Adjustable turbulence scale inhibitor device and scale inhibition method

A technology of turbulent flow and anti-scaling, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. The effect cannot be guaranteed and other problems, to achieve the effect of improving the ability to release free electrons, improving the effect of scale inhibition and descaling, increasing the contact area and water flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

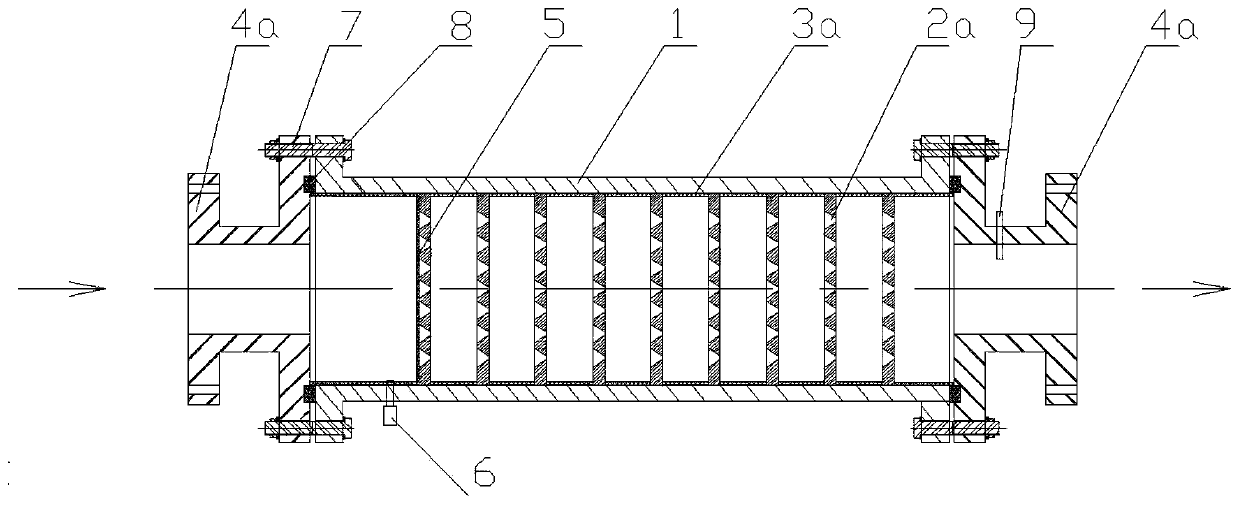

[0067] Such as figure 1 As shown, in this embodiment, an adjustable scale dissolving component in an adjustable turbulent flow scale dissolving device consists of a plurality of disc-shaped turbulent bodies 2a arranged at intervals in the cylinder body 1 and a disc-shaped turbulent body arranged in each disc-shaped turbulent body. 2a, and the isolation sleeve 3a between the disk-shaped turbulent body 2a and the inlet and outlet connectors; both the inlet and outlet connectors are flanges 4a.

[0068] The installation process of the adjustable turbulent flow descaling device is as follows: install the sealing ring 8 in the sealing ring groove of the flange 4a as the outlet connector, and connect the inner flange plate of the flange 4a to the cylinder through the bolt 7 The flanges at one end of the water outlet of 1 are connected together, and then 10 steel spacer sleeves 3a and 9 disc-shaped turbulent bodies 2a are spaced into the cylinder 1; the circular surface of the disc-s...

