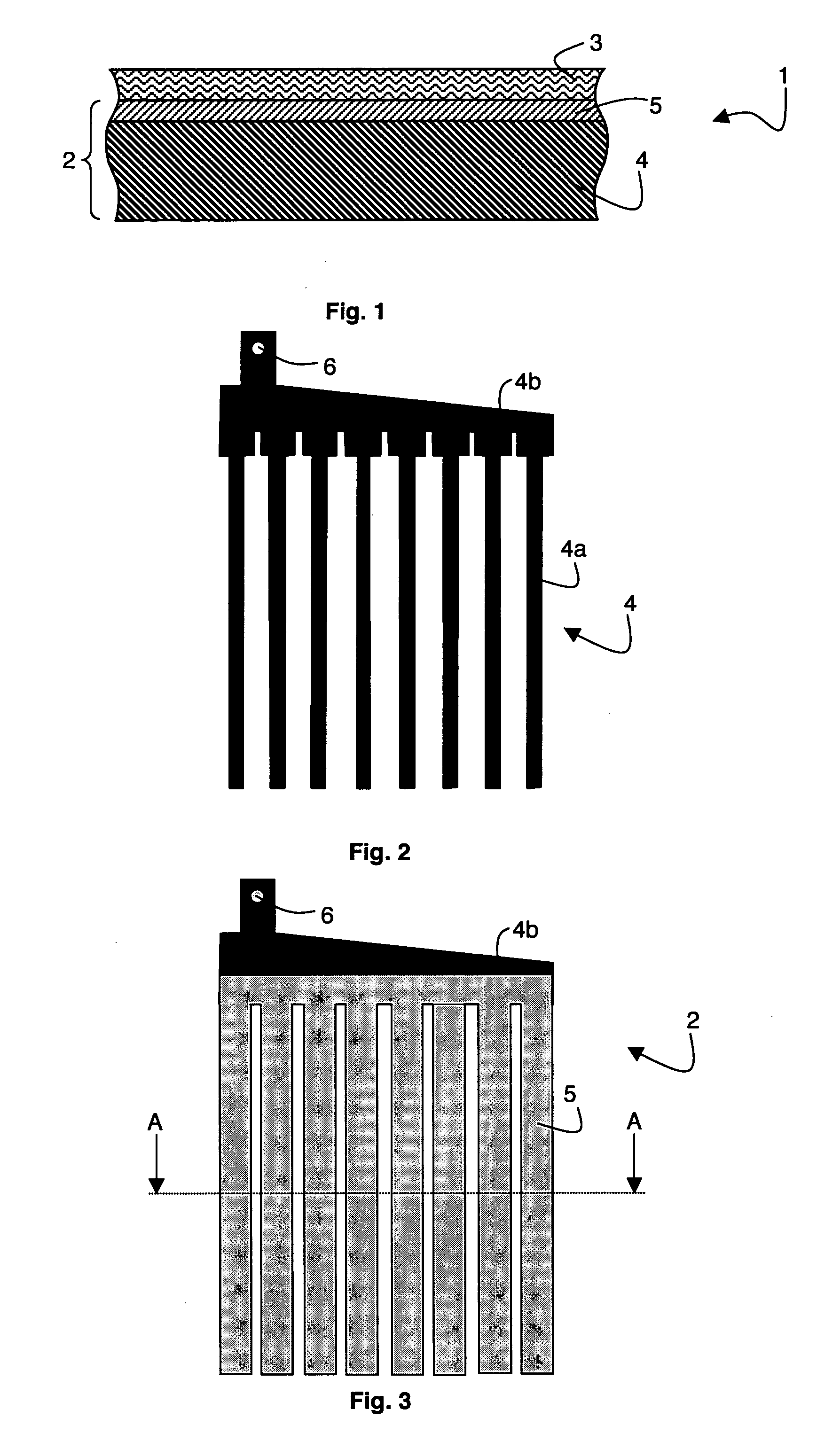

[0038]As represented in FIG. 1, an electrode 1 for lead-battery comprises a current collector 2 covered by an active layer 3 of lead-containing paste. The current collector 2 is formed by a glassy carbon substrate 4 on which is deposited an intermediate layer 5. The glassy carbon substrate 4 has preferably a thickness comprised between 1 mm and 3 mm whereas the thickness of the intermediate layer 5 is advantageously comprised between 50 μm and 200 μm.

[0039]The glassy carbon material is also called vitreous carbon, glassy polymeric carbon or vitreous polymeric carbon. The glassy carbon is a special form of carbon. It is a low-porous carbon. Thus, the glassy carbon substrate 4 comprises pores but the volume of these pores only represent between 0% and 10% of the apparent volume of the substrate. More particularly, the ratio between the volume of pores and the apparent volume is comprised between 1% and 6%. In addition, the glassy carbon material presents high electric conductivity pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com