CMP conditioner and method of manufacturing the same

a conditioner and conditioner technology, applied in the field of chemical mechanical polishing conditioners, can solve the problems of increasing the self-weight of the conditioner, reducing the polishing speed or irregular polishing, and affecting the polishing effect, so as to reduce the deformation of the metal plate, increase the strength of the contacting surface of the cmp conditioning pad, and reduce the effect of external for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

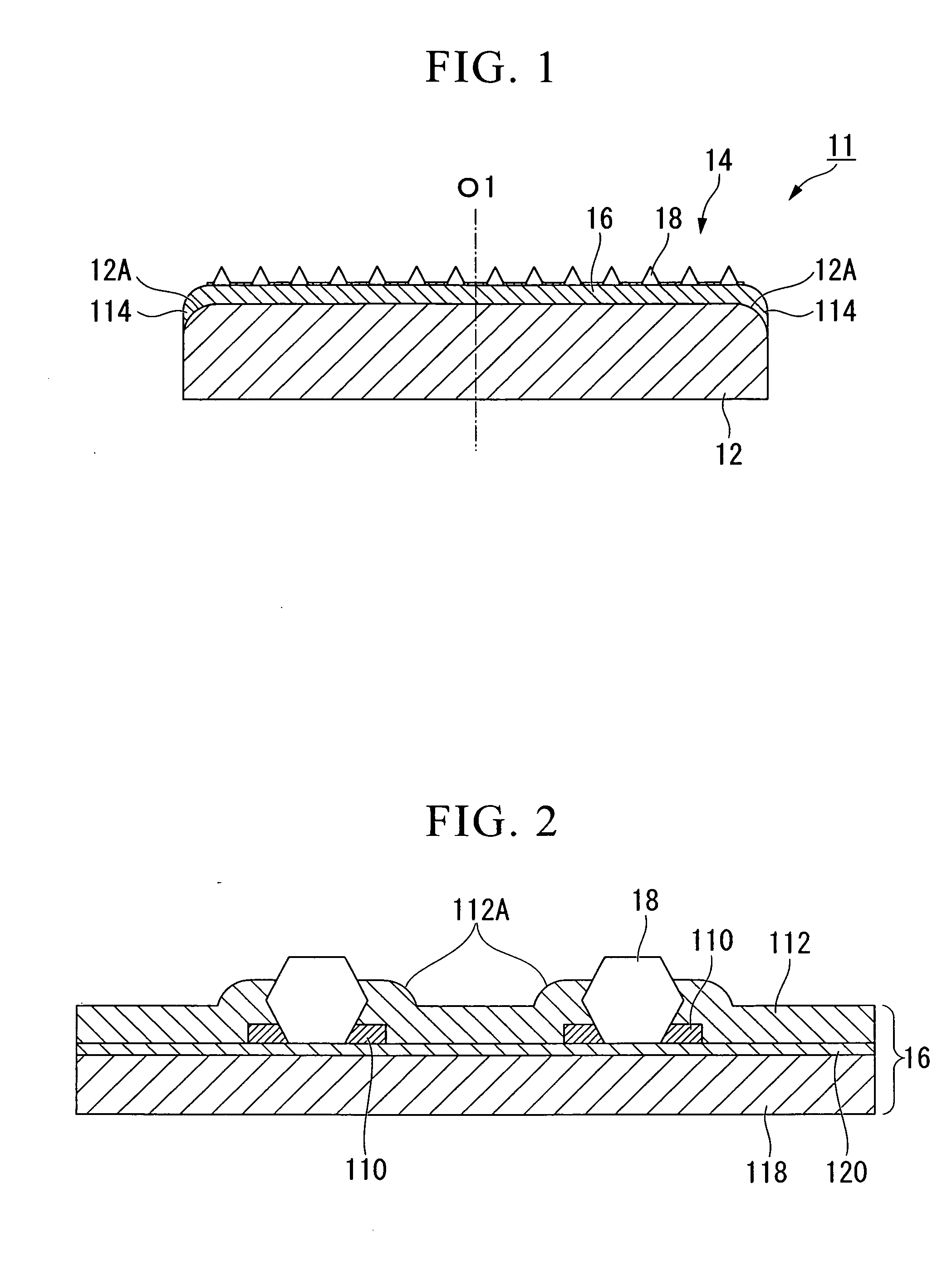

[0055]Hereinafter, an embodiment of the present invention is described in detail. FIG. 1 schematically illustrates a CMP conditioner 11 according to an embodiment of the present invention. The CMP conditioner 11 includes a body 12 having a circular disc shape with respect to the axial line O1, a metal plating layer 16, and diamond abrasive grits 18. The body 12 may be formed of resin, and preferably, of polyphenylene-based resin materials having a glass-transition temperature of 211° C. and a water absorption coefficient of 0.050% such as PPE and PPS. Further, the metal plating layer 16 includes a base plating layer 118, a Ni-strike plating layer 120, an underlying plating layer 110, and a buried plating layer 112. A coating layer (not shown) may be further provided on the buried plating layer 112.

[0056]A peripheral edge 12A of a surface facing to an abrasive pad (not shown) of the body 12 is chamfered in an R-shape around the entire circumference. The metal plating layer 16 is prov...

second embodiment

[0076]Referring to FIGS. 5 and 6, the CMP pad conditioner 21 according to the second embodiment of the present invention includes a base body 22 which has a circular disc shape and rotates with respect to the axial line O2 and a metal plating plate (or metal plate) 26 which is disposed on the base body 22 and has a circular disc shape with the diamond abrasive grits (or cutting blade) 28 being protruded on the surface 26A. The CMP pad conditioner 21 is used in the CMP machine to perform a grinding process by the diamond abrasive grits 28 on the CMP pad (not shown) disposed to face the surface 26A of the metal plating plate 26. The CMP pad is used to polish semiconductor wafers.

[0077]The base body22 and the metal plating plate 26 are bonded to each other with the adhesive B2. According to the second embodiment of the present invention, a two-liquid mixed type is used as the adhesive B2.

[0078]The base body 22 is formed on a resin material such as engineering plastics. According to the...

third embodiment

[0119]Next, the third embodiment of the present invention will be described with reference to FIGS. 10 and 11. The reference numerals in the aforementioned embodiments are used to the same members in this embodiment, and descriptions thereof will be omitted.

[0120]The CMP pad conditioner 211 according to the third embodiment is different from the CMP pad conditioner 21 of the aforementioned embodiment in that the protrusions 23 are set such that the areas of the leading ends increase gradually from the center to the outer circumference on the provided surface 22A thereof.

[0121]Referring to FIG. 10, a plurality of protrusions 23 having a circular column shape of a circular disc shape are provided on the surface 22A of the base body 22, and these protrusions 23 have the same shape. In addition, in the CMP pad conditioner 211 of the present embodiment, the protrusions 23 are arranged gradually densely from the center to the outer circumference in a radial direction on the surface 22A.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com