Embodiment 2

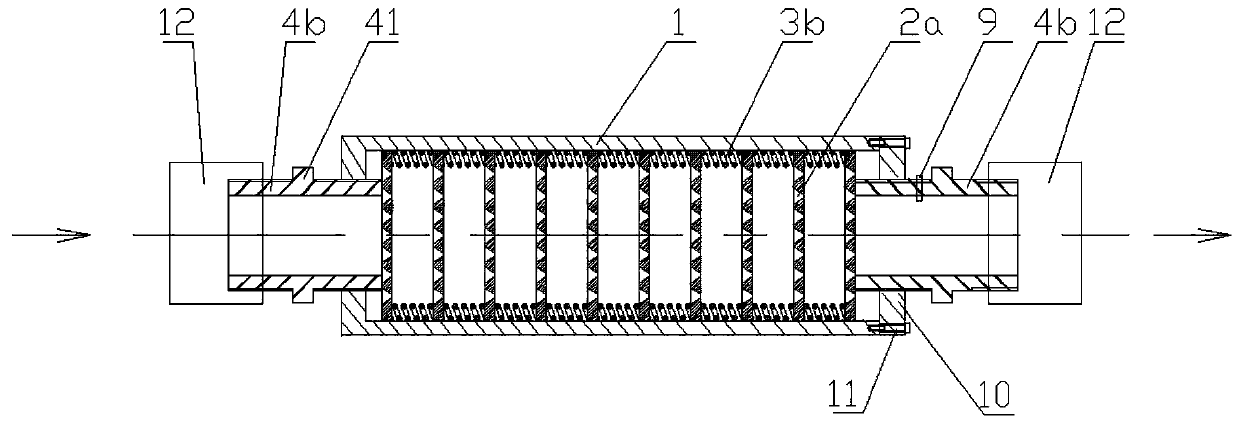

[0071] Such as figure 2 As shown, in this embodiment, an adjustable scale dissolving assembly in an adjustable turbulent flow scale dissolving device consists of a plurality of disc-shaped turbulent bodies 2a arranged at intervals in the cylinder body 1 and a disc-shaped turbulent body arranged in each disc-shaped turbulent body. 2a between a plurality of springs 3b; inlet connectors, outlet connectors are external wire head 4b. The two ends of the cylinder 1 are provided with sealing heads 10, wherein the sealing head 10 at the water inlet end is integrated with the cylindrical body 1, and the sealing head 10 at the water outlet end is an end cap structure, and the end cap structure is integrated with the cylindrical body 1. The corresponding ends are fixedly connected by screws 11.

[0072] The installation process of the adjustable turbulent flow descaling device is as follows: screw the external wire head 4b as the inlet connector into the internal thread hole opened in ...

Embodiment 3

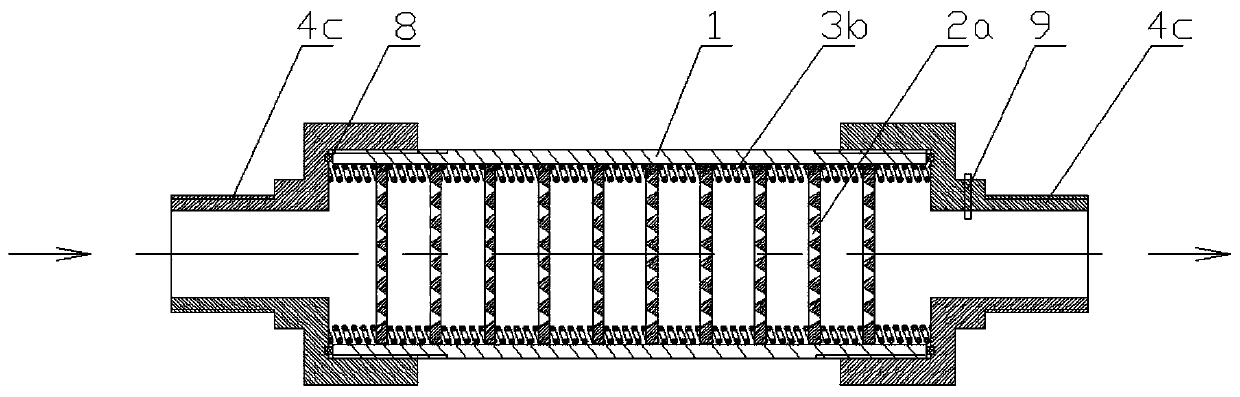

[0075] Such as image 3 As shown, in this embodiment, the adjustable scale dissolving component in the adjustable turbulent flow scale dissolver consists of a plurality of disc-shaped turbulent bodies 2a arranged at intervals in the cylinder body 1 and a plurality of disc-shaped turbulent bodies 2a arranged between each disc-shaped turbulent body 2a , and a plurality of springs 3b between the disc-shaped turbulent body 2a and the inlet connector and the outlet connector; both the inlet connector and the outlet connector are internally threaded bobbins 4c. Both ends of the cylindrical body 1 are provided with external threads.

[0076] When installing the adjustable turbulent flow descaling device, first place the sealing ring 8 in the sealing ring groove on the inner end surface of the two internally threaded bobbins 4c as the inlet connector and the outlet connector, and then place the seal ring 8 as the inlet connector. The inner threaded bobbin head 4c is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com