Workpiece clamping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

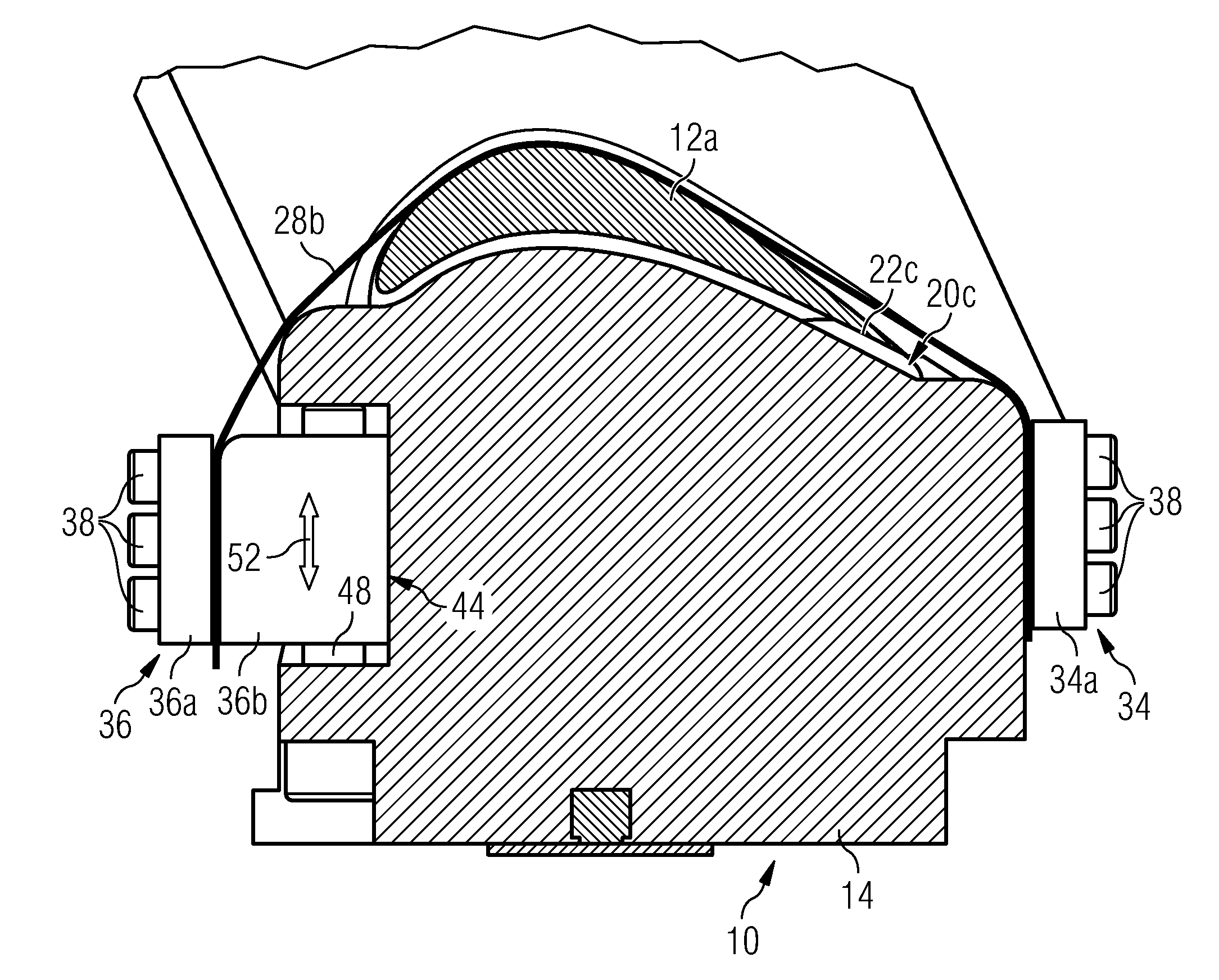

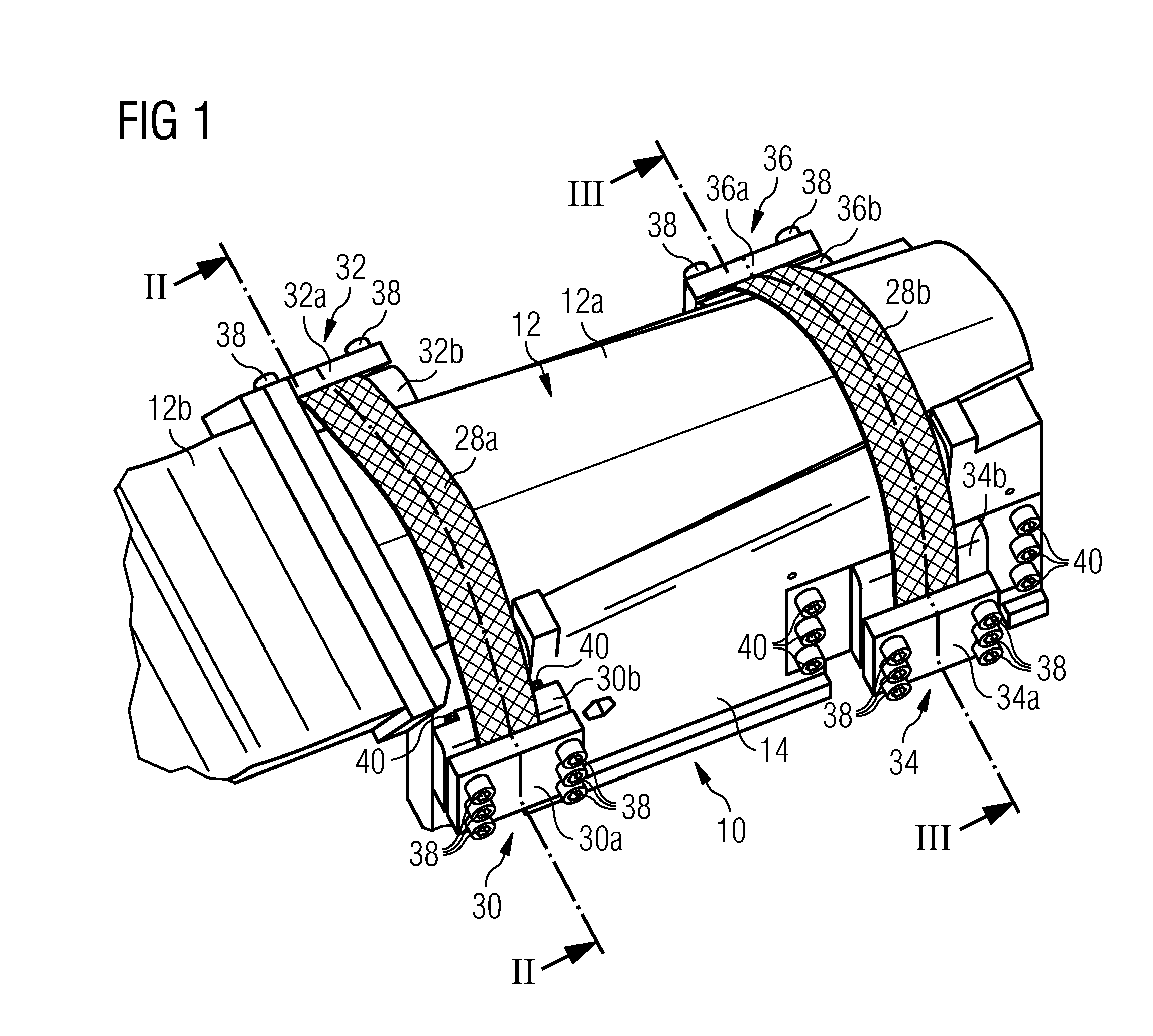

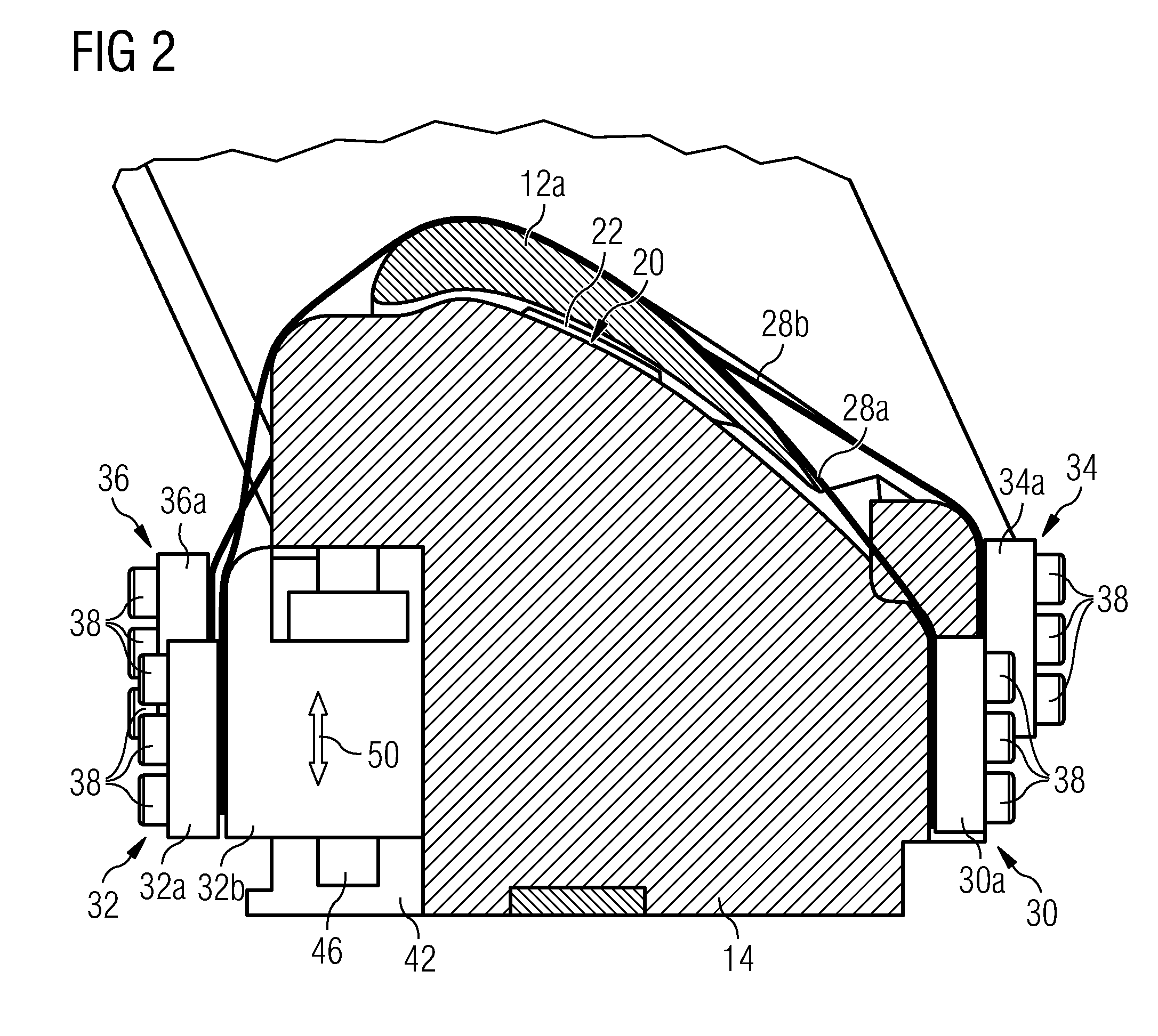

[0031]FIGS. 1 to 7 show a first embodiment of a workpiece clamping device 10 according to the invention, on which is clamped a workpiece in the form of a turbine blade 12 which has a blade airfoil 12a and a blade root 12b. The workpiece clamping device 10 comprises a basic body 14 consisting of metal, on the upper side of which a workpiece seat 16 for seating of the blade airfoil 12a of the turbine blade 12 is formed. The workpiece seat 16 comprises a base surface 18, the contour of which is essentially geometrically adapted to the outer contour of the underside of the blade airfoil 12a of the turbine blade 12. In addition, the workpiece seat 16 has three support elements 20 which project from the base surface 18, are geometrically adapted to the contour of the underside of the blade airfoil 12a, and in each case define a support surface 22 on which rests the underside of the blade airfoil 12a of the turbine blade 12. As a result of these support elements 20 a stable three-point bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com