Variable pitch/yaw bearing ring raceway laser phase change hardening method and machining device

A technology of laser phase change hardening and yaw bearings, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as scrapping, difficult processing, thermal deformation, etc., achieve universal applicability, improve wear resistance and corrosion resistance performance, improving contact strength and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in combination with specific implementation examples.

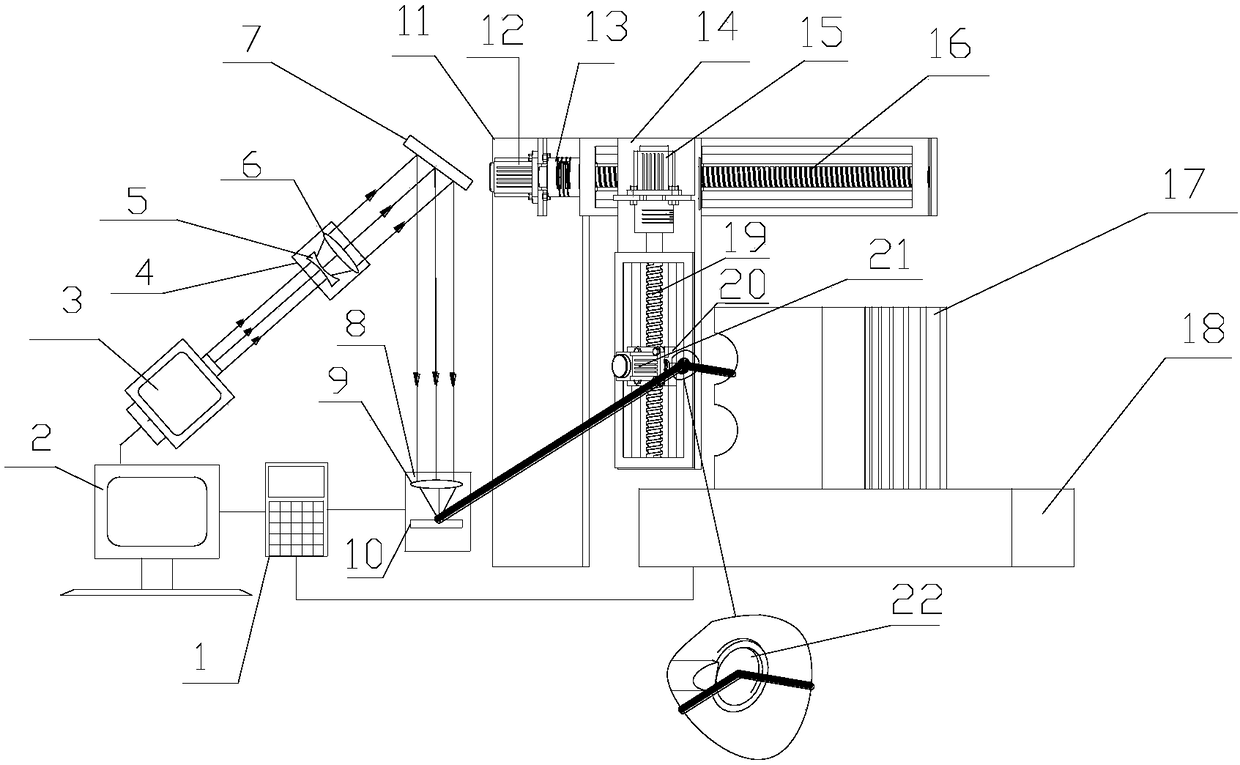

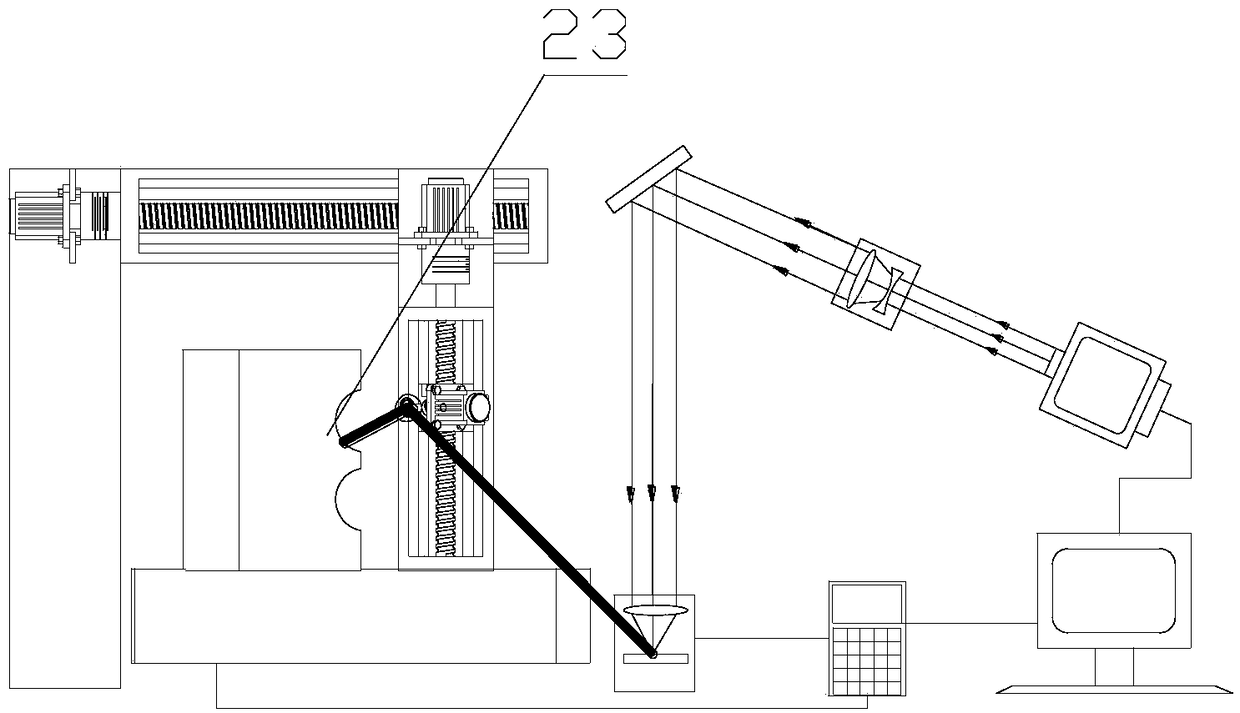

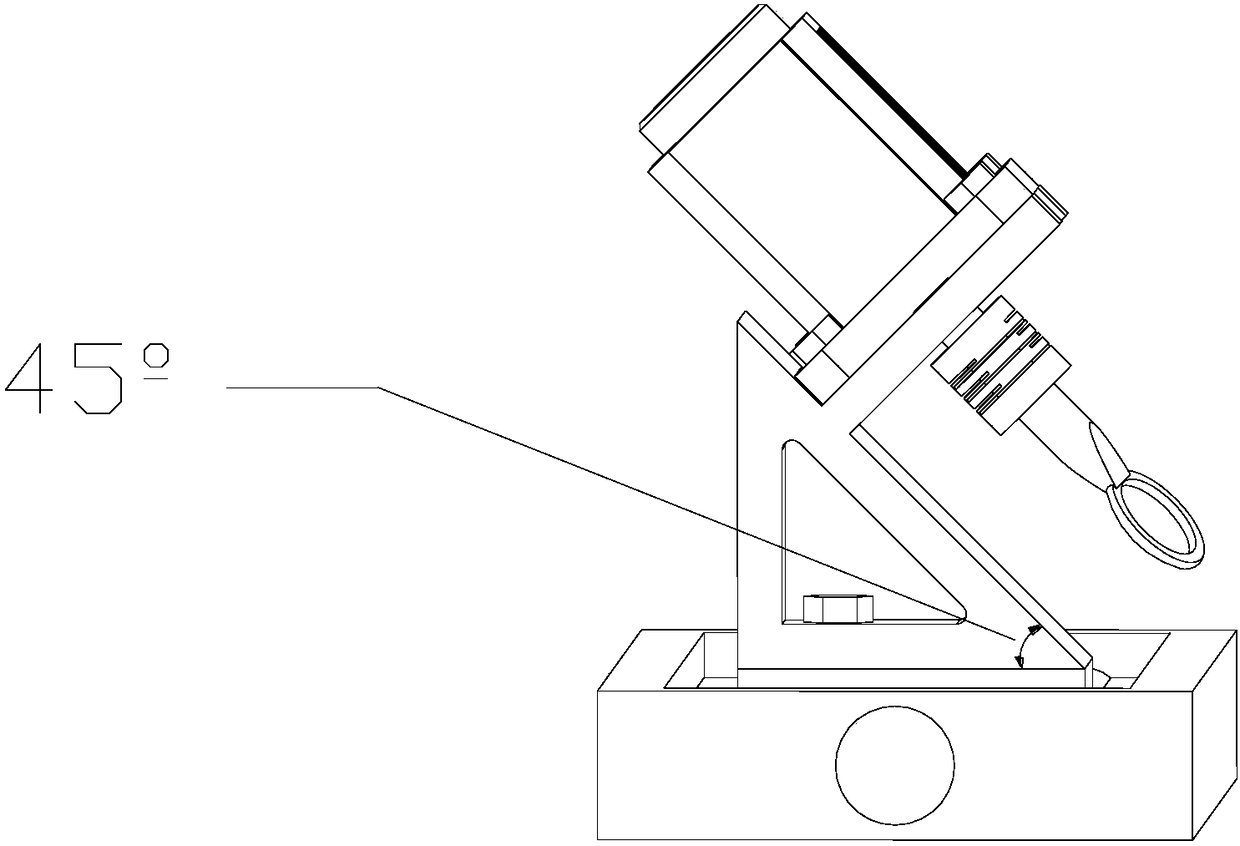

[0030] Such as figure 1 As shown, the bearing inner ring 17 is fixed on the rotary platform 18, and the material of the bearing ring is 42CrMo. At the same time, a cantilever beam 11 is fixed on the outer working surface of the rotary platform 18, and the first ball bearing is installed on the cantilever beam 11. Lead screw 16, the left side of the cantilever beam 11 is connected with the first servo motor 12 through bolts, the first servo motor 12 and the first ball screw 16 are coaxially matched by the first coupling 13, and the first coupling 13 The output torque of the first servo motor 12 can be transmitted to the first ball screw 16, the support frame 14 is fixed on the slider of the first ball screw 16 by bolts, the second ball screw 19 is housed on the support frame, and the second ball screw 19 is mounte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